- Jan 28, 2017

- 49

- 12

- 28

Convertible owners should enjoy this as well as coup

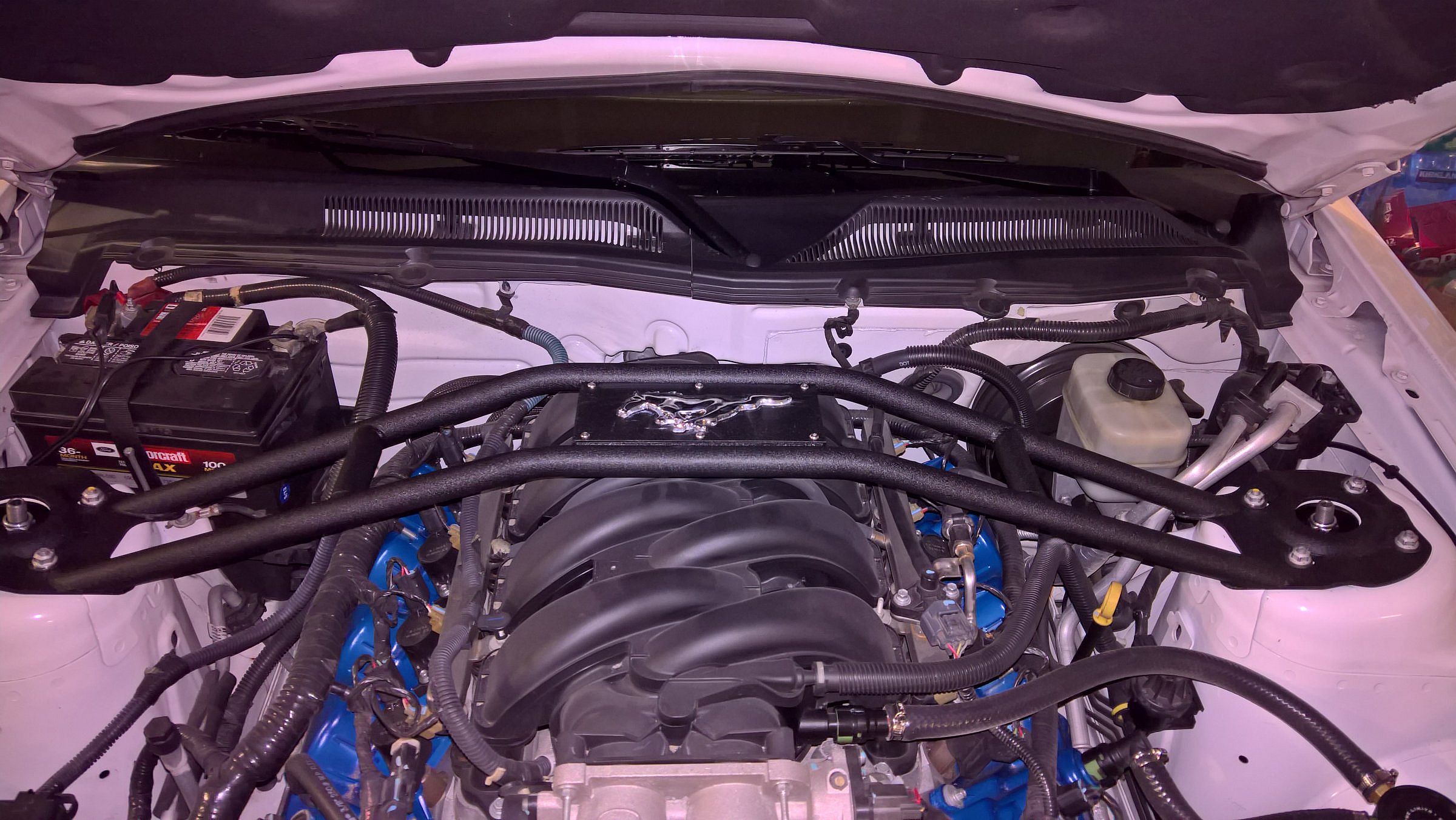

Project Car - My 2008 GT CS Convertible 68,000 miles

So I decided to do a suspension upgrade. Not that it needed anything but I wanted to 1) Lower it a bit 2) Tighten the suspension for better performance but keep a nice ride and not have a harsh bump mobile

Parts

Did the rear end yesterday to start - and if you are a convertible owner you will want to pay attention

PART 1 - The rear end install

Shock removal starts inside the car and 100% you need the universal too that holds the shaft from spinning - you can get it here and is saved me

Amazon product ASIN B000CO88C6View: https://www.amazon.com/gp/product/B000CO88C6/ref=oh_aui_detailpage_o00_s00?ie=UTF8&psc=1

