'87-'95 Heads, Cam, Intake Install Help

Checklist and Suggested Parts:

Parts are specific for 87-93 although most parts are the same for 94/95.

Head Gaskets - ROL-HG32841HR (.039) or ROL-HG32841HT (.045)

Lower Intake Gasket – FEL-MS93334 (stock) or FEL1250S

Upper to Lower Intake Gasket – Depends on Intake Used.

Valve Cover Gaskets* - FMS-M-6584-A50 (OEM)

Thermostat Gasket - FEL-35440

Timing Cover/Front Seal/Water Pump/Oil Pan U Gasket Kit - FEL-TCS45449

Water Pump Gasket - FEL-35211 (Plate to Block), FEL-35380 (Pump to Plate)

Head Bolts - FEL-ES72155 (stock), ARP-154-3601 (7/16”, recommended)

Header/Manifold Gaskets – FEL-1415

EGR Valve Gasket* - EDL-3830 (65-70mm TB/EGR/Plate to Valve Gasket)

Throttle Body Gasket - Same as above.

Intake Air Bypass Valve Gasket* - Same as above.

Hardened Pushrods

Timing Chain/Gear - FMS-M-6268-A302 or RollMaster - CS3071

Fuel Injectors

Mass Air Flow Sensor Calibrated for Injector

Fuel Pump (Stock is 88 or 95lph – Upgrade to 155/190/255lph)

*Optional

There are many different brands of products that you could use above instead of the ones outlined.

Tools:

¼”-15/16” Shallow and Deep Well Sockets and Wrenches

Combination of Extensions

Break Over Bar

Torque Wrench

Harmonic Balancer Puller

Gear Puller* (optional for stubborn timing chain)

Moroso Oil Pump Primer* - MOR-62210

A/C and Fuel Line Disconnect Tools*

Allen Wrenches*

Adjustable Wrench

Flathead and Phillips Screwdriver

Cam Degree Kit*

LocTite

Ultra Black RTV

Antiseize

Thread Sealer for Lower Head Bolts and Coolant Sensors

Assembly Lube or Oil for cam/lifters

Two Oil Changes and Filters

Ford Thermactor Plugs* (2 extra plugs if no smog equipment)

Gasket Scraper

Brake Cleaner

Degreaser*

Ziploc Bags*

Masking Tape*

Marker*

*Optional

Check out www.rockauto.com for any more parts/tools you may need.

Torque Specs:

Camshaft Thrust Plate Bolts: 108-144 in. lbs (6-9 ft. lbs)

Camshaft Sprocket Bolt: 40-45 ft. lbs

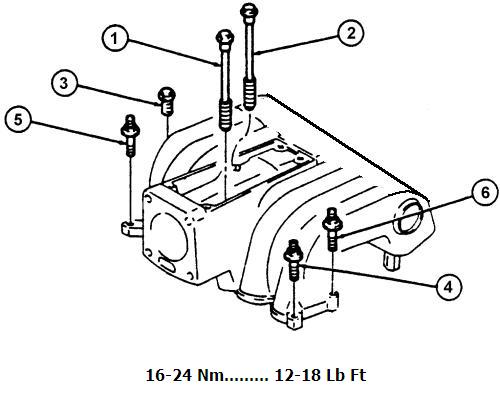

Timing Cover Bolts: 12-18 ft. lbs

Water Pump Bolts: 15-21 ft. lbs

Water Pump Pulley Bolts: 15-21 ft. lbs

Harmonic Balancer: 70-90 ft. lbs

Crankshaft Pulley Bolts: 35-50 ft. lbs

Cylinder Head Bolts: 70 ft. lbs for Aluminum Heads*

Rocker Studs: 60 ft. lbs

Exhaust Manifold/Header Bolts: 26-32 ft. lbs

Valve Cover Bolts: 3-5 ft. lbs

Rocker Arm Fulcrum Bolts (Pedestal Mounted): 18-25 ft. lbs

Lower Intake Manifold Bolts: 23-25 ft. lbs**

Thermostat Housing: 12-18 ft. lbs

Upper Intake Bolts: 10-12 ft. lbs

*Read head bolt instructions and torque in stages

**Retorque in tightening sequence after a couple heat cycles

Extra Torque Specs:

Main Bearing Caps: 60-70 ft. lbs

Connecting Rod Bolts: 25 ft. lbs

Oil Pan Bolts: 9-11 ft. lbs/18 ft. lbs at timing cover and rear main side.

Flywheel Bolts: 75-85 ft. lbs

Loc-Tite Camshaft Sprocket Bolt and Thrust Washer Bolts.

