Well my old cam card doesn't have anything after the part number. I would degree it just to be sure. Or send Ed an email asking him.

Definitely not a bad idea to email Ed. Let me ask another question about cam end play. When I bolt on the thrust plate/retaining plate, the cam has all sorts of room behind it. When I bolt up the sprocket, it pulls the cam forward and relatively tight against the thrust plate. What exactly am I measuring with the feeler guages? I cant get anything behind the cam sprocket, so Im a bit confused. The sprocket doesnt really move at all (forward and backward), so Im nervous that I need to adjust it somehow. It does spin with relative ease. Someone educate me please.

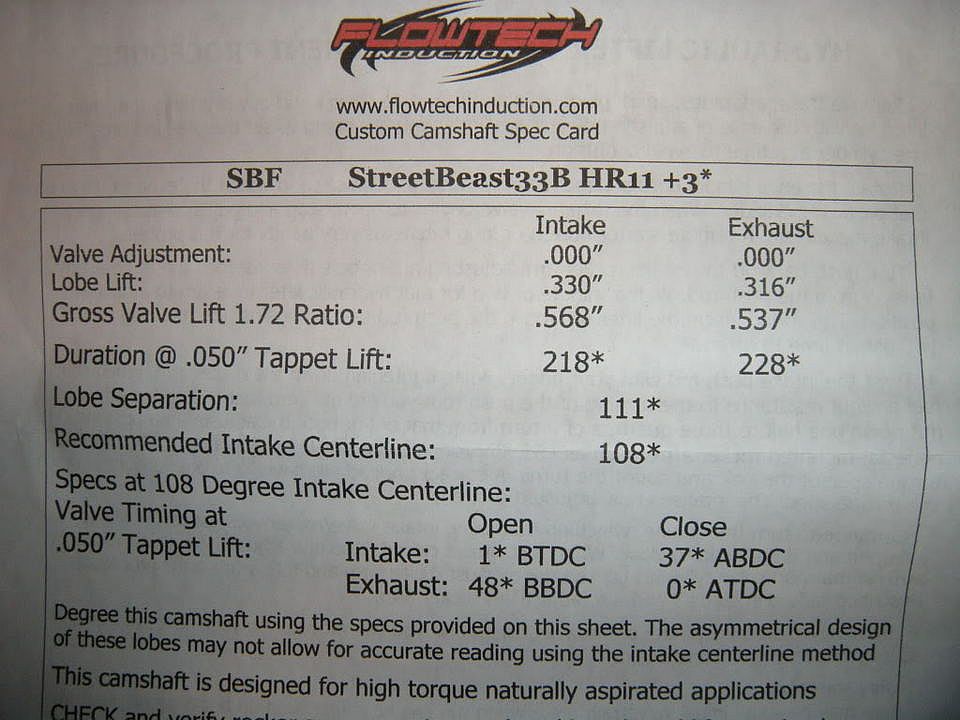

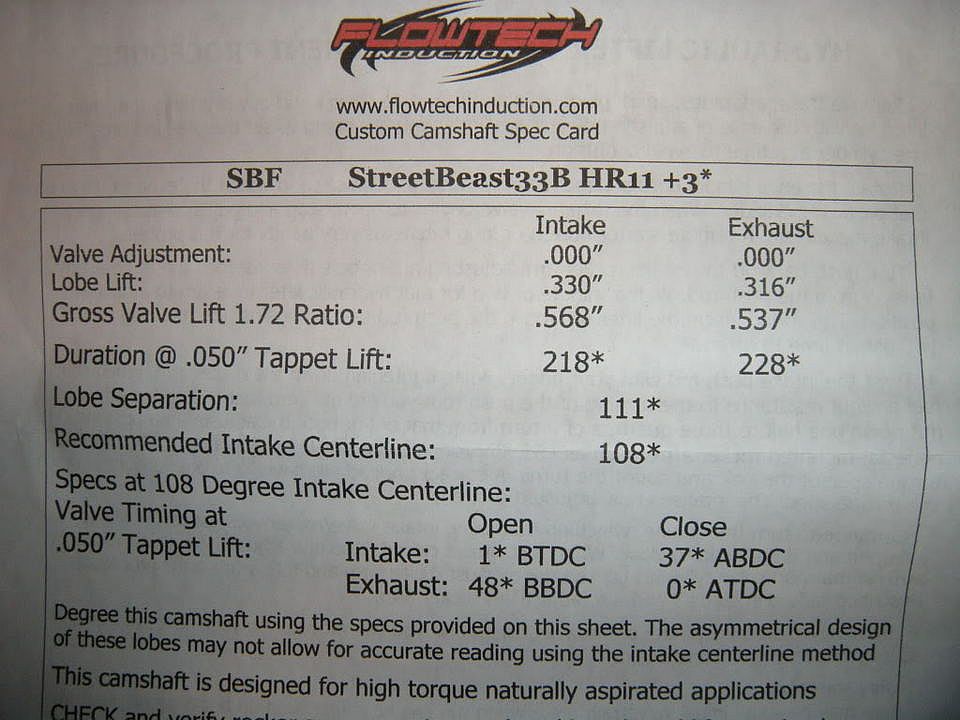

This is what the directions with the cam say:

If the new camshaft being installed is a hydraulic or solid flat tappet cam, this step is not necessary. Flat tappet cams have taper ground into their lobes, which pushes the cam into the proper position and holds it there while the engine is running. Checking endplay is also unnecessary in engines equipped with cam retaining plates, whether the cam used is a flat tappet or roller.

This is what the timing chain instructions say:

End-play should be checked before final assembly of the engine. Install the camshaft, the thrust plate in its normal position, and the cam sprocket. Tighten the cam sprocket to specified torque rating. Now, use the feeler guages to check the clearance between thrust plate and the front cam-bearing-jornal thrust face. The maximum thickness feeler gauge represents camshaft end play. End play should be 0.001-0.007 in.

Im confused. Im under the impression that I dont need to worry about end play since our engine is equipped with a cam retaining plate...