In case I missed it, do you have stock computer and what codes did you get when you dumped them?I might have found the idle problem when I unplug the mass air meter it idles great plug it back up and it dies

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Engine 1993 doesnt want to idle

- Thread starter j l smith

- Start date

-

Sponsors (?)

stock computer I haven't dump them but I'm getting ready tooIn case I missed it, do you have stock computer and what codes did you get when you dumped them?

only code that was in it was 15stock computer I haven't dump them but I'm getting ready too

Did you get just 1 set of codes? You should get engine not running and engine running codes.only code that was in it was 15

that was it just the 15 and like I said I can start it and it will not idle unplug the meter idles great so what do u think

Here are some simple tests that you can do to check the MAF sensor for proper operation. Most of the time a bad MAF sensor will set code 66 but not all the time.

Code 66 or 157 MAF below minimum test voltage.

Revised 15 mar 2018 to clarify how to do resistance checks on the MAF wiring

Insufficient or no voltage from MAF. Dirty MAF element, bad MAF, bad MAF wiring, missing power to MAF. Check for missing +12 volts on this circuit. Check the two links for a wiring diagram to help you find the red wire for computer power relay switched +12 volts. Check for 12 volts between the red and black wires on the MAF heater (usually pins A & B). while the connector is plugged into the MAF. This may require the use of a couple of safety pins to probe the MAF connector from the back side of it.

