Hi All

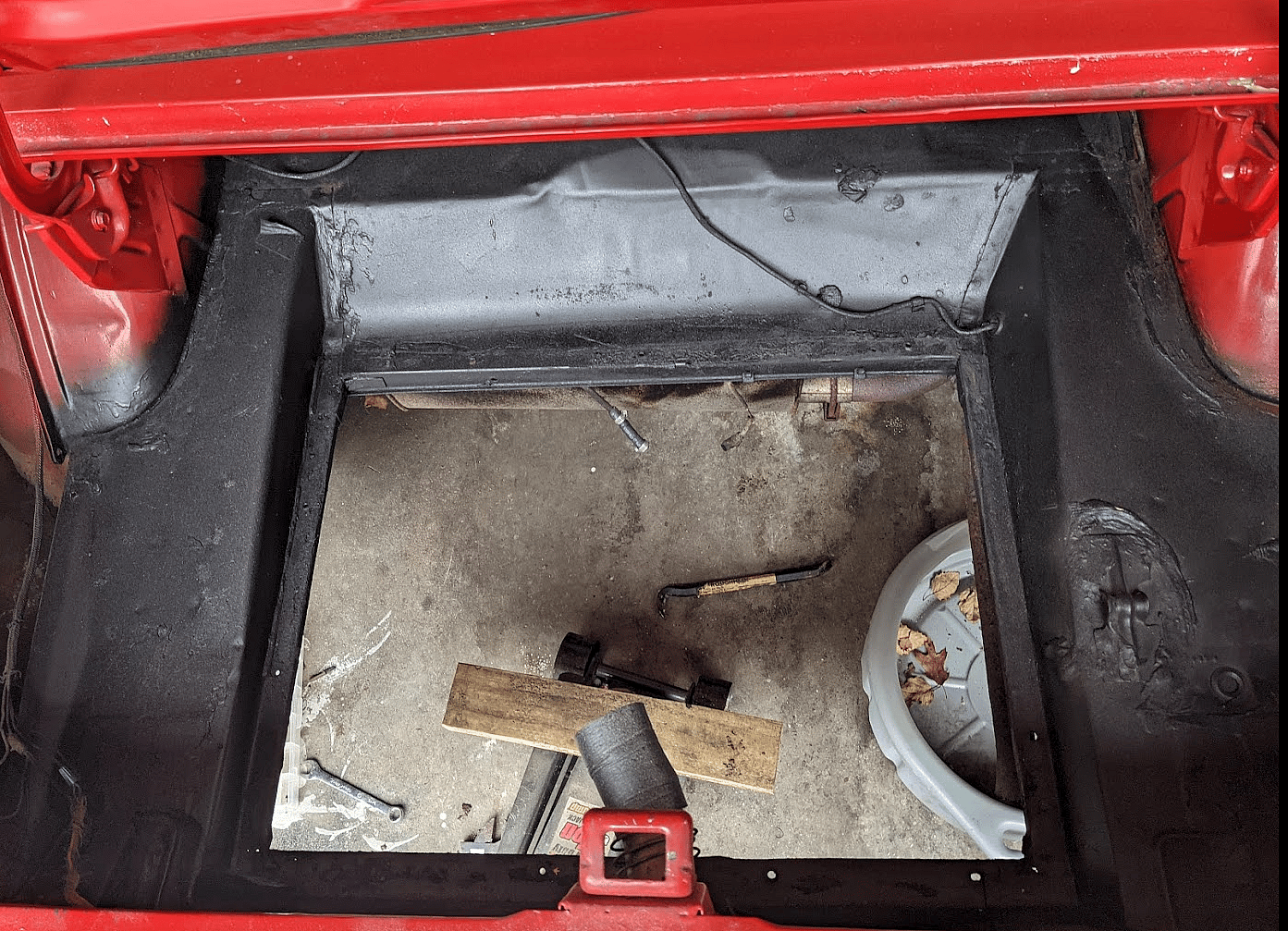

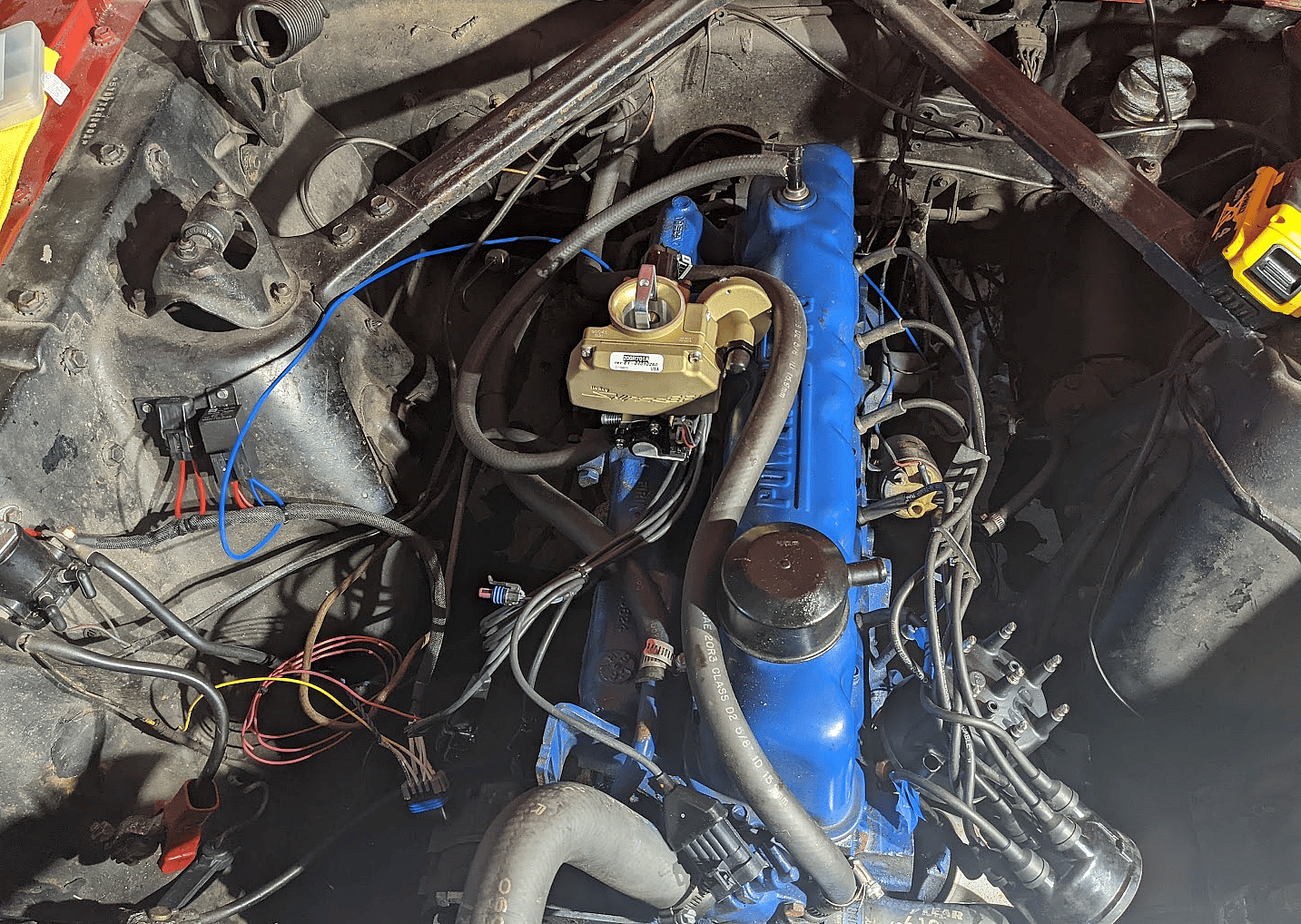

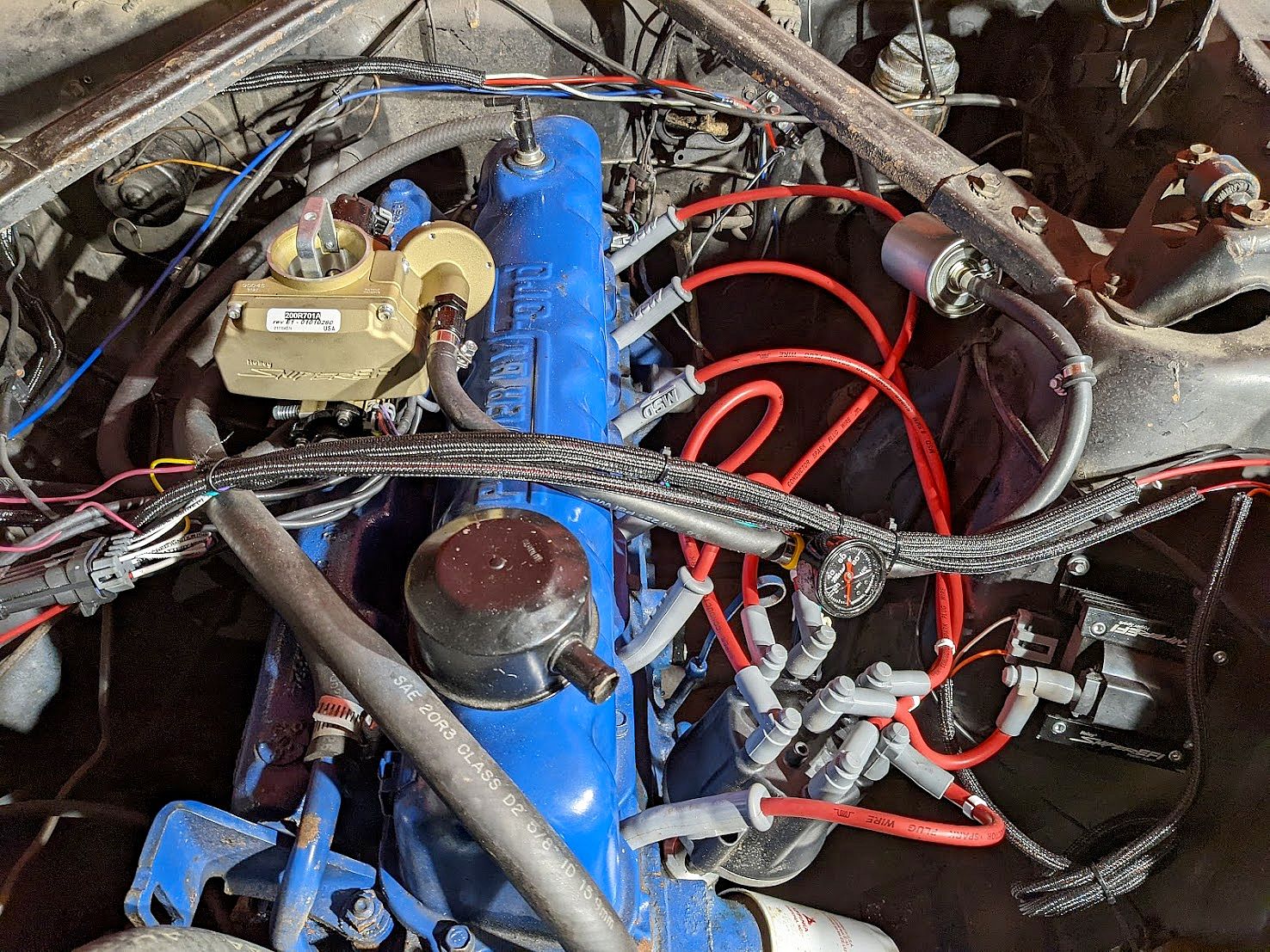

