I believe I had heard that the 65 motor mounts sit the engine slightly lower than 66 mounts. Is that true? How much?

Are there any disadvantages to the 65 mounts (i had heard that they might not be good for transmission-to-differential pinion angle, and that they aren't as strong... are either of these major concerns)?

If the 65's aren't lower or I can't use them, what companies offer aftermarket drop mounts for 66s?

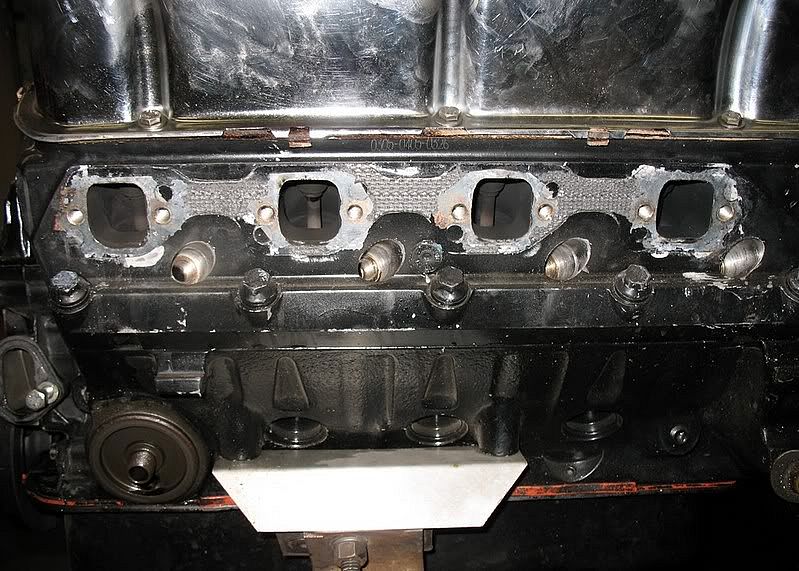

I'm trying to get my 351w with Weiand Stealth intake under the stock hood. My first attempt with a drop-base air cleaner (a mild drop base) was unsuccessful, gonna need to trim an inch or two off the total height. I got summit's lowest profile circular air cleaner, but if that doesn't work I'm gonna have to address it via motor mounts.

Are there any disadvantages to the 65 mounts (i had heard that they might not be good for transmission-to-differential pinion angle, and that they aren't as strong... are either of these major concerns)?

If the 65's aren't lower or I can't use them, what companies offer aftermarket drop mounts for 66s?

I'm trying to get my 351w with Weiand Stealth intake under the stock hood. My first attempt with a drop-base air cleaner (a mild drop base) was unsuccessful, gonna need to trim an inch or two off the total height. I got summit's lowest profile circular air cleaner, but if that doesn't work I'm gonna have to address it via motor mounts.