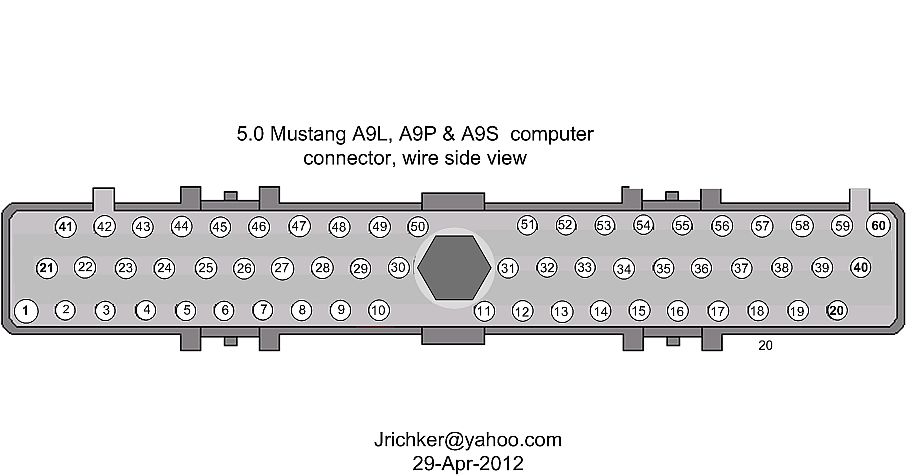

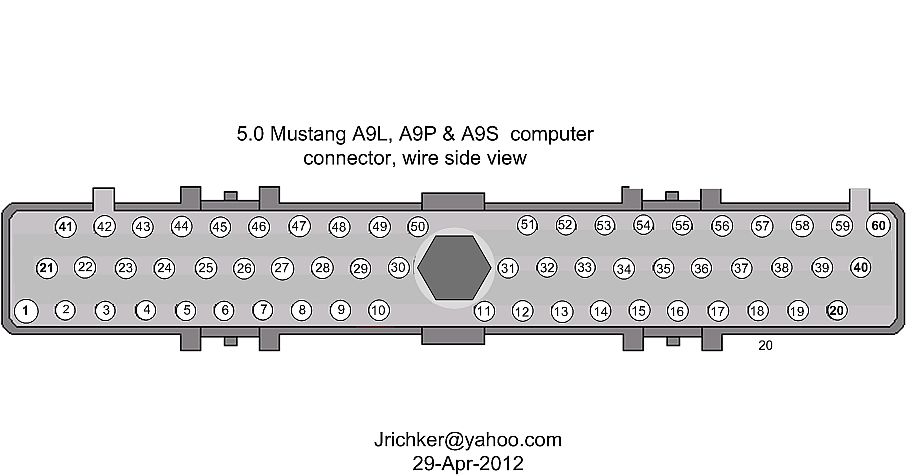

Computer wiring harness connector, wire side

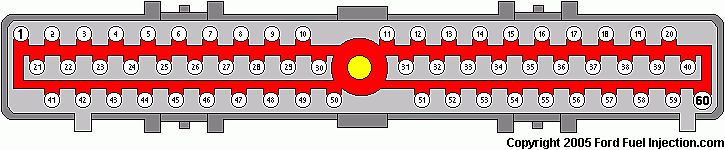

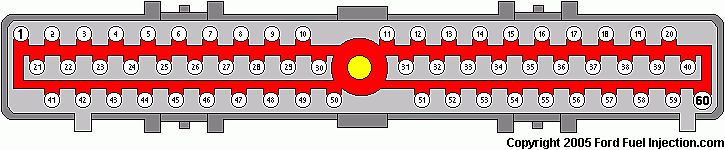

Computer wiring harness connector, computer side side

Diagrams courtesy of Tmoss and Stang&2Birds

ECC Diagram for 88-90 5.0 Mustangs

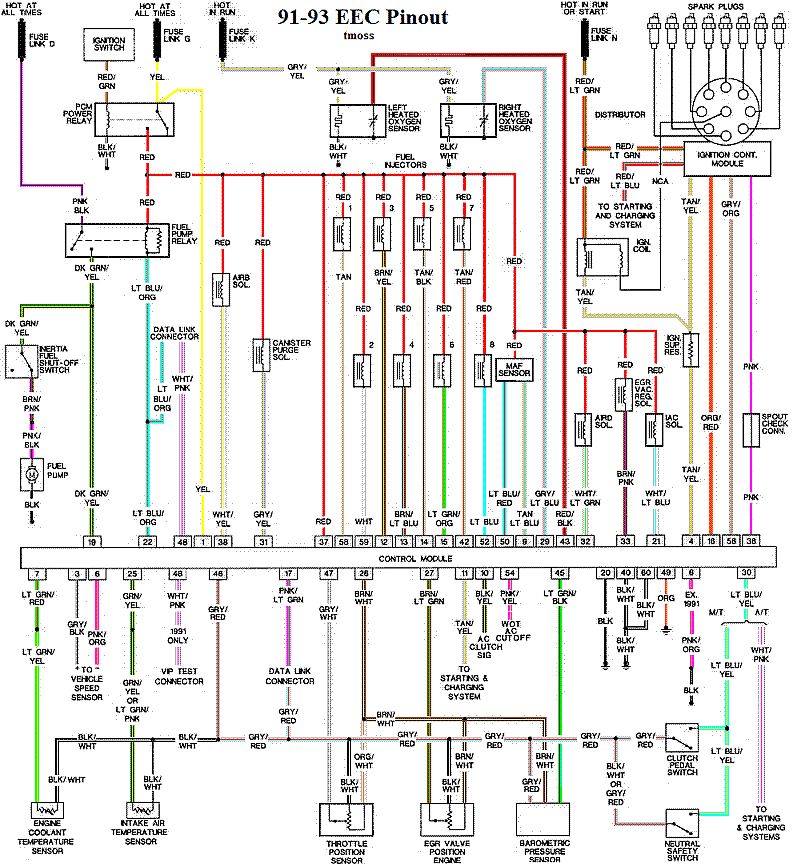

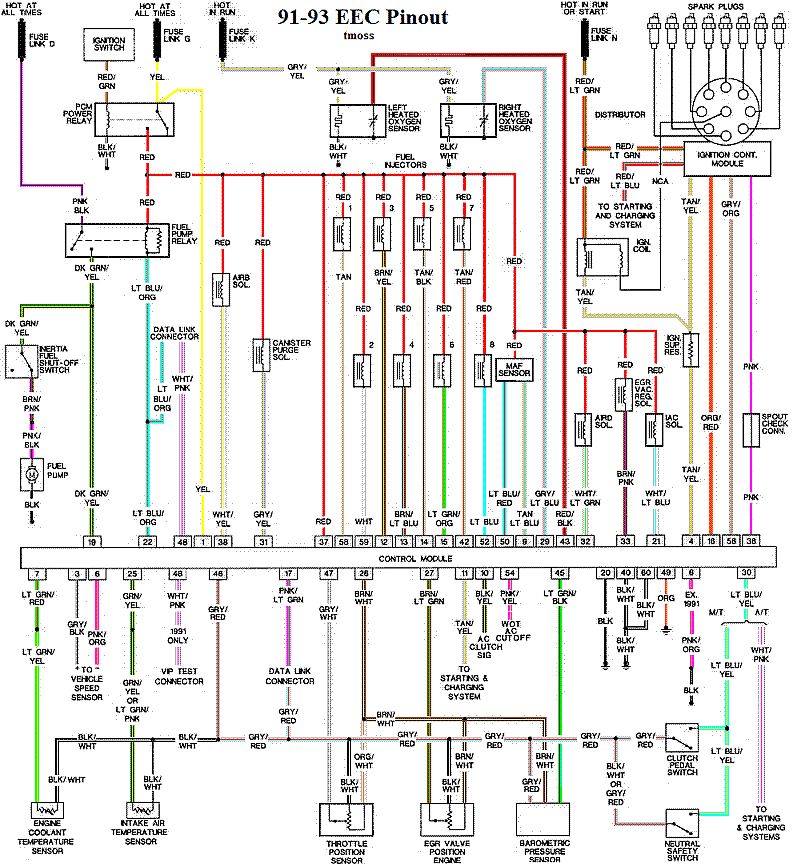

ECC Diagram for 91-93 5.0 Mustangs

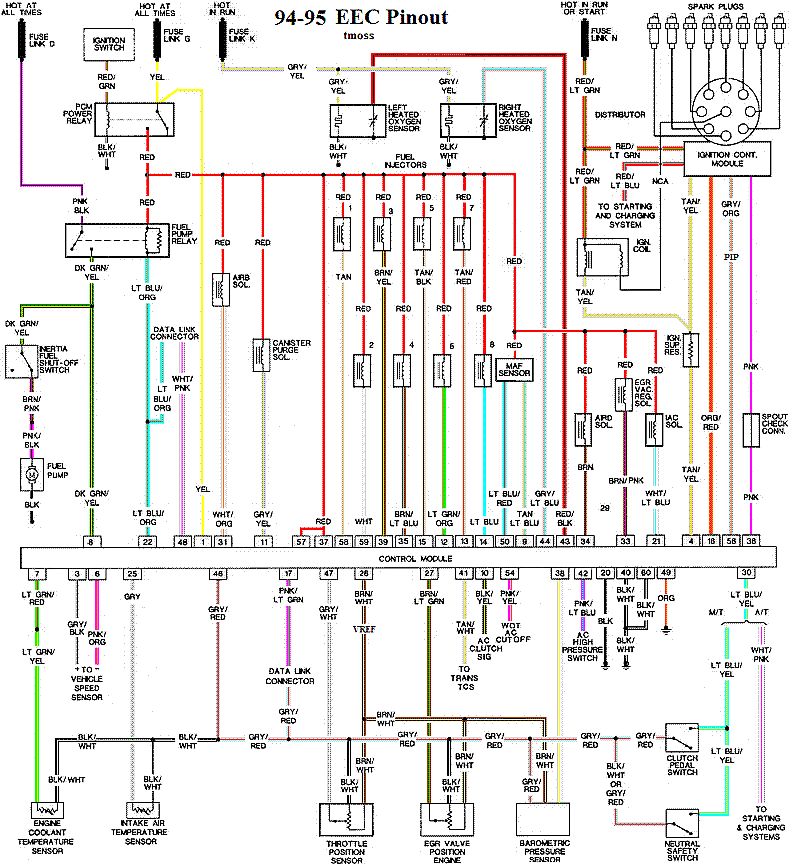

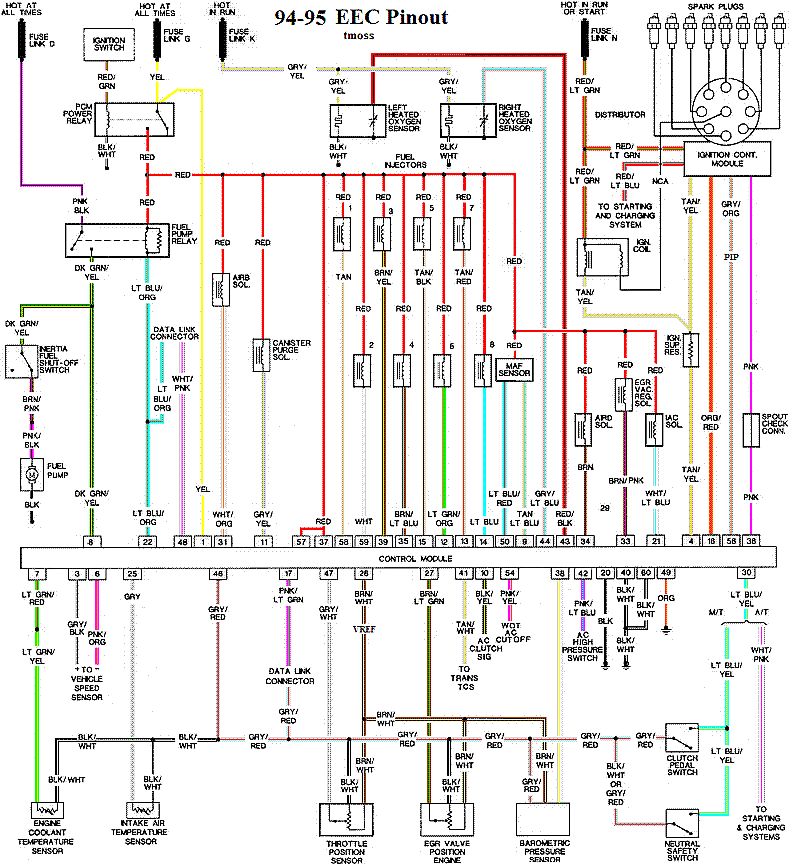

94-95 Diagram for 94-95 5.0 Mustangs[/b]

How the MAF works

There are three parts in a MAF: the heater, the sensor element and the amplifier. The heater heats the MAF sensor element causing the resistance to increase. The amplifier buffers the MAF output signal and has a resistor that is laser trimmed to provide an output range compatible with the computer's load tables. Changes in RPM causes the airflow to increase or decrease, changing the voltage output.. The increase of air across the MAF sensor element causes it to cool, allowing more voltage to pass and telling the computer to increase the fuel flow. A decrease in airflow causes the MAF sensor element to get warmer, decreasing the voltage and reducing the fuel flow.