5/16” Bolt Head – Intake Air Bypass Valve, Fuel Rail

3/8” Bolt Head – Timing Cover Bottom

7/16” Bolt Head – Water Pump Pulley, Valve Cover, Header/Manifold

1/2” Bolt Head – Lower/Upper Intake, Head, Throttle Body, T-Stat, Timing Cover

9/16” Bolt Head – A/C Bracket, Alternator

5/8” Bolt Head – Long Alternator, Water Pump, Oil Pan

Disassembly:

Mark all your hoses and connections with the tape and marker to help you put it together later on. Take pictures if need be. Relieve the fuel pressure by either having the car sit for a few hours or remove the schrader valve cap and use a small flathead screwdriver to press into the valve and release the pressure. Have a towel handy to absob the fuel that will come out. On 87-95 cars the schrader valve is located on a fuel rail located behind the alternator. Remove your air inlet tube whether it be a cold air intake or the stock plastic air box. Remove the MAF by undoing the connection from it. Begin to remove the throttle body by unbolting it from the 4 studs screwed into the upper intake held on by the 4 matching bolts. Also release the TPS sensor (on top of throttle body) connection along with the throttle linkage that pops off. Unbolt the upper intake (6 bolts I believe) and make sure you get the ones underneath the upper intake plate held onto it by some screws. Prepare for later to possibly replace the bolts or reuse them depending on what intake you are going to use. Before lifting it off completely remove the vacuum hoses from the upper intake so you can bring it up without tearing a line. When you unbolt the upper intake before hand it gives you more hand room to get those hoses and lines off nicely. The distributor is held in by one bolt located on the right side of the shaft. Make note of the firing order and where your spark plug wires went. Put a paper towel in the distributor hole so you don’t get any tools or debris in the engine.

Now that the upper intake is removed go ahead and unbolt the 4 bolts that hold the fuel rail onto the lower intake. On the front passenger side head bolt, the fuel rail is held on by a bolt to hold the rail in place. Unbolt it so you can swing the fuel rail out of the way once you remove the rail from the injectors. The injectors will just pop out of your fuel rail and lower intake. Your local parts store will have a/c & fuel line disconnect tools that will let you disconnect the fuel rail easily. Unbolt the thermostat housing, which is held on by two bolts on the front of your lower intake. Go ahead and loosen all the 12 bolts that hold your lower intake on. The lower intake will be a bit hard to get off. Pry it off carefully and remove it after you have the hoses, sensors, lines removed from the lower intake. Swing those connections out of the way. Now that both the upper and lower intake are off it would be a good time to “reinstall” the upper and lower intake sensors and hoses onto your new intake.

Next I would go ahead and begin to remove the radiator and pull it out along with the fan shroud and stock fan and fan clutch. Remove your overflow tank. Unbolt the a/c condenser (in front of radiator) and swing it out of the way. This will now allow plenty of room for you to pull and install your cam later on. Start to remove the accessories on your engine. The alternator is bolted onto a bracket, which is held on by 3 bolts. Undo the alternator connections and remove it along with its bracket. Next remove the smog pump, if equipped, and then remove the a/c compressor by removing the bolts and swing it out of the way as well so you do not “bleed” the system and have to refill that later on. Next remove the power steering and remember how all the accessories bolt up for future reference.

Removal of the harmonic balancer is next after you remove the four bolts from the crankshaft pulley. And you have to break loose the 15/16th bolt that holds the balancer on. Put your car in 5th gear or Park with the e-brake on and someone stepping on the brake, if need be. You can then put a break-over bar and turn it counterclockwise to break the bolt loose. Removing the balancer is next. You need to get a harmonic balancer removal tool from your local parts store. Take bolt out and remove the washer. Thread the bolt back in about half way in. You are now ready to bolt up the harmonic balancer puller and use it. Next I would remove the water pump and timing chain. To save time and a gasket you can remove them as one piece. Try to remove the bolts/studs out carefully because some pass through water ports and the bolts can rust and break in the block or covers. Make sure you remove the front 4 oil pan bolts to get the timing cover off from the bottom. The timing cover is also aligned by dowel pins (2 on each side). Once this is removed you will see the timing chain and the front of the oil pan. Put some paper towels or rags in the front of the cover to prevent dropping any object in there.

Now you can remove the 6 valve cover bolts from each valve cover on the left and right. Remove the head bolts so you can pop the heads off along with the rockers still bolted down. But before completely removing the heads go underneath the car and remove the 2 bolts on each side of the engine that hold the mid-pipe onto the headers. You can remove the heads with the headers still attached. The pushrods will fall out. I then removed the spider bar in the lifter valley to allow access to the X shaped lifter holders. The spider bar is held down by two bolts. I then removed the lifters one by one until I got all 16 of them out. Next you can go ahead and unbolt the cam bolt and pull the timing chain off by hand. Remove the cam retaining plate held on by two bolts and you now have access to your cam. Put in a longer bolt into the end of the cam to get better leverage when removing the cam. Take the cam out very slowly and be careful of the cam dropping between cam bearings.

Plug all your little threaded holes and coolant passages with small pieces of paper towel before doing the following. It would be a good idea next to go ahead and try to clean the head gasket mating surface area along with the tops of the pistons. A can of spray brake cleaner with a gasket scraper will work. Be careful not to nick the pistons or block. It should take a while to get the head gasket area and piston tops clean, but take your time. Clean the timing cover mating surface.