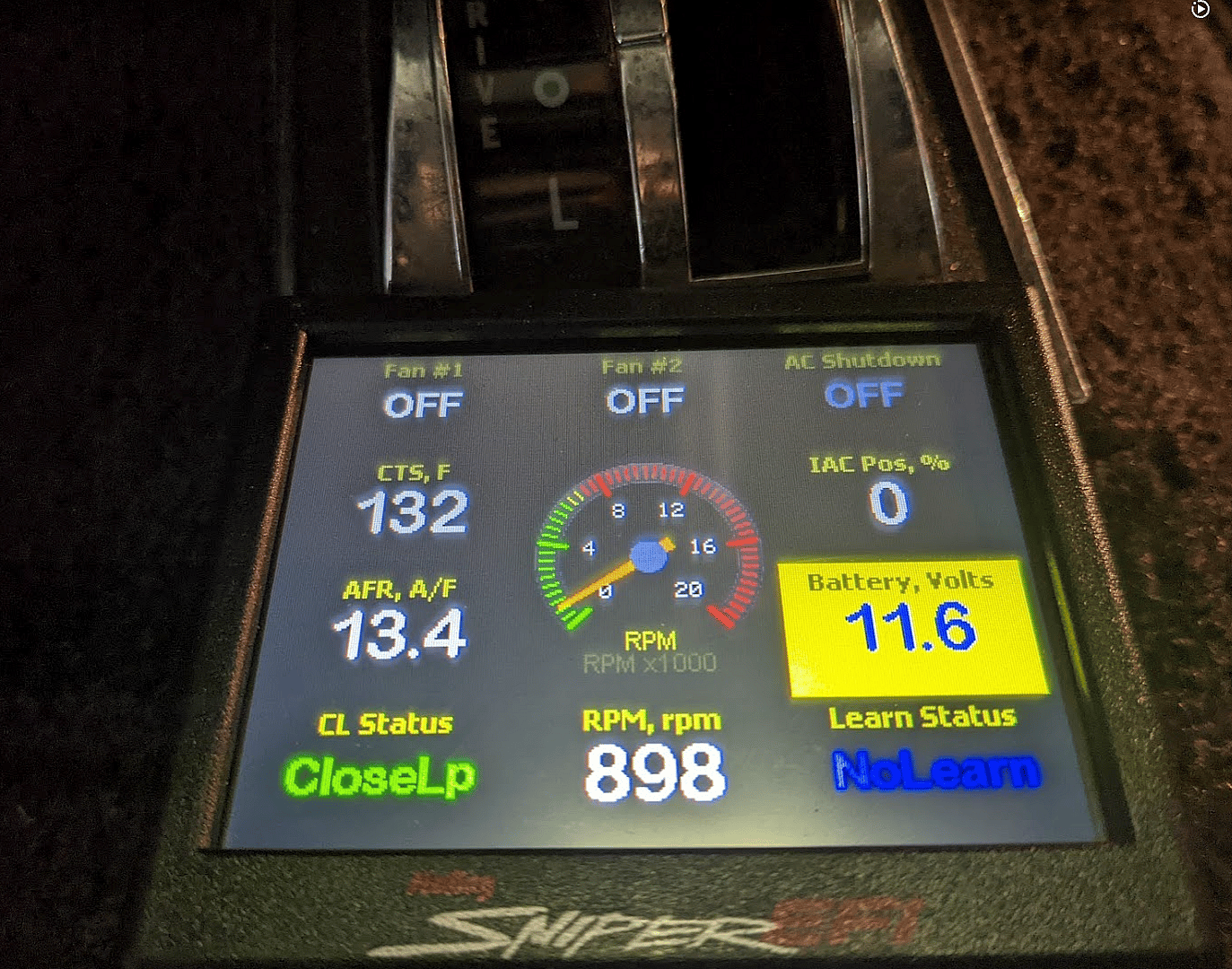

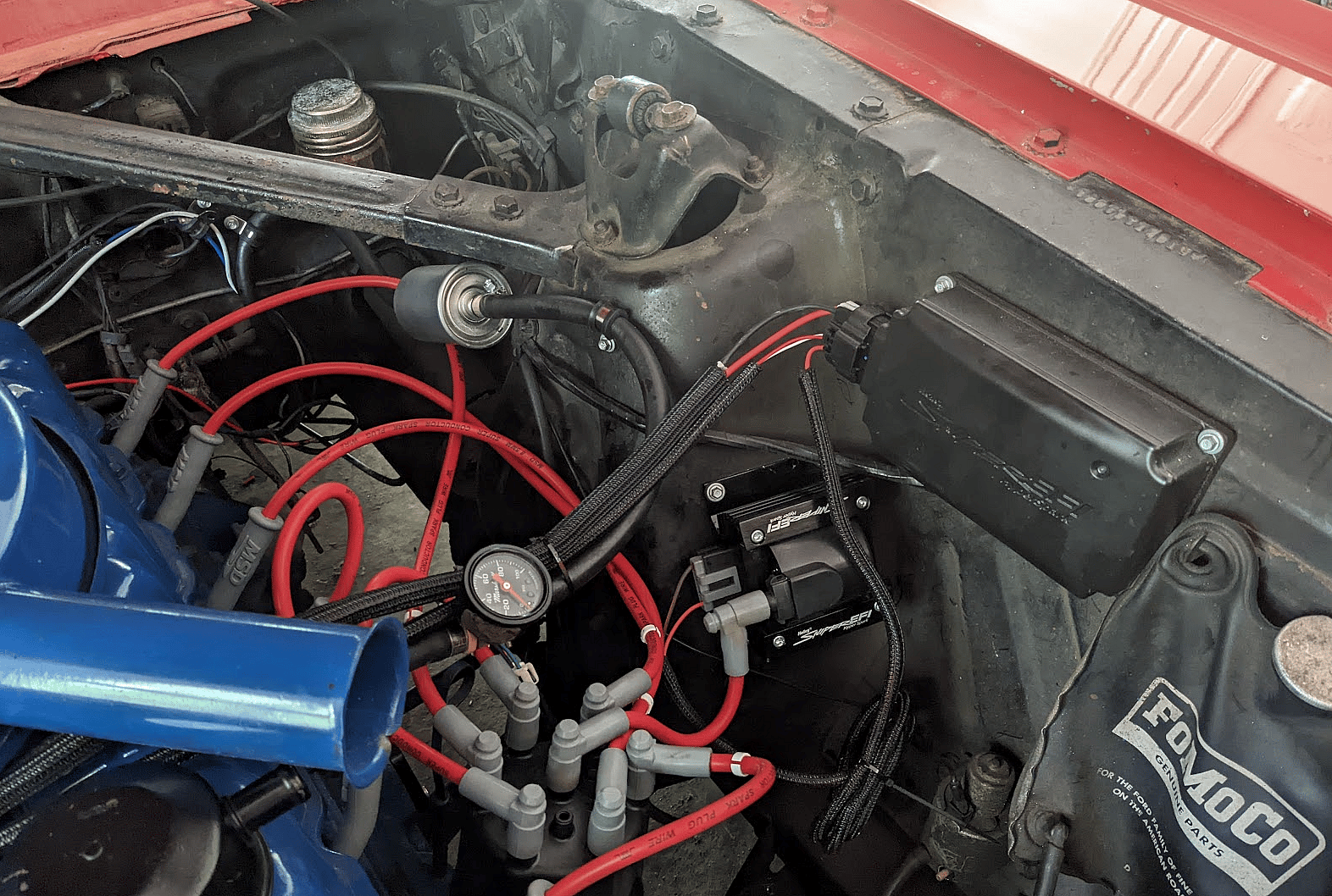

This summer I bought a 65 Coupe - clean and fairly original 6. Once I took ownership I kept running into carb issues. I never really got to enjoy it. Those 1 barrels are less than fun. So I decided to do a EFI swap as Holley makes an EFI setup for the Autolite 1100. I ordered the parts and they trickled in for months. This week the Sniper EFI finally showed up (ordered in June!). This is what I ordered for those interested.