The MAF element is secured by 2 screws & has 1 wiring connector. To clean the element, remove it from the MAF housing and spray it down with electronic parts cleaner or non-inflammable brake parts cleaner (same stuff in a bigger can and cheaper too).

89-90 Model cars: Measure the MAF output at pins C & D on the MAF connector (dark blue/orange and tan/light blue) or at pins 50 & 9 on the computer. Be sure to measure the sensor output by measuring across the pins and not between the pins and ground.

91-95 Model cars: Measure the MAF output at pins C & D on the MAF connector light blue/red and tan/light blue) or at pins 50 & 9 on the computer. Be sure to measure the sensor output by measuring across the pins and not between the pins and ground.

At idle = approximately .6 volt

20 MPH = approximately 1.10 volt

40 MPH = approximately 1.70 volt

60 MPH = approximately 2.10 volt

Actually MAF pins C & D float with reference to ground. The signal output of the MAF is a differential amplifier setup. Pins C & D both carry the output signal, but one pin's output is inverted from the other. The difference in signal between C & D is what the computer's input circuit is looking for. The difference in the two outputs helps cancel out electrical noise generated by the ignition system and other components. Since the noise will be of the same polarity, wave shape and magnitude, the differential input of the computer electronically subtracts it from the signal. Then it passes the signal on to an Analog to Digital converter section inside the computer's CPU chip.

Check the resistance of the MAF signal wiring

For the next 2 checks make your measurement with the MAF disconnected from the wiring harness.

Pin D on the MAF wiring harness and pin 50 on the computer (dark blue/orange wire) should be less than 2 ohms. Pin C on the MAF wiring harness and pin 9 on the computer (tan/light blue wire) should be less than 2 ohms.

There should be a minimum of 10K ohms between either pin C or D on the MAF wiring connector and pins A or B.

Reconnect the MAF to the wiring harness and proceed to the next section.

See the following website for some help from Tmoss (diagram designer) & Stang&2Birds (website host) for help on 88-95 wiring http://www.veryuseful.com/mustang/tech/engine/

Ignition switch wiring

http://www.veryuseful.com/mustang/tech/engine/images/IgnitionSwitchWiring.gif

Fuel pump, alternator, ignition & A/C wiring

http://www.veryuseful.com/mustang/tech/engine/images/fuel-alt-links-ign-ac.gif

Computer,. actuator & sensor wiring

http://www.veryuseful.com/mustang/tech/engine/images/88-91_5.0_EEC_Wiring_Diagram.gif

Fuse panel layout

http://www.veryuseful.com/mustang/tech/engine/images/MustangFuseBox.gif

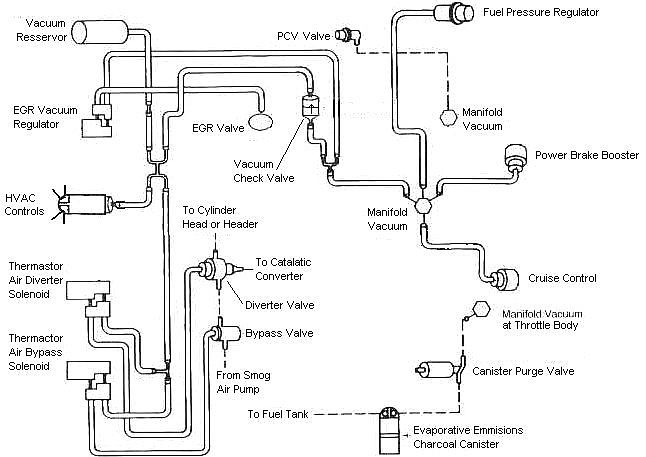

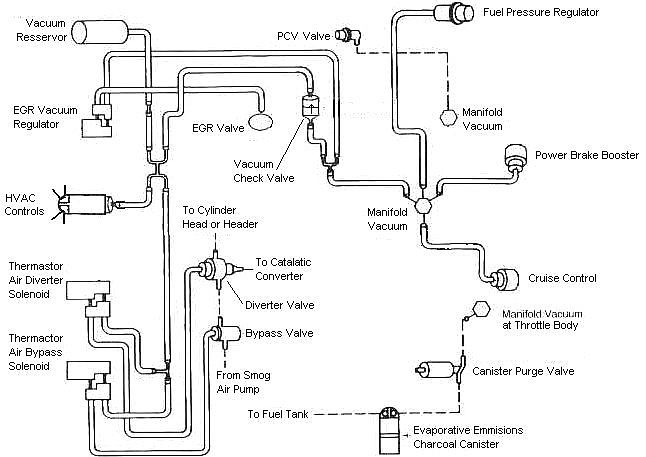

Vacuum routing

http://www.veryuseful.com/mustang/tech/engine/images/mustangFoxFordVacuumDiagram.jpg

Code 66 or 157 MAF below minimum test voltage.

Revised 15 mar 2018 to clarify how to do resistance checks on the MAF wiring

Insufficient or no voltage from MAF. Dirty MAF element, bad MAF, bad MAF wiring, missing power to MAF. Check for missing +12 volts on this circuit. Check the two links for a wiring diagram to help you find the red wire for computer power relay switched +12 volts. Check for 12 volts between the red and black wires on the MAF heater (usually pins A & B). while the connector is plugged into the MAF. This may require the use of a couple of safety pins to probe the MAF connector from the back side of it.

