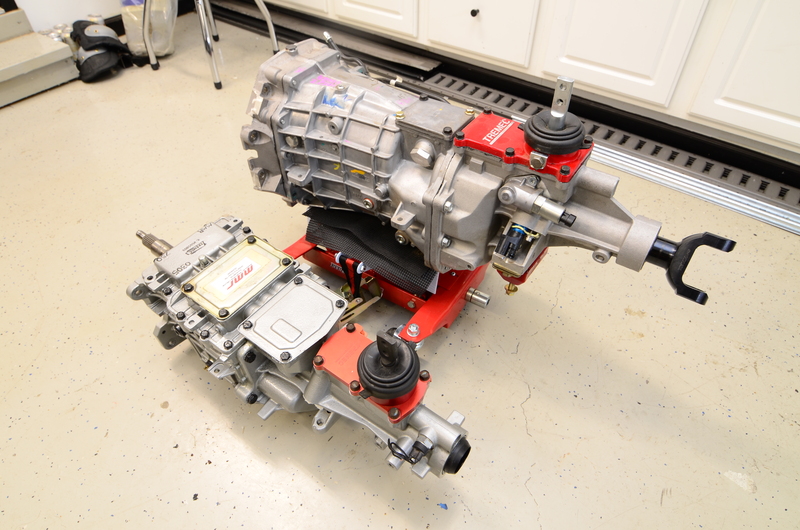

So the T56 Magnum install is underway. Now I know why they call it the Magnum. Summa bish is huge. Sitting next to the TKO-500 here.

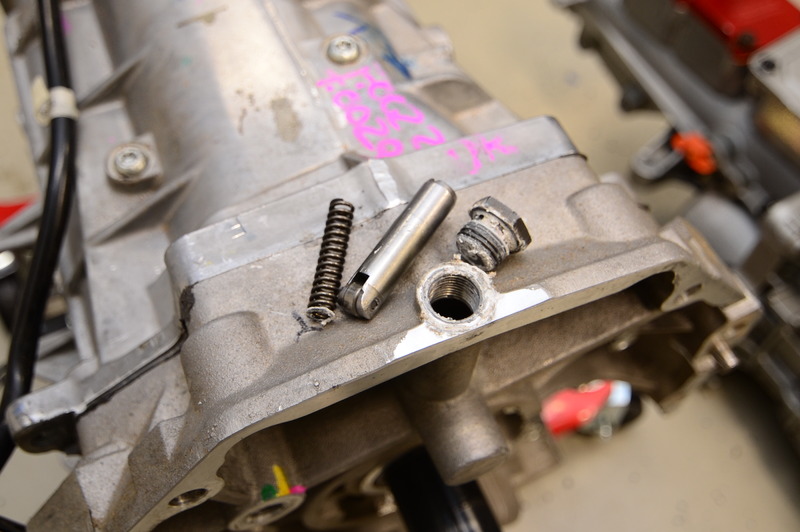

I'm going to chronicle the install here. I didn't find a whole lot of installation details with pictures online, so hopefully my experience will help others. Aligning the bellhousing with the Magnum is a little different than other transmissions because the bellhousing doesn't have a concentric circle that can be used to dial it in. The front plate of the transmission needs to be removed and then bolted to the bellhousing without the rest of the transmission behind it. First thing is to remove the detent bolt and spring.