Reassembly:

Go ahead and get your new cam ready for install. Clean the cam before applying assembly lube. You will need some assembly lube to help protect the cam during those first few seconds of initial start-up. Install the assembly lube on the cam lobes and distributor gear. Cover all the areas of contact. Get your cam ready to install by putting in that same long bolt you used earlier for leverage. Install it very slowly and carefully try not to bang the cam bearings or cam lobes. Work the cam lobes from left to right to help it roll in and it will eventually get to the back of the block. I would go ahead and now install the harmonic balancer bolt into the crankshaft and spin the crank over until the #1 piston (front passenger side piston) is at the very top of its travel so you are at TDC (top dead center). Go ahead and reinstall the cam retainer plate with those two bolts applied with loctite. Get your timing chain ready to install the cam dot to dot. Dot to dot simply means that the two dots on the timing chain will be next to each other. The dot on the crankshaft gear of the timing chain will be at the 12 o’clock position and the dot on the camshaft gear of the timing chain sprocket will be positioned at the 6 o’clock position. When trying to align these dots in that order again remember to keep the #1 piston at TDC and use the dowel pin hole in the timing chain to align with the dowel pin in the end of your new cam. Your cam will then be installed “dot to dot” and in most instances the performance is just fine.

There is another procedure after installing the cam to further assure your cam is installed correctly. It is called, degreeing the cam and you need a cam degreeing kit. I would really look into degreeing your cam in when you buy a custom cam. If you do not degree the cam in for your custom cam you can lose the “custom effect”…so be practical in what you decide. If you decide to degree the cam with the method provided you will need a solid lifter or reuse an old lifter you removed and weld two spot welds on the top of the lifter to keep the plunger from plunging and it will act like a temporary solid lifter.

How To Degree The Camshaft

Once you get the timing of the cam set go ahead and bolt down the timing chain bolt and apply loctite on it. Go ahead and install new lifters with assembly lube on the rolling end and on the pushrod seat end. The lifters have oil bleed holes on one side of each lifter. The position of the holes does not matter. Install the X shaped lifter hold down brackets back over the lifters. Bolt down the spider bar that holds the lifter hold down brackets.

Go ahead and get ready to install the timing cover and water pump back on. If you got a new timing cover gasket and U shaped oil pan gasket, then now is the time to use it. Again make sure the oil pan lip and timing cover gasket area are clean to help with gasket placement. Put a very thin layer of rtv silicone on the block and then apply the gaskets and then put another layer of thin silicone on the other side of the gaskets. Put a nice dollop of the silicone in the 2 corners where the timing cover/block/oil pan meets to prevent a leak. Put your U shaped oil pan gasket on the bottom of the timing cover before install. Then put the timing cover in place. Make sure you put the timing cover on smoothly as not to disturb your gasket placements. You can then bolt up the timing cover and remember to put the oil pan bolts back on that go thru the bottom of the timing cover.

Installing the heads on your newly cleaned block is next. Clean your head bolt holes with a thread chaser to help provide a better torque reading and smoother bolt installation. Make sure you have thermactor plugs installed in the front of your heads. They screw into the front and back (if no smog equipment) of your heads. Put silicone on the threads to prevent any exhaust leak when installing them. The thermactor plugs you will use for the front (same as back) will go to make the head holes smaller so the accessories can bolt up. One is for the power steering stud and one of the larger alternator bolts that go through you alternator bracket. The back thermactor plugs you will use just block off and delete the smog equipment’s previous hookups. Get the heads ready to install. Get your new head gaskets and put them on the block mating surface. Make sure they are facing the right direction (should be labeled FRONT). Put some light oil on the valves of your heads so that the car valves are not started up dry. Get your torque wrench ready along with your new headbolts. Use thread sealer as well for the bottom bolts that go through coolant passages so that it can seal off coolant. Cover the threads well and completely on the bottom bolts. Put 30w oil or moly lube on the top bolt threads to help with the torque reading accuracy. Put antiseize underneath the washers supplied with the head bolts. When installing the heads make sure that they drop on the dowel pins on the block so they heads will be held in place while you bolt them down.

Use the proper torque sequence for the heads when installing them.

If your looking down at the top of the head here is the torque sequence order:

Intake side

9 5 1 3 7

Exhaust side

10 6 2 4 8

This is the tightening procedure I used on my AFR heads:

Top bolts: 30lbs, 50lbs, 70lbs, 80lbs

Bottom bolts: 30lbs, 50lbs, 70lbs, 75lbs

Installing the valvetrain, which includes setting the guideplates to help with proper valvetrain geometry and installing the roller rockers in the proper fashion. Stud mounted roller rockers have guideplates that help keep the roller rocker tip on the valvestem end stay centered. Now of course you don’t want the guideplates to rub against the hardened pushrods as much as possible. To keep this simple you want to be able to move around the guideplates so you can adjust the position to help keep the roller rocker tip in the center of the valve stem during rotation of the engine. Go ahead and remove the studs and apply loctite one at a time. I did the intake part of the guideplate and the exhaust part of the guideplate separately to allow me to apply loctite and be done with it before the other side dried. You will want to setup your valvetrain using the following method so you can rotate the engine and adjust the guideplates as need be. Torque the rocker studs down in your aluminum head. Here is the stud mounted roller rocker adjustment procedure for hydraulic lifters.

