So my AODE To T5 conversion has been done for a few years.

Ever since I completed it, the lower shift boot has been bothering me.

With the factory shifter, it always stretched a bit and the rubber would be torn after a while.

With the Steeda Tri-Ax, forget it!

It would stretch and be torn very quickly.

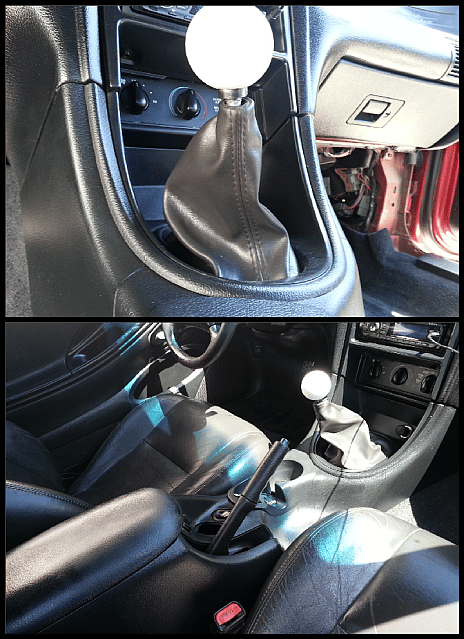

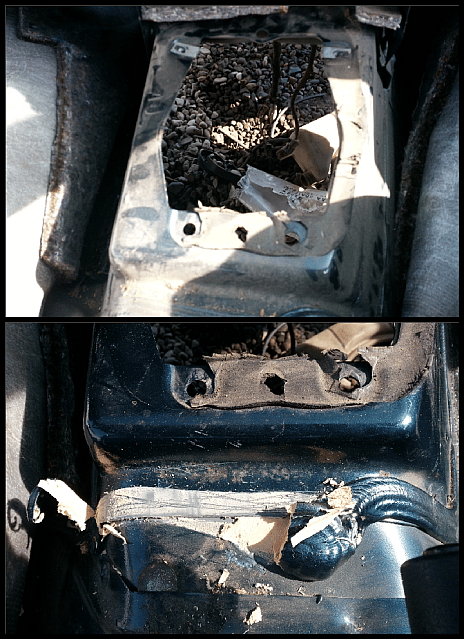

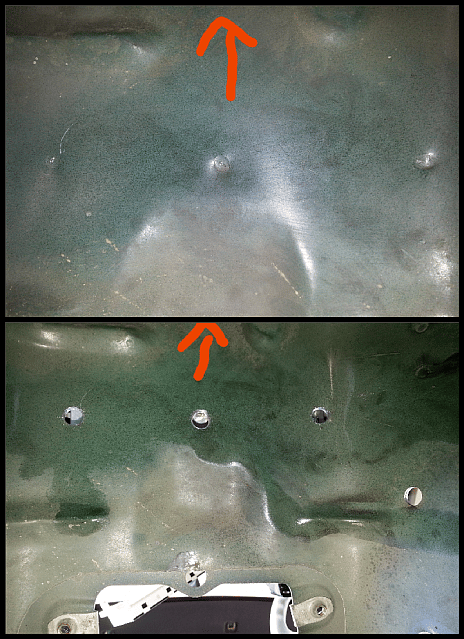

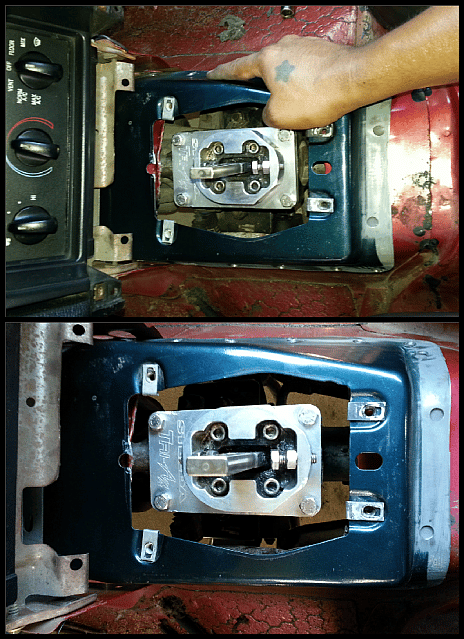

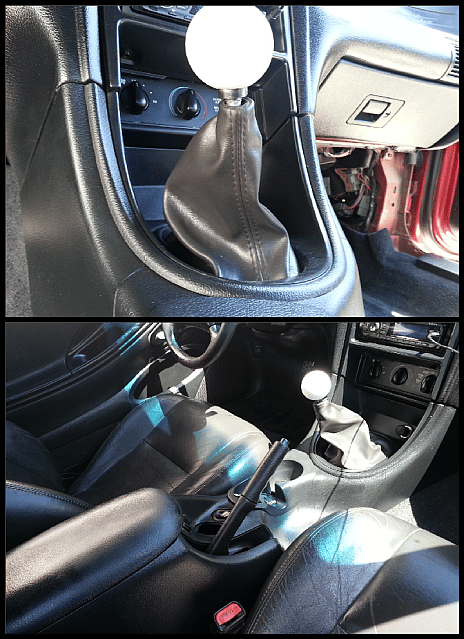

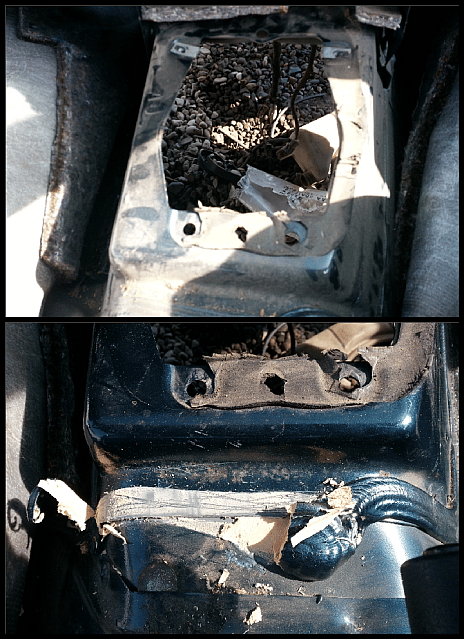

