I ran into more problems I was cleaning the MAF and checking the air pump cause codes 44-94 when I put everything together and fire up the car I got very very rough idle ,car stumbles, shakes,and surges and smokes my engine has little over 2300 miles I just replaced and everything is new (FUEL PUMP,FUEL PRESSURE REGULATOR,IGNITION COIL,DISTRUBUTOR,DISTRIBUTOR CAP AND WIRES IAC,TPS,IGNITION MODULE,) I went to get also a new MAF and car still running like I mention,I get this codes KOEO 34,81,85,63,66....and KOER 24,21,41,92,34 please help my fuel pressure is 42 with out vacum I also check the compression on engine and is ok please help ........ I did check the plugs and they had like a little carbon .........

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

car stalling idles erratically!!!!! help! please!

- Thread starter latinmustang90

- Start date

-

Sponsors (?)

I got the stock fuel pressure regulator I cant make any adjustments is about 40psi and with hose connected 32psi.I'm no expert but I had similar problems when I tried to up my fuel pressure from 40psi. Try setting it down to 40 and see what you get. Mine seems to like it the best.

Good Luck.

Your fuel pressure is OK, there is no need to make any changes in it. Two or three PSI high isn't going to have much effect. The computer can compensate for that small variation if all the sensors are working correctly.

Fix the codes first before doing anything else.

If you go through and carefully read and do all of the code definitions and fixes you stand an excellent chance of fixing the problem. If you get scared and run away because it looks like a lot of work you aren't going to have much success. If you were looking to bolt on some $15 part, to fix the problem, it probably isn't going to be that easy.

Persistence is often of greater value than genius.

Code 21 – ECT sensor out of range. Broken or damaged wiring, bad ECT sensor.

Note that that if the outside air temp is below 50 degrees F that the test for the ECT can be in error. Warm the engine up until you get good hot air from the heater and then dump the codes again.

The ECT sensor has absolutely nothing to do with the temperature gauge. They are different animals. The ECT sensor is normally located it the passenger side front of the engine in the water feed tubes for the heater.

The ACT & ECT have the same thermistor, so the table values are the same

ACT & ECT test data:

Use Pin 46 on the computer for ground for both ECT & ACT to get most accurate readings.

Pin 7 on the computer - ECT signal in. at 176 degrees F it should be .80 volts

Pin 25 on the computer - ACT signal in. at 50 degrees F it should be 3.5 volts. It is a good number if the ACT is mounted in the inlet airbox. If it is mounted in the lower intake manifold, the voltage readings will be lower because of the heat transfer.

Voltages may be measured across the ECT/ACT by probing the connector from the rear. A pair of safety pins may be helpful in doing this. Use care in doing it so that you don't damage the wiring or connector.

Here's the table :

50 degrees F = 3.52 v

68 degrees F = 3.02 v

86 degrees F = 2.62 v

104 degrees F = 2.16 v

122 degrees F = 1.72 v

140 degrees F = 1.35 v

158 degrees F = 1.04 v

176 degrees F = .80 v

194 degrees F = .61

212 degrees F = .47 v

230 degrees F = .36 v

248 degrees F = .28 v

Ohms measures at the computer with the computer disconnected, or at the sensor with the sensor disconnected.

50 degrees F = 58.75 K ohms

68 degrees F = 37.30 K ohms

86 degrees F = 27.27 K ohms

104 degrees F = 16.15 K ohms

122 degrees F = 10.97 K ohms

140 degrees F = 7.60 K ohms

158 degrees F = 5.37 K ohms

176 degrees F = 3.84 K ohms

194 degrees F = 2.80 K ohms

212 degrees F = 2.07 K ohms

230 degrees F = 1.55 K ohms

248 degrees F = 1.18 k ohms

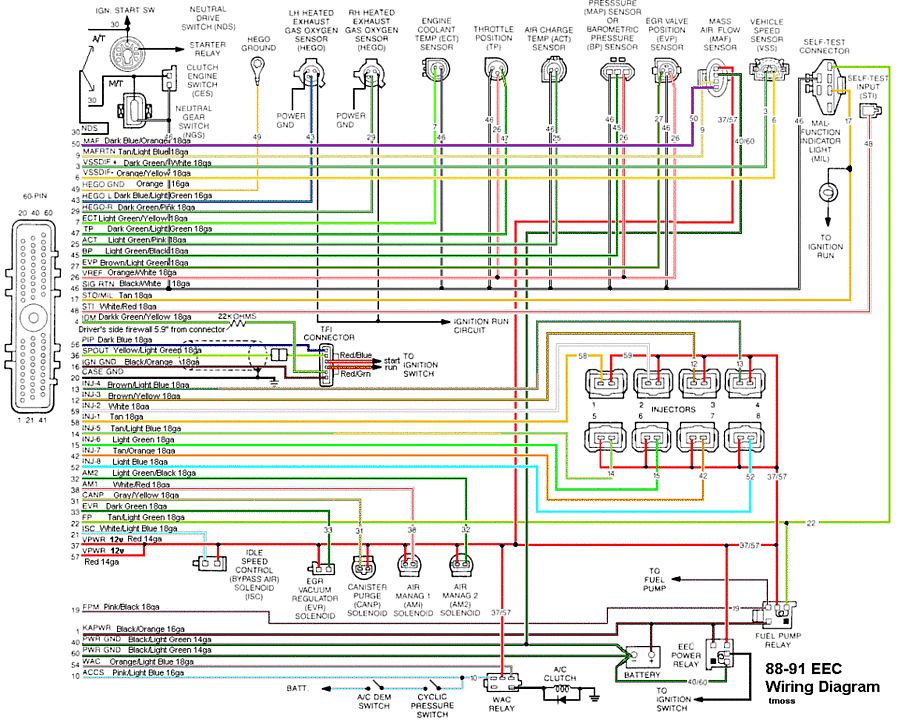

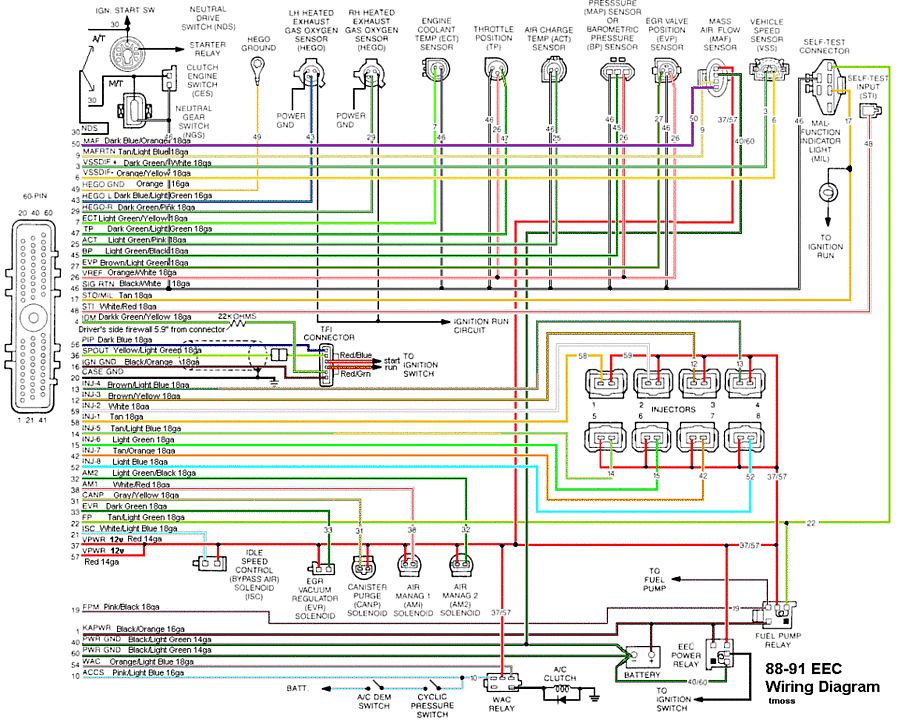

Diagram courtesy of Tmoss & Stang&2birds

See the following website for some help from Tmoss (diagram designer) & Stang&2Birds

(website host) for help on 88-95 wiring http://www.veryuseful.com/mustang/tech/engine/

Ignition switch wiring

http://www.veryuseful.com/mustang/tech/engine/images/IgnitionSwitchWiring.gif

Fuel, alternator, A/C and ignition wiring

http://www.veryuseful.com/mustang/tech/engine/images/fuel-alt-links-ign-ac.gif

Complete computer, actuator & sensor wiring diagram for 88-91 Mass Air Mustangs

http://www.veryuseful.com/mustang/tech/engine/images/88-91_5.0_EEC_Wiring_Diagram.gif

Vacuum diagram 89-93 Mustangs

http://www.veryuseful.com/mustang/tech/engine/images/mustangFoxFordVacuumDiagram.jpg

Code 24 - Intake Air Temperature (ACT) sensor out of range.

Bad sensor, bad wiring. The ACT for Mustangs built before 95 is in the

#5 intake runner. It measures the air temperature in the intake to help

computer the proper air/fuel ratio.

Note that that if the outside air temp is below 50 degrees F that the test for the ACT can be in error.

ACT & ECT test data:

The ACT & ECT have the same thermistor, so the table values are the same

Pin 7 on the computer - ECT signal in. at 176 degrees F it should be .80 volts

Pin 25 on the computer - ACT signal in. at 50 degrees F it should be 3.5 volts.

It is a good number if the ACT is mounted in the inlet airbox. If it is mounted in

the lower intake manifold, the voltage readings will be lower because of the heat transfer.