1. Remove the valve covers, and pick a cylinder you are going to set the pre-load on. Only do one cylinder at a time.

2. Rotate the engine in its normal direction of rotation (clockwise) and watch the exhaust valve on that particular cylinder. When the exhaust valve begins to open, stop and adjust that cylinder's intake rocker arm.

3. To adjust, back off the intake rocker arm adjusting nut and remove any tension from the push rod. Wait a minute or two for that hydraulic lifter to return to a neutral position. The spring inside the lifter will move the push rod seat up against the retaining lock, if you give it time to do so.

4. Twist the intake push rod with your fingers while tightening down the rocker arm. When you feel a slight resistance to the turning of the push rod, you are at "Zero Lash". Turn the adjusting nut down one half to three-quarters of a turn from that point for street applications. Use 1/8 to 1/4 turn for race applications. Lock the adjuster into position. The intake is now adjusted properly.

5. Continue to turn the engine, watching that same intake valve/rocker you just set. It will go to full open and then begin to close. When it is almost closed, stop and adjust the exhaust rocker arm on that particular cylinder. Loosen the exhaust rocker arm and follow the same procedure described before in steps 3 and 4 to adjust this rocker arm.

6. Both valves on this cylinder are now adjusted, and you can move on to your next cylinder and follow the same procedure again.

There may be some initial valvetrain noise when the engine is first fired up but once oil pressure has stabilized and the engine heats up, it should quiet right down to a normal level.

Remember that some racier camshafts will have a mechanical sound to them and will not be a silent as factory units.

This link will help you with roller rocker arm installation and adjustment (stock style pedestal and/or Stud Mount): Pedestal Mount Adjustment

After setting your valvetrain you can go ahead and install your valve covers if you would like if they will not interfere with your header install. I would recommend putting on a new valve cover gasket unless you would like to use the original ones which are reusable for many uses. After installing the valve covers rotate the engine over and make sure your roller rockers don’t hit the valve covers. Then you may bolt them down.

Go ahead and start putting on the accessories: smog pump, power steering bracket and pump, air conditioning, and alternator. Next will be installing your intake…which is shown below…and installing everything to get everything buttoned back up: thermostat, vacuum lines, radiator, fan shroud, etc.

Make sure you clean the heads off (if they are new heads you don’t need to) real clean and smooth so your intake gasket has a nice surface to adhere to and seal against. Brake or Carb Cleaner along with a razor or gasket scraper would work well. I would stuff your heads ports with paper towels or something similar to keep the scrapings from entering into where the valves and combustion chamber are. Also cover the lifter valley with a towel or more paper towels to keep the shavings out as well and use a shop vacuum to help with clean up. Now if you have new heads the cleaning the head/intake/gasket surface will not be necessary.

I put a nice thick bead of high temp silicone on the block ends (I don’t like using the rubber ends that are supplied with your intake gaskets…they can slip out and cause a leak) and let it sit for about 10 minutes to "film" over and then set the lower intake on: Before putting on the intake, put a couple dollops of silicone under the lower intake gasket and position the gasket over the ports as perfect as possible and then allow those dollops under the gasket to dry. Trim a little bit of the coolant passages on the gasket because it will protrude into the passageway. To help insure proper intake alignment as it is being dropped down I used my old intake bolts and cut the hex-heads off of them and threaded them into the heads. I used 4 of them and made a rectangular shape out of them to cover all angles when dropped down. Once you get the intake down you can then unscrew the studs you made and start to install your new intake bolts, if purchased. If you did not buy new ones you can probably just find some studs to use temporarily.

I slightly torque the intake down after the rtv starts filming just to get a little squish on the silicone and let it sit overnight. The next day go thru the final torque procedure with the torque numbers. Use the proper torque sequence to tighten the bolts and you will need to go through the torque sequence probably 4 or 5 times to get all the play out of the bolts when it compresses the rtv and gasket.

Here is the lower intake tightening sequence order:

Here is the upper intake tightening sequence order:

Just in case you forgot where some of your intake vacuum lines go I’ll try to jog the memory a bit with a little bit of a description: If your looking at the front of the engine and you look on the upper intake on the front left of it, that line goes to the charcoal canister. The vacuum line just to the right of it (thicker) goes around to a two way valve on the bottom right side of your upper intake and continues on into the back bottom of the lower intake where your pcv valve is located at. On the back of your upper intake you have a little intake tree that comes out of the back of the upper intake. It has three possible hose connections. The thicker one goes to the firewall vacuum tree where it is labeled as “S” (it will be a little up and to the right of the upper intake on the firewall along with other abbreviations like “B/R” and “A/C”…but connect it to the “S”. The other two possible vacuum lines are easy. One is red (mine was) and goes to your fuel pressure regulator and the other one goes to your EGR. If installing new injectors at the same time you won’t need O-rings because your injectors will have them on already. I lubed mine up with a tiny bit of Vaseline to help them slide in the intake and fuel railing. Install upper intake. Install throttle body and air inlet tube with the mass air flow sensor. Recheck all connections.