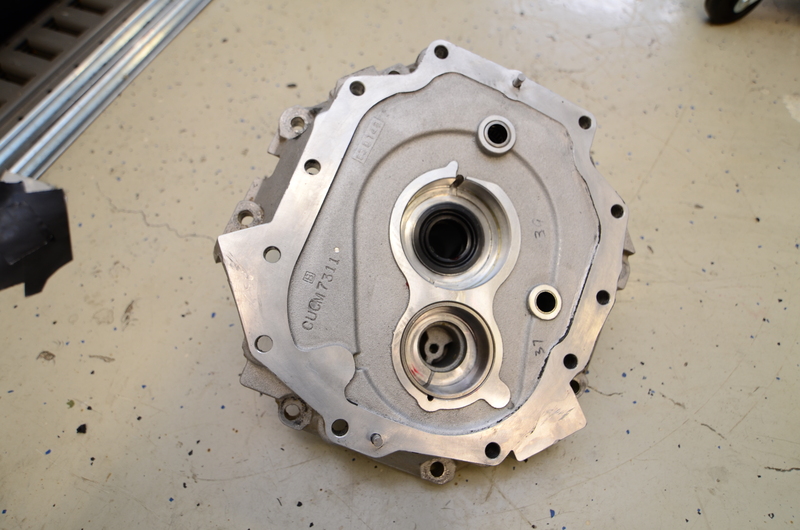

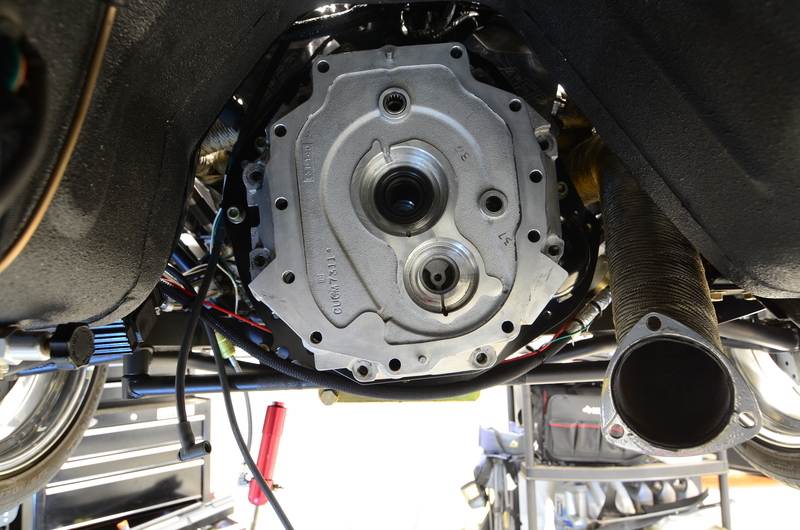

Once that is out, removing all the bolts on the plate will allow it to be removed. There are two pry spots on each side of the case that make removal with a screwdriver easy. Here's the plate off the trans. I already scraped off all the RTV that was sealing it to the case.

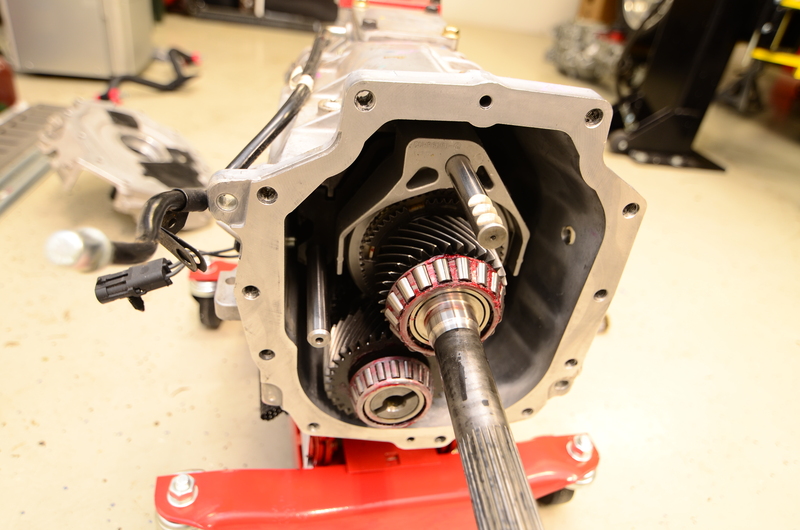

Inside of the mighty Magnum.

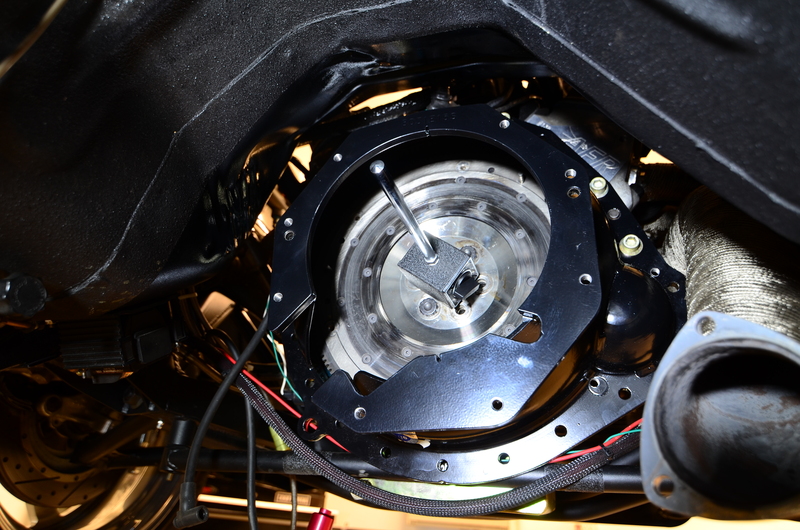

I then bolted up the bellhousing with just the flywheel installed. You can see why it's not possible to index this bellhousing without the front plate.