Computer wiring harness connector, wire side

Computer wiring harness connector, computer side side

Diagrams courtesy of Tmoss and Stang&2Birds

ECC Diagram for 88-90 5.0 Mustangs

ECC Diagram for 91-93 5.0 Mustangs

94-95 Diagram for 94-95 5.0 Mustangs[/b]

How the MAF works

There are three parts in a MAF: the heater, the sensor element and the amplifier. The heater heats the MAF sensor element causing the resistance to increase. The amplifier buffers the MAF output signal and has a resistor that is laser trimmed to provide an output range compatible with the computer's load tables. Changes in RPM causes the airflow to increase or decrease, changing the voltage output.. The increase of air across the MAF sensor element causes it to cool, allowing more voltage to pass and telling the computer to increase the fuel flow. A decrease in airflow causes the MAF sensor element to get warmer, decreasing the voltage and reducing the fuel flow.

The MAF element is secured by 2 screws & has 1 wiring connector. To clean the element, remove it from the MAF housing and spray it down with electronic parts cleaner or non-inflammable brake parts cleaner (same stuff in a bigger can and cheaper too).

89-90 Model cars: Measure the MAF output at pins C & D on the MAF connector (dark blue/orange and tan/light blue) or at pins 50 & 9 on the computer. Be sure to measure the sensor output by measuring across the pins and not between the pins and ground.

91-95 Model cars: Measure the MAF output at pins C & D on the MAF connector light blue/red and tan/light blue) or at pins 50 & 9 on the computer. Be sure to measure the sensor output by measuring across the pins and not between the pins and ground.

At idle = approximately .6 volt

20 MPH = approximately 1.10 volt

40 MPH = approximately 1.70 volt

60 MPH = approximately 2.10 volt

Actually MAF pins C & D float with reference to ground. The signal output of the MAF is a differential amplifier setup. Pins C & D both carry the output signal, but one pin's output is inverted from the other. The difference in signal between C & D is what the computer's input circuit is looking for. The difference in the two outputs helps cancel out electrical noise generated by the ignition system and other components. Since the noise will be of the same polarity, wave shape and magnitude, the differential input of the computer electronically subtracts it from the signal. Then it passes the signal on to an Analog to Digital converter section inside the computer's CPU chip.

Check the resistance of the MAF signal wiring

For the next 2 checks make your measurement with the MAF disconnected from the wiring harness.

Pin D on the MAF wiring harness and pin 50 on the computer (dark blue/orange wire) should be less than 2 ohms. Pin C on the MAF wiring harness and pin 9 on the computer (tan/light blue wire) should be less than 2 ohms.

There should be a minimum of 10K ohms between either pin C or D on the MAF wiring connector and pins A or B.

Reconnect the MAF to the wiring harness and proceed to the next section.

See the following website for some help from Tmoss (diagram designer) & Stang&2Birds (website host) for help on 88-95 wiring http://www.veryuseful.com/mustang/tech/engine/

Ignition switch wiring

http://www.veryuseful.com/mustang/tech/engine/images/IgnitionSwitchWiring.gif

Fuel pump, alternator, ignition & A/C wiring

http://www.veryuseful.com/mustang/tech/engine/images/fuel-alt-links-ign-ac.gif

Computer,. actuator & sensor wiring

http://www.veryuseful.com/mustang/tech/engine/images/88-91_5.0_EEC_Wiring_Diagram.gif

Fuse panel layout

http://www.veryuseful.com/mustang/tech/engine/images/MustangFuseBox.gif

Vacuum routing

http://www.veryuseful.com/mustang/tech/engine/images/mustangFoxFordVacuumDiagram.jpg

I have checked it some and it is getting 12v but im still up in the air about it , its a new meter but it still could be bad . all I know is I've checked everything I can think of and it still wont idle until I unplug that maf

Go back and reread the tech note until you understand what it says and how to properly test it. The 12 volts is input voltage that powers the MAF electronics. What you are interested in is the MAF output voltage that varies with road speed.I have checked it some and it is getting 12v but im still up in the air about it , its a new meter but it still could be bad . all I know is I've checked everything I can think of and it still wont idle until I unplug that maf

Blucifer99

I only understand every 3rd word

ok thanks I will do that and if that's not what it is I dot know

Sounds to me like you have the wrong lb/h mass air.. Miss matched.. What injectors u running and what type of maf u have? Nobodies asked u that question yet?

Blown88GT

Founding Member

Unplugging the MAF puts the ECU into "limp home" mode.

Remove the SCT chip & plug the MAF back in. Does it now idle well?

Remove the SCT chip & plug the MAF back in. Does it now idle well?

nope I tried that too .I think the lower intake gasket might be leaking i'll know in a few days and i'll let u guys know.