Prime your engine with the oil primer tool by putting it in the distributor hole and spinning counterclockwise with a drill for 1-2 minutes until oil pressure is built up, or disconnect coil by starter solenoid and crank the engine over until oil pressure is built up.

Of course after the initial install and setting your timing, fuel pressure, connections, and break-in, retighten the lower intake bolts again after a few heat cycles. Change oil after the first start-up.

Checklist and Suggested Parts:

Parts are specific for 87-93 although most parts are the same for 94/95.

Head Gaskets - ROL-HG32841HR (.039) or ROL-HG32841HT (.045)

Lower Intake Gasket – FEL-MS93334 (stock) or FEL1250S

Upper to Lower Intake Gasket – Depends on Intake Used.

Valve Cover Gaskets* - FMS-M-6584-A50 (OEM)

Thermostat Gasket - FEL-35440

Timing Cover/Front Seal/Water Pump/Oil Pan U Gasket Kit - FEL-TCS45449

Water Pump Gasket - FEL-35211 (Plate to Block), FEL-35380 (Pump to Plate)

Head Bolts - FEL-ES72155 (stock), ARP-154-3601 (7/16”, recommended)

Header/Manifold Gaskets – FEL-1415

EGR Valve Gasket* - EDL-3830 (65-70mm TB/EGR/Plate to Valve Gasket)

Throttle Body Gasket - Same as above.

Intake Air Bypass Valve Gasket* - Same as above.

Hardened Pushrods

Timing Chain/Gear - FMS-M-6268-A302 or RollMaster - CS3071

Fuel Injectors

Mass Air Flow Sensor Calibrated for Injector

Fuel Pump (Stock is 88 or 95lph – Upgrade to 155/190/255lph)

*Optional

There are many different brands of products that you could use above instead of the ones outlined.

Tools:

¼”-15/16” Shallow and Deep Well Sockets and Wrenches

Combination of Extensions

Break Over Bar

Torque Wrench

Harmonic Balancer Puller

Gear Puller* (optional for stubborn timing chain)

Moroso Oil Pump Primer* - MOR-62210

A/C and Fuel Line Disconnect Tools*

Allen Wrenches*

Adjustable Wrench

Flathead and Phillips Screwdriver

Cam Degree Kit*

LocTite

Ultra Black RTV

Antiseize

Thread Sealer for Lower Head Bolts and Coolant Sensors

Assembly Lube or Oil for cam/lifters

Two Oil Changes and Filters

Ford Thermactor Plugs* (2 extra plugs if no smog equipment)

Gasket Scraper

Brake Cleaner

Degreaser*

Ziploc Bags*

Masking Tape*

Marker*

*Optional

Check out www.rockauto.com for any more parts/tools you may need.

Torque Specs:

Camshaft Thrust Plate Bolts: 108-144 in. lbs (6-9 ft. lbs)

Camshaft Sprocket Bolt: 40-45 ft. lbs

Timing Cover Bolts: 12-18 ft. lbs

Water Pump Bolts: 15-21 ft. lbs

Water Pump Pulley Bolts: 15-21 ft. lbs

Harmonic Balancer: 70-90 ft. lbs

Crankshaft Pulley Bolts: 35-50 ft. lbs

Cylinder Head Bolts: 70 ft. lbs for Aluminum Heads*

Rocker Studs: 60 ft. lbs

Exhaust Manifold/Header Bolts: 26-32 ft. lbs

Valve Cover Bolts: 3-5 ft. lbs

Rocker Arm Fulcrum Bolts (Pedestal Mounted): 18-25 ft. lbs

Lower Intake Manifold Bolts: 23-25 ft. lbs**

Thermostat Housing: 12-18 ft. lbs

Upper Intake Bolts: 10-12 ft. lbs

*Read head bolt instructions and torque in stages

**Retorque in tightening sequence after a couple heat cycles

Extra Torque Specs:

Main Bearing Caps: 60-70 ft. lbs

Connecting Rod Bolts: 25 ft. lbs

Oil Pan Bolts: 9-11 ft. lbs/18 ft. lbs at timing cover and rear main side.

Flywheel Bolts: 75-85 ft. lbs

Loc-Tite Camshaft Sprocket Bolt and Thrust Washer Bolts.

5/16” Bolt Head – Intake Air Bypass Valve, Fuel Rail

3/8” Bolt Head – Timing Cover Bottom

7/16” Bolt Head – Water Pump Pulley, Valve Cover, Header/Manifold

1/2” Bolt Head – Lower/Upper Intake, Head, Throttle Body, T-Stat, Timing Cover

9/16” Bolt Head – A/C Bracket, Alternator

5/8” Bolt Head – Long Alternator, Water Pump, Oil Pan

Disassembly:

Mark all your hoses and connections with the tape and marker to help you put it together later on. Take pictures if need be. Relieve the fuel pressure by either having the car sit for a few hours or remove the schrader valve cap and use a small flathead screwdriver to press into the valve and release the pressure. Have a towel handy to absob the fuel that will come out. On 87-95 cars the schrader valve is located on a fuel rail located behind the alternator. Remove your air inlet tube whether it be a cold air intake or the stock plastic air box. Remove the MAF by undoing the connection from it. Begin to remove the throttle body by unbolting it from the 4 studs screwed into the upper intake held on by the 4 matching bolts. Also release the TPS sensor (on top of throttle body) connection along with the throttle linkage that pops off. Unbolt the upper intake (6 bolts I believe) and make sure you get the ones underneath the upper intake plate held onto it by some screws. Prepare for later to possibly replace the bolts or reuse them depending on what intake you are going to use. Before lifting it off completely remove the vacuum hoses from the upper intake so you can bring it up without tearing a line. When you unbolt the upper intake before hand it gives you more hand room to get those hoses and lines off nicely. The distributor is held in by one bolt located on the right side of the shaft. Make note of the firing order and where your spark plug wires went. Put a paper towel in the distributor hole so you don’t get any tools or debris in the engine.

Now that the upper intake is removed go ahead and unbolt the 4 bolts that hold the fuel rail onto the lower intake. On the front passenger side head bolt, the fuel rail is held on by a bolt to hold the rail in place. Unbolt it so you can swing the fuel rail out of the way once you remove the rail from the injectors. The injectors will just pop out of your fuel rail and lower intake. Your local parts store will have a/c & fuel line disconnect tools that will let you disconnect the fuel rail easily. Unbolt the thermostat housing, which is held on by two bolts on the front of your lower intake. Go ahead and loosen all the 12 bolts that hold your lower intake on. The lower intake will be a bit hard to get off. Pry it off carefully and remove it after you have the hoses, sensors, lines removed from the lower intake. Swing those connections out of the way. Now that both the upper and lower intake are off it would be a good time to “reinstall” the upper and lower intake sensors and hoses onto your new intake.

Next I would go ahead and begin to remove the radiator and pull it out along with the fan shroud and stock fan and fan clutch. Remove your overflow tank. Unbolt the a/c condenser (in front of radiator) and swing it out of the way. This will now allow plenty of room for you to pull and install your cam later on. Start to remove the accessories on your engine. The alternator is bolted onto a bracket, which is held on by 3 bolts. Undo the alternator connections and remove it along with its bracket. Next remove the smog pump, if equipped, and then remove the a/c compressor by removing the bolts and swing it out of the way as well so you do not “bleed” the system and have to refill that later on. Next remove the power steering and remember how all the accessories bolt up for future reference.

Removal of the harmonic balancer is next after you remove the four bolts from the crankshaft pulley. And you have to break loose the 15/16th bolt that holds the balancer on. Put your car in 5th gear or Park with the e-brake on and someone stepping on the brake, if need be. You can then put a break-over bar and turn it counterclockwise to break the bolt loose. Removing the balancer is next. You need to get a harmonic balancer removal tool from your local parts store. Take bolt out and remove the washer. Thread the bolt back in about half way in. You are now ready to bolt up the harmonic balancer puller and use it. Next I would remove the water pump and timing chain. To save time and a gasket you can remove them as one piece. Try to remove the bolts/studs out carefully because some pass through water ports and the bolts can rust and break in the block or covers. Make sure you remove the front 4 oil pan bolts to get the timing cover off from the bottom. The timing cover is also aligned by dowel pins (2 on each side). Once this is removed you will see the timing chain and the front of the oil pan. Put some paper towels or rags in the front of the cover to prevent dropping any object in there.

Now you can remove the 6 valve cover bolts from each valve cover on the left and right. Remove the head bolts so you can pop the heads off along with the rockers still bolted down. But before completely removing the heads go underneath the car and remove the 2 bolts on each side of the engine that hold the mid-pipe onto the headers. You can remove the heads with the headers still attached. The pushrods will fall out. I then removed the spider bar in the lifter valley to allow access to the X shaped lifter holders. The spider bar is held down by two bolts. I then removed the lifters one by one until I got all 16 of them out. Next you can go ahead and unbolt the cam bolt and pull the timing chain off by hand. Remove the cam retaining plate held on by two bolts and you now have access to your cam. Put in a longer bolt into the end of the cam to get better leverage when removing the cam. Take the cam out very slowly and be careful of the cam dropping between cam bearings.

Plug all your little threaded holes and coolant passages with small pieces of paper towel before doing the following. It would be a good idea next to go ahead and try to clean the head gasket mating surface area along with the tops of the pistons. A can of spray brake cleaner with a gasket scraper will work. Be careful not to nick the pistons or block. It should take a while to get the head gasket area and piston tops clean, but take your time. Clean the timing cover mating surface.

