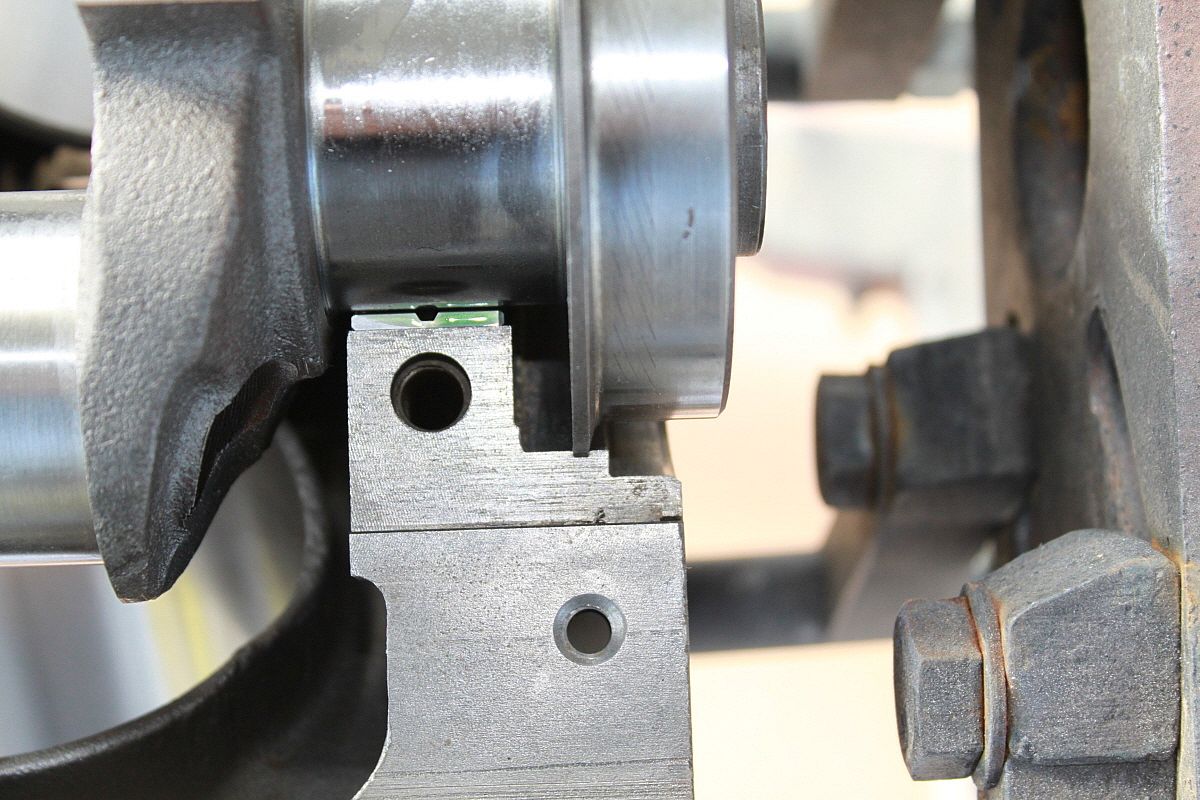

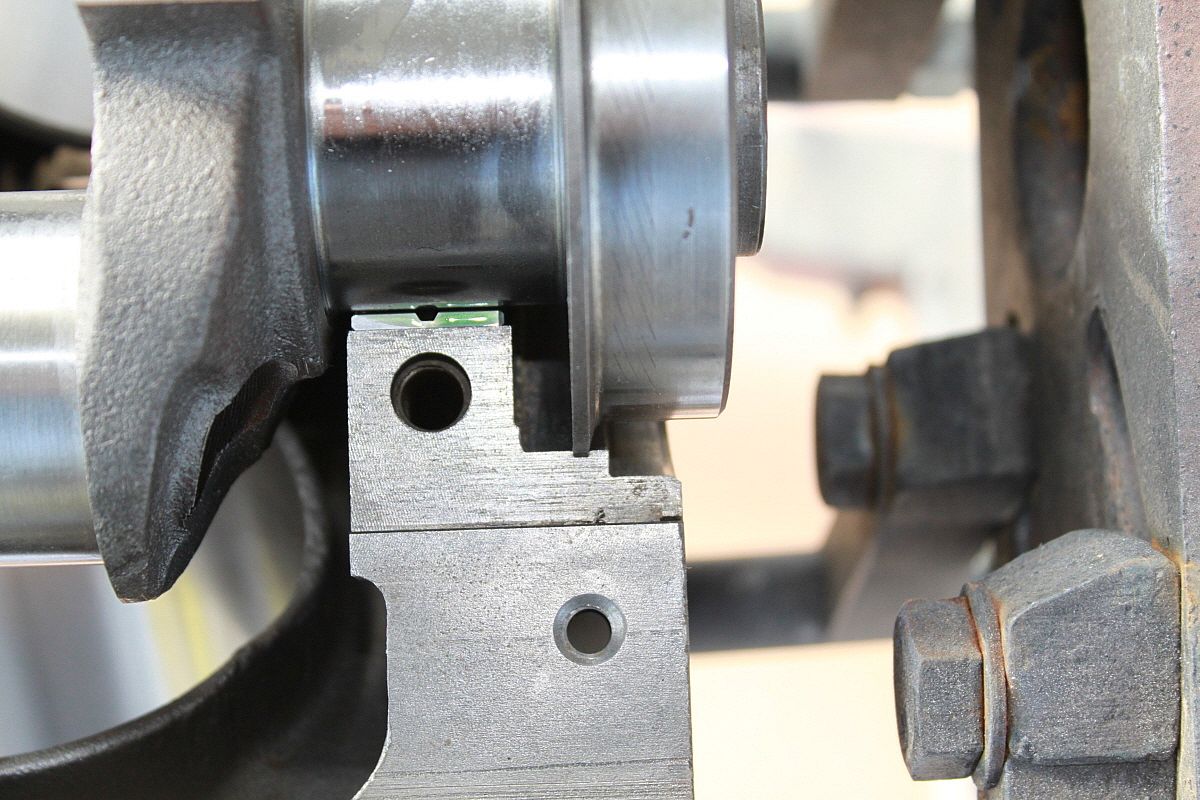

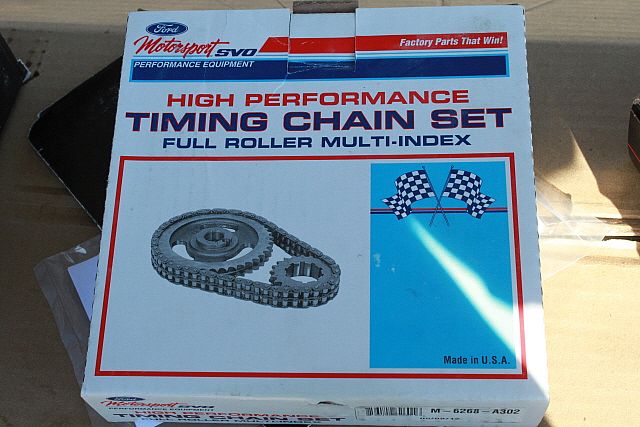

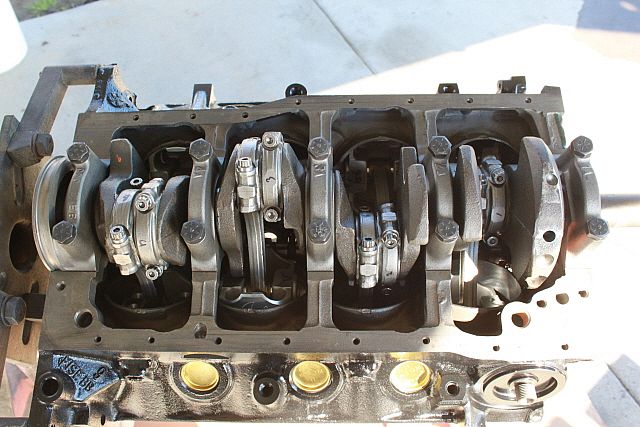

got the crank back with the slinger turned down .the internals will be 28 oz all the way,balancer to the fly wheel so no problem there .the balancing was done at another shop from the machine shop.they orderd the new race preped rods and a new balancer

to match the crank so should be smooth sailing from here on out. the problem started when the crank had to be sent out to be turned and that shop returned the early crank. it went straight to the balancing shop without me seeing it first ,wont make that mistake again . now i am ready to check clearances and assemble . any time you send a motor part out for machining mark it especially if you want that part back