I put the front plate in place and noticed it was crooked. After talking to some people, I'm told this is normal and that transmissions typically favor the driver. I had to stop at this point anyway because my dial indicator base is too thick and wont let me install the plate because the input shaft sleeve sits too close to the flywheel.

Speaking of the input shaft sleeve, there is a lot of information on the internet that the sleeve needs to be shortened when using a twin disc clutch.

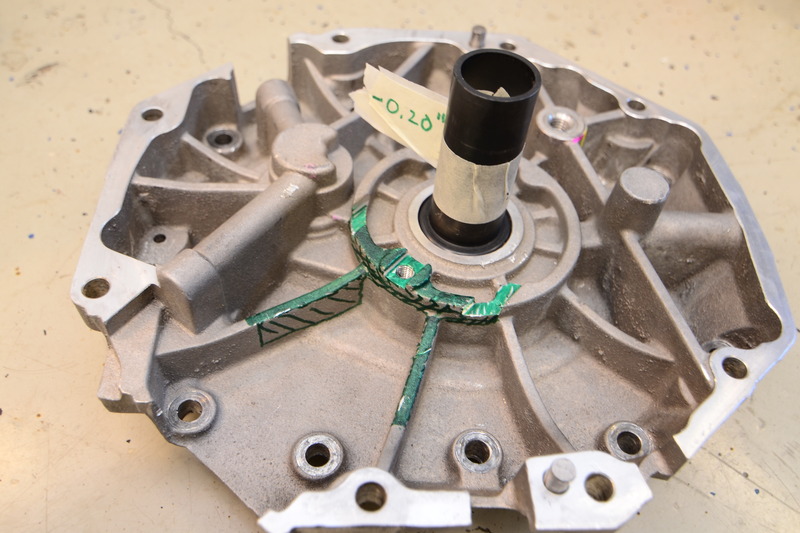

After some measuring, I only have 1/8" clearance to the sleeve once both clutch discs are installed. I'm going to shorten the sleeve the 0.20" that I have seen recommended online.

The webbing of the front plate also needs to be trimmed back thanks to the extra space that the twin disc takes up. The clutch fork hits the plate in certain areas. The green spots are marked up for my machine shop. I'm going to have him shorten the sleeve and machine down those spots at the same time.

Once the sleeve is machined, my dial indicator base will actually fit so I can get back to aligning the bellhousing.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Build Thread Want To Blow 5 Years And $50k On A Foxbody? Step By Step Instructions Inside!

- Thread starter RacEoHolic330

- Start date

-

Sponsors (?)

Sorry I know this is a few months old but I'm currently putting a 2015 coyote with a t56 magnum in my 67 mustang and I'm reading up on this alignment discussion as this is new to me . My question is ..... Do I have to machine the webbing on the front plate if I'm using a Hydro throw out bearing? Or the only reason you had to is because you are using a fork?

Also I'm putting on a McLeod RST twin disk clutch will I have to also trim 0.20" off the sleeve? Thank you in advance

Also I'm putting on a McLeod RST twin disk clutch will I have to also trim 0.20" off the sleeve? Thank you in advance

PM me if you want/need that T/O bearing. I have a brand new Mccleod that I never used sitting in a box. Much cheaper than new.Sorry I know this is a few months old but I'm currently putting a 2015 coyote with a t56 magnum in my 67 mustang and I'm reading up on this alignment discussion as this is new to me . My question is ..... Do I have to machine the webbing on the front plate if I'm using a Hydro throw out bearing? Or the only reason you had to is because you are using a fork?

Also I'm putting on a McLeod RST twin disk clutch will I have to also trim 0.20" off the sleeve? Thank you in advance

We had to do no modifications to my t56 magnum / coyote swap - quicktime bell and centerforce dual friction (single) clutch and cable pedal, Ive heard otherwise with hydraulic.... also we just installed it without all the steps Scott took... hardest part is working the bell around the longtubes..... Tremec support has some very helpful guys there as well....

