You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Power Steering Pump Leak

- Thread starter from6to8

- Start date

-

Sponsors (?)

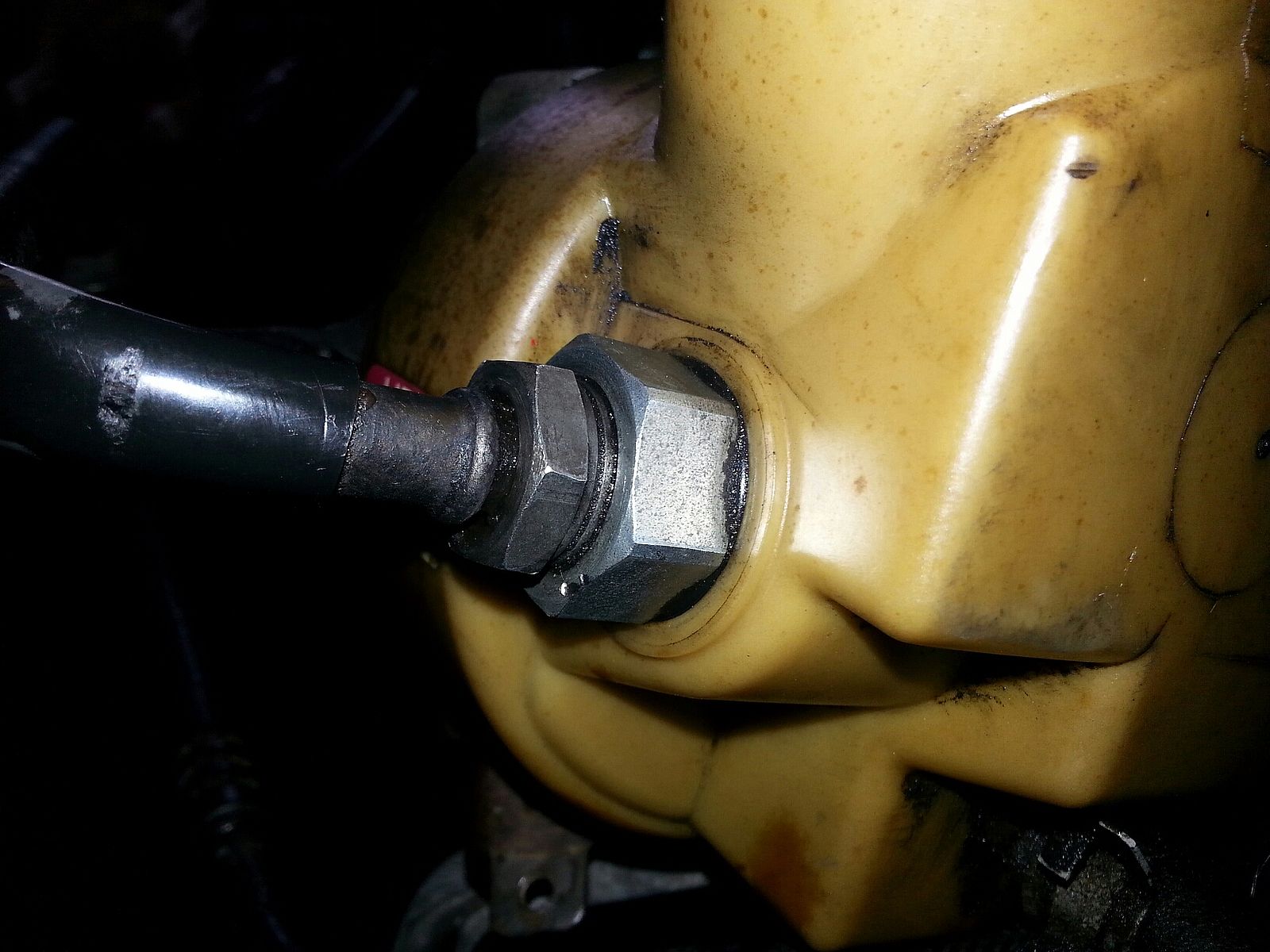

it's actually leaking right where the hose joins with the first nut, must be a seal or something so im wondering if the hose needs to just be replaced? I saw where it connects right below the motor mount and in an area that's a must to take off while car is on a lift so i know i won't be changing that hose out. I also wonder about a power steering stop leak?