Raise the car and put jack stands under axle to support the suspension

Remove shock bolts - on the convertible you DONT have lower the sway bay to get to the bolt like they say on coups

Remove the shocks

Now remove the bolts for the panhard bar - I had to loosen the panhard bar support bolt passenger side to get it to come out as it holds tight ..just loosen a bit

Reinstall the new panhard bar adjusted to the same size. DONT FORGET TO RETIGHTEN the PANHARD support bolt you loosened to get it out

So far so good

Now on to the springs and here is where it gets interesting

Rejack the car and put the stands under the lift points - not the suspension

NOTE - BEFORE LOWERING THE REAR TO HANG - remove the bolt on each side holding the brake line in place so its free or you will stretch it and possible damage - very easy

This is so you can drop the suspension to get the springs out - or so you think because it all would work except the DAMN convertible V brace that stops the axle from going low enough - YES, you do have to remove this and the Ford guide also has a sequence for removal and reinstall (Like a valve cover) - so I do this but it gets better

The bolts near the rear and near the doors are easily accessible but #3 on each is up a welded bar ABOVE the suspension I the most inaccessible frustrating spot unless you on a lit. I got around this by putting a socket on an 18" extension, worked it up there and got on the bolt to remove (trust me it was even more fun on reinstall)

Anyway, removed the bars, NOW lower the rear, put a jack under one side to raise it so the other side dropped and let me swap springs - then did the other

Reinstall the v brace - oh joy on bolt #3 on each try to start the threads where you cant possible reach but again - 18" extension did the trick

Back on the stands under the axle - reinstall the lower shock bolts. Remove and install the new bump stops

Lower the car, add the nuts to the top of the shocks I the trunk and you are done with the rear

End of PART 1

Project Car - My 2008 GT CS Convertible 68,000 miles

So I decided to do a suspension upgrade. Not that it needed anything but I wanted to 1) Lower it a bit 2) Tighten the suspension for better performance but keep a nice ride and not have a harsh bump mobile

Parts

- GT500 Lower control arms front

- Bilstein B12 Pro kit (shocks, struts and it comes with Eibach lowering springs progressive) - lowers 1.25 front and 1.50 rear on convertible

- GT500 upper strut mounts

- Steeda Panhard Bar

- FP Bump stops

- Proforged Bump steer tie rod ends (very much worth the price to save the geometry on a lowered car and no funky adjustments or washers to deal with

- Proforged inner tie rods

Did the rear end yesterday to start - and if you are a convertible owner you will want to pay attention

PART 1 - The rear end install

Shock removal starts inside the car and 100% you need the universal too that holds the shaft from spinning - you can get it here and is saved me

Amazon product ASIN B000CO88C6View: https://www.amazon.com/gp/product/B000CO88C6/ref=oh_aui_detailpage_o00_s00?ie=UTF8&psc=1

Raise the car and put jack stands under axle to support the suspension

Remove shock bolts - on the convertible you DONT have lower the sway bay to get to the bolt like they say on coups

Remove the shocks

Now remove the bolts for the panhard bar - I had to loosen the panhard bar support bolt passenger side to get it to come out as it holds tight ..just loosen a bit

Reinstall the new panhard bar adjusted to the same size. DONT FORGET TO RETIGHTEN the PANHARD support bolt you loosened to get it out

So far so good

Now on to the springs and here is where it gets interesting

Rejack the car and put the stands under the lift points - not the suspension

NOTE - BEFORE LOWERING THE REAR TO HANG - remove the bolt on each side holding the brake line in place so its free or you will stretch it and possible damage - very easy

This is so you can drop the suspension to get the springs out - or so you think because it all would work except the DAMN convertible V brace that stops the axle from going low enough - YES, you do have to remove this and the Ford guide also has a sequence for removal and reinstall (Like a valve cover) - so I do this but it gets better

The bolts near the rear and near the doors are easily accessible but #3 on each is up a welded bar ABOVE the suspension I the most inaccessible frustrating spot unless you on a lit. I got around this by putting a socket on an 18" extension, worked it up there and got on the bolt to remove (trust me it was even more fun on reinstall)

Anyway, removed the bars, NOW lower the rear, put a jack under one side to raise it so the other side dropped and let me swap springs - then did the other

Reinstall the v brace - oh joy on bolt #3 on each try to start the threads where you cant possible reach but again - 18" extension did the trick

Back on the stands under the axle - reinstall the lower shock bolts. Remove and install the new bump stops

Lower the car, add the nuts to the top of the shocks I the trunk and you are done with the rear

End of PART 1