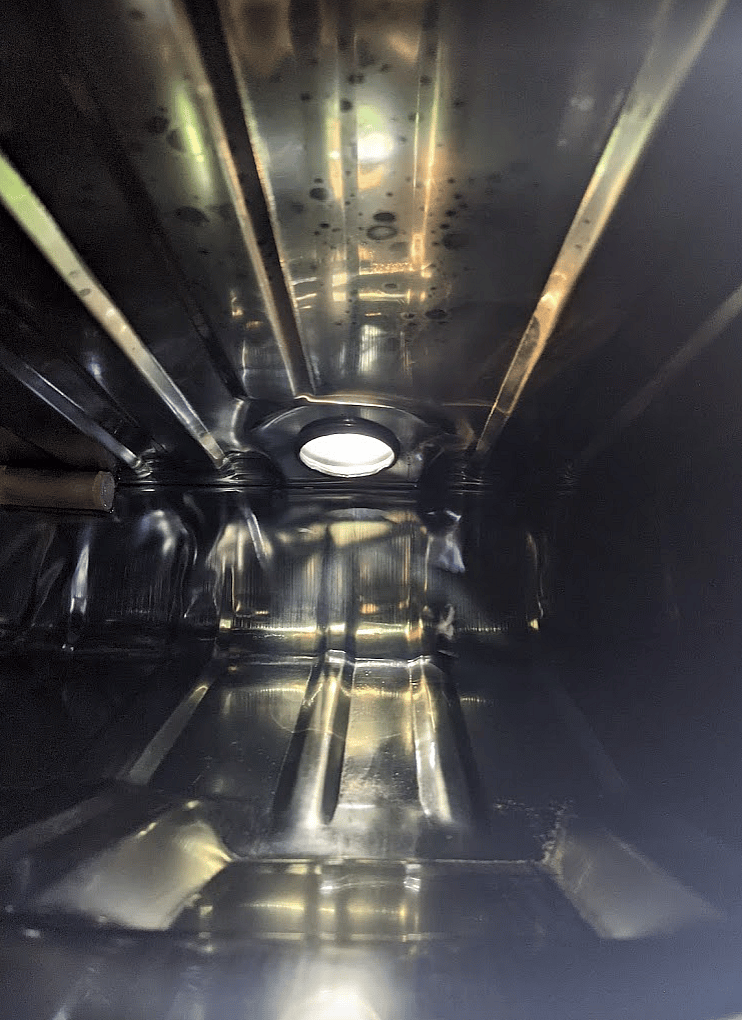

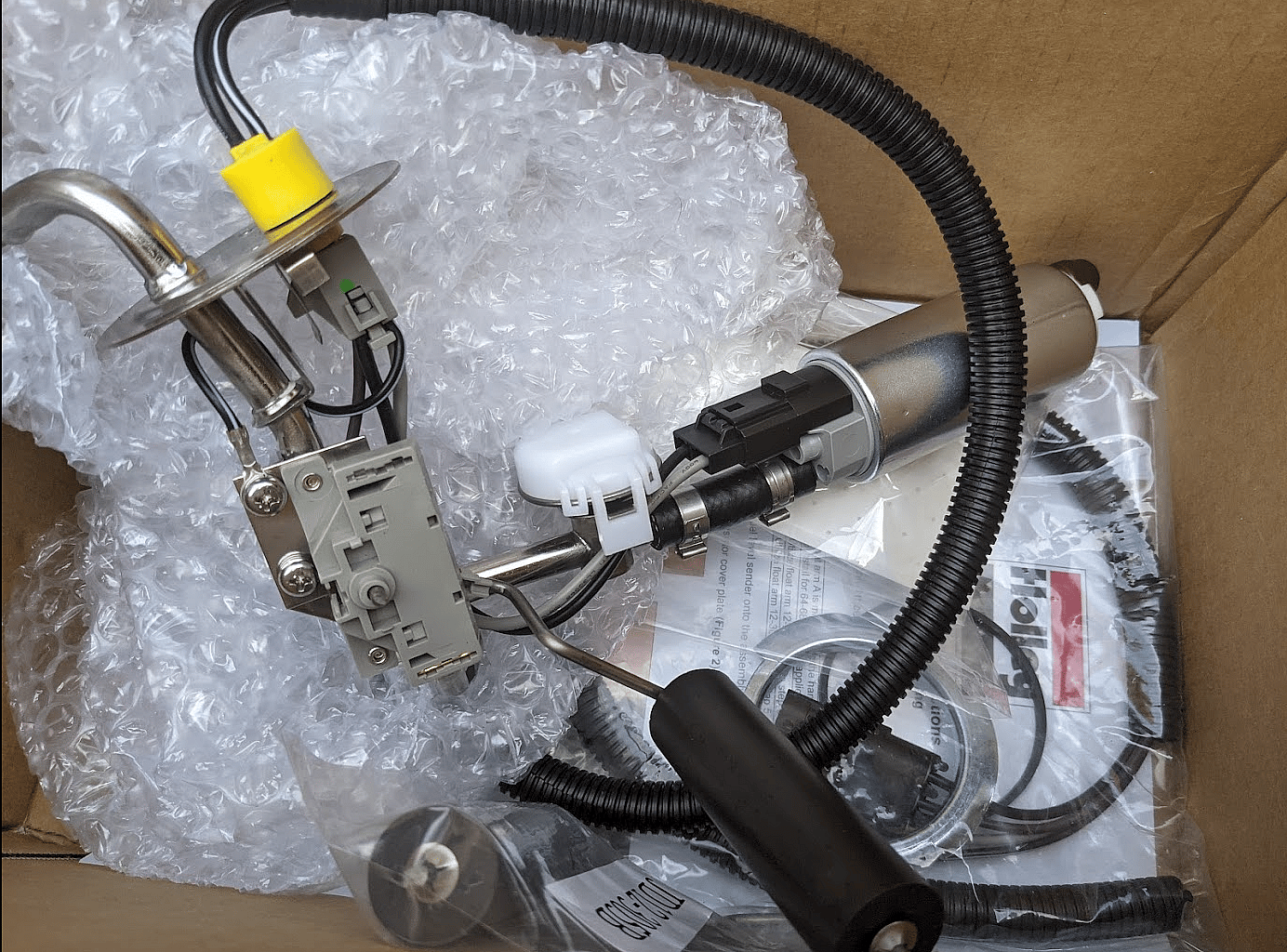

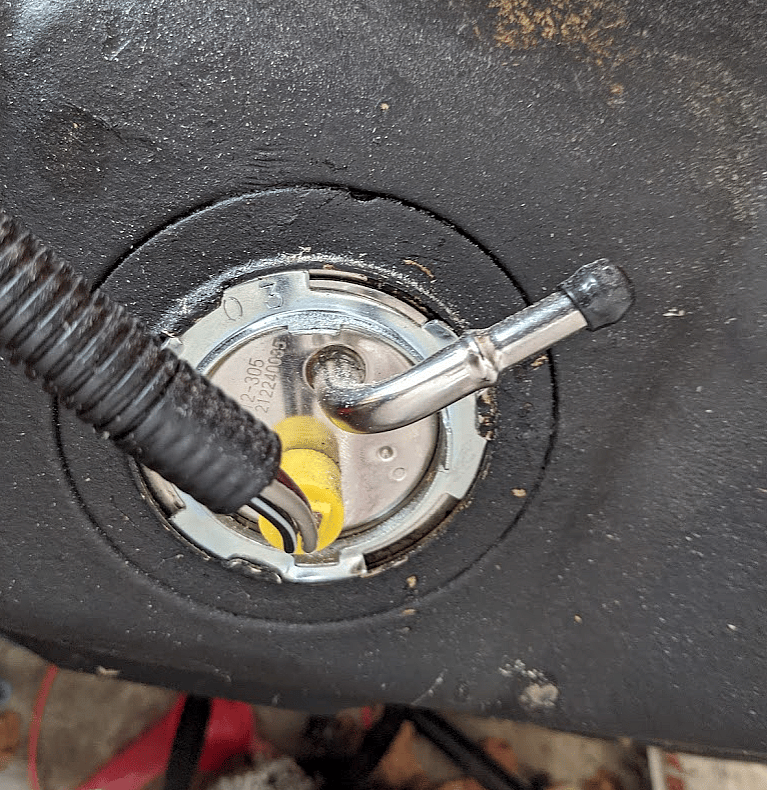

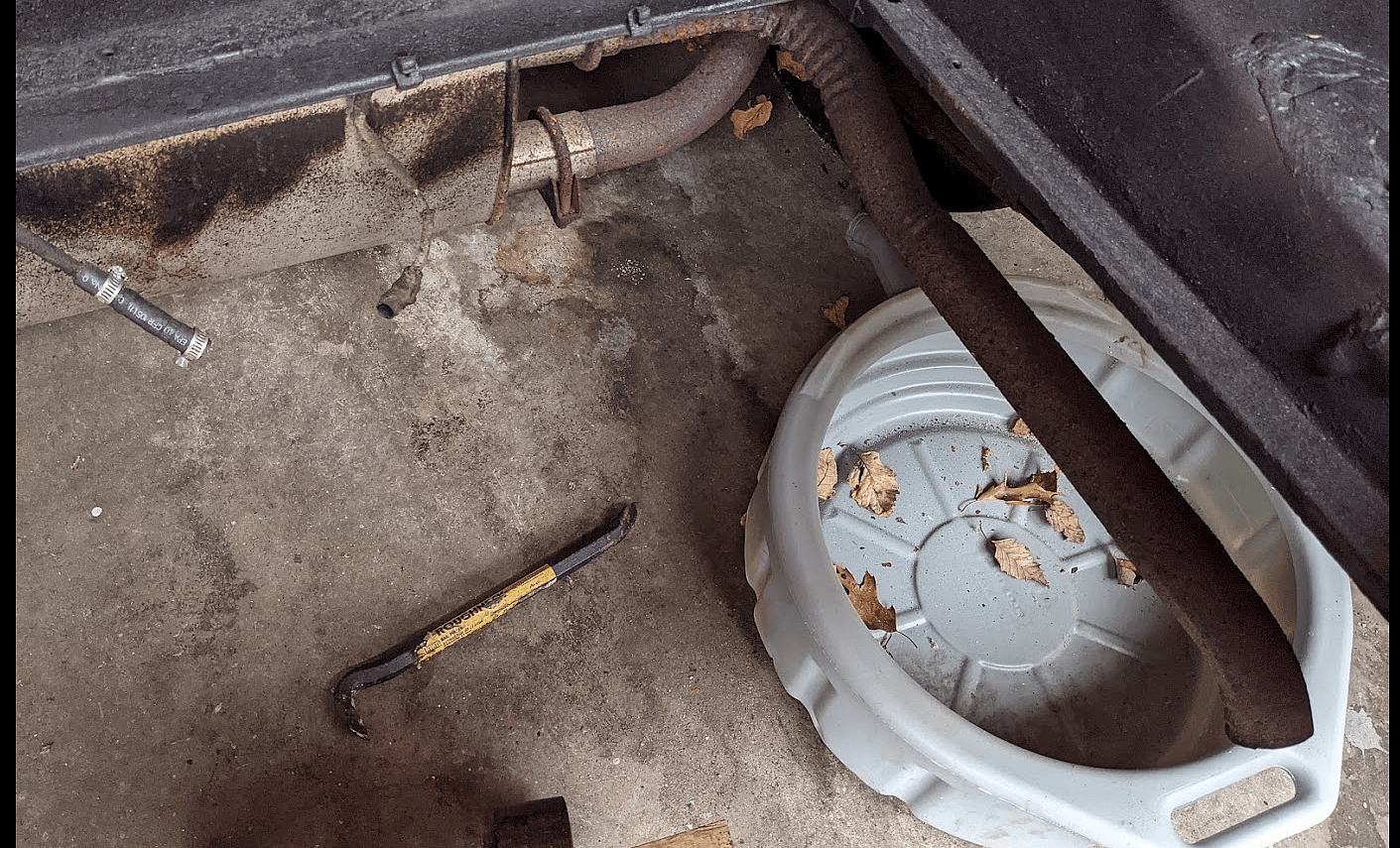

I'll document the process if anyone is interested. I just got the new Fuel pump in this passed weekend so the project is moving! Once this is done I want to do the front disc conversion as well. Im looking at the Wilwood and SSBC kits. Im going to leave it a 6 - maybe rebuild it with those Aussie heads/intake. Finding performance parts is rough for this motor. The vintage inlines guy seems pretty backed up.

If you have any tips or tricks I'm all ears. And as I said - I can post updates below.