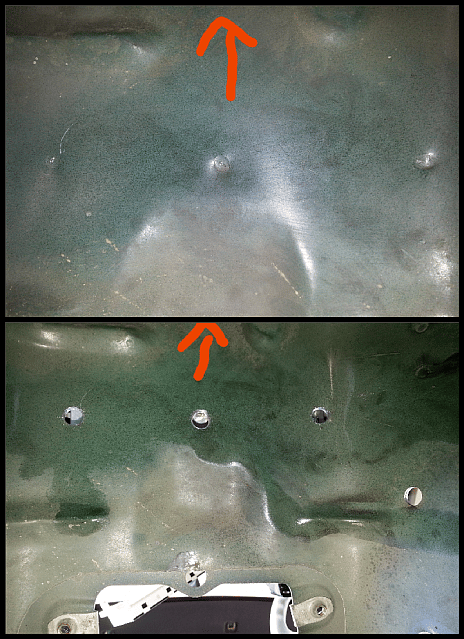

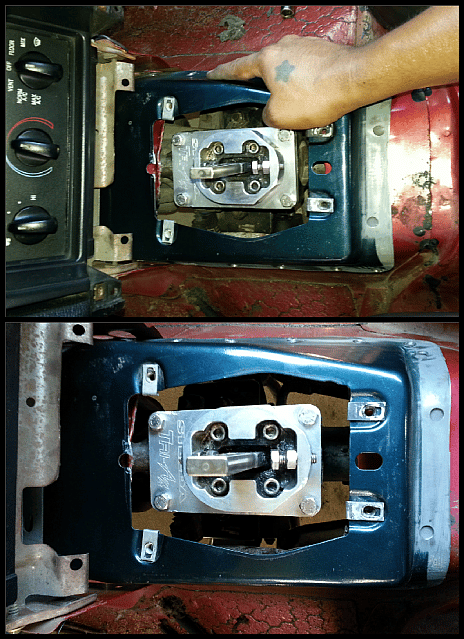

After some research, I determined that I need the factory tranny tunnel "Hat", that is spot welded onto all factory manual Mustangs.

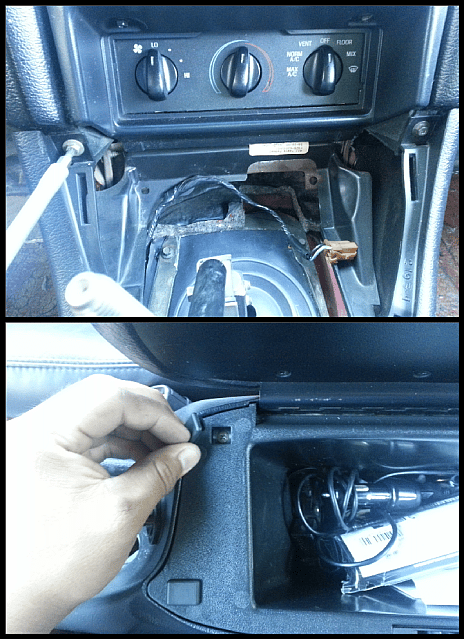

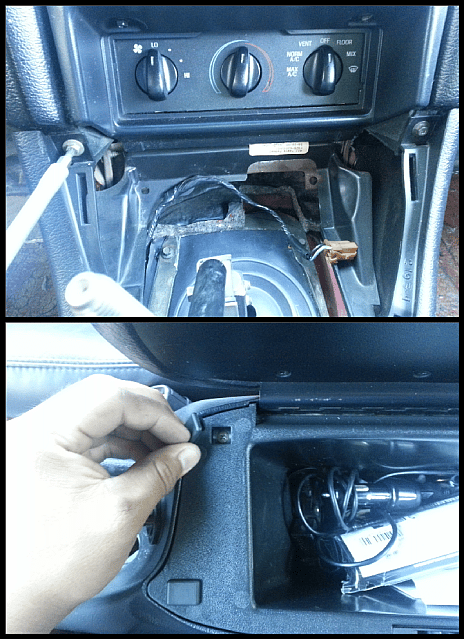

Note the two top pictures, a 99 and 97 factory manual and the lower, a 94 AODE.

I also saw a factory 94 GT manual with the "Hat" yesterday which I failed to get a picture of.

I had a little time this week, and decided to take care of it.

