I guess it's about time I made this post. I've had this all ready to post a few times, just to lose inspiration and shelve it for a while. But here we go.

I've spent time during this pandemic learning how to do body work and paint, practicing on my 94 Cobra clone, and was able to fix its damaged rear quarter panel. That thread is here - https://www.stangnet.com/mustang-fo...iring-my-94-cobras-rear-quarter-panel.920903/ I learned a lot fixing that rear quarter panel - mostly things NOT to do. Most of the problems I ran into wouldn't have happened if I just done two things: a better job sanding at the primer stage, and laid down thicker paint when I sprayed the topcoat. But sometimes, you learn more from your mistakes than you do if you did things right the first time.

Now, it's time to apply those lessons and repaint the faded black paint on the car. I have the skills and the knowledge, but I lack enough practice to get a consistent result. I also don't have a large painting booth where I can paint half the car at once. Thus, the plan is to paint one or two parts at a time. This will not only give me the practice I need, it also lets me fix any issues on a single painted part. That way I won't spray the whole car wrong and have to do it all over again. I used cheap paint to practice with, but the new stuff is much more expensive. I want to waste as little of it as possible.

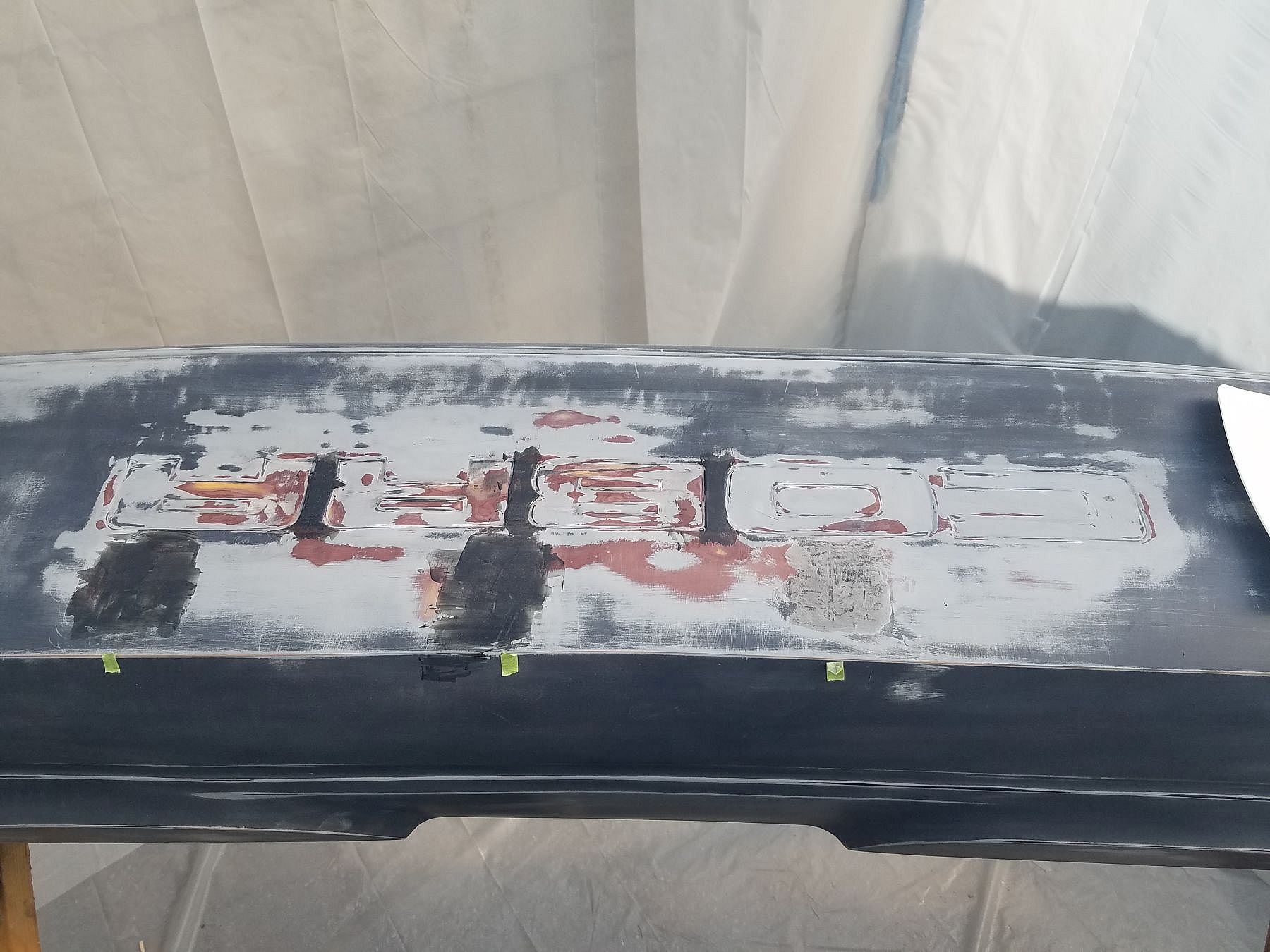

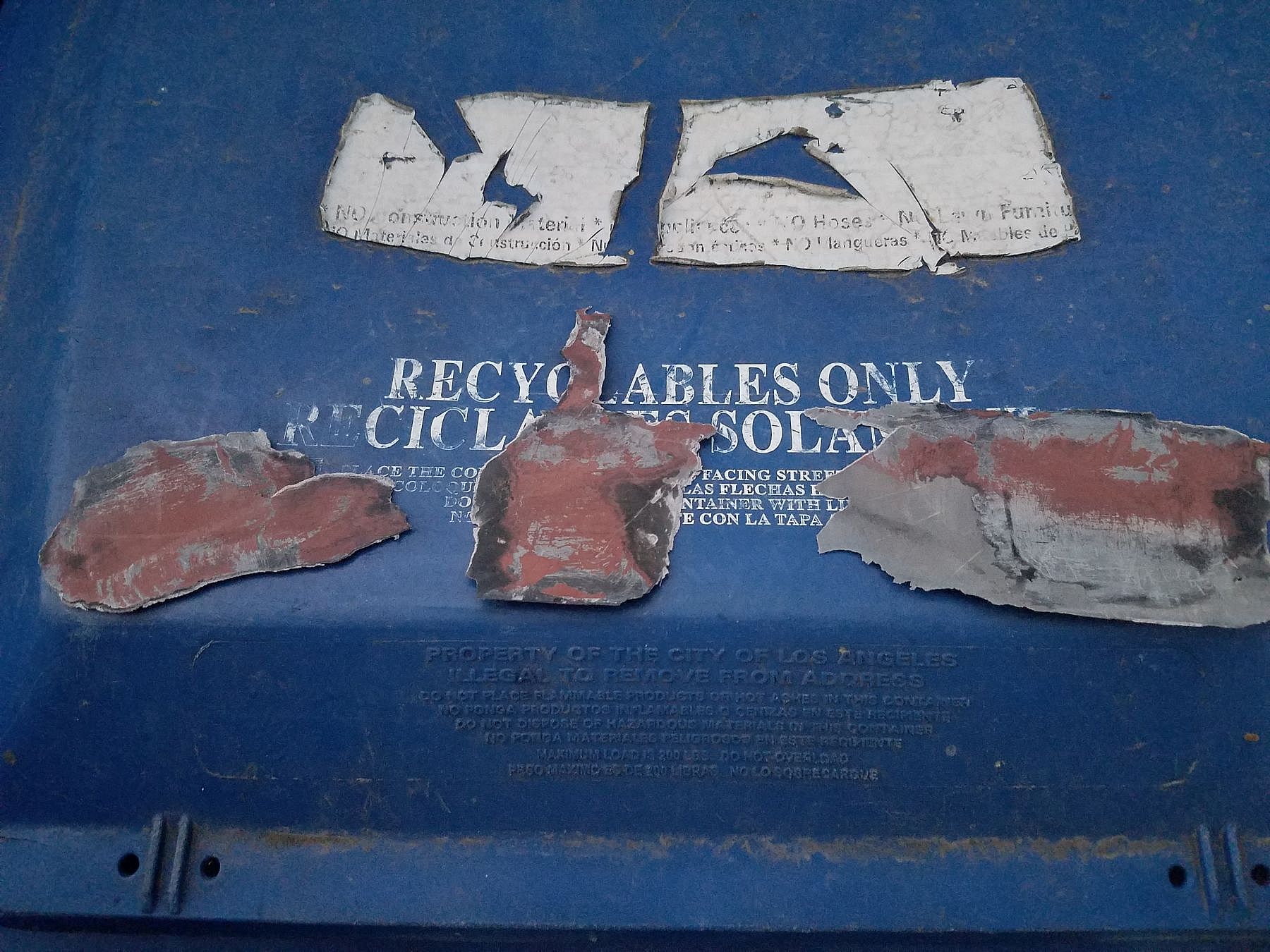

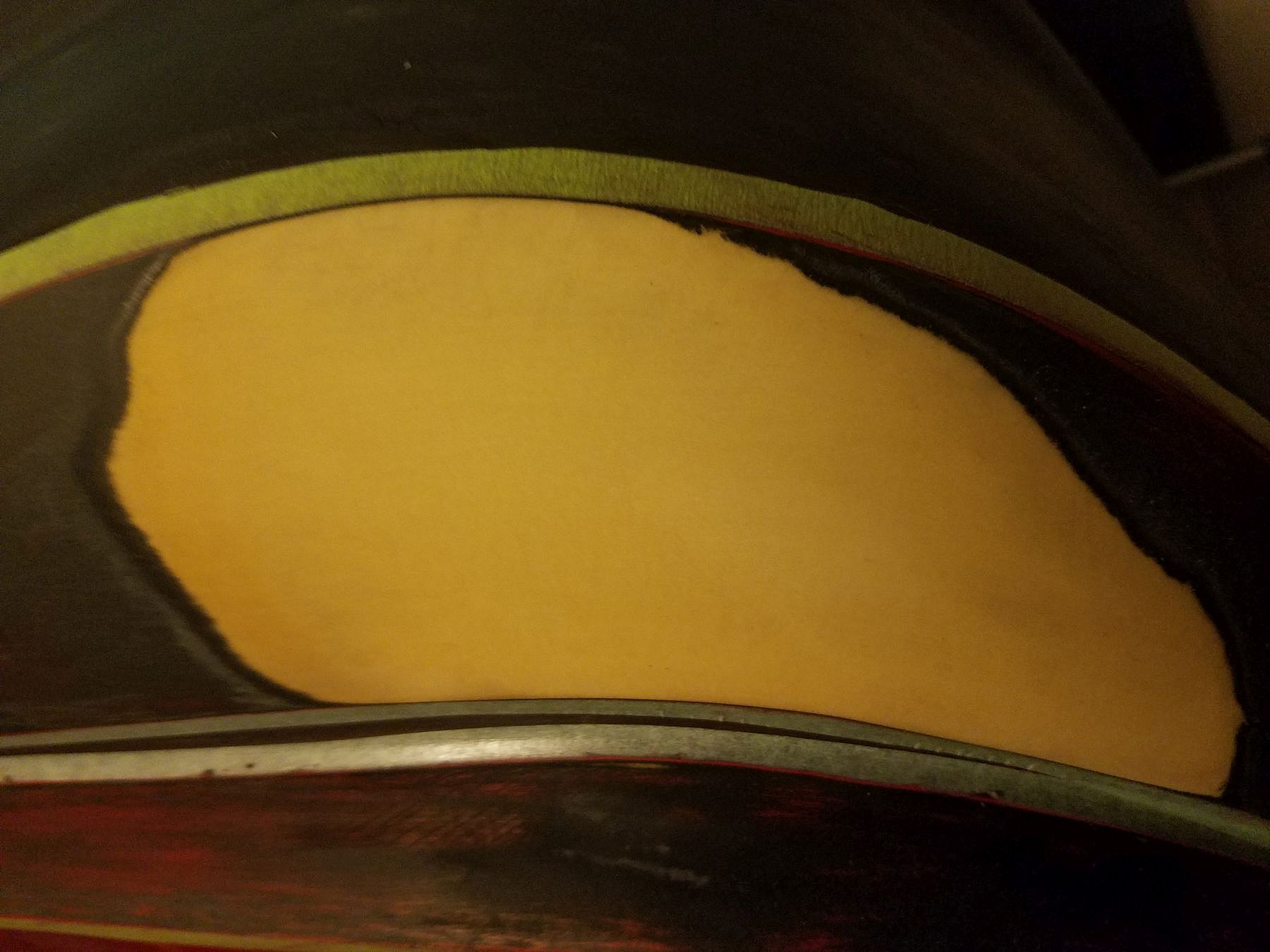

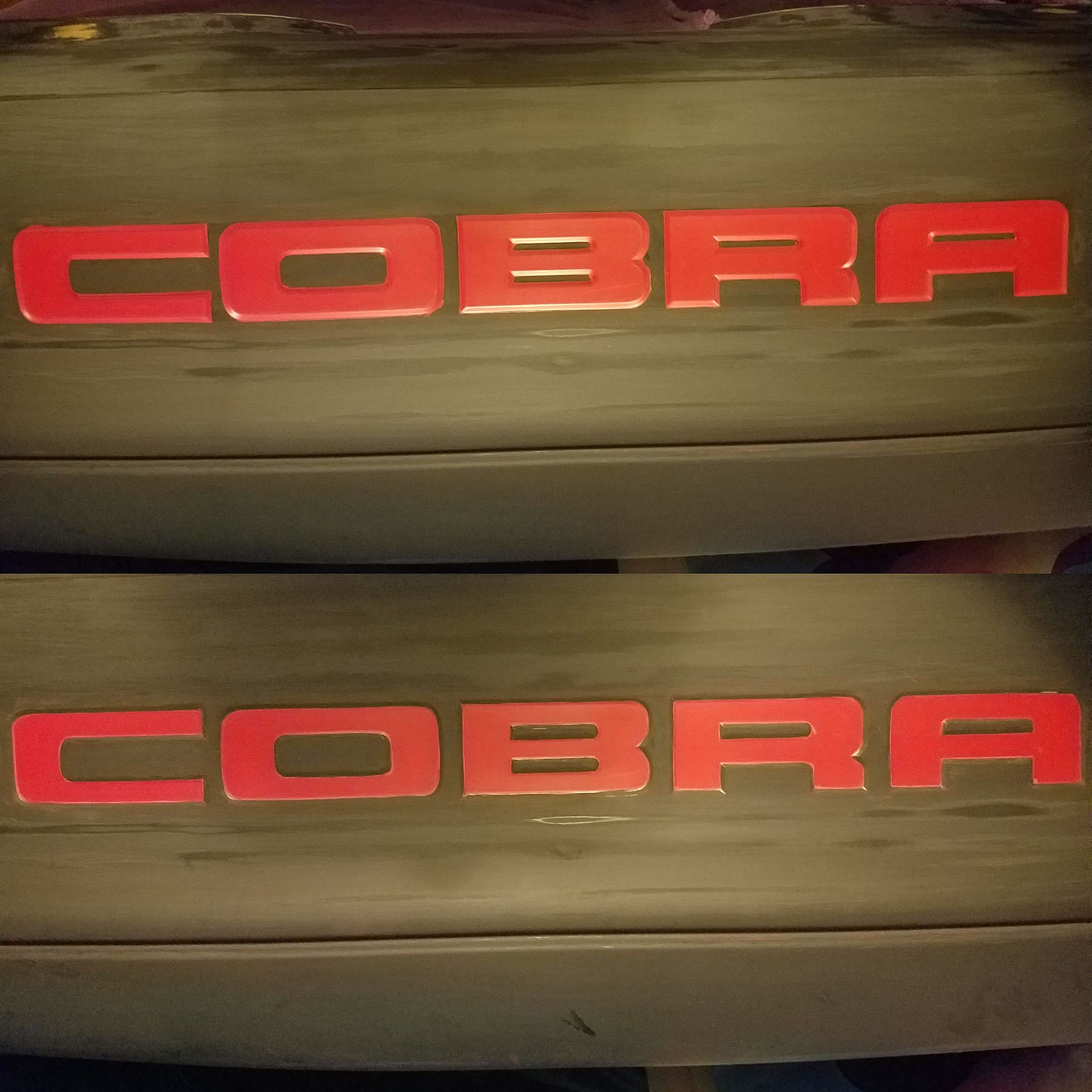

I have a used 'COBRA' rear bumper that I've wanted to put on the car for a while, which made it the perfect part to start with. However, it's been painted with some rattle can paint that was supposed to be Ford UA black. Sadly, the paint had some sort of metallic flake in it. Thick paint on a bumper tends to crack, so I need to take that paint off before respraying. I started sanding, and realized I had laid the primer on pretty thick. Since I originally painted this bumper, I've learned a LOT more about sanding and prepping primer and paint. I decided it was better to start over and strip everything off the bumper. In hindsight, I am so glad I did that - even though it cost me a lot of time and money.