Thanks!

This summer I bought a 65 Coupe - clean and fairly original 6. Once I took ownership I kept running into carb issues. I never really got to enjoy it. Those 1 barrels are less than fun. So I decided to do a EFI swap as Holley makes an EFI setup for the Autolite 1100. I ordered the parts and they trickled in for months. This week the Sniper EFI finally showed up (ordered in June!). This is what I ordered for those interested.

| fuel pump | 12-305 | 375.00 | 375.00 | 1 | 1 | Holley | ||

| Fuel system | 526-9 | 160.00 | 160.00 | 1 | 1 | Holley | ||

| Sniper | 550-552 | 803.95 | 803.95 | 1 | 0 | Holley | ||

| Igniition Box | 556-151 | 221.95 | 221.95 | 1 | 1 | Holley | ||

| Coil | 556-152 | 42.00 | 42.00 | 1 | 1 | Holley | ||

| Distributor | 565-315 | 268.00 | 268.00 | 1 | 1 | Holley |

I'll document the process if anyone is interested. I just got the new Fuel pump in this passed weekend so the project is moving! Once this is done I want to do the front disc conversion as well. Im looking at the Wilwood and SSBC kits. Im going to leave it a 6 - maybe rebuild it with those Aussie heads/intake. Finding performance parts is rough for this motor. The vintage inlines guy seems pretty backed up.

If you have any tips or tricks I'm all ears. And as I said - I can post updates below.

Thanks!