Here's the table :

50 degrees F = 3.52 v

68 degrees F = 3.02 v

86 degrees F = 2.62 v

104 degrees F = 2.16 v

122 degrees F = 1.72 v

140 degrees F = 1.35 v

158 degrees F = 1.04 v

176 degrees F = .80 v

194 degrees F = .61

212 degrees F = .47 v

230 degrees F = .36 v

248 degrees F = .28 v

Ohms measures at the computer with the computer disconnected,

or at the sensor with the sensor disconnected.

50 degrees F = 58.75 K ohms

68 degrees F = 37.30 K ohms

86 degrees F = 27.27 K ohms

104 degrees F = 16.15 K ohms

122 degrees F = 10.97 K ohms

140 degrees F = 7.60 K ohms

158 degrees F = 5.37 K ohms

176 degrees F = 3.84 K ohms

194 degrees F = 2.80 K ohms

212 degrees F = 2.07 K ohms

230 degrees F = 1.55 K ohms

248 degrees F = 1.18 k ohms

Code 34 Or 334 - EGR voltage above closed limit –

Revised 26-Sep-2011 to add EGR cleaning and movement test for pintle when vacuum is applied to diaphragm

Failed sensor, carbon between EGR pintle valve and seat holding the valve off its seat. Remove the EGR valve and clean it with carbon remover. Prior to re-installing see if you can blow air through the flange side of the EGR by mouth. If it leaks, there is carbon stuck on the pintle valve seat clean or, replace the EGR valve ($85-$95).

Recommended procedure for cleaning the EGR:

Conventional cleaning methods like throttle body cleaner aren’t very effective. The best method is a soak type cleaner used for carburetors. If you are into fixing motorcycles, jet skis, snowmobiles or anything else with a small carburetor, you probably have used the one gallon soak cleaners like Gunk or Berryman. One of the two should be available at your local auto parts store for $22-$29. There is a basket to set the parts in while they are soaking. Soak the metal body in the carb cleaner overnight. Don’t immerse the diaphragm side, since the carb cleaner may damage the diaphragm. If you get any of the carb cleaner on the diaphragm, rinse it off with water immediately. Rinse the part off with water and blow it dry with compressed air. Once it has dried, try blowing through the either hole and it should block the air flow. Do not put parts with water on them or in them in the carb cleaner. If you do, it will weaken the carb cleaner and it won’t clean as effectively.

Gunk Dip type carb & parts soaker:

If you have a handy vacuum source, apply it to the diaphragm and watch to see if the pintle moves freely. Try blowing air through either side and make sure it flows when the pintle retracts and blocks when the pintle is seated. If it does not, replace the EGR.

If the blow by test passes, and you have replaced the sensor, then you have electrical ground problems. Check the resistance between the black/white wire on the MAP/BARO sensor and then the black/white wire on the EGR and the same wire on the TPS. It should be less than 1.5 ohm. Next check the resistance between the black/white wire and the negative battery post. It should be less than 1.5 ohm.

Note that all resistance tests must be done with power off. Measuring resistance with a circuit powered on will give false readings and possibly damage the meter.

Let’s put on our Inspector Gadget propeller head beanies and think about how this works:

The EGR sensor is a variable resistor with ground on one leg and Vref (5 volts) on the other. Its’ resistance ranges from 4000 to 5500 Ohms measured between Vref & ground, depending on the sensor. The center connection of the variable resistor is the slider that moves in response to the amount of vacuum applied. The slider has some minimum value of resistance greater than 100 ohms so that the computer always sees a voltage present at its’ input. If the value was 0 ohms, there would be no voltage output. Then the computer would not be able to distinguish between a properly functioning sensor and one that had a broken wire or bad connection. The EGR I have in hand reads 700 Ohms between the slider (EPV) and ground (SIG RTN) at rest with no vacuum applied. The EGR valve or sensor may cause the voltage to be above closed limits due to the manufacturing tolerances that cause the EGR sensor to rest at a higher position than it should.

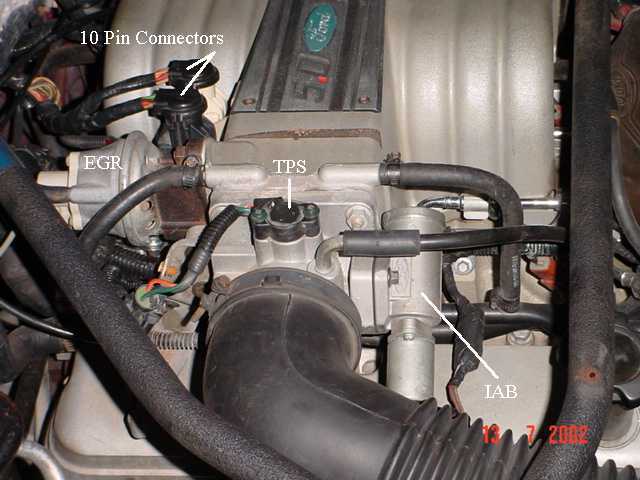

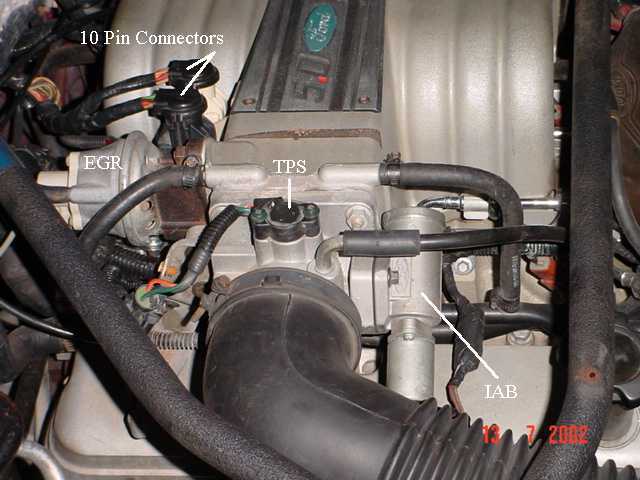

The following sensors are connected to the white 10 pin connector (salt & pepper engine harness connectors)

This will affect idle quality by diluting the intake air charge

Code 41 or 91 Three digit code 172 or 176 - O2 sensor indicates system lean. Look for a vacuum leak or failing O2 sensor.

Revised 20-Nov-2011 to include computer pin numbers for O2 sensor wiring for resistance checks

Code 41 is a RH side sensor,

Code 91 is the LH side sensor.

Code 172 is the RH side sensor

Code 176 is the LH side sensor

The computer sees a lean mixture signal coming from the O2 sensors and tries to compensate by adding more fuel. Many times the end result is an engine that runs pig rich and stinks of unburned fuel.

The following is a Quote from Charles O. Probst, Ford fuel Injection & Electronic Engine control:

"When the mixture is lean, the exhaust gas has oxygen, about the same amount as the ambient air. So the sensor will generate less than 400 Millivolts. Remember lean = less voltage.

When the mixture is rich, there's less oxygen in the exhaust than in the ambient air , so voltage is generated between the two sides of the tip. The voltage is greater than 600 millivolts. Remember rich = more voltage.

Here's a tip: the newer the sensor, the more the voltage changes, swinging from as low as 0.1 volt to as much as 0.9 volt. As an oxygen sensor ages, the voltage changes get smaller and slower - the voltage change lags behind the change in exhaust gas oxygen.

Because the oxygen sensor generates its own voltage, never apply voltage and never measure resistance of the sensor circuit. To measure voltage signals, use an analog voltmeter with a high input impedance, at least 10 megohms. Remember, a digital voltmeter will average a changing voltage." End Quote

Testing the O2 sensors 87-93 5.0 Mustangs

Measuring the O2 sensor voltage at the computer will give you a good idea of how well they are working. You'll have to pull the passenger side kick panel off to gain access to the computer connector. Remove the plastic wiring cover to get to the back side of the wiring. Use a safety pin or paper clip to probe the connections from the rear.

87-90 5.0 Mustangs:

Computer pin 43 Dark blue/Lt green – LH O2 sensor

Computer pin 29 Dark Green/Pink – RH O2 sensor

The computer pins are 29 (LH O2 with a dark green/pink wire) and 43 (RH O2 with a dark blue/pink wire). Use the ground next to the computer to ground the voltmeter. The O2 sensor voltage should switch between .2-.9 volt at idle.

91-93 5.0 Mustangs:

Computer pin 43 Red/Black – LH O2 sensor

Computer pin 29 Gray/Lt blue – RH O2 sensor

The computer pins are 29 (LH O2 with a Gray/Lt blue wire) and 43 (RH O2 with a Red/Black wire). Use the ground next to the computer to ground the voltmeter. The O2 sensor voltage should switch between .2-.9 volt at idle.

Testing the O2 sensors 94-95 5.0 Mustangs

Measuring the O2 sensor voltage at the computer will give you a good idea of how well they are working. You'll have to pull the passenger side kick panel off to gain access to the computer connector. Remove the plastic wiring cover to get to the back side of the wiring. Use a safety pin or paper clip to probe the connections from the rear. The computer pins are 29 (LH O2 with a red/black wire) and 27 (RH O2 with a gray/lt blue wire). Use pin 32 (gray/red wire) to ground the voltmeter. The O2 sensor voltage should switch between .2-.9 volt at idle.

Note that all resistance tests must be done with power off. Measuring resistance with a circuit powered on will give false readings and possibly damage the meter. Do not attempt to measure the resistance of the O2 sensors, it may damage them.