We had to do no modifications to my t56 magnum / coyote swap - quicktime bell and centerforce dual friction (single) clutch and cable pedal, Ive heard otherwise with hydraulic.... also we just installed it without all the steps Scott took... hardest part is working the bell around the longtubes..... Tremec support has some very helpful guys there as well....

We had to do no modifications to my t56 magnum / coyote swap - quicktime bell and centerforce dual friction (single) clutch and cable pedal, Ive heard otherwise with hydraulic.... also we just installed it without all the steps Scott took... hardest part is working the bell around the longtubes..... Tremec support has some very helpful guys there as well....

I was planning on using Dougs headers (for coyote swap) what did you end up using? Or what did you use? To make things work

@67coyote, MM K, stiffler trans cross, bbk coyote LT, BBK 3" catted X, custom X to 2.5" Dynomax ultras to 2.5 tips. QT bell, MM cable etc.

Start a new thread so we dont clog up Scott's thread and call me @89oem and @TOOLOW91 and @RacEoHolic330 and we can get u going... others will join in....

Start a new thread so we dont clog up Scott's thread and call me @89oem and @TOOLOW91 and @RacEoHolic330 and we can get u going... others will join in....

Sorry I know this is a few months old but I'm currently putting a 2015 coyote with a t56 magnum in my 67 mustang and I'm reading up on this alignment discussion as this is new to me . My question is ..... Do I have to machine the webbing on the front plate if I'm using a Hydro throw out bearing? Or the only reason you had to is because you are using a fork?

Also I'm putting on a McLeod RST twin disk clutch will I have to also trim 0.20" off the sleeve? Thank you in advance

The webbing modifications was only because of the twin disc and the clutch fork. You won't have to touch it with a hydraulic TOB.

You will probably will have to shorten the collar with the twin disc regardless of the engine. It takes up a lot of real estate inside the bellhousing and the outer disc tends to hit the collar. If you take some careful measurements, you'll know if there is an interference or not before you put everything together.

The car finally saw the light of day yesterday for the first time since October. My test drive for the new trans was a 40 mile trip to a local show. I took first in the fox class, so that was cool.

Two issues popped up. Small trans fluid leak and I couldn't get the reverse lockout solenoid to work properly.

The fluid leak was coming from the mechanical VSS sensor. I'm using that sensor for my electronic speedometer, but without the cable plugged in. It never leaked in the TKO, but was weeping fluid from the new trans. I sealed up the area where the cable should go with some RTV. Should do the trick.

I have an Accutach unit for the reverse lockout solenoid that allows it to operate when the brake pedal is pressed and when the car is moving at less than 5mph. It wasn't working, so I had to overpower the solenoid with brute force during my trip. Not fun.

I realized this morning that I tapped the VSS return instead of the signal. Works great now.

What's the verdict on the T56 Magnum? Effin awesome! I really love this trans. The shifts are smooth and precise. There is just enough notchy-ness that it feels like a performance trans, but it's not so intense that you feel like you're forcing it into gear all the time. RPMs in 6th at 70mph are around 1700.

The Maximum Motorsports quadrant and cable combined with the twin disc clutch create a pedal feel that is from the heavens. It's literally lighter than the pedal in my fiancée's Focus ST. Two fingers will get the clutch to the floor with ease.

The car is a ton of fun to drive. I just need to take it easy while the trans is breaking in.

Two issues popped up. Small trans fluid leak and I couldn't get the reverse lockout solenoid to work properly.

The fluid leak was coming from the mechanical VSS sensor. I'm using that sensor for my electronic speedometer, but without the cable plugged in. It never leaked in the TKO, but was weeping fluid from the new trans. I sealed up the area where the cable should go with some RTV. Should do the trick.

I have an Accutach unit for the reverse lockout solenoid that allows it to operate when the brake pedal is pressed and when the car is moving at less than 5mph. It wasn't working, so I had to overpower the solenoid with brute force during my trip. Not fun.

I realized this morning that I tapped the VSS return instead of the signal. Works great now.

What's the verdict on the T56 Magnum? Effin awesome! I really love this trans. The shifts are smooth and precise. There is just enough notchy-ness that it feels like a performance trans, but it's not so intense that you feel like you're forcing it into gear all the time. RPMs in 6th at 70mph are around 1700.

The Maximum Motorsports quadrant and cable combined with the twin disc clutch create a pedal feel that is from the heavens. It's literally lighter than the pedal in my fiancée's Focus ST. Two fingers will get the clutch to the floor with ease.