Each hose uses an O ring on each end to seal them. The hoses will swivel when they are installed and tightened into place. That is why there are O rings on the fittings. The O ring is the part that actually makes the pressure seal. If you slide the nut all the way back as far as it will go, you will see the O ring and the groove cut into the center section of the fitting. The auto parts stores I tried seemed to have a problem finding the correct O ring for the pump end high pressure fitting. I had persistent leaks until I gave up and replaced the hose assembly.

Sometimes you will get some white Teflon rings with the pump or rack. The rings go on the threaded part of the fitting to reduce or prevent small leaks. They are not meant to seal the pressure part of the line or substitute for the rubber O ring. Heat the white Teflon seals in hot water and they will be easier to install. You can install the fittings without them and not have any leaks if the O rings seal good.

The return hoses are all low pressure and are most commonly secured to the pump and associated plumbing with worm gear hose clamps. After a while they will frequently soften up at the end where they are clamped, and should be replaced. The auto parts store will sell you hose by the foot and it takes about 3 feet or less, depending if you have the fluid cooler in the low pressure side of the line.

You may find it is easier to drop the rack down to get to the hose fittings. If you try and do it with the rack in place it takes about 20 minutes per fitting to loosen them with a fancy Snap-On 45/65 degree angle head open end wrench. Putting them back on takes even longer. To drop the steering rack, the flex coupling for the steering shaft needs to be disconnected before you can get the rack out. You should disassemble the coupling by undoing the 2 bolts that hold it together.

Remove the two bolts that bolt the rack assembly to the frame and then pull the rack down. Get a catch pan to dump the fluid in when you disconnect the hydraulic lines. I replaced the rack mount bushings with some Energy Suspension urethane ones. When you re-install the rack assembly, put the rear bushings in the rack assembly and lift it into place. Then install the front bushings & washers and tighten down the nuts. Doing it this way makes room for the hydraulic lines without having them bind against the frame.

Sometimes you will get some white Teflon rings with the pump or rack. The rings go on the threaded part of the fitting to reduce or prevent small leaks. They are not meant to seal the pressure part of the line or substitute for the rubber O ring. Heat the white Teflon seals in hot water and they will be easier to install. You can install the fittings without them and not have any leaks if the O rings seal good.

The return hoses are all low pressure and are most commonly secured to the pump and associated plumbing with worm gear hose clamps. After a while they will frequently soften up at the end where they are clamped, and should be replaced. The auto parts store will sell you hose by the foot and it takes about 3 feet or less, depending if you have the fluid cooler in the low pressure side of the line.

You may find it is easier to drop the rack down to get to the hose fittings. If you try and do it with the rack in place it takes about 20 minutes per fitting to loosen them with a fancy Snap-On 45/65 degree angle head open end wrench. Putting them back on takes even longer. To drop the steering rack, the flex coupling for the steering shaft needs to be disconnected before you can get the rack out. You should disassemble the coupling by undoing the 2 bolts that hold it together.

Remove the two bolts that bolt the rack assembly to the frame and then pull the rack down. Get a catch pan to dump the fluid in when you disconnect the hydraulic lines. I replaced the rack mount bushings with some Energy Suspension urethane ones. When you re-install the rack assembly, put the rear bushings in the rack assembly and lift it into place. Then install the front bushings & washers and tighten down the nuts. Doing it this way makes room for the hydraulic lines without having them bind against the frame.

Each hose uses an O ring on each end to seal them. The hoses will swivel when they are installed and tightened into place. That is why there are O rings on the fittings. The O ring is the part that actually makes the pressure seal. If you slide the nut all the way back as far as it will go, you will see the O ring and the groove cut into the center section of the fitting. The auto parts stores I tried seemed to have a problem finding the correct O ring for the pump end high pressure fitting. I had persistent leaks until I gave up and replaced the hose assembly.

Sometimes you will get some white Teflon rings with the pump or rack. The rings go on the threaded part of the fitting to reduce or prevent small leaks. They are not meant to seal the pressure part of the line or substitute for the rubber O ring. Heat the white Teflon seals in hot water and they will be easier to install. You can install the fittings without them and not have any leaks if the O rings seal good.