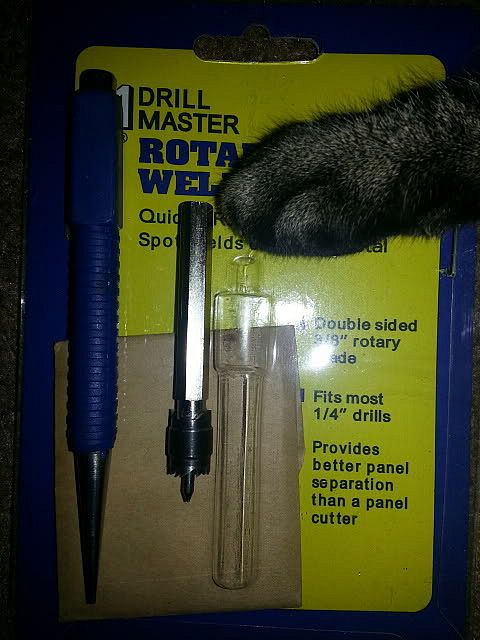

***Tools Needed***

1-package 3M double sided moulding tape

1-1/4 ratchet

1-5/16, 1/4 drive deep socket

1-3/8 ratchet

1-10mm socket

1-T47, 3/8 drive Torx bit

1-scrapper

1-cordless drill

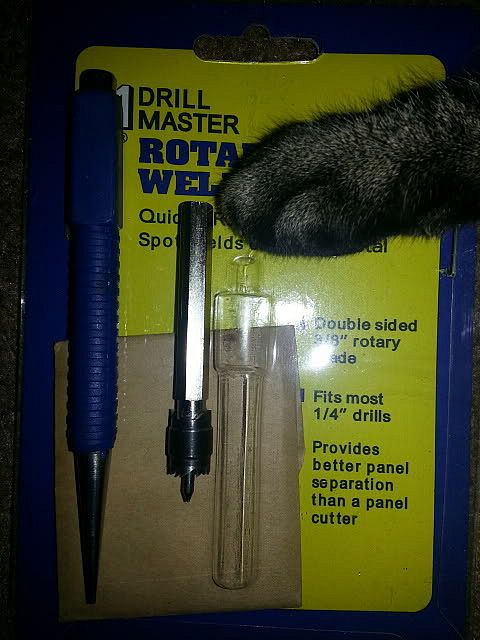

1-spot weld cutter bit

1-flat head screwdriver

1-Philips screwdriver

1-T20 driver

1-hammer

1-center punch

1-wire brush drill attachment

1-piece of sandpaper

1-15mm wrench (if removing seats & carpet)

1-15mm, 3/8 drive socket (if removing seats & carpet)

***Interior Disassembly***

1-remove shifter knob (this varies, I use a Hurst knob, so I used a 3/4 wrench)

2-pull up on edge of shifter bezal to release the clips.

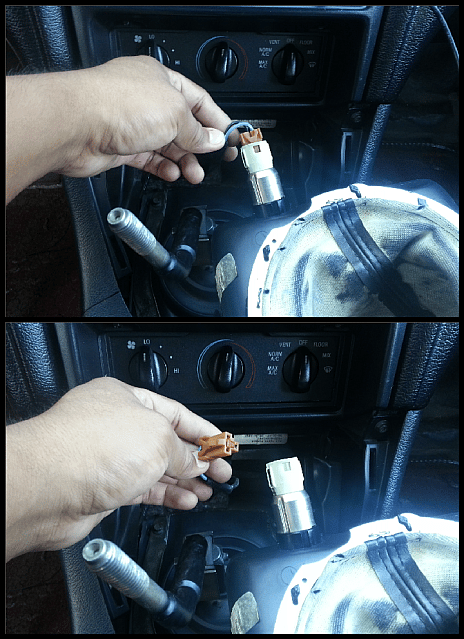

3-flip over and disconnect power point/cigarette lighter and set aside.

4-with T20 driver, remove the two screws at the front of the center console, then under the two rubber stops, remove the two Philips screws.

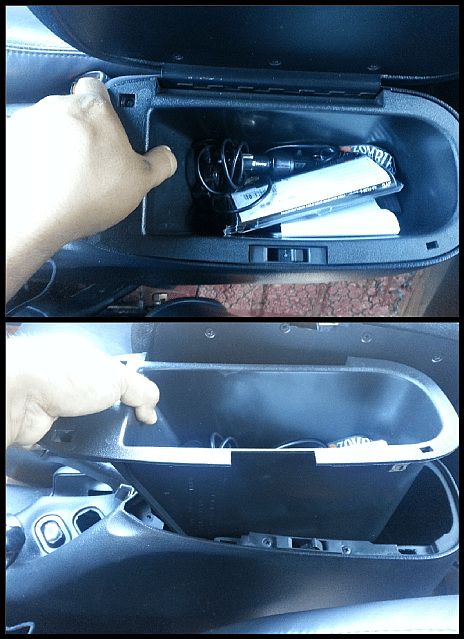

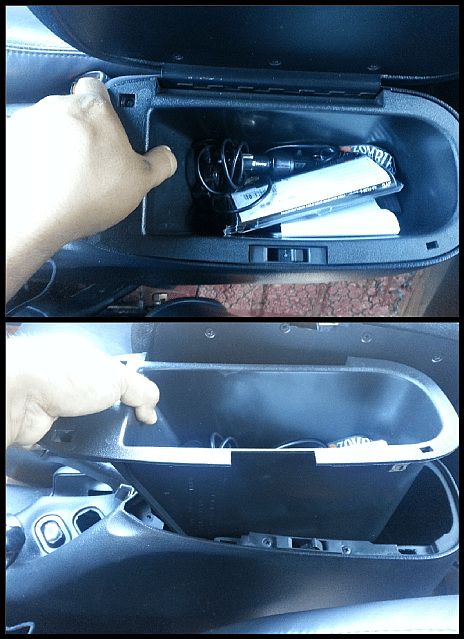

5-pull up on center console storage, set aside.

6-under the storage, remove two T20 screws, then pull up on parking brake handle as much as you can (without breaking it, of course).

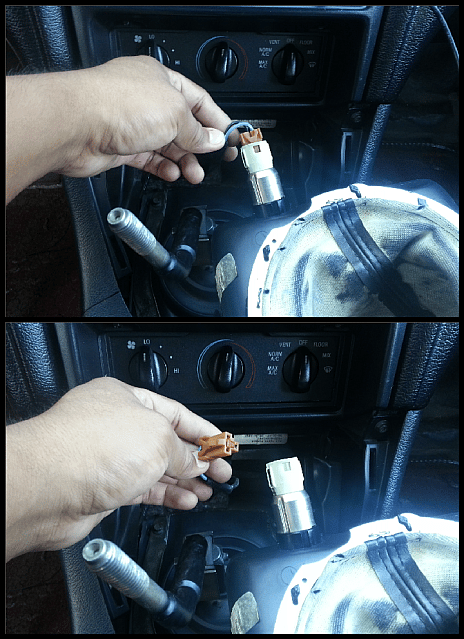

7-reach through the center console and disconnect the console wire harness.

8-pull center console back, and tilt the front of the console up and slide it over the parking brake handle, set console aside.

9-remove 4- 5/16 bolts around lower shifter boot, set aside.

