JUST BUY THE DAMN THING ALREADY!

your killing me here!

i'd trade three tubular intakes and even throw in an extra explorer upper!

your killing me here!

i'd trade three tubular intakes and even throw in an extra explorer upper!

So are you saying it would need a different manifold if I wanted to swap to that flowzilla inlet? Sorry for all the questions but before I dive into this I want to make sure I can use it and not have to start hunting for other parts etc.

When I swapped mine, there was a different manifold. I remember sealing it to the top of the blower with the RED loc-tite looking stuff. I'm racking my brain trying to recall the differences and I recall so far is that the Flowzilla manifold was a little taller and was dual plane inside so that the bypass air passed into the lower section, flow to the driver side, then up over and back toward the passenger side. I do not believe that the old manifold can be used instead.So are you saying it would need a different manifold if I wanted to swap to that flowzilla inlet? Sorry for all the questions but before I dive into this I want to make sure I can use it and not have to start hunting for other parts etc.

So I chatted with the previous owner of this unit he said he sold it to this guy for 2800. He also said that the side of the manifold which faces the drivers shock tower would have to be welded unless I was planning on trying to intercool it or something, and that I would have to have the other side of the manifold where the elbow from the flowzilla inlet attaches fabricated