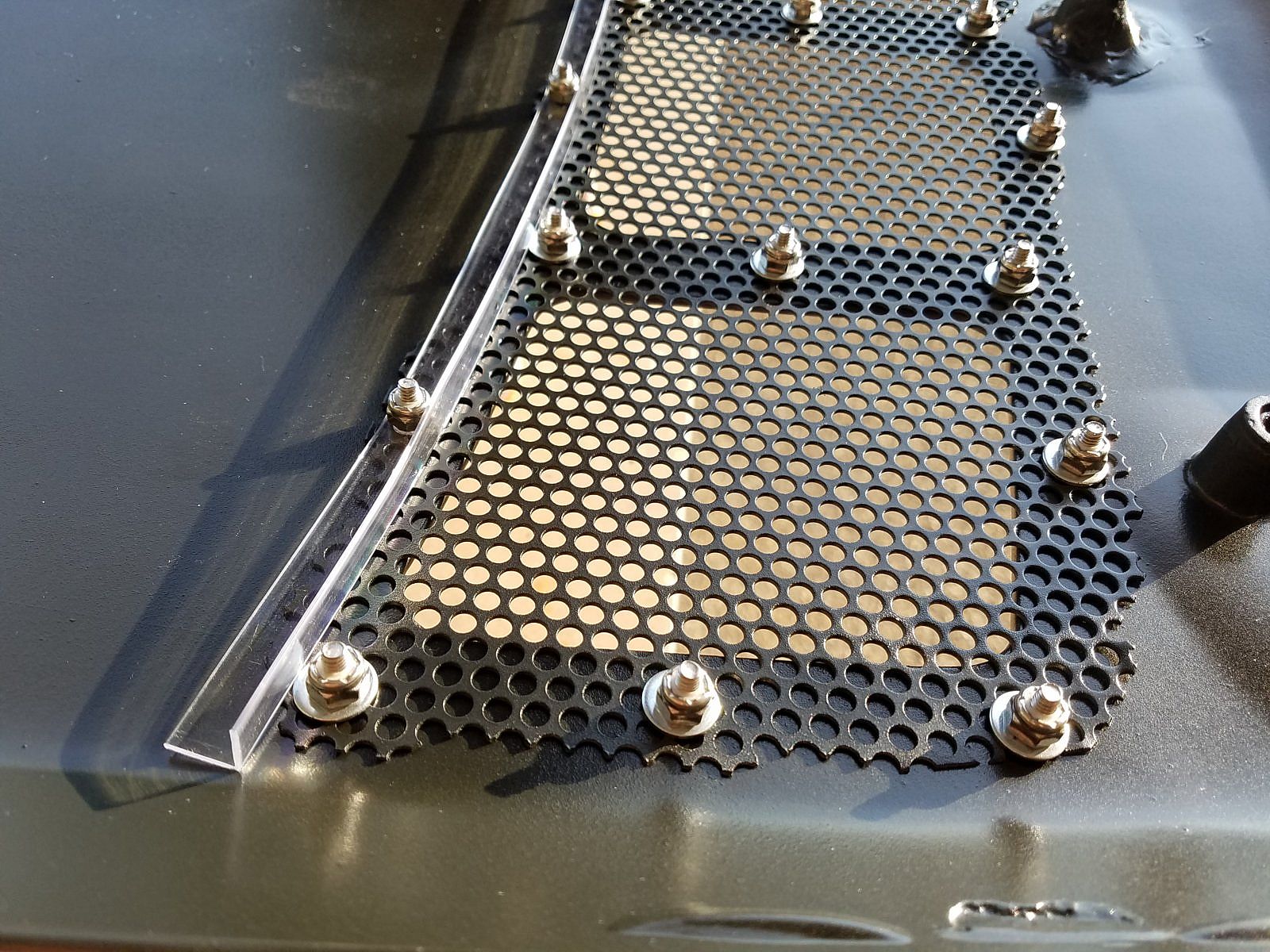

Another shot. Obviously still need to clean up the cut edges (particularly where the hole saw broke through), and blend the tangent points. The vents will be screened with perforated aluminum sheet, attached with stainless hardware, and there will be internal water baffles so I can still wash the car and it can see rain without flooding the engine bay. The bulge itself will be painted a satin or semi-gloss black (for an almost-shaker-hood-like look), and the screen will be flat black.

FYI- jigsaw blades for wood do NOT survive cutting glass-reinforced material like this. I ended up doing most of the cutting with a HSS blade.

FYI- jigsaw blades for wood do NOT survive cutting glass-reinforced material like this. I ended up doing most of the cutting with a HSS blade.