Finding vacuum leaks

Revised 6 May 2018 to add carbon canister plumbing as a common leak area.

There is no easy way to find vacuum leaks. It is a time consuming job that requires close inspection of each and every hose and connection.

Small vacuum leaks may not show much change using a vacuum gauge. The range of "good readings" varies so much from engine to engine that it may be difficult to detect small leaks. The engine in my first Mustang pulled about 16.5" of vacuum at 650-725 RPM, which I consider rather low. It was a mass market remanufactured rebuild, so no telling what kind of camshaft it had. Average readings seem to run 16"-18" inches at idle and 18"-21" at 1000 RPM. The only sure comparison is a reading taken when your car was performing at its best through all the RPM ranges and what it is doing now. Use one of the spare ports on the vacuum tree that is mounted on the firewall near the windshield wiper motor.

Use a squirt can of motor oil to squirt around the mating surfaces of the manifold & TB. The oil will be sucked into the leaking area and the engine will change speed. Avoid using flammable substitutes for the oil such as starting fluid, propane or throttle body cleaner. Fire is an excellent hair removal agent, and no eyebrows is not cool...

After you have done the simple visual checks and the check for vacuum leak on the underside of the intake manifold, consider doing a smoke test.

Some of the guys here have built smoke machines used to find automotive vacuum leaks. They seem to work quite well and are made mostly with parts you would have laying around in your garage. Check out smoke machine vacuum leak - YouTube and see if there is one that you could build.

The vacuum line plumbing is old and brittle on many of these cars, so replacing the lines with new hose is a good plan. The common 1/8” and ¼” vacuum hose works well and isn’t expensive.

The PCV grommet and the power brake booster check valve grommet are two places that often get overlooked when checking for vacuum leaks. The rubber grommets get hard and lose their ability to seal properly. The PVC grommet is difficult to see if it is correctly seated and fitting snugly.

The hoses and connections for the evaporative emissions (carbon canister and purge valve) are other common sources of vacuum leaks. The large vacuum outlets on the bottom side of the upper intake manifold are common hiding places for deteriorated vacuum lines and caps over unused vacuum ports.

Fuel injector O rings can get old and hard. When they do, they are prone to leaking once the engine warms up. This can be difficult to troubleshoot, since it is almost impossible to get to the injectors to squirt oil into the fuel injector mounting bosses. If the plastic caps on the fuel injectors (pintle caps) are missing, the O rings will slide off the injectors and fall into the intake manifold.

Fuel injector seal kits with 2 O rings and a pintle cap (Borg-Warner P/N 274081) are available at Pep Boys auto parts. Cost is about $3-$4 per kit. The following are listed at the Borg-Warner site ( http://www.borg-warner.com ) as being resellers of Borg-Warner parts:

http://www.partsplus.com/ or http://www.autovalue.com/ or http://www.pepboys.com/ or http://www.federatedautoparts.com/

Most of the links above have store locators for find a store in your area.

Use motor oil on the O rings when you re-assemble them & everything will slide into place. The gasoline will wash away any excess oil that gets in the wrong places and it will burn up in the combustion chamber. Heat the pintle caps in boiling water to soften them to make them easier to install.

Diagram courtesy of Tmoss & Stang&2birds

Vacuum leak due to slipped lower intake manifold gasket...

Ask Nicoleb3x3 about the intake gasket that slipped out of place and caused idle and vacuum leak problems that could not be seen or found by external examination. I don't care what you spray with, you won't find the leak when it is sucking air from the lifter valley. It simply isn't possible to spray anything in there with the lower manifold bolted in place.

Determining if you have a leak due to a slipped intake gasket as shown above. This test is only good if you can get the engine to run somewhere in the 1000-1700 RPM range

If your valve cover oil filler & PVC systems are still in the original configuration, try this:

Cap or plug the hose from the intake manifold to the PVC valve with a bolt.

Cap or plug the PVC valve with a piece of hose with a plug or bolt in it.

At that point the only vent for the crankcase is the tube from the oil filler neck to the throttle body.

Disconnect the tube that runs from the oil filler neck to the throttle body. Make sure the oil filler cap is on securely. Start the engine and put your thumb over the end of the tube that comes from the oil filler cap. If you feel suction, there is a leak. Another thing to do is to extend the tubing from the filler neck so that there is enough to stick the end in a jar or cup filled with motor oil. If it sucks up the oil, you definitely have a leak at the underside of intake manifold.

This isn't necessarily the definitive test, but it is the best thing I could come up with on short notice. If there is a lot of blowby, this obviously won't be of much help.