Testing the O2 sensor wiring harness

Most of the common multimeters have a resistance scale. Be sure the O2 sensors are disconnected and measure the resistance from the O2 sensor body harness to the pins on the computer. Using the Low Ohms range (usually 200 Ohms) you should see less than 1.5 Ohms.

87-90 5.0 Mustangs:

Computer pin 43 Dark blue/Lt green – LH O2 sensor

Computer pin 29 Dark Green/Pink – RH O2 sensor

Disconnect the connector from the O2 sensor and measure the resistance:

From the Dark blue/Lt green wire in the LH O2 sensor harness and the Dark blue/Lt green wire on the computer pin 43

From the Dark Green/Pink wire on the RH Os sensor harness and the Dark Green/Pink wire on the computer pin 43

91-93 5.0 Mustangs:

Computer pin 43 Red/Black – LH O2 sensor

Computer pin 29 Gray/Lt blue – RH O2 sensor

Disconnect the connector from the O2 sensor and measure the resistance:

From the Red/Black wire in the LH O2 sensor harness and the Red/Black wire on the computer pin 43

From the Dark Green/Pink Gray/Lt blue wire on the RH Os sensor harness and the Gray/Lt blue wire on the computer pin 29

94-95 5.0 Mustangs:

Computer pin 29 Red/Black – LH O2 sensor

Computer pin 27 Gray/Lt blue – RH O2 sensor

From the Red/Black wire in the LH O2 sensor harness and the Red/Black wire on the computer pin 29

From the Dark Green/Pink Gray/Lt blue wire on the RH Os sensor harness and the Gray/Lt blue wire on the computer pin 27

There is a connector between the body harness and the O2 sensor harness. Make sure the connectors are mated together, the contacts and wiring are not damaged and the contacts are clean and not coated with oil.

The O2 sensor ground (orange wire with a ring terminal on it) is in the wiring harness for the fuel injection wiring. I grounded mine to one of the intake manifold bolts

Make sure you have the proper 3 wire O2 sensors. Only the 4 cylinder cars used a 4 wire sensor, which is not compatible with the V8 wiring harness.

Replace the O2 sensors in pairs if replacement is indicated. If one is weak or bad, the other one probably isn't far behind.

If you get only code 41 and have changed the sensor, look for vacuum leaks. This is especially true if you are having idle problems. The small plastic tubing is very brittle after many years of the heating it receives. Replace the tubing and check the PVC and the hoses connected to it.

A secondary problem with only a code 41 is for cars with an intact smog pump and cats. If the tube on the back of the heads clogs up the driver’s side, all the air from the smog pump gets dumped into one side. This excess air upsets the O2 sensor calibration and can set a false code 41. The cure is to remove the crossover tube and thoroughly clean the insides so that there is no carbon blocking the free flow of air to both heads.

Code 42 & 92 (engine running) System rich - Fuel control or (memory) System was rich for 15 seconds or more (no HO2S switching) - Fuel control. Look for leaking injectors, fuel pressure too high, cylinder(s) not firing due to bad ignition.

Code 42 is the RH side sensor,

Code 92 is the LH side sensor.

Testing the O2 sensors

Measuring the O2 sensor voltage at the computer will give you a good idea of how well they are working. You'll have to pull the passenger side kick panel off to gain access to the computer connector. Remove the plastic wiring cover to get to the back side of the wiring. Use a safety pin or paper clip to probe the connections from the rear. The computer pins are 29 (LH O2 with a dark green/pink wire) and 43 (RH O2 with a dark blue/pink wire). Use the ground next to the computer to ground the voltmeter. The O2 sensor voltage should switch between .2-.9 volt at idle.

There is a fuse link for the O2 sensor heater power. According to Ranchero50, it is in the wiring near the passenger side hood hinge. Measuring the voltages will give a clue if it has shorted to the O2 sensor signal lead. The O2 sensor voltage should switch between .2-.9 volt at idle.

Code 63 - Throttle Position Sensor (TPS) signal too low.

Revised 02-Jul-2009 to update TPS setting procedure & add 10 pin connector layout.

Vref missing (5 volt reference voltage supplied by the computer), bad connections or damaged wiring, TPS sensor failed, TPS sensor way out of adjustment. Use a DVM to check for 5 volts on the Orange wire. If it is missing, look for +5 volts at the Orange wire on the EGR or MAP/Baro sensor located on the firewall near the center of the car. If there is +5 volts on the MAP/Baro sensor, but not on the EGR, clean the #2 & #5 pin on the white 10 pin connector. If there is +5 volts on the EGR but not on the TPS, look for bad wiring inside the engine fuel injector harness.

See the graphic for the 10 pin connector circuit layout.

Setting the TPS voltage

You'll need a Digital Voltmeter (DVM) to do the job.

Wire colors & functions:

Orange/white = 5 volt VREF from the computer

Dark Green/lt green = TPS output to computer

Black/white = Signal ground from computer

Always use the Dark Green/lt green & Black/white wires to set the TPS base voltage.

Do the test with the ignition switch in the Run position without the engine running.

Use the Orange/white & Black white wires to verify the TPS has the correct 5 volts source from the computer.

Setting the TPS: you'll need a good Digital Voltmeter (DVM) to do the job. Set the TPS voltage at .5- 1.1 range. Because of the variables involved with the tolerances of both computer and DVM, I would shoot for somewhere between .6 and 1.0 volts. Unless you have a Fluke or other high grade DVM, the second digit past the decimal point on cheap DVM’s is probably fantasy.

Since the computer zeros out the TPS voltage every time it powers up, playing with the settings isn't an effective aid to performance or drivability. The main purpose of checking the TPS is to make sure it isn't way out of range and causing problems.

The Orange/White wire is the VREF 5 volts from the computer. You use the Dark Green/Lt green wire (TPS signal) and the Black/White wire (TPS ground) to set the TPS. Use a pair of safety pins to probe the TPS connector from the rear of the connector. You may find it a little difficult to make a good connection, but keep trying. Put the safety pins in the Dark Green/Lt green wire and Black/White wire. Make sure the ignition switch is in the Run position but the engine isn't running.

Always adjust the TPS and Idle with the engine at operating temp. Dive it around for a bit if you can and get it nice and warm.

When you probe the leads of the TPS, do not use an engine ground, put the ground probe into the lead of the TPS. You should be connecting both meter probes to the TPS and not one to the TPS and the other to ground.

The TPS is a variable resistor, much like the volume control knob on a cheap radio. We have all heard them crackle and pop when the volume is adjusted. The TPS sensor has the same problem: wear on the resistor element makes places that create electrical noise. This electrical noise confuses the computer, because it expects to see a smooth increase or decrease as the throttle is opened or closed.

TPS testing: most of the time a failed TPS will set code 23 or 63, but not always. Use either an analog meter or a DVM with an analog bar graph and connect the leads as instructed above. Turn the ignition switch to the Run position, but do not start the engine. Note the voltage with the throttle closed. Slowly open the throttle and watch the voltage increase smoothly, slowly close the throttle and watch the voltage decrease smoothly. If the voltage jumps around and isn’t smooth, the TPS has some worn places in the resistor element. When the throttle is closed, make sure that the voltage is the same as what it was when you started. If it varies more than 10%, the TPS is suspect of being worn in the idle range of its travel.

Code 66 MAF below minimum test voltage.

Insufficient or no voltage from MAF. Dirty MAF element, bad MAF, bad MAF wiring, missing power to MAF. Check for missing +12 volts on this circuit. Check the two links for a wiring diagram to help you find the red wire for computer power relay switched +12 volts. Check for 12 volts between the red and black wires on the MAF heater (usually pins A & B). while the connector is plugged into the MAF. This may require the use of a couple of safety pins to probe the MAF connector from the back side of it.

There are three parts in a MAF: the heater, the sensor element and the amplifier. The heater heats the MAF sensor element causing the resistance to increase. The amplifier buffers the MAF output signal and has a resistor that is laser trimmed to provide an output range compatible with the computer's load tables.

The MAF element is secured by 2 screws & has 1 wiring connector. To clean the element, remove it from the MAF housing and spray it down with electronic parts cleaner or non-inflammable brake parts cleaner (same stuff in a bigger can and cheaper too).

Changes in RPM causes the airflow to increase or decease, changing the voltage output.. The increase of air across the MAF sensor element causes it to cool, allowing more voltage to pass and telling the computer to increase the fuel flow. A decrease in airflow causes the MAF sensor element to get warmer, decreasing the voltage and reducing the fuel flow.

Measure the MAF output at pins C & D on the MAF connector (dark blue/orange and tan/light blue) or at pins 50 & 9 on the computer. Be sure to measure the sensor output by measuring across the pins and not between the pins and ground.

At idle = approximately .6 volt

20 MPH = approximately 1.10 volt

40 MPH = approximately 1.70 volt

60 MPH = approximately 2.10 volt

Check the resistance of the MAF signal wiring. Pin D on the MAF and pin 50 on the computer (dark blue/orange wire) should be less than 2 ohms. Pin C on the MAF and pin 9 on the computer (tan/light blue wire) should be less than 2 ohms.

There should be a minimum of 10K ohms between either pin C or D on the MAF wiring connector and pins A or B. Make your measurement with the MAF disconnected from the wiring harness.