The return hoses are all low pressure and are most commonly secured to the pump and associated plumbing with worm gear hose clamps. After a while they will frequently soften up at the end where they are clamped, and should be replaced. The auto parts store will sell you hose by the foot and it takes about 3 feet or less, depending if you have the fluid cooler in the low pressure side of the line.

You may find it is easier to drop the rack down to get to the hose fittings. If you try and do it with the rack in place it takes about 20 minutes per fitting to loosen them with a fancy Snap-On 45/65 degree angle head open end wrench. Putting them back on takes even longer. To drop the steering rack, the flex coupling for the steering shaft needs to be disconnected before you can get the rack out. You should disassemble the coupling by undoing the 2 bolts that hold it together.

Remove the two bolts that bolt the rack assembly to the frame and then pull the rack down. Get a catch pan to dump the fluid in when you disconnect the hydraulic lines. I replaced the rack mount bushings with some Energy Suspension urethane ones. When you re-install the rack assembly, put the rear bushings in the rack assembly and lift it into place. Then install the front bushings & washers and tighten down the nuts. Doing it this way makes room for the hydraulic lines without having them bind against the frame.

yeah i will just replace the hose

Grabbin' Asphalt

5 Year Member

The person to ask would be... Rick91GT. He custom builds 5.0 Mustang engines in all configurations.hey J richer are u knowledgeable about looking at cylinder walls and telling if they are coked, fine , or what? Just asking someone else

well now engine is apart as i have to get heads fixed but how will i tell if it has pressure?Does the high pressure line have pressure with engine off??

i mean it will still swivel freely right now. And actually from the feel of the line it doesnt seem to be pressurized

ok will see if i can pm himThe person to ask would be... Rick91GT. He custom builds 5.0 Mustang engines in all configurations.

wha

how does the hose at the end of the metal pipe under the motor mount disconnect?Each hose uses an O ring on each end to seal them. The hoses will swivel when they are installed and tightened into place. That is why there are O rings on the fittings. The O ring is the part that actually makes the pressure seal. If you slide the nut all the way back as far as it will go, you will see the O ring and the groove cut into the center section of the fitting. The auto parts stores I tried seemed to have a problem finding the correct O ring for the pump end high pressure fitting. I had persistent leaks until I gave up and replaced the hose assembly.

Sometimes you will get some white Teflon rings with the pump or rack. The rings go on the threaded part of the fitting to reduce or prevent small leaks. They are not meant to seal the pressure part of the line or substitute for the rubber O ring. Heat the white Teflon seals in hot water and they will be easier to install. You can install the fittings without them and not have any leaks if the O rings seal good.

The return hoses are all low pressure and are most commonly secured to the pump and associated plumbing with worm gear hose clamps. After a while they will frequently soften up at the end where they are clamped, and should be replaced. The auto parts store will sell you hose by the foot and it takes about 3 feet or less, depending if you have the fluid cooler in the low pressure side of the line.

You may find it is easier to drop the rack down to get to the hose fittings. If you try and do it with the rack in place it takes about 20 minutes per fitting to loosen them with a fancy Snap-On 45/65 degree angle head open end wrench. Putting them back on takes even longer. To drop the steering rack, the flex coupling for the steering shaft needs to be disconnected before you can get the rack out. You should disassemble the coupling by undoing the 2 bolts that hold it together.

Remove the two bolts that bolt the rack assembly to the frame and then pull the rack down. Get a catch pan to dump the fluid in when you disconnect the hydraulic lines. I replaced the rack mount bushings with some Energy Suspension urethane ones. When you re-install the rack assembly, put the rear bushings in the rack assembly and lift it into place. Then install the front bushings & washers and tighten down the nuts. Doing it this way makes room for the hydraulic lines without having them bind against the frame.

Grabbin' Asphalt

5 Year Member

Oh sorry , I meant as a general operational question about the power steering pump. Similar to the operation of a fuel pump?? ...ie: it only primes with pressure key forward. Does the high pressure line suppose to always have pressure even with the engine off? -(anyone know?)well now engine is apart as i have to get heads fixed but how will i tell if it has pressure?

well mine didnt seem to have any pressure with key not switched on but will double checkOh sorry , I meant as a general operational question about the power steering pump. Similar to the operation of a fuel pump?? ...ie: it only primes with pressure key forward. Does the high pressure line suppose to always have pressure even with the engine off? -(anyone know?)