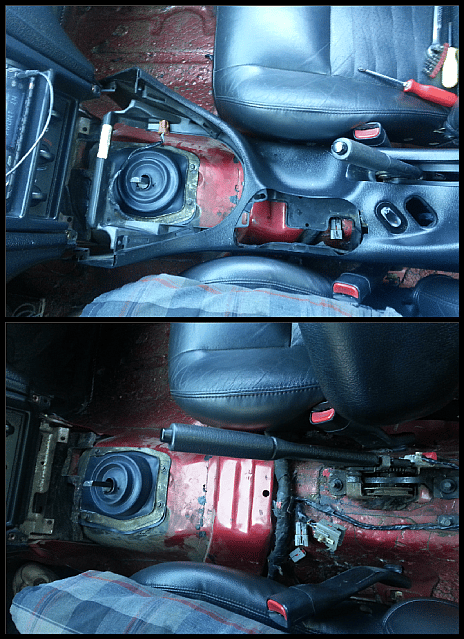

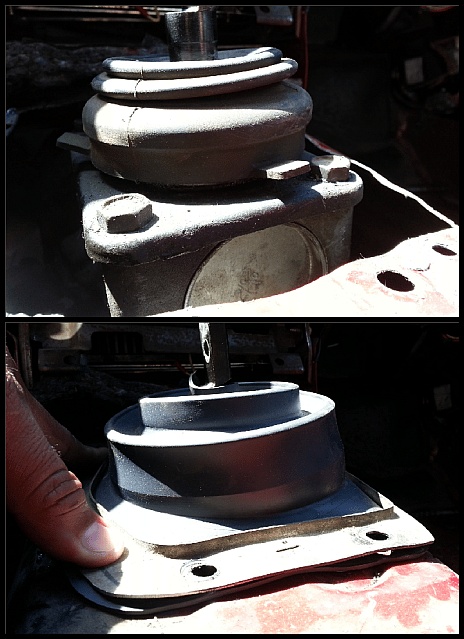

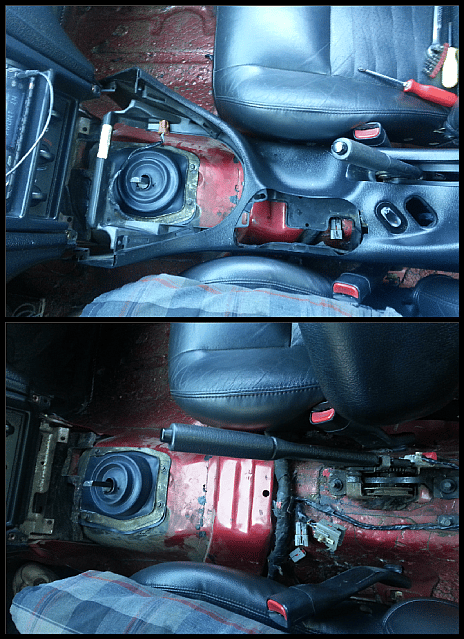

***Factory Tranny "Hat" Removal***

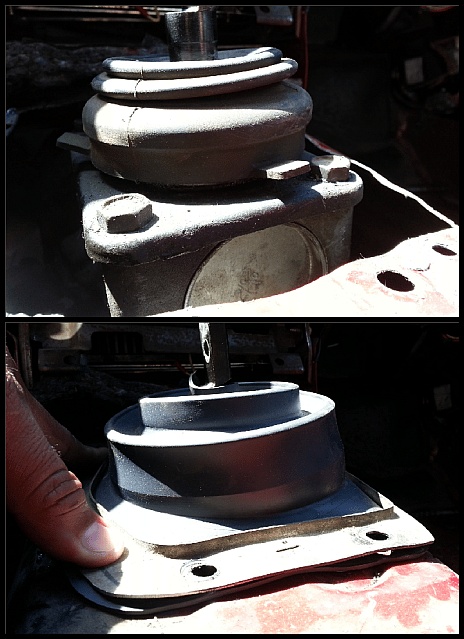

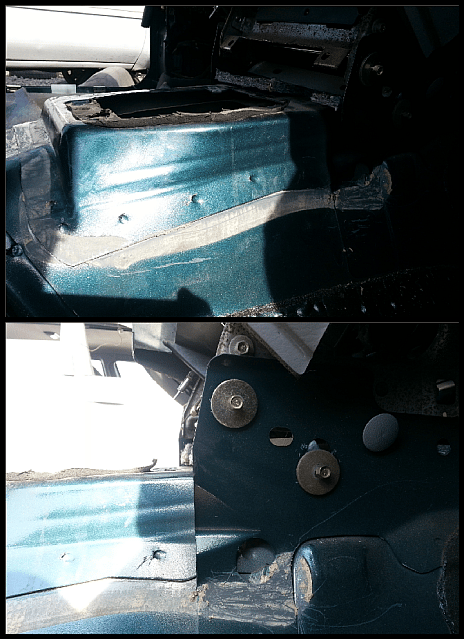

For the following steps, you will need your drill, spot weld cutter, center punch (Spinner says Hi) and hammer.

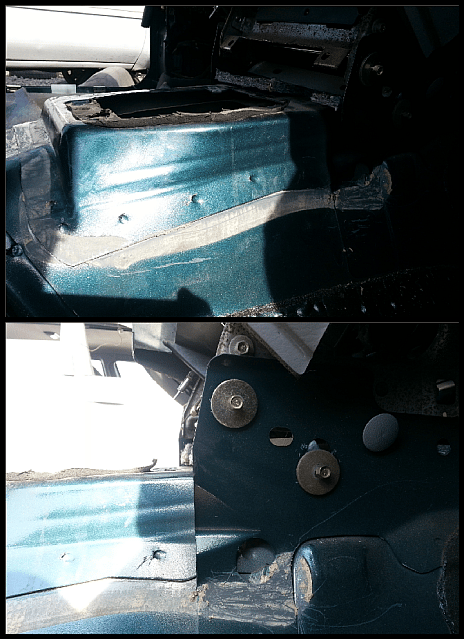

10-Scrape off all the seam sealer around the Hat. (Note, I cut the carpet and moved it out of the way, as this was a junk yard car. Also, I had removed my carpet prior to Hat install. You may be able to move your carpet out of the way and work around it, I'm not sure.)