The car is a ton of fun to drive. I just need to take it easy while the trans is breaking in.

Last edited:

Exactly!!

and I had same drip, got a NOS speedsensor set and no more drip...

and I had same drip, got a NOS speedsensor set and no more drip...

The car finally saw the light of day yesterday for the first time since October. My test drive for the new trans was a 40 mile trip to a local show. I took first in the fox class, so that was cool.

Two issues popped up. Small trans fluid leak and I couldn't get the reverse lockout solenoid to work properly.

The fluid leak was coming from the mechanical VSS sensor. I'm using that sensor for my electronic speedometer, but without the cable plugged in. It never leaked in the TKO, but was weeping fluid from the new trans. I sealed up the area where the cable should go with some RTV. Should do the trick.

I have an Accutach unit for the reverse lockout solenoid that allows it to operate when the brake pedal is pressed and when the car is moving at less than 5mph. It wasn't working, so I had to overpower the solenoid with brute force during my trip. Not fun.

I realized this morning that I tapped the VSS return instead of the signal. Works great now.

What's the verdict on the T56 Magnum? Effin awesome! I really love this trans. The shifts are smooth and precise. There is just enough notchy-ness that it feels like a performance trans, but it's not so intense that you feel like you're forcing it into gear all the time. RPMs in 6th at 70mph are around 1700.

The Maximum Motorsports quadrant and cable combined with the twin disc clutch create a pedal feel that is from the heavens. It's literally lighter than the pedal in my fiancée's Focus ST. Two fingers will get the clutch to the floor with ease.

The car is a ton of fun to drive. I just need to take it easy while the trans is breaking in.

So strange. I think I got mine from LRS. It's just weird that it didn't leak a drop from the TKO. There must be more fluid splashed around that area in the magnum..Exactly!!

and I had same drip, got a NOS speedsensor set and no more drip...

lrs, me too, hmm.. we then threw a shop one on but it was worse. ordered a nos and leak was gone. but dang I love that shift feel of this trans!! no question whats going on! by 3rd youre way over the speed limit, lol....

That's the truth. Especially with the wide ratio trans and my 3.27 rear gears. The car is such a blast to drive.lrs, me too, hmm.. we then threw a shop one on but it was worse. ordered a nos and leak was gone. but dang I love that shift feel of this trans!! no question whats going on! by 3rd youre way over the speed limit, lol....

It's PERFECT! Start the Space Odyssey video first then immediately start @RacEoHolic330 's video 10ish seconds after.

Jeez, after watching that I'm all sweaty and feel like I should give you a fifty.....

Your really going to make me bring my buffer home and buff my entire exhaust, aren't you.

Damn, that is sweet. Thanks for doing what you did man, it really makes me push harder on mine.

Looks Great brother....

Be honest though-you shot that video laying on a creeper right? Lol

That would be so perfect. I went back into the video and tried to find the orchestra song from YouTube's list of licensed songs, but no dice.

Jeez, after watching that I'm all sweaty and feel like I should give you a fifty.....

Your really going to make me bring my buffer home and buff my entire exhaust, aren't you.

Damn, that is sweet. Thanks for doing what you did man, it really makes me push harder on mine.

Better break out the sandpaper too! The buffing was a the easy part on the exhaust. The sanding suuuuuucked.

Glad I can be of some inspiration!

Looks Great brother....

Be honest though-you shot that video laying on a creeper right? Lol

My camera was laying on the creeper. I was behind it just shuffling back and forth. That's why there's no sound in the video. All you can hear is my sneakers on the garage floor. It sounds like a basketball game.

Attach your GoPro under your car and go for a drive....

I have considered this, and there is enough tubular stuff underneath that it would be possible. Once I get the trans broken and and the fluid flushed, you may see a video. Would be cool to see the IRS in action under load.

Suck or not, I can't unsee what you have done!Better break out the sandpaper too! The buffing was a the easy part on the exhaust. The sanding suuuuuucked.

Glad I can be of some inspiration!

I'll be sanding and buffing, smh. Oh well, it won't take for ever and it looks so nice.

What grit did you start with?

Similar threads

- Replies

- 32

- Views

- 42K

Progress Thread

'67 Mustang 351C > C4 trans > Clueless 21 year old

- Replies

- 5

- Views

- 3K

- Replies

- 3

- Views

- 11K

- Replies

- 1

- Views

- 7K

- Replies

- 2

- Views

- 3K