Reassembly:

Go ahead and get your new cam ready for install. Clean the cam before applying assembly lube. You will need some assembly lube to help protect the cam during those first few seconds of initial start-up. Install the assembly lube on the cam lobes and distributor gear. Cover all the areas of contact. Get your cam ready to install by putting in that same long bolt you used earlier for leverage. Install it very slowly and carefully try not to bang the cam bearings or cam lobes. Work the cam lobes from left to right to help it roll in and it will eventually get to the back of the block. I would go ahead and now install the harmonic balancer bolt into the crankshaft and spin the crank over until the #1 piston (front passenger side piston) is at the very top of its travel so you are at TDC (top dead center). Go ahead and reinstall the cam retainer plate with those two bolts applied with loctite. Get your timing chain ready to install the cam dot to dot. Dot to dot simply means that the two dots on the timing chain will be next to each other. The dot on the crankshaft gear of the timing chain will be at the 12 o’clock position and the dot on the camshaft gear of the timing chain sprocket will be positioned at the 6 o’clock position. When trying to align these dots in that order again remember to keep the #1 piston at TDC and use the dowel pin hole in the timing chain to align with the dowel pin in the end of your new cam. Your cam will then be installed “dot to dot” and in most instances the performance is just fine.

There is another procedure after installing the cam to further assure your cam is installed correctly. It is called, degreeing the cam and you need a cam degreeing kit. I would really look into degreeing your cam in when you buy a custom cam. If you do not degree the cam in for your custom cam you can lose the “custom effect”…so be practical in what you decide. If you decide to degree the cam with the method provided you will need a solid lifter or reuse an old lifter you removed and weld two spot welds on the top of the lifter to keep the plunger from plunging and it will act like a temporary solid lifter.

How To Degree The Camshaft

Once you get the timing of the cam set go ahead and bolt down the timing chain bolt and apply loctite on it. Go ahead and install new lifters with assembly lube on the rolling end and on the pushrod seat end. The lifters have oil bleed holes on one side of each lifter. The position of the holes does not matter. Install the X shaped lifter hold down brackets back over the lifters. Bolt down the spider bar that holds the lifter hold down brackets.

Go ahead and get ready to install the timing cover and water pump back on. If you got a new timing cover gasket and U shaped oil pan gasket, then now is the time to use it. Again make sure the oil pan lip and timing cover gasket area are clean to help with gasket placement. Put a very thin layer of rtv silicone on the block and then apply the gaskets and then put another layer of thin silicone on the other side of the gaskets. Put a nice dollop of the silicone in the 2 corners where the timing cover/block/oil pan meets to prevent a leak. Put your U shaped oil pan gasket on the bottom of the timing cover before install. Then put the timing cover in place. Make sure you put the timing cover on smoothly as not to disturb your gasket placements. You can then bolt up the timing cover and remember to put the oil pan bolts back on that go thru the bottom of the timing cover.

Installing the heads on your newly cleaned block is next. Clean your head bolt holes with a thread chaser to help provide a better torque reading and smoother bolt installation. Make sure you have thermactor plugs installed in the front of your heads. They screw into the front and back (if no smog equipment) of your heads. Put silicone on the threads to prevent any exhaust leak when installing them. The thermactor plugs you will use for the front (same as back) will go to make the head holes smaller so the accessories can bolt up. One is for the power steering stud and one of the larger alternator bolts that go through you alternator bracket. The back thermactor plugs you will use just block off and delete the smog equipment’s previous hookups. Get the heads ready to install. Get your new head gaskets and put them on the block mating surface. Make sure they are facing the right direction (should be labeled FRONT). Put some light oil on the valves of your heads so that the car valves are not started up dry. Get your torque wrench ready along with your new headbolts. Use thread sealer as well for the bottom bolts that go through coolant passages so that it can seal off coolant. Cover the threads well and completely on the bottom bolts. Put 30w oil or moly lube on the top bolt threads to help with the torque reading accuracy. Put antiseize underneath the washers supplied with the head bolts. When installing the heads make sure that they drop on the dowel pins on the block so they heads will be held in place while you bolt them down.

Use the proper torque sequence for the heads when installing them.

If your looking down at the top of the head here is the torque sequence order:

Intake side

9 5 1 3 7

Exhaust side

10 6 2 4 8

This is the tightening procedure I used on my AFR heads:

Top bolts: 30lbs, 50lbs, 70lbs, 80lbs

Bottom bolts: 30lbs, 50lbs, 70lbs, 75lbs

Installing the valvetrain, which includes setting the guideplates to help with proper valvetrain geometry and installing the roller rockers in the proper fashion. Stud mounted roller rockers have guideplates that help keep the roller rocker tip on the valvestem end stay centered. Now of course you don’t want the guideplates to rub against the hardened pushrods as much as possible. To keep this simple you want to be able to move around the guideplates so you can adjust the position to help keep the roller rocker tip in the center of the valve stem during rotation of the engine. Go ahead and remove the studs and apply loctite one at a time. I did the intake part of the guideplate and the exhaust part of the guideplate separately to allow me to apply loctite and be done with it before the other side dried. You will want to setup your valvetrain using the following method so you can rotate the engine and adjust the guideplates as need be. Torque the rocker studs down in your aluminum head. Here is the stud mounted roller rocker adjustment procedure for hydraulic lifters.

1. Remove the valve covers, and pick a cylinder you are going to set the pre-load on. Only do one cylinder at a time.

2. Rotate the engine in its normal direction of rotation (clockwise) and watch the exhaust valve on that particular cylinder. When the exhaust valve begins to open, stop and adjust that cylinder's intake rocker arm.