See the following website for some help from Tmoss (diagram designer) & Stang&2Birds (website host) for help on 88-95 wiring http://www.veryuseful.com/mustang/tech/engine/

Ignition switch wiring

http://www.veryuseful.com/mustang/tech/engine/images/IgnitionSwitchWiring.gif

Fuel pump, alternator, ignition & A/C wiring

http://www.veryuseful.com/mustang/tech/engine/images/fuel-alt-links-ign-ac.gif

Computer,. actuator & sensor wiring

http://www.veryuseful.com/mustang/tech/engine/images/88-91_5.0_EEC_Wiring_Diagram.gif

Fuse panel layout

http://www.veryuseful.com/mustang/tech/engine/images/MustangFuseBox.gif

Vacuum routing

http://www.veryuseful.com/mustang/tech/engine/images/mustangFoxFordVacuumDiagram.jpg

Code 81 – Secondary Air Injection Diverter Solenoid failure AM2. The solenoid valve located on the back side of the passenger side wheel well is not functional. Possible bad wiring, bad connections, missing or defective solenoid valve. Check the solenoid valve for +12 volts at the Red wire and look for the Lt Green/Black wire to switch from +12 volts to 1 volt or less. The computer controls the valve by providing a ground path on the LT Green/Black wire for the solenoid valve.

With the with the ignition on, look for 12 volts on the red wire on the solenoid connector. No 12 volts and you have wiring problems.

With the engine running, stick a safety pin in the LT Green/Black wire for the solenoid valve & ground it. That should turn the solenoid on and cause air to flow out the port that goes to the pipe connected to the cats. If it doesn't, the valve is bad. If it does cause the airflow to switch, the computer or wiring going to the computer is not signaling the solenoid valve to open.

Putting the computer into self test mode will cause the solenoid valve to toggle. If you listen carefully, you may hear it change states.

Code 85 - CANP solenoid - The Carbon Canister solenoid is inoperative or missing. Check vacuum lines for leaks and cracks. Check electrical wiring for loose connections, damaged wiring and insulation. Check solenoid valve operation by grounding the gray/yellow wire to the solenoid and blowing through it.

The computer provides the ground for the solenoid. The red wire to the solenoid is always energized any time the ignition switch is in the run position.

Charcoal canister plumbing - one 3/8" tube from the bottom of the upper manifold to the rubber hose. Rubber hose connects to one side of the canister solenoid valve. Other side of the solenoid valve connects to one side of the canister. The other side of the canister connects to a rubber hose that connects to a line that goes all the way back to the gas tank. There is an electrical connector coming from the passenger side injector harness near #1 injector that plugs into the canister solenoid valve. It's purpose is to vent the gas tank. The solenoid valve opens at cruse to provide some extra fuel. The canister is normally mounted on the passenger side frame rail near the smog pump pulley.

It does not weigh but a pound or so and helps richen up the cruse mixture. It draws no HP & keeps the car from smelling like gasoline in a closed garage. So with all these good things and no bad ones, why not hook it up & use it?

The purge valve solenoid connector is a dangling wire that is near the ECT sensor and oil filler on the passenger side rocker cover. The actual solenoid valve is down next to the carbon canister. There is about 12"-16" of wire that runs parallel to the canister vent hose that comes off the bottom side of the upper intake manifold. That hose connects one port of the solenoid valve; the other port connects to the carbon canister.

The purge valve solenoid should be available at your local auto parts store.

Purge valve solenoid:

The carbon canister is normally mounted on the passenger side frame rail near the smog pump pulley.

Carbon Canister:

Fix the codes first before doing anything else.

If you go through and carefully read and do all of the code definitions and fixes you stand an excellent chance of fixing the problem. If you get scared and run away because it looks like a lot of work you aren't going to have much success. If you were looking to bolt on some $15 part, to fix the problem, it probably isn't going to be that easy.

Persistence is often of greater value than genius.

Code 21 – ECT sensor out of range. Broken or damaged wiring, bad ECT sensor.

Note that that if the outside air temp is below 50 degrees F that the test for the ECT can be in error. Warm the engine up until you get good hot air from the heater and then dump the codes again.

The ECT sensor has absolutely nothing to do with the temperature gauge. They are different animals. The ECT sensor is normally located it the passenger side front of the engine in the water feed tubes for the heater.

The ACT & ECT have the same thermistor, so the table values are the same

ACT & ECT test data:

Use Pin 46 on the computer for ground for both ECT & ACT to get most accurate readings.

Pin 7 on the computer - ECT signal in. at 176 degrees F it should be .80 volts

Pin 25 on the computer - ACT signal in. at 50 degrees F it should be 3.5 volts. It is a good number if the ACT is mounted in the inlet airbox. If it is mounted in the lower intake manifold, the voltage readings will be lower because of the heat transfer.

Voltages may be measured across the ECT/ACT by probing the connector from the rear. A pair of safety pins may be helpful in doing this. Use care in doing it so that you don't damage the wiring or connector.

Here's the table :

50 degrees F = 3.52 v

68 degrees F = 3.02 v

86 degrees F = 2.62 v

104 degrees F = 2.16 v

122 degrees F = 1.72 v

140 degrees F = 1.35 v

158 degrees F = 1.04 v

176 degrees F = .80 v

194 degrees F = .61

212 degrees F = .47 v

230 degrees F = .36 v

248 degrees F = .28 v

Ohms measures at the computer with the computer disconnected, or at the sensor with the sensor disconnected.

50 degrees F = 58.75 K ohms

68 degrees F = 37.30 K ohms

86 degrees F = 27.27 K ohms

104 degrees F = 16.15 K ohms

122 degrees F = 10.97 K ohms

140 degrees F = 7.60 K ohms

158 degrees F = 5.37 K ohms

176 degrees F = 3.84 K ohms

194 degrees F = 2.80 K ohms

212 degrees F = 2.07 K ohms

230 degrees F = 1.55 K ohms

248 degrees F = 1.18 k ohms

Diagram courtesy of Tmoss & Stang&2birds

See the following website for some help from Tmoss (diagram designer) & Stang&2Birds

(website host) for help on 88-95 wiring http://www.veryuseful.com/mustang/tech/engine/

Ignition switch wiring

http://www.veryuseful.com/mustang/tech/engine/images/IgnitionSwitchWiring.gif

Fuel, alternator, A/C and ignition wiring

http://www.veryuseful.com/mustang/tech/engine/images/fuel-alt-links-ign-ac.gif

Complete computer, actuator & sensor wiring diagram for 88-91 Mass Air Mustangs

http://www.veryuseful.com/mustang/tech/engine/images/88-91_5.0_EEC_Wiring_Diagram.gif

Vacuum diagram 89-93 Mustangs

http://www.veryuseful.com/mustang/tech/engine/images/mustangFoxFordVacuumDiagram.jpg

Code 24 - Intake Air Temperature (ACT) sensor out of range.

Bad sensor, bad wiring. The ACT for Mustangs built before 95 is in the

#5 intake runner. It measures the air temperature in the intake to help

computer the proper air/fuel ratio.

Note that that if the outside air temp is below 50 degrees F that the test for the ACT can be in error.

ACT & ECT test data:

The ACT & ECT have the same thermistor, so the table values are the same

Pin 7 on the computer - ECT signal in. at 176 degrees F it should be .80 volts

Pin 25 on the computer - ACT signal in. at 50 degrees F it should be 3.5 volts.

It is a good number if the ACT is mounted in the inlet airbox. If it is mounted in

the lower intake manifold, the voltage readings will be lower because of the heat transfer.

Here's the table :

50 degrees F = 3.52 v

68 degrees F = 3.02 v

86 degrees F = 2.62 v

104 degrees F = 2.16 v

122 degrees F = 1.72 v

140 degrees F = 1.35 v

158 degrees F = 1.04 v

176 degrees F = .80 v

194 degrees F = .61

212 degrees F = .47 v

230 degrees F = .36 v

248 degrees F = .28 v

Ohms measures at the computer with the computer disconnected,

or at the sensor with the sensor disconnected.

50 degrees F = 58.75 K ohms

68 degrees F = 37.30 K ohms

86 degrees F = 27.27 K ohms

104 degrees F = 16.15 K ohms

122 degrees F = 10.97 K ohms

140 degrees F = 7.60 K ohms

158 degrees F = 5.37 K ohms

176 degrees F = 3.84 K ohms

194 degrees F = 2.80 K ohms

212 degrees F = 2.07 K ohms

230 degrees F = 1.55 K ohms

248 degrees F = 1.18 k ohms

Code 34 Or 334 - EGR voltage above closed limit –

Revised 26-Sep-2011 to add EGR cleaning and movement test for pintle when vacuum is applied to diaphragm

Failed sensor, carbon between EGR pintle valve and seat holding the valve off its seat. Remove the EGR valve and clean it with carbon remover. Prior to re-installing see if you can blow air through the flange side of the EGR by mouth. If it leaks, there is carbon stuck on the pintle valve seat clean or, replace the EGR valve ($85-$95).

Recommended procedure for cleaning the EGR:

Conventional cleaning methods like throttle body cleaner aren’t very effective. The best method is a soak type cleaner used for carburetors. If you are into fixing motorcycles, jet skis, snowmobiles or anything else with a small carburetor, you probably have used the one gallon soak cleaners like Gunk or Berryman. One of the two should be available at your local auto parts store for $22-$29. There is a basket to set the parts in while they are soaking. Soak the metal body in the carb cleaner overnight. Don’t immerse the diaphragm side, since the carb cleaner may damage the diaphragm. If you get any of the carb cleaner on the diaphragm, rinse it off with water immediately. Rinse the part off with water and blow it dry with compressed air. Once it has dried, try blowing through the either hole and it should block the air flow. Do not put parts with water on them or in them in the carb cleaner. If you do, it will weaken the carb cleaner and it won’t clean as effectively.