11-with a bit of sand paper, sand over the spot weld. I do this so I can see them a bit better.

With your center punch and hammer, punch the center of all spot welds.

12-with your spot weld cutter bit and drill, drill out all spot welds.

I used some WD40 on the bit while cutting.

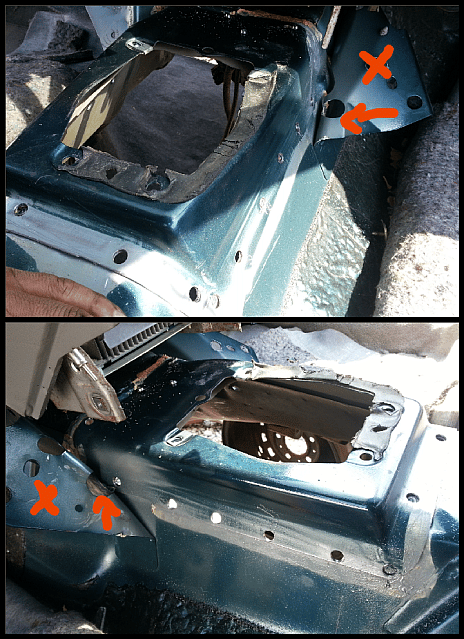

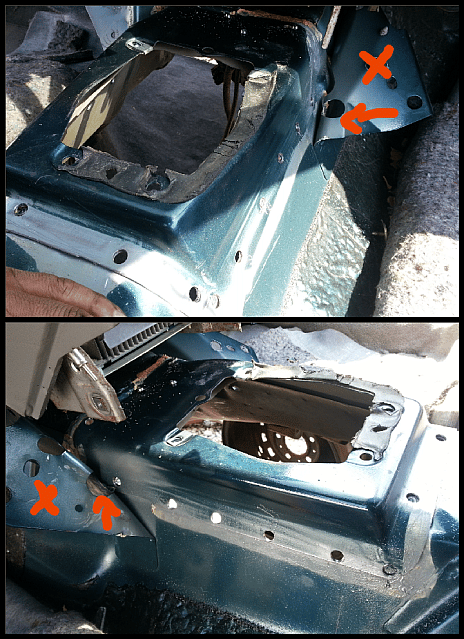

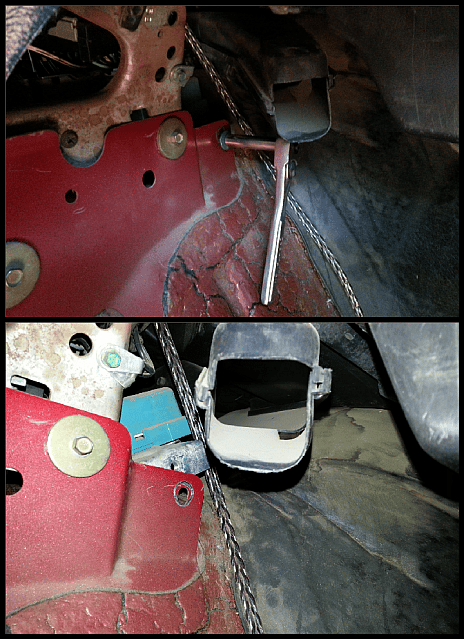

Please note the side brackets (Red X), I bent these out of the way to look for more spot welds, there were none.

The forward most side spot welds can be drilled through the factory holes (Red Arrow) on the side brackets.

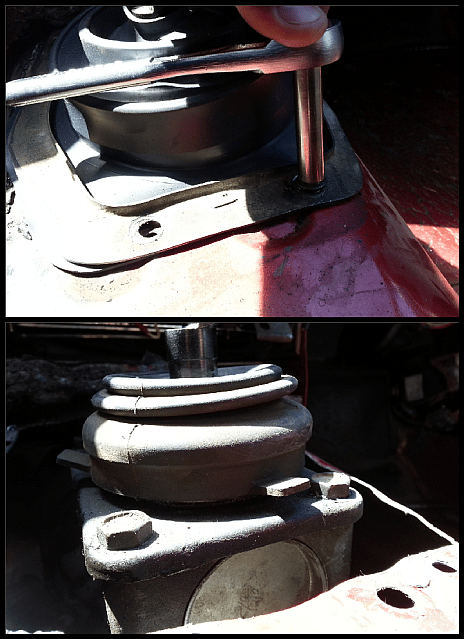

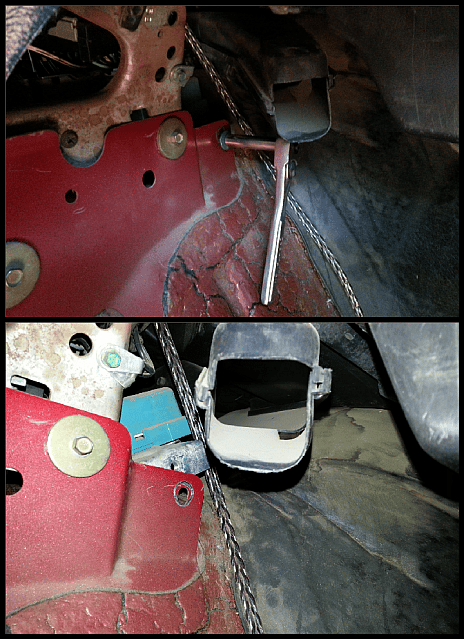

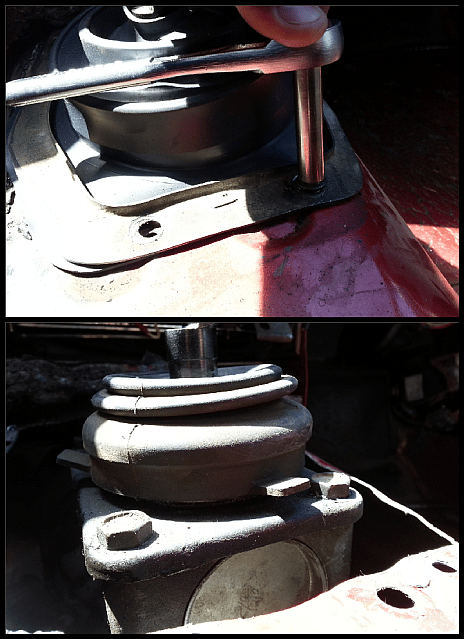

13-there are three more spot welds on the front of the Hat (Red Arrow = Front Of Car), unfortunately due to the dashboard and center stack, you cannot reach these from inside the car with your drill.