3. To adjust, back off the intake rocker arm adjusting nut and remove any tension from the push rod. Wait a minute or two for that hydraulic lifter to return to a neutral position. The spring inside the lifter will move the push rod seat up against the retaining lock, if you give it time to do so.

4. Twist the intake push rod with your fingers while tightening down the rocker arm. When you feel a slight resistance to the turning of the push rod, you are at "Zero Lash". Turn the adjusting nut down one half to three-quarters of a turn from that point for street applications. Use 1/8 to 1/4 turn for race applications. Lock the adjuster into position. The intake is now adjusted properly.

5. Continue to turn the engine, watching that same intake valve/rocker you just set. It will go to full open and then begin to close. When it is almost closed, stop and adjust the exhaust rocker arm on that particular cylinder. Loosen the exhaust rocker arm and follow the same procedure described before in steps 3 and 4 to adjust this rocker arm.

6. Both valves on this cylinder are now adjusted, and you can move on to your next cylinder and follow the same procedure again.

There may be some initial valvetrain noise when the engine is first fired up but once oil pressure has stabilized and the engine heats up, it should quiet right down to a normal level.

Remember that some racier camshafts will have a mechanical sound to them and will not be a silent as factory units.

This link will help you with roller rocker arm installation and adjustment (stock style pedestal and/or Stud Mount): Pedestal Mount Adjustment

After setting your valvetrain you can go ahead and install your valve covers if you would like if they will not interfere with your header install. I would recommend putting on a new valve cover gasket unless you would like to use the original ones which are reusable for many uses. After installing the valve covers rotate the engine over and make sure your roller rockers don’t hit the valve covers. Then you may bolt them down.

Go ahead and start putting on the accessories: smog pump, power steering bracket and pump, air conditioning, and alternator. Next will be installing your intake…which is shown below…and installing everything to get everything buttoned back up: thermostat, vacuum lines, radiator, fan shroud, etc.

Make sure you clean the heads off (if they are new heads you don’t need to) real clean and smooth so your intake gasket has a nice surface to adhere to and seal against. Brake or Carb Cleaner along with a razor or gasket scraper would work well. I would stuff your heads ports with paper towels or something similar to keep the scrapings from entering into where the valves and combustion chamber are. Also cover the lifter valley with a towel or more paper towels to keep the shavings out as well and use a shop vacuum to help with clean up. Now if you have new heads the cleaning the head/intake/gasket surface will not be necessary.

I put a nice thick bead of high temp silicone on the block ends (I don’t like using the rubber ends that are supplied with your intake gaskets…they can slip out and cause a leak) and let it sit for about 10 minutes to "film" over and then set the lower intake on: Before putting on the intake, put a couple dollops of silicone under the lower intake gasket and position the gasket over the ports as perfect as possible and then allow those dollops under the gasket to dry. Trim a little bit of the coolant passages on the gasket because it will protrude into the passageway. To help insure proper intake alignment as it is being dropped down I used my old intake bolts and cut the hex-heads off of them and threaded them into the heads. I used 4 of them and made a rectangular shape out of them to cover all angles when dropped down. Once you get the intake down you can then unscrew the studs you made and start to install your new intake bolts, if purchased. If you did not buy new ones you can probably just find some studs to use temporarily.

I slightly torque the intake down after the rtv starts filming just to get a little squish on the silicone and let it sit overnight. The next day go thru the final torque procedure with the torque numbers. Use the proper torque sequence to tighten the bolts and you will need to go through the torque sequence probably 4 or 5 times to get all the play out of the bolts when it compresses the rtv and gasket.

Here is the lower intake tightening sequence order:

Here is the upper intake tightening sequence order:

Just in case you forgot where some of your intake vacuum lines go I’ll try to jog the memory a bit with a little bit of a description: If your looking at the front of the engine and you look on the upper intake on the front left of it, that line goes to the charcoal canister. The vacuum line just to the right of it (thicker) goes around to a two way valve on the bottom right side of your upper intake and continues on into the back bottom of the lower intake where your pcv valve is located at. On the back of your upper intake you have a little intake tree that comes out of the back of the upper intake. It has three possible hose connections. The thicker one goes to the firewall vacuum tree where it is labeled as “S” (it will be a little up and to the right of the upper intake on the firewall along with other abbreviations like “B/R” and “A/C”…but connect it to the “S”. The other two possible vacuum lines are easy. One is red (mine was) and goes to your fuel pressure regulator and the other one goes to your EGR. If installing new injectors at the same time you won’t need O-rings because your injectors will have them on already. I lubed mine up with a tiny bit of Vaseline to help them slide in the intake and fuel railing. Install upper intake. Install throttle body and air inlet tube with the mass air flow sensor. Recheck all connections.

Prime your engine with the oil primer tool by putting it in the distributor hole and spinning counterclockwise with a drill for 1-2 minutes until oil pressure is built up, or disconnect coil by starter solenoid and crank the engine over until oil pressure is built up.

Of course after the initial install and setting your timing, fuel pressure, connections, and break-in, retighten the lower intake bolts again after a few heat cycles. Change oil after the first start-up.