Gunk Dip type carb & parts soaker:

If you have a handy vacuum source, apply it to the diaphragm and watch to see if the pintle moves freely. Try blowing air through either side and make sure it flows when the pintle retracts and blocks when the pintle is seated. If it does not, replace the EGR.

If the blow by test passes, and you have replaced the sensor, then you have electrical ground problems. Check the resistance between the black/white wire on the MAP/BARO sensor and then the black/white wire on the EGR and the same wire on the TPS. It should be less than 1.5 ohm. Next check the resistance between the black/white wire and the negative battery post. It should be less than 1.5 ohm.

Note that all resistance tests must be done with power off. Measuring resistance with a circuit powered on will give false readings and possibly damage the meter.

Let’s put on our Inspector Gadget propeller head beanies and think about how this works:

The EGR sensor is a variable resistor with ground on one leg and Vref (5 volts) on the other. Its’ resistance ranges from 4000 to 5500 Ohms measured between Vref & ground, depending on the sensor. The center connection of the variable resistor is the slider that moves in response to the amount of vacuum applied. The slider has some minimum value of resistance greater than 100 ohms so that the computer always sees a voltage present at its’ input. If the value was 0 ohms, there would be no voltage output. Then the computer would not be able to distinguish between a properly functioning sensor and one that had a broken wire or bad connection. The EGR I have in hand reads 700 Ohms between the slider (EPV) and ground (SIG RTN) at rest with no vacuum applied. The EGR valve or sensor may cause the voltage to be above closed limits due to the manufacturing tolerances that cause the EGR sensor to rest at a higher position than it should.

The following sensors are connected to the white 10 pin connector (salt & pepper engine harness connectors)

This will affect idle quality by diluting the intake air charge

Code 41 or 91 Three digit code 172 or 176 - O2 sensor indicates system lean. Look for a vacuum leak or failing O2 sensor.

Revised 20-Nov-2011 to include computer pin numbers for O2 sensor wiring for resistance checks

Code 41 is a RH side sensor,

Code 91 is the LH side sensor.

Code 172 is the RH side sensor

Code 176 is the LH side sensor

The computer sees a lean mixture signal coming from the O2 sensors and tries to compensate by adding more fuel. Many times the end result is an engine that runs pig rich and stinks of unburned fuel.

The following is a Quote from Charles O. Probst, Ford fuel Injection & Electronic Engine control:

"When the mixture is lean, the exhaust gas has oxygen, about the same amount as the ambient air. So the sensor will generate less than 400 Millivolts. Remember lean = less voltage.

When the mixture is rich, there's less oxygen in the exhaust than in the ambient air , so voltage is generated between the two sides of the tip. The voltage is greater than 600 millivolts. Remember rich = more voltage.

Here's a tip: the newer the sensor, the more the voltage changes, swinging from as low as 0.1 volt to as much as 0.9 volt. As an oxygen sensor ages, the voltage changes get smaller and slower - the voltage change lags behind the change in exhaust gas oxygen.

Because the oxygen sensor generates its own voltage, never apply voltage and never measure resistance of the sensor circuit. To measure voltage signals, use an analog voltmeter with a high input impedance, at least 10 megohms. Remember, a digital voltmeter will average a changing voltage." End Quote

Testing the O2 sensors 87-93 5.0 Mustangs

Measuring the O2 sensor voltage at the computer will give you a good idea of how well they are working. You'll have to pull the passenger side kick panel off to gain access to the computer connector. Remove the plastic wiring cover to get to the back side of the wiring. Use a safety pin or paper clip to probe the connections from the rear.

87-90 5.0 Mustangs:

Computer pin 43 Dark blue/Lt green – LH O2 sensor

Computer pin 29 Dark Green/Pink – RH O2 sensor

The computer pins are 29 (LH O2 with a dark green/pink wire) and 43 (RH O2 with a dark blue/pink wire). Use the ground next to the computer to ground the voltmeter. The O2 sensor voltage should switch between .2-.9 volt at idle.

91-93 5.0 Mustangs:

Computer pin 43 Red/Black – LH O2 sensor

Computer pin 29 Gray/Lt blue – RH O2 sensor

The computer pins are 29 (LH O2 with a Gray/Lt blue wire) and 43 (RH O2 with a Red/Black wire). Use the ground next to the computer to ground the voltmeter. The O2 sensor voltage should switch between .2-.9 volt at idle.

Testing the O2 sensors 94-95 5.0 Mustangs

Measuring the O2 sensor voltage at the computer will give you a good idea of how well they are working. You'll have to pull the passenger side kick panel off to gain access to the computer connector. Remove the plastic wiring cover to get to the back side of the wiring. Use a safety pin or paper clip to probe the connections from the rear. The computer pins are 29 (LH O2 with a red/black wire) and 27 (RH O2 with a gray/lt blue wire). Use pin 32 (gray/red wire) to ground the voltmeter. The O2 sensor voltage should switch between .2-.9 volt at idle.

Note that all resistance tests must be done with power off. Measuring resistance with a circuit powered on will give false readings and possibly damage the meter. Do not attempt to measure the resistance of the O2 sensors, it may damage them.

Testing the O2 sensor wiring harness

Most of the common multimeters have a resistance scale. Be sure the O2 sensors are disconnected and measure the resistance from the O2 sensor body harness to the pins on the computer. Using the Low Ohms range (usually 200 Ohms) you should see less than 1.5 Ohms.

87-90 5.0 Mustangs:

Computer pin 43 Dark blue/Lt green – LH O2 sensor

Computer pin 29 Dark Green/Pink – RH O2 sensor

Disconnect the connector from the O2 sensor and measure the resistance:

From the Dark blue/Lt green wire in the LH O2 sensor harness and the Dark blue/Lt green wire on the computer pin 43

From the Dark Green/Pink wire on the RH Os sensor harness and the Dark Green/Pink wire on the computer pin 43

91-93 5.0 Mustangs:

Computer pin 43 Red/Black – LH O2 sensor

Computer pin 29 Gray/Lt blue – RH O2 sensor

Disconnect the connector from the O2 sensor and measure the resistance:

From the Red/Black wire in the LH O2 sensor harness and the Red/Black wire on the computer pin 43

From the Dark Green/Pink Gray/Lt blue wire on the RH Os sensor harness and the Gray/Lt blue wire on the computer pin 29

94-95 5.0 Mustangs:

Computer pin 29 Red/Black – LH O2 sensor

Computer pin 27 Gray/Lt blue – RH O2 sensor

From the Red/Black wire in the LH O2 sensor harness and the Red/Black wire on the computer pin 29

From the Dark Green/Pink Gray/Lt blue wire on the RH Os sensor harness and the Gray/Lt blue wire on the computer pin 27

There is a connector between the body harness and the O2 sensor harness. Make sure the connectors are mated together, the contacts and wiring are not damaged and the contacts are clean and not coated with oil.

The O2 sensor ground (orange wire with a ring terminal on it) is in the wiring harness for the fuel injection wiring. I grounded mine to one of the intake manifold bolts

Make sure you have the proper 3 wire O2 sensors. Only the 4 cylinder cars used a 4 wire sensor, which is not compatible with the V8 wiring harness.

Replace the O2 sensors in pairs if replacement is indicated. If one is weak or bad, the other one probably isn't far behind.

If you get only code 41 and have changed the sensor, look for vacuum leaks. This is especially true if you are having idle problems. The small plastic tubing is very brittle after many years of the heating it receives. Replace the tubing and check the PVC and the hoses connected to it.

A secondary problem with only a code 41 is for cars with an intact smog pump and cats. If the tube on the back of the heads clogs up the driver’s side, all the air from the smog pump gets dumped into one side. This excess air upsets the O2 sensor calibration and can set a false code 41. The cure is to remove the crossover tube and thoroughly clean the insides so that there is no carbon blocking the free flow of air to both heads.

Code 42 & 92 (engine running) System rich - Fuel control or (memory) System was rich for 15 seconds or more (no HO2S switching) - Fuel control. Look for leaking injectors, fuel pressure too high, cylinder(s) not firing due to bad ignition.

Code 42 is the RH side sensor,

Code 92 is the LH side sensor.

Testing the O2 sensors

Measuring the O2 sensor voltage at the computer will give you a good idea of how well they are working. You'll have to pull the passenger side kick panel off to gain access to the computer connector. Remove the plastic wiring cover to get to the back side of the wiring. Use a safety pin or paper clip to probe the connections from the rear. The computer pins are 29 (LH O2 with a dark green/pink wire) and 43 (RH O2 with a dark blue/pink wire). Use the ground next to the computer to ground the voltmeter. The O2 sensor voltage should switch between .2-.9 volt at idle.

There is a fuse link for the O2 sensor heater power. According to Ranchero50, it is in the wiring near the passenger side hood hinge. Measuring the voltages will give a clue if it has shorted to the O2 sensor signal lead. The O2 sensor voltage should switch between .2-.9 volt at idle.

Code 63 - Throttle Position Sensor (TPS) signal too low.

Revised 02-Jul-2009 to update TPS setting procedure & add 10 pin connector layout.

Vref missing (5 volt reference voltage supplied by the computer), bad connections or damaged wiring, TPS sensor failed, TPS sensor way out of adjustment. Use a DVM to check for 5 volts on the Orange wire. If it is missing, look for +5 volts at the Orange wire on the EGR or MAP/Baro sensor located on the firewall near the center of the car. If there is +5 volts on the MAP/Baro sensor, but not on the EGR, clean the #2 & #5 pin on the white 10 pin connector. If there is +5 volts on the EGR but not on the TPS, look for bad wiring inside the engine fuel injector harness.