You will need to drill these from under the car.

Fortunately for me, the tranny was already removed from this car.

14-from under car, center punch the three spot welds.

Lube and drill them out (Wear Eye Protection!!).

15-back inside the car, pry up around edges with your screwdriver and remove from car.

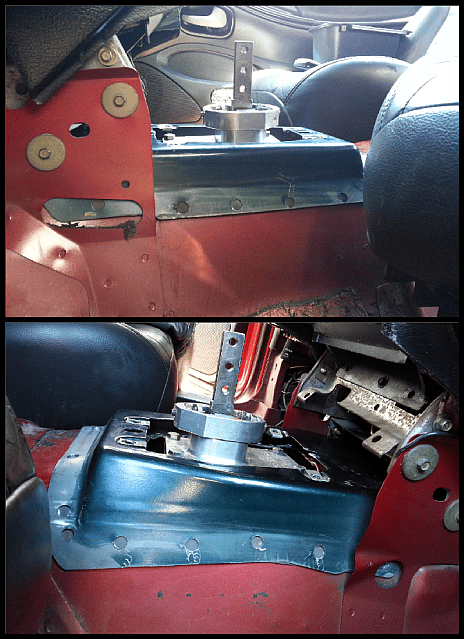

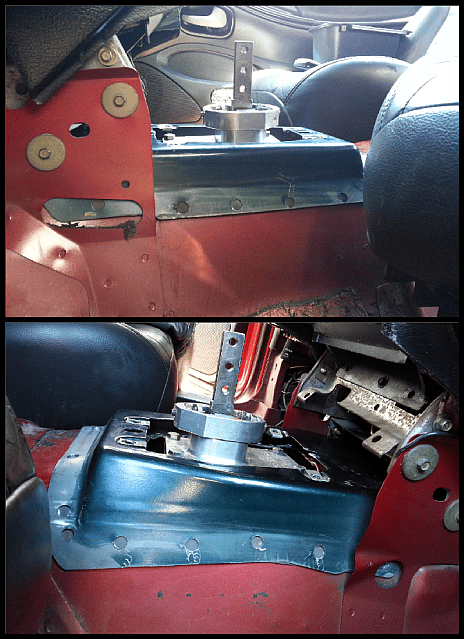

***Tranny Hat Install***

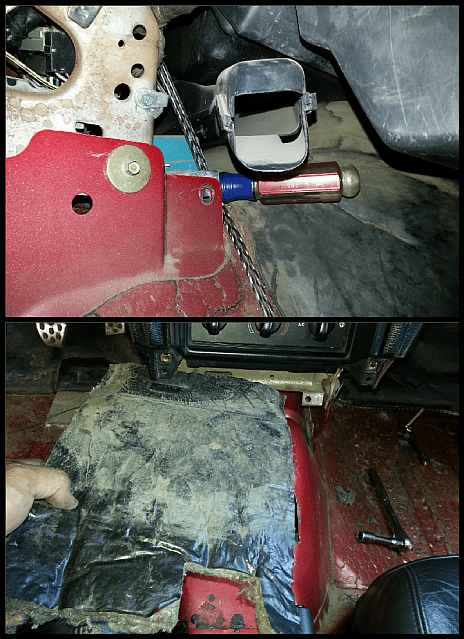

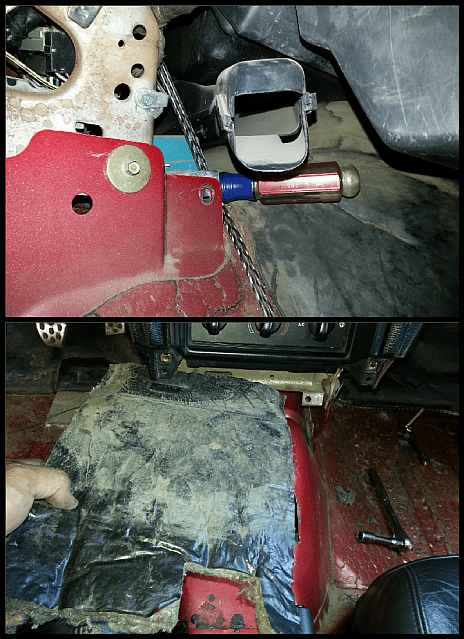

16-On each side of tranny tunnel, remove 1-5/16 green bolt.

This attaches the Air Bag Module bracket to body.

17-lift up air bag bracket and with flat head screwdriver, pry up the insulation pad and set aside.