i do need to know how that hose comes off at the line end down there connected near tie rod.Oh sorry , I meant as a general operational question about the power steering pump. Similar to the operation of a fuel pump?? ...ie: it only primes with pressure key forward. Does the high pressure line suppose to always have pressure even with the engine off? -(anyone know?)

dirty down there and cant see rather its a nut or what. Not worried about getting up under it quite yet but i will at some point so i can go ahead and get the hose and see rather i can get it loose at that spot or not or rather i wana take it to a shop or something when I get car back together. Sort of hope i can get to it nice an easy now while everythign is off

Grabbin' Asphalt

5 Year Member

Believe no electrical connections are involved with the pump, so it's a mechanical pressure from the pulley, I just was wondering once it gets pressure does it hold it continuously or bleed off. Someone has to have a video on the web about line, rack removal too. I always like to see it with my eyes.

Last edited:

to

yeah i know, i will clean up that area and see how the other hose end connects to the end of the line right under/near the motor mount. If i can get to it then i will go ahead and change it out before i put everything back together. I would hate to have to have someone take those things back off just to change that line plus i will have everything cleaned up and wont want to get oil back on stuff and dirty them up.

yeah im surprised there werent alot of different videos on several things i would think would be on youtube

Believe no electrical connections are involved with the pump, so it's a mechanical pressure from the pulley, I just was wondering once it gets pressure does it hold it continuously or bleed off. Someone has to have a video on the web about line, rack removal too. I always like to see it with my eyes.

yeah i know, i will clean up that area and see how the other hose end connects to the end of the line right under/near the motor mount. If i can get to it then i will go ahead and change it out before i put everything back together. I would hate to have to have someone take those things back off just to change that line plus i will have everything cleaned up and wont want to get oil back on stuff and dirty them up.

yeah im surprised there werent alot of different videos on several things i would think would be on youtube

There is no pressure in the line once the pump stops turning. If you have and concerns in that area, just try to turn the steering wheel when the engine isn't running. That would relieve any remaining pressure that didn't bleed off when the pump quit turning.

Don't try to change the power steering lines without dropping the rack. There simply is no wrench room unless you have one of the Snap-On 65/45 degree offset open end wrenches. Even the it is way faster and easier to drop the steering rack. Two bolts and the steering shaft coupler comes apart. Two more bolts and the rack drops down from the frame and gives you sufficient wrench room to do the job without a lot of effort and bruises.

Don't try to change the power steering lines without dropping the rack. There simply is no wrench room unless you have one of the Snap-On 65/45 degree offset open end wrenches. Even the it is way faster and easier to drop the steering rack. Two bolts and the steering shaft coupler comes apart. Two more bolts and the rack drops down from the frame and gives you sufficient wrench room to do the job without a lot of effort and bruises.

here is a link to a thread i read where a guy didnt take the rack loose and seemed to be up my alley. I dont mind turning in small increments if its not that bad.There is no pressure in the line once the pump stops turning. If you have and concerns in that area, just try to turn the steering wheel when the engine isn't running. That would relieve any remaining pressure that didn't bleed off when the pump quit turning.

Don't try to change the power steering lines without dropping the rack. There simply is no wrench room unless you have one of the Snap-On 65/45 degree offset open end wrenches. Even the it is way faster and easier to drop the steering rack. Two bolts and the steering shaft coupler comes apart. Two more bolts and the rack drops down from the frame and gives you sufficient wrench room to do the job without a lot of effort and bruises.

and my question is, with the rack loose, would that throw the alignment off?

http://thelincolnmarkviiclub.org/phpBB3/viewtopic.php?f=19&t=6240

here is a link to a thread i read where a guy didnt take the rack loose and seemed to be up my alley. I dont mind turning in small increments if its not that bad.

and my question is, with the rack loose, would that throw the alignment off?

http://thelincolnmarkviiclub.org/phpBB3/viewtopic.php?f=19&t=6240

The tie rods are not disconnected or adjusted when you lower the rack to change the power steering lines. Since you are not tightening or loosening the tie rods, or permanently repositioning the steering rack, the toe in/out alignment will not change when the rack is bolted back in place.

Similar threads

- Replies

- 51

- Views

- 3K

Wheels-Tires

Power Steering Pump

- Replies

- 5

- Views

- 428

- Replies

- 8

- Views

- 1K

- Replies

- 12

- Views

- 3K