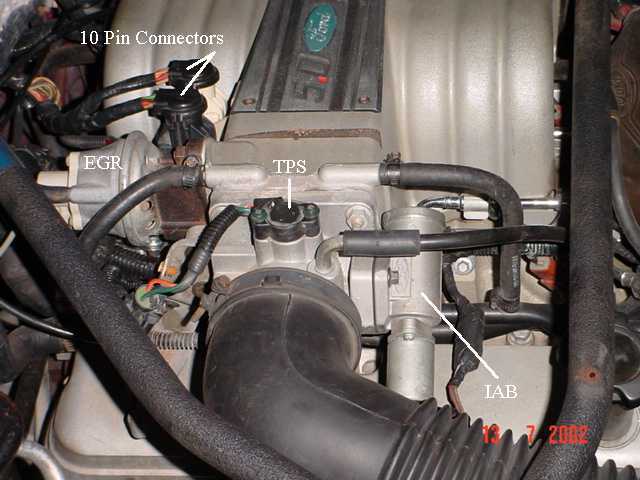

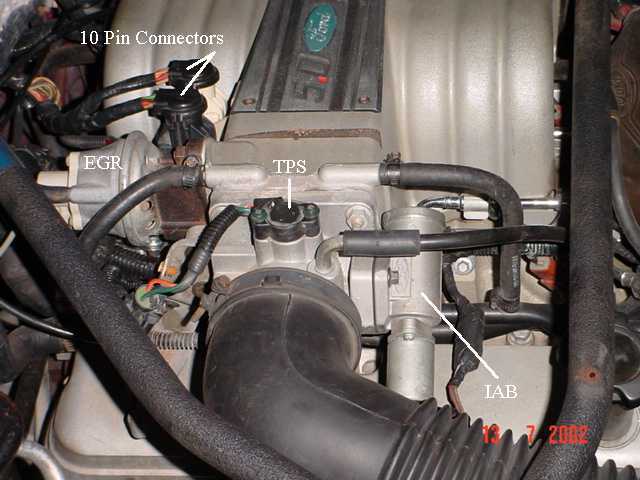

See the picture below to see the breather tube where in connects to the throttle body. It is close to the TPS and runs over the top of the IAC.

The following are diagrams courtesy of Tmoss & Stang&2birds

See the following website for some help from Tmoss (diagram designer) & Stang&2Birds (website host) for help on 88-95 wiring http://www.veryuseful.com/mustang/tech/engine/ Everyone should bookmark this site.

Ignition switch wiring

http://www.veryuseful.com/mustang/tech/engine/images/IgnitionSwitchWiring.gif

Fuel, alternator, A/C and ignition wiring

http://www.veryuseful.com/mustang/tech/engine/images/fuel-alt-links-ign-ac.gif

Complete computer, actuator & sensor wiring diagram for 88-91 Mass Air Mustangs

http://www.veryuseful.com/mustang/tech/engine/images/88-91_5.0_EEC_Wiring_Diagram.gif

Vacuum diagram 89-93 Mustangs

http://www.veryuseful.com/mustang/tech/engine/images/mustangFoxFordVacuumDiagram.jpg

HVAC vacuum diagram

http://www.veryuseful.com/mustang/tech/engine/images/Mustang_AC_heat_vacuum_controls.gif

TFI module differences & pinout

http://www.veryuseful.com/mustang/tech/engine/images/TFI_5.0_comparison.gif

Fuse box layout

http://www.veryuseful.com/mustang/tech/engine/images/MustangFuseBox.gif

Revised 6 May 2018 to add carbon canister plumbing as a common leak area.

There is no easy way to find vacuum leaks. It is a time consuming job that requires close inspection of each and every hose and connection.

Small vacuum leaks may not show much change using a vacuum gauge. The range of "good readings" varies so much from engine to engine that it may be difficult to detect small leaks. The engine in my first Mustang pulled about 16.5" of vacuum at 650-725 RPM, which I consider rather low. It was a mass market remanufactured rebuild, so no telling what kind of camshaft it had. Average readings seem to run 16"-18" inches at idle and 18"-21" at 1000 RPM. The only sure comparison is a reading taken when your car was performing at its best through all the RPM ranges and what it is doing now. Use one of the spare ports on the vacuum tree that is mounted on the firewall near the windshield wiper motor.

Use a squirt can of motor oil to squirt around the mating surfaces of the manifold & TB. The oil will be sucked into the leaking area and the engine will change speed. Avoid using flammable substitutes for the oil such as starting fluid, propane or throttle body cleaner. Fire is an excellent hair removal agent, and no eyebrows is not cool...

After you have done the simple visual checks and the check for vacuum leak on the underside of the intake manifold, consider doing a smoke test.

Some of the guys here have built smoke machines used to find automotive vacuum leaks. They seem to work quite well and are made mostly with parts you would have laying around in your garage. Check out smoke machine vacuum leak - YouTube and see if there is one that you could build.

The vacuum line plumbing is old and brittle on many of these cars, so replacing the lines with new hose is a good plan. The common 1/8” and ¼” vacuum hose works well and isn’t expensive.

The PCV grommet and the power brake booster check valve grommet are two places that often get overlooked when checking for vacuum leaks. The rubber grommets get hard and lose their ability to seal properly. The PVC grommet is difficult to see if it is correctly seated and fitting snugly.

The hoses and connections for the evaporative emissions (carbon canister and purge valve) are other common sources of vacuum leaks. The large vacuum outlets on the bottom side of the upper intake manifold are common hiding places for deteriorated vacuum lines and caps over unused vacuum ports.