See the graphic for the 10 pin connector circuit layout.

Setting the TPS voltage

You'll need a Digital Voltmeter (DVM) to do the job.

Wire colors & functions:

Orange/white = 5 volt VREF from the computer

Dark Green/lt green = TPS output to computer

Black/white = Signal ground from computer

Always use the Dark Green/lt green & Black/white wires to set the TPS base voltage.

Do the test with the ignition switch in the Run position without the engine running.

Use the Orange/white & Black white wires to verify the TPS has the correct 5 volts source from the computer.

Setting the TPS: you'll need a good Digital Voltmeter (DVM) to do the job. Set the TPS voltage at .5- 1.1 range. Because of the variables involved with the tolerances of both computer and DVM, I would shoot for somewhere between .6 and 1.0 volts. Unless you have a Fluke or other high grade DVM, the second digit past the decimal point on cheap DVM’s is probably fantasy.

Since the computer zeros out the TPS voltage every time it powers up, playing with the settings isn't an effective aid to performance or drivability. The main purpose of checking the TPS is to make sure it isn't way out of range and causing problems.

The Orange/White wire is the VREF 5 volts from the computer. You use the Dark Green/Lt green wire (TPS signal) and the Black/White wire (TPS ground) to set the TPS. Use a pair of safety pins to probe the TPS connector from the rear of the connector. You may find it a little difficult to make a good connection, but keep trying. Put the safety pins in the Dark Green/Lt green wire and Black/White wire. Make sure the ignition switch is in the Run position but the engine isn't running.

Always adjust the TPS and Idle with the engine at operating temp. Dive it around for a bit if you can and get it nice and warm.

When you probe the leads of the TPS, do not use an engine ground, put the ground probe into the lead of the TPS. You should be connecting both meter probes to the TPS and not one to the TPS and the other to ground.

The TPS is a variable resistor, much like the volume control knob on a cheap radio. We have all heard them crackle and pop when the volume is adjusted. The TPS sensor has the same problem: wear on the resistor element makes places that create electrical noise. This electrical noise confuses the computer, because it expects to see a smooth increase or decrease as the throttle is opened or closed.

TPS testing: most of the time a failed TPS will set code 23 or 63, but not always. Use either an analog meter or a DVM with an analog bar graph and connect the leads as instructed above. Turn the ignition switch to the Run position, but do not start the engine. Note the voltage with the throttle closed. Slowly open the throttle and watch the voltage increase smoothly, slowly close the throttle and watch the voltage decrease smoothly. If the voltage jumps around and isn’t smooth, the TPS has some worn places in the resistor element. When the throttle is closed, make sure that the voltage is the same as what it was when you started. If it varies more than 10%, the TPS is suspect of being worn in the idle range of its travel.

Code 66 MAF below minimum test voltage.

Insufficient or no voltage from MAF. Dirty MAF element, bad MAF, bad MAF wiring, missing power to MAF. Check for missing +12 volts on this circuit. Check the two links for a wiring diagram to help you find the red wire for computer power relay switched +12 volts. Check for 12 volts between the red and black wires on the MAF heater (usually pins A & B). while the connector is plugged into the MAF. This may require the use of a couple of safety pins to probe the MAF connector from the back side of it.

There are three parts in a MAF: the heater, the sensor element and the amplifier. The heater heats the MAF sensor element causing the resistance to increase. The amplifier buffers the MAF output signal and has a resistor that is laser trimmed to provide an output range compatible with the computer's load tables.

The MAF element is secured by 2 screws & has 1 wiring connector. To clean the element, remove it from the MAF housing and spray it down with electronic parts cleaner or non-inflammable brake parts cleaner (same stuff in a bigger can and cheaper too).

Changes in RPM causes the airflow to increase or decease, changing the voltage output.. The increase of air across the MAF sensor element causes it to cool, allowing more voltage to pass and telling the computer to increase the fuel flow. A decrease in airflow causes the MAF sensor element to get warmer, decreasing the voltage and reducing the fuel flow.

Measure the MAF output at pins C & D on the MAF connector (dark blue/orange and tan/light blue) or at pins 50 & 9 on the computer. Be sure to measure the sensor output by measuring across the pins and not between the pins and ground.

At idle = approximately .6 volt

20 MPH = approximately 1.10 volt

40 MPH = approximately 1.70 volt

60 MPH = approximately 2.10 volt

Check the resistance of the MAF signal wiring. Pin D on the MAF and pin 50 on the computer (dark blue/orange wire) should be less than 2 ohms. Pin C on the MAF and pin 9 on the computer (tan/light blue wire) should be less than 2 ohms.

There should be a minimum of 10K ohms between either pin C or D on the MAF wiring connector and pins A or B. Make your measurement with the MAF disconnected from the wiring harness.

See the following website for some help from Tmoss (diagram designer) & Stang&2Birds (website host) for help on 88-95 wiring http://www.veryuseful.com/mustang/tech/engine/

Ignition switch wiring

http://www.veryuseful.com/mustang/tech/engine/images/IgnitionSwitchWiring.gif

Fuel pump, alternator, ignition & A/C wiring

http://www.veryuseful.com/mustang/tech/engine/images/fuel-alt-links-ign-ac.gif

Computer,. actuator & sensor wiring

http://www.veryuseful.com/mustang/tech/engine/images/88-91_5.0_EEC_Wiring_Diagram.gif

Fuse panel layout

http://www.veryuseful.com/mustang/tech/engine/images/MustangFuseBox.gif

Vacuum routing

http://www.veryuseful.com/mustang/tech/engine/images/mustangFoxFordVacuumDiagram.jpg

Code 81 – Secondary Air Injection Diverter Solenoid failure AM2. The solenoid valve located on the back side of the passenger side wheel well is not functional. Possible bad wiring, bad connections, missing or defective solenoid valve. Check the solenoid valve for +12 volts at the Red wire and look for the Lt Green/Black wire to switch from +12 volts to 1 volt or less. The computer controls the valve by providing a ground path on the LT Green/Black wire for the solenoid valve.

With the with the ignition on, look for 12 volts on the red wire on the solenoid connector. No 12 volts and you have wiring problems.

With the engine running, stick a safety pin in the LT Green/Black wire for the solenoid valve & ground it. That should turn the solenoid on and cause air to flow out the port that goes to the pipe connected to the cats. If it doesn't, the valve is bad. If it does cause the airflow to switch, the computer or wiring going to the computer is not signaling the solenoid valve to open.

Putting the computer into self test mode will cause the solenoid valve to toggle. If you listen carefully, you may hear it change states.

Code 85 - CANP solenoid - The Carbon Canister solenoid is inoperative or missing. Check vacuum lines for leaks and cracks. Check electrical wiring for loose connections, damaged wiring and insulation. Check solenoid valve operation by grounding the gray/yellow wire to the solenoid and blowing through it.

The computer provides the ground for the solenoid. The red wire to the solenoid is always energized any time the ignition switch is in the run position.

Charcoal canister plumbing - one 3/8" tube from the bottom of the upper manifold to the rubber hose. Rubber hose connects to one side of the canister solenoid valve. Other side of the solenoid valve connects to one side of the canister. The other side of the canister connects to a rubber hose that connects to a line that goes all the way back to the gas tank. There is an electrical connector coming from the passenger side injector harness near #1 injector that plugs into the canister solenoid valve. It's purpose is to vent the gas tank. The solenoid valve opens at cruse to provide some extra fuel. The canister is normally mounted on the passenger side frame rail near the smog pump pulley.

It does not weigh but a pound or so and helps richen up the cruse mixture. It draws no HP & keeps the car from smelling like gasoline in a closed garage. So with all these good things and no bad ones, why not hook it up & use it?

The purge valve solenoid connector is a dangling wire that is near the ECT sensor and oil filler on the passenger side rocker cover. The actual solenoid valve is down next to the carbon canister. There is about 12"-16" of wire that runs parallel to the canister vent hose that comes off the bottom side of the upper intake manifold. That hose connects one port of the solenoid valve; the other port connects to the carbon canister.

The purge valve solenoid should be available at your local auto parts store.

Purge valve solenoid:

The carbon canister is normally mounted on the passenger side frame rail near the smog pump pulley.

Carbon Canister:

Blown88GT

Founding Member

I

cThat many seemingly unrelated codes would indicate the most likely item to check:

I did double check salt and pepper connectors and still idles bad could my problem be the ecm? i check trouble codes again and I got this KOER 12 21 24 91 34 and KOEO 34 81 85 I dont know I give up I problably take it to a ford dealer = {

Time to quit crying and get to work...

The Ford dealer will probably tell you they won't work on it becasue it is too old.

Fix the codes and then retest! There is possibly a bad signal ground which would affect all engine mounted sensors. Check and clean the 10 pin connectors!!!

The computer pin 46 signal ground is a critical component: it provides ground for the

Map/Baro, TPS, ECT, EGR position sensor and ACT. Signal ground is used in many circuits that have analog inputs to isolate the electrical noise. It is always separate from power ground, although both may have a common connection origination point. Signal ground usually has some conditioning that reduces the electrical noise to prevent false readings. The black/white wire (pin 46) is signal ground for the computer. It provides a dedicated ground for the EGR, Baro, ACT, ECT, & TPS sensors as well as the ground to put the computer into self test mode. If this ground is bad, none of the sensors mentioned will work properly. That will severely affect the car's performance. You will have hard starting, low power and drivability problems. What sometimes happens is that the test connector black/white wire gets jumpered to power which either burns up the wiring or burns the trace off the pc board inside the computer. That trace connects pins 46 to pins 40 & 60.

See http://www.stangnet.com/mustang-forums/749974-computer-issue.html#post7490537 for Joel5.0’s fix to the computer internal signal ground.

If the ground for the TPS goes bad, the TPS output voltage increases and the idle speed may fluctuate..

Troubleshooting signal ground problems:

Note that all resistance tests must be done with power off. Measuring resistance with a circuit powered on will give false readings and possibly damage the meter. That means disconnecting the battery positive cable since there is always some current draw due to the computer and radio circuits.

1.) With the power off, measure the resistance between the computer test ground

(black/white wire) on the self test connector and battery ground. You should see less than 1.5 ohms.

2.) MAP circuit: Check the resistance between the black/white wire on the MAP/BARO sensor and then the black/white wire on the EGR and the same wire on the TPS. It should be less than 1 ohms. Higher resistance than 1 ohms indicates a problem with the 10 pin connector or the splice inside the main harness where the wire from the 10 pin connectors joins the rest of the black/white wire. Next check the resistance between the black/white wire and the negative battery cable. It should be less than 1.5 ohms.

3.) Engine mounted sensor circuit: Check the resistance between the black/white wire on the TPS and battery ground. It should be less than 1.5 ohms. Higher resistance than 1.5 ohms indicates a problem with the 10 pin connector or the splice inside the main harness where the wire from the 10 pin connectors joins the rest of the black/white wire.

Repeat the process for the ACT and ECT sensors. Your results should have the same specifications.

See the graphic for the location of the 10 pin connectors:

Diagram courtesy of Tmoss & Stang&2birds

See the graphic for the 10 pin connector circuit layout.

The injector power pin is the VPWR pin in the black 10 pin connector.

The Ford dealer will probably tell you they won't work on it becasue it is too old.

Fix the codes and then retest! There is possibly a bad signal ground which would affect all engine mounted sensors. Check and clean the 10 pin connectors!!!

The computer pin 46 signal ground is a critical component: it provides ground for the

Map/Baro, TPS, ECT, EGR position sensor and ACT. Signal ground is used in many circuits that have analog inputs to isolate the electrical noise. It is always separate from power ground, although both may have a common connection origination point. Signal ground usually has some conditioning that reduces the electrical noise to prevent false readings. The black/white wire (pin 46) is signal ground for the computer. It provides a dedicated ground for the EGR, Baro, ACT, ECT, & TPS sensors as well as the ground to put the computer into self test mode. If this ground is bad, none of the sensors mentioned will work properly. That will severely affect the car's performance. You will have hard starting, low power and drivability problems. What sometimes happens is that the test connector black/white wire gets jumpered to power which either burns up the wiring or burns the trace off the pc board inside the computer. That trace connects pins 46 to pins 40 & 60.

See http://www.stangnet.com/mustang-forums/749974-computer-issue.html#post7490537 for Joel5.0’s fix to the computer internal signal ground.

If the ground for the TPS goes bad, the TPS output voltage increases and the idle speed may fluctuate..

Troubleshooting signal ground problems:

Note that all resistance tests must be done with power off. Measuring resistance with a circuit powered on will give false readings and possibly damage the meter. That means disconnecting the battery positive cable since there is always some current draw due to the computer and radio circuits.

1.) With the power off, measure the resistance between the computer test ground

(black/white wire) on the self test connector and battery ground. You should see less than 1.5 ohms.

2.) MAP circuit: Check the resistance between the black/white wire on the MAP/BARO sensor and then the black/white wire on the EGR and the same wire on the TPS. It should be less than 1 ohms. Higher resistance than 1 ohms indicates a problem with the 10 pin connector or the splice inside the main harness where the wire from the 10 pin connectors joins the rest of the black/white wire. Next check the resistance between the black/white wire and the negative battery cable. It should be less than 1.5 ohms.

3.) Engine mounted sensor circuit: Check the resistance between the black/white wire on the TPS and battery ground. It should be less than 1.5 ohms. Higher resistance than 1.5 ohms indicates a problem with the 10 pin connector or the splice inside the main harness where the wire from the 10 pin connectors joins the rest of the black/white wire.

Repeat the process for the ACT and ECT sensors. Your results should have the same specifications.

See the graphic for the location of the 10 pin connectors:

Diagram courtesy of Tmoss & Stang&2birds

See the graphic for the 10 pin connector circuit layout.

The injector power pin is the VPWR pin in the black 10 pin connector.

I've perfom the computer ground test and I didnt get any readings from my DVM I noticed on the ECM are two capacitors leaking is that normal? or that could be an open circuit?

The open circuit between the computer test connector and battery ground is a sign that the internal signal ground has been burned off the computer circuit board or the wiring is damaged. The leaking electrolytic caps are a trouble sign of a computer subjected to electrical over stress or abuse. With both of these symptoms present, I would recommend that you check with your local auto parts store about a replacement computer. Don't try to fix the computer yourself unless you are experienced in repairing PC boards and electronic components..

well I got a new ecm and it doesnt make any difference the car still running rough stalling erratic etc etc... help please!!

DUDE, I had the same type isuess for ever.. listen to him and just be patient, follow what he says to the letter an you will get it fixed.. The list he puts out work, just have to follow them step by step, skip like I did and youll still be mad it isnt fixed.. Just give it time and do all the steps he throws at you and it will be back in action..

I Know he's the best I realy appreciate what he does for me I will like to shake he's hand and thank him for helping me thanks Mr.Jrichker !!!! the codes I got next..... KOEO...34,81,82,10,11 KOER......64,98 .... ACT sensor brand new ...

!!!! the codes I got next..... KOEO...34,81,82,10,11 KOER......64,98 .... ACT sensor brand new ...

Disconnect the battery, turn the head light switch on and wait 5 minutes. Turn the headlight switch off and reconnect the battery.Then drive the car and dump the codes again.

If you still get a bunch codes, here's some more help:

Did you remove the EGR valve, test and clean in as previously instructed in the code 34 test path?

Code 98 - basic computer internal tests not passed before it started processing the request to dump codes. Do a Key On Engine Off test before starting the engine. Wait until you see the 11 flash before pressing any buttons if you have a hand operated scanner. The computer is operating in Limp mode, so fix any codes it dumps prior to doing anything else.

Code 64 – ACT (Air Charge Temperature) signal low or grounded. Bad sensor, sensor wiring on pin 25 shorted to ground, or bad computer.

Note that all resistance tests must be done with power off. Measuring resistance with a circuit powered on will give false readings and possibly damage the meter.

1.) The ACT is located in the #5 intake runner on Mustangs built from 86-93 . Disconnect the sensor by removing the sensor wiring connector. Measure the resistance across the sensor pins.

Ohms measures at the computer with the computer disconnected, or at the sensor with the sensor disconnected.

50 degrees F = 58.75 K ohms

68 degrees F = 37.30 K ohms

86 degrees F = 27.27 K ohms

104 degrees F = 16.15 K ohms

122 degrees F = 10.97 K ohms

140 degrees F = 7.60 K ohms

158 degrees F = 5.37 K ohms

176 degrees F = 3.84 K ohms

194 degrees F = 2.80 K ohms

2.) If the sensor resistances read good according to the table, remove the passenger side kick panel and disconnect the computer connector. A single 10 MM bolt secures the connector in place. With the sensor connector still disconnected, measure the resistance between pin 25 (lt green/pink wire) and ground. If you wish, you can make your measurements at the ACT sensor end. This will save you from counting the computer connector pins to locate the correct one. However, you will still have to disconnect the computer connector. You should see 100K Ohms or greater between pin 25 and ground.

Less than that indicates wiring problems with the pin 25 lt green/pink wire shorted to ground. Note that the following diagram on the connector displays the pins viewed from the computer side.

See following website for some help from Tmoss (diagram designer) & Stang&2Birds (website host) for

help on 88-95 wiring http://www.veryuseful.com/mustang/tech/engine/

http://www.veryuseful.com/mustang/tech/engine/images/88-91eecPinout.gif

Diagram courtesy of Tmoss & Stang&2birds

Code 81 – Secondary Air Injection Diverter Solenoid failure AM2. The solenoid valve located on the back side of the passenger side wheel well is not functional. Possible bad wiring, bad connections, missing or defective solenoid valve. Check the solenoid valve for +12 volts at the Red wire and look for the Lt Green/Black wire to switch from +12 volts to 1 volt or less. The computer controls the valve by providing a ground path on the LT Green/Black wire for the solenoid valve.

With the with the ignition on, look for 12 volts on the red wire on the solenoid connector. No 12 volts and you have wiring problems.

With the engine running, stick a safety pin in the LT Green/Black wire for the solenoid valve & ground it. That should turn the solenoid on and cause air to flow out the port that goes to the pipe connected to the cats. If it doesn't, the valve is bad. If it does cause the airflow to switch, the computer or wiring going to the computer is not signaling the solenoid valve to open.

Putting the computer into self test mode will cause the solenoid valve to toggle. If you listen carefully, you may hear it change states.