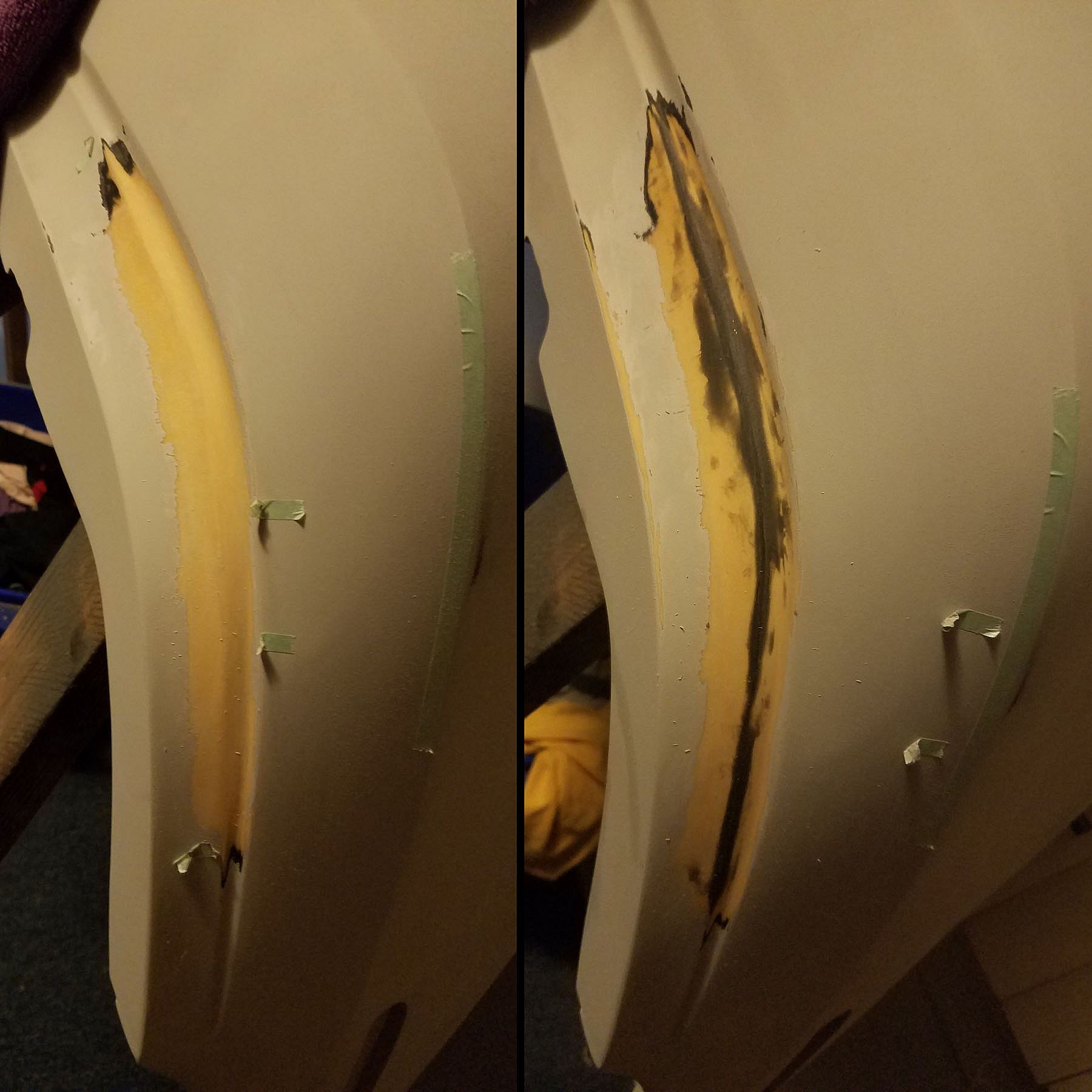

I used acetone and a lot of the blue shop paper towels to dissolve the paint and primer. This first photo is partway through that process. Feel free to ignore the laundry basket and the nosy cat.

I've spent time during this pandemic learning how to do body work and paint, practicing on my 94 Cobra clone, and was able to fix its damaged rear quarter panel. That thread is here - https://www.stangnet.com/mustang-fo...iring-my-94-cobras-rear-quarter-panel.920903/ I learned a lot fixing that rear quarter panel - mostly things NOT to do. Most of the problems I ran into wouldn't have happened if I just done two things: a better job sanding at the primer stage, and laid down thicker paint when I sprayed the topcoat. But sometimes, you learn more from your mistakes than you do if you did things right the first time.

Now, it's time to apply those lessons and repaint the faded black paint on the car. I have the skills and the knowledge, but I lack enough practice to get a consistent result. I also don't have a large painting booth where I can paint half the car at once. Thus, the plan is to paint one or two parts at a time. This will not only give me the practice I need, it also lets me fix any issues on a single painted part. That way I won't spray the whole car wrong and have to do it all over again. I used cheap paint to practice with, but the new stuff is much more expensive. I want to waste as little of it as possible.

I have a used 'COBRA' rear bumper that I've wanted to put on the car for a while, which made it the perfect part to start with. However, it's been painted with some rattle can paint that was supposed to be Ford UA black. Sadly, the paint had some sort of metallic flake in it. Thick paint on a bumper tends to crack, so I need to take that paint off before respraying. I started sanding, and realized I had laid the primer on pretty thick. Since I originally painted this bumper, I've learned a LOT more about sanding and prepping primer and paint. I decided it was better to start over and strip everything off the bumper. In hindsight, I am so glad I did that - even though it cost me a lot of time and money.

I used acetone and a lot of the blue shop paper towels to dissolve the paint and primer. This first photo is partway through that process. Feel free to ignore the laundry basket and the nosy cat.

Thanks for the compliment.

Thanks for the compliment.