Fuel injector O rings can get old and hard. When they do, they are prone to leaking once the engine warms up. This can be difficult to troubleshoot, since it is almost impossible to get to the injectors to squirt oil into the fuel injector mounting bosses. If the plastic caps on the fuel injectors (pintle caps) are missing, the O rings will slide off the injectors and fall into the intake manifold.

Fuel injector seal kits with 2 O rings and a pintle cap (Borg-Warner P/N 274081) are available at Pep Boys auto parts. Cost is about $3-$4 per kit. The following are listed at the Borg-Warner site ( http://www.borg-warner.com ) as being resellers of Borg-Warner parts:

http://www.partsplus.com/ or http://www.autovalue.com/ or http://www.pepboys.com/ or http://www.federatedautoparts.com/

Most of the links above have store locators for find a store in your area.

Use motor oil on the O rings when you re-assemble them & everything will slide into place. The gasoline will wash away any excess oil that gets in the wrong places and it will burn up in the combustion chamber. Heat the pintle caps in boiling water to soften them to make them easier to install.

Diagram courtesy of Tmoss & Stang&2birds

Vacuum leak due to slipped lower intake manifold gasket...

Ask Nicoleb3x3 about the intake gasket that slipped out of place and caused idle and vacuum leak problems that could not be seen or found by external examination. I don't care what you spray with, you won't find the leak when it is sucking air from the lifter valley. It simply isn't possible to spray anything in there with the lower manifold bolted in place.

Determining if you have a leak due to a slipped intake gasket as shown above. This test is only good if you can get the engine to run somewhere in the 1000-1700 RPM range

If your valve cover oil filler & PVC systems are still in the original configuration, try this:

Cap or plug the hose from the intake manifold to the PVC valve with a bolt.

Cap or plug the PVC valve with a piece of hose with a plug or bolt in it.

At that point the only vent for the crankcase is the tube from the oil filler neck to the throttle body.

Disconnect the tube that runs from the oil filler neck to the throttle body. Make sure the oil filler cap is on securely. Start the engine and put your thumb over the end of the tube that comes from the oil filler cap. If you feel suction, there is a leak. Another thing to do is to extend the tubing from the filler neck so that there is enough to stick the end in a jar or cup filled with motor oil. If it sucks up the oil, you definitely have a leak at the underside of intake manifold.

This isn't necessarily the definitive test, but it is the best thing I could come up with on short notice. If there is a lot of blowby, this obviously won't be of much help.

See the picture below to see the breather tube where in connects to the throttle body. It is close to the TPS and runs over the top of the IAC.

The following are diagrams courtesy of Tmoss & Stang&2birds

See the following website for some help from Tmoss (diagram designer) & Stang&2Birds (website host) for help on 88-95 wiring http://www.veryuseful.com/mustang/tech/engine/ Everyone should bookmark this site.

Ignition switch wiring

http://www.veryuseful.com/mustang/tech/engine/images/IgnitionSwitchWiring.gif

Fuel, alternator, A/C and ignition wiring

http://www.veryuseful.com/mustang/tech/engine/images/fuel-alt-links-ign-ac.gif

Complete computer, actuator & sensor wiring diagram for 88-91 Mass Air Mustangs

http://www.veryuseful.com/mustang/tech/engine/images/88-91_5.0_EEC_Wiring_Diagram.gif

Vacuum diagram 89-93 Mustangs

http://www.veryuseful.com/mustang/tech/engine/images/mustangFoxFordVacuumDiagram.jpg

HVAC vacuum diagram

http://www.veryuseful.com/mustang/tech/engine/images/Mustang_AC_heat_vacuum_controls.gif

TFI module differences & pinout

http://www.veryuseful.com/mustang/tech/engine/images/TFI_5.0_comparison.gif

Fuse box layout

http://www.veryuseful.com/mustang/tech/engine/images/MustangFuseBox.gif

thanks because that's all great info, I have the intake off and it looks like the gasket is leaking into the water ports and also might have slipped down some .

Blucifer99

I only understand every 3rd word

thanks because that's all great info, I have the intake off and it looks like the gasket is leaking into the water ports and also might have slipped down some .

When putting on the new gasket. Use some high tac or weatherstripping to hold the gasket in place while droppin the intake on.. Or if ur using new bolts. Cut the heads off the old ones and use the studs as a drop down guide so the gasket stays in place

When putting on the new gasket. Use some high tac or weatherstripping to hold the gasket in place while droppin the intake on.. Or if ur using new bolts. Cut the heads off the old ones and use the studs as a drop down guide so the gasket stays in place

Good advice. In addition to above, I use a skim coat of rtv sealer around the water jacket ports on both the head and intake sides of the gasket. It’s some extra insurance to prevent coolant leaks

Similar threads

- Replies

- 20

- Views

- 4K

- Replies

- 0

- Views

- 4K

- Replies

- 4

- Views

- 2K

- Replies

- 48

- Views

- 6K

- Replies

- 27

- Views

- 7K