Code 82 – Secondary Air Injection Diverter Solenoid failure AM1. Possible bad wiring, bad connections, missing or defective solenoid valve. Check the solenoid valve for +12 volts at the Red wire and look for the Red/White wire to switch from +12 volts to 1 volt or less. The computer controls the valve by providing a ground path on the Red/White wire for the solenoid valve

With the engine running, stick a safety pin in the Red/White wire for the solenoid valve & ground it. That should turn the solenoid on and cause air to flow out the port that goes to the pipe connected to the heads. If it doesn't, the valve is bad. If it does cause the airflow to switch, the computer or wiring going to the computer is not signaling the solenoid valve to open.

Both 81 & 82 codes usually mean that some uneducated person removed the solenoid control valves for the Thermactor Air system in an attempt to make the car faster. It doesn't work that way: no working control valves can cause the cat converters to choke and clog. If you do not have cat converters on the car, you can ignore the 81 & 82 codes.

If you still get a bunch codes, here's some more help:

Did you remove the EGR valve, test and clean in as previously instructed in the code 34 test path?

Code 98 - basic computer internal tests not passed before it started processing the request to dump codes. Do a Key On Engine Off test before starting the engine. Wait until you see the 11 flash before pressing any buttons if you have a hand operated scanner. The computer is operating in Limp mode, so fix any codes it dumps prior to doing anything else.

Code 64 – ACT (Air Charge Temperature) signal low or grounded. Bad sensor, sensor wiring on pin 25 shorted to ground, or bad computer.

Note that all resistance tests must be done with power off. Measuring resistance with a circuit powered on will give false readings and possibly damage the meter.

1.) The ACT is located in the #5 intake runner on Mustangs built from 86-93 . Disconnect the sensor by removing the sensor wiring connector. Measure the resistance across the sensor pins.

Ohms measures at the computer with the computer disconnected, or at the sensor with the sensor disconnected.

50 degrees F = 58.75 K ohms

68 degrees F = 37.30 K ohms

86 degrees F = 27.27 K ohms

104 degrees F = 16.15 K ohms

122 degrees F = 10.97 K ohms

140 degrees F = 7.60 K ohms

158 degrees F = 5.37 K ohms

176 degrees F = 3.84 K ohms

194 degrees F = 2.80 K ohms

2.) If the sensor resistances read good according to the table, remove the passenger side kick panel and disconnect the computer connector. A single 10 MM bolt secures the connector in place. With the sensor connector still disconnected, measure the resistance between pin 25 (lt green/pink wire) and ground. If you wish, you can make your measurements at the ACT sensor end. This will save you from counting the computer connector pins to locate the correct one. However, you will still have to disconnect the computer connector. You should see 100K Ohms or greater between pin 25 and ground.

Less than that indicates wiring problems with the pin 25 lt green/pink wire shorted to ground. Note that the following diagram on the connector displays the pins viewed from the computer side.

See following website for some help from Tmoss (diagram designer) & Stang&2Birds (website host) for

help on 88-95 wiring http://www.veryuseful.com/mustang/tech/engine/

http://www.veryuseful.com/mustang/tech/engine/images/88-91eecPinout.gif

Diagram courtesy of Tmoss & Stang&2birds

Code 81 – Secondary Air Injection Diverter Solenoid failure AM2. The solenoid valve located on the back side of the passenger side wheel well is not functional. Possible bad wiring, bad connections, missing or defective solenoid valve. Check the solenoid valve for +12 volts at the Red wire and look for the Lt Green/Black wire to switch from +12 volts to 1 volt or less. The computer controls the valve by providing a ground path on the LT Green/Black wire for the solenoid valve.

With the with the ignition on, look for 12 volts on the red wire on the solenoid connector. No 12 volts and you have wiring problems.

With the engine running, stick a safety pin in the LT Green/Black wire for the solenoid valve & ground it. That should turn the solenoid on and cause air to flow out the port that goes to the pipe connected to the cats. If it doesn't, the valve is bad. If it does cause the airflow to switch, the computer or wiring going to the computer is not signaling the solenoid valve to open.

Putting the computer into self test mode will cause the solenoid valve to toggle. If you listen carefully, you may hear it change states.

Code 82 – Secondary Air Injection Diverter Solenoid failure AM1. Possible bad wiring, bad connections, missing or defective solenoid valve. Check the solenoid valve for +12 volts at the Red wire and look for the Red/White wire to switch from +12 volts to 1 volt or less. The computer controls the valve by providing a ground path on the Red/White wire for the solenoid valve

With the engine running, stick a safety pin in the Red/White wire for the solenoid valve & ground it. That should turn the solenoid on and cause air to flow out the port that goes to the pipe connected to the heads. If it doesn't, the valve is bad. If it does cause the airflow to switch, the computer or wiring going to the computer is not signaling the solenoid valve to open.

Both 81 & 82 codes usually mean that some uneducated person removed the solenoid control valves for the Thermactor Air system in an attempt to make the car faster. It doesn't work that way: no working control valves can cause the cat converters to choke and clog. If you do not have cat converters on the car, you can ignore the 81 & 82 codes.

the car still bone stock I got the cats they seem to get really hot when I turn the car on they maybe clog u think? I clean up the egr block and bypass tube in the back of the heads and it was all clean I removed the upper intake manifold check all the hoses didnt find anything still getting the same codes  .......the ACT sensor is brand new check the readings with a dvm looks ok

.......the ACT sensor is brand new check the readings with a dvm looks ok

.......the ACT sensor is brand new check the readings with a dvm looks ok

.......the ACT sensor is brand new check the readings with a dvm looks okACT - The code you are getting points to a short to ground in the sensor or wiring for the ACT. See item #2 in the ACT code test path I posted for the test proceedure to help diagnose the short circuit.

Thermactor Air System

Some review of how it works...

Revised 17-Sept-2011 to add testing procedure.

The Thermactor air pump (smog pump) supplies air to the heads or catalytic converters. This air helps break down the excess HC (hydrocarbons) and CO (carbon monoxide). The air supplied to the catalytic converters helps create the catalytic reaction that changes the HC & CO into CO2 and water vapor. Catalytic converters on 5.0 Mustangs are designed to use the extra air provided by the smog pump. Without the extra air, the catalytic converters will clog and fail.

The Thermactor air pump draws air from an inlet filter in the front of the pump. The smog pump puts air into the heads when the engine is cold and then into the catalytic converters when it is warm. The Thermactor control valves serve to direct the flow. The first valve, TAB (Thermactor Air Bypass) or AM1 valve) either dumps air to the atmosphere or passes it on to the second valve. The second valve, TAD (Thermactor Air Diverter valve or AM2 valve) directs it to the heads or the catalytic converters. Check valves located after the TAB & TAD solenoids prevent hot exhaust gases from damaging the control valves or pump in case of a backfire. The air serves to help consume any unburned hydrocarbons by supplying extra oxygen to the catalytic process. The computer tells the Thermactor Air System to open the Bypass valve at WOT (wide open throttle) minimizing engine drag. This dumps the pump's output to the atmosphere, and reduces the parasitic drag caused by the smog pump to about 2-4 HP at WOT. The Bypass valve also opens during deceleration to reduce or prevent backfires.

Code 44 RH side air not functioning.

Code 94 LH side air not functioning.

The computer uses the change in the O2 sensor readings to detect operation of the Thermactor control valves. When the dump valve opens, it reduces the O2 readings in the exhaust system. Then it closes the dump valve and the O2 readings increase. By toggling the dump valve (TAB), the computer tests for the 44/94 codes.

Failure mode is usually due to a clogged air crossover tube, where one or both sides of the tube clog with carbon. The air crossover tube mounts on the back of the cylinder heads and supplies air to each of the Thermactor air passages cast into the cylinder heads. When the heads do not get the proper air delivery, they set codes 44 & 94, depending on which passage is clogged. It is possible to get both 44 & 94, which would suggest that the air pump or control valves are not working correctly, or the crossover tube is full of carbon or missing.

Computer operation & control for the Thermactor Air System

Automobile computers use current sink technology. They do not source power to any relay, solenoid or actuator like the IAC, fuel pump relay, or fuel injectors. Instead the computer provides a ground path for the positive battery voltage to get back to the battery negative terminal. That flow of power from positive to negative is what provides the energy to make the IAC, fuel pump relay, or fuel injectors work. No ground provided by the computer, then the actuators and relays don't operate.

One side of the any relay/actuator/solenoid in the engine compartment will be connected to a red wire that has 12-14 volts anytime the ignition switch is in the run position. The other side will have 12-14 volts when the relay/actuator/solenoid isn't turned on. Once the computer turns on the clamp side, the voltage on the computer side of the wire will drop down to 1 volt or less.

In order to test the TAD/TAB solenoids, you need to ground the white/red wire on the TAB solenoid or the light green/black wire on the TAD solenoid.

For 94-95 cars: the colors are different. The White/Red wire (TAB control) is White/Orange (Pin 31 on the PCM). The Green/Black wire (TAD control) should be Brown (pin 34 at the PCM). Thanks to HISSIN50 for this tip.

Testing the system:

To test the computer, you can use a test light across the TAB or TAD wiring connectors and dump the codes. When you dump the codes, the computer does a self test that toggles every relay/actuator/solenoid on and off. When this happens, the test light will flicker.

Disconnect the big hose from smog pump: with the engine running you should feel air output. Reconnect the smog pump hose & apply vacuum to the first vacuum controlled valve: Its purpose is to either dump the pump's output to the atmosphere or pass it to the next valve.

The next vacuum controlled valve directs the air to either the cylinder heads when the engine is cold or to the catalytic converter when the engine is warm. Disconnect the big hoses from the back side of the vacuum controlled valve and start the engine. Apply vacuum to the valve and see if the airflow changes from one hose to the next.