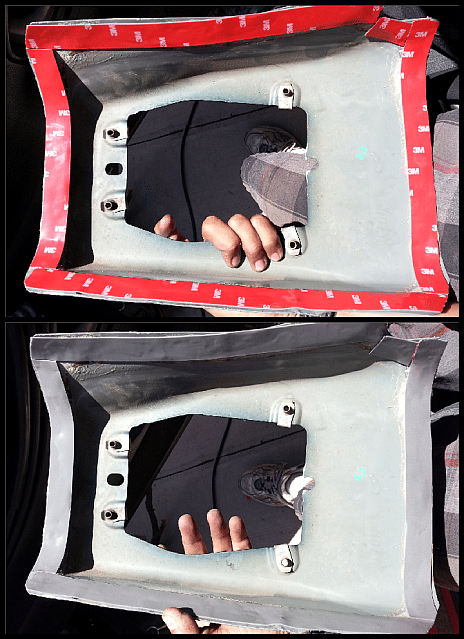

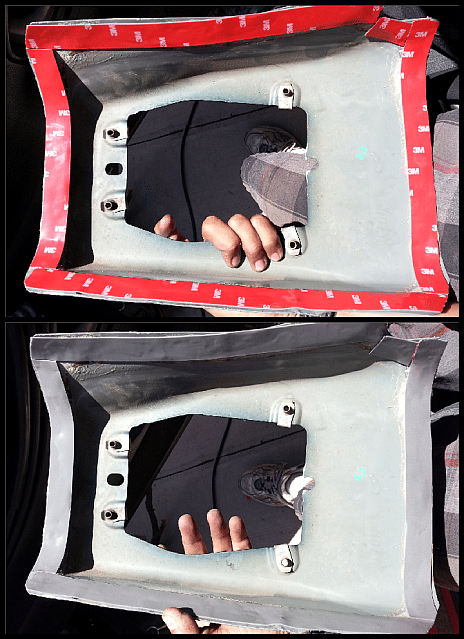

18-with a wire brush, clean up the under side of the Hat.

I used some alcohol to clean up prior to sticking on the double sided tape.

Yes, spot welds and seam sealer or even panel adhesive would have been a better choice, but seeing as how the hat is not a load bearing panel and does not move, I think the double sided tape is more then adequate.

19-remove the tape backing, without letting the tape touch the body, position over tranny tunnel.

When it looks good, press the Hat onto the tranny tunnel.

20-I gave the Hat a good tug and it didn't budge.

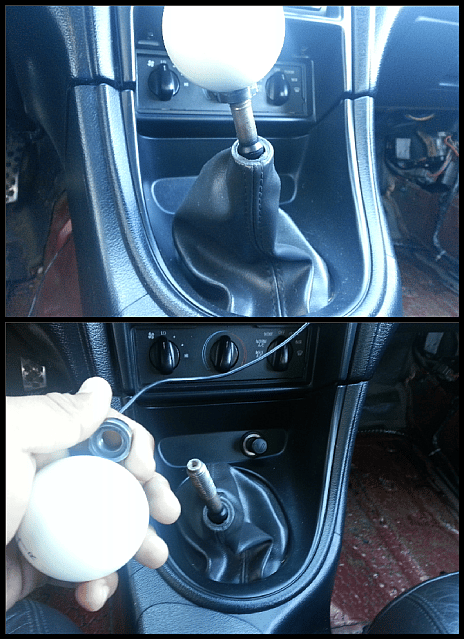

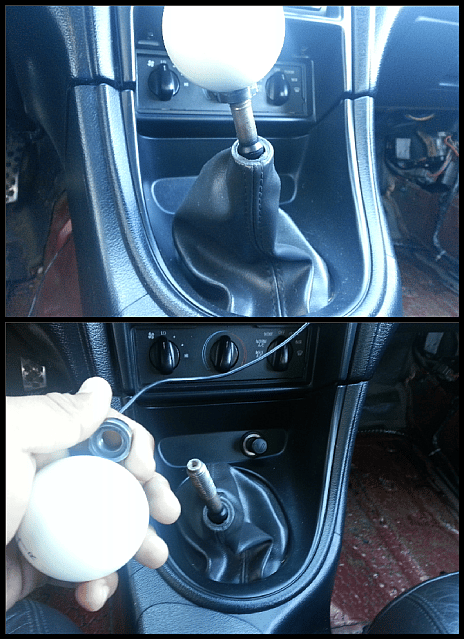

Reinstall is pretty much the reverse of removal, but here are some highlights.

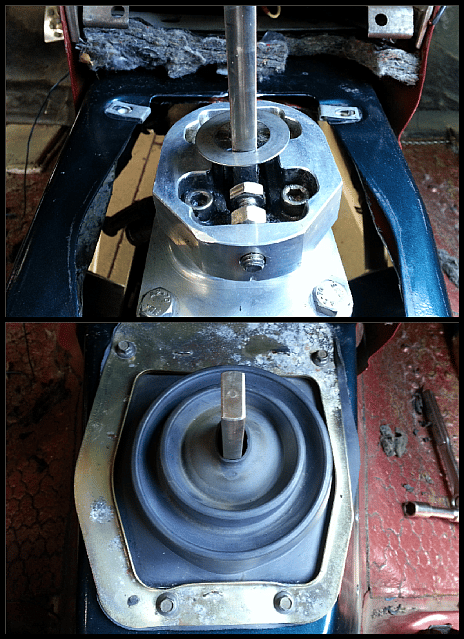

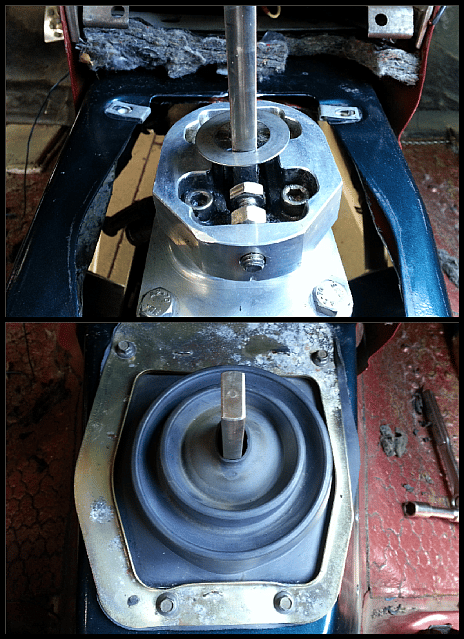

21-Prior to lower shifter boot install, my Tri-Ax requires this spacer.

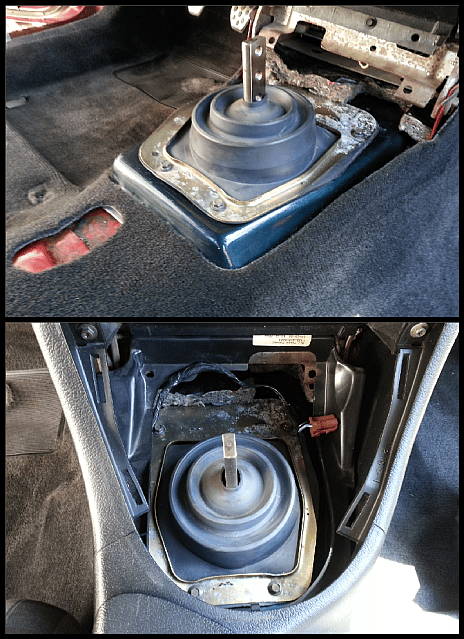

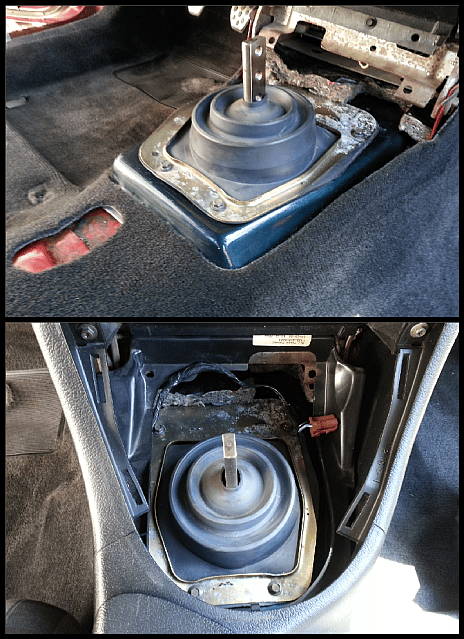

22-I reinstalled my carpet.

23-Shifter handle.

24-and there it is with full interior.

Gave it a drive.

Nice and quiet and I checked the boot after my drive.

All is well, no torn or stretched lower boot.

Ever since I completed it, the lower shift boot has been bothering me.

With the factory shifter, it always stretched a bit and the rubber would be torn after a while.

With the Steeda Tri-Ax, forget it!

It would stretch and be torn very quickly.

After some research, I determined that I need the factory tranny tunnel "Hat", that is spot welded onto all factory manual Mustangs.

Note the two top pictures, a 99 and 97 factory manual and the lower, a 94 AODE.

I also saw a factory 94 GT manual with the "Hat" yesterday which I failed to get a picture of.

I had a little time this week, and decided to take care of it.

***Tools Needed***

1-package 3M double sided moulding tape

1-1/4 ratchet

1-5/16, 1/4 drive deep socket

1-3/8 ratchet

1-10mm socket

1-T47, 3/8 drive Torx bit

1-scrapper

1-cordless drill

1-spot weld cutter bit

1-flat head screwdriver

1-Philips screwdriver

1-T20 driver

1-hammer

1-center punch

1-wire brush drill attachment

1-piece of sandpaper

1-15mm wrench (if removing seats & carpet)

1-15mm, 3/8 drive socket (if removing seats & carpet)

***Interior Disassembly***

1-remove shifter knob (this varies, I use a Hurst knob, so I used a 3/4 wrench)

2-pull up on edge of shifter bezal to release the clips.

3-flip over and disconnect power point/cigarette lighter and set aside.

4-with T20 driver, remove the two screws at the front of the center console, then under the two rubber stops, remove the two Philips screws.

5-pull up on center console storage, set aside.

6-under the storage, remove two T20 screws, then pull up on parking brake handle as much as you can (without breaking it, of course).

7-reach through the center console and disconnect the console wire harness.

8-pull center console back, and tilt the front of the console up and slide it over the parking brake handle, set console aside.

9-remove 4- 5/16 bolts around lower shifter boot, set aside.

***Factory Tranny "Hat" Removal***

For the following steps, you will need your drill, spot weld cutter, center punch (Spinner says Hi) and hammer.

10-Scrape off all the seam sealer around the Hat. (Note, I cut the carpet and moved it out of the way, as this was a junk yard car. Also, I had removed my carpet prior to Hat install. You may be able to move your carpet out of the way and work around it, I'm not sure.)

11-with a bit of sand paper, sand over the spot weld. I do this so I can see them a bit better.

With your center punch and hammer, punch the center of all spot welds.

12-with your spot weld cutter bit and drill, drill out all spot welds.

I used some WD40 on the bit while cutting.

Please note the side brackets (Red X), I bent these out of the way to look for more spot welds, there were none.

The forward most side spot welds can be drilled through the factory holes (Red Arrow) on the side brackets.

13-there are three more spot welds on the front of the Hat (Red Arrow = Front Of Car), unfortunately due to the dashboard and center stack, you cannot reach these from inside the car with your drill.

You will need to drill these from under the car.

Fortunately for me, the tranny was already removed from this car.

14-from under car, center punch the three spot welds.

Lube and drill them out (Wear Eye Protection!!).

15-back inside the car, pry up around edges with your screwdriver and remove from car.

***Tranny Hat Install***

16-On each side of tranny tunnel, remove 1-5/16 green bolt.

This attaches the Air Bag Module bracket to body.

17-lift up air bag bracket and with flat head screwdriver, pry up the insulation pad and set aside.

18-with a wire brush, clean up the under side of the Hat.

I used some alcohol to clean up prior to sticking on the double sided tape.

Yes, spot welds and seam sealer or even panel adhesive would have been a better choice, but seeing as how the hat is not a load bearing panel and does not move, I think the double sided tape is more then adequate.

19-remove the tape backing, without letting the tape touch the body, position over tranny tunnel.

When it looks good, press the Hat onto the tranny tunnel.

20-I gave the Hat a good tug and it didn't budge.

Reinstall is pretty much the reverse of removal, but here are some highlights.

21-Prior to lower shifter boot install, my Tri-Ax requires this spacer.

22-I reinstalled my carpet.

23-Shifter handle.

24-and there it is with full interior.

Gave it a drive.

Nice and quiet and I checked the boot after my drive.

All is well, no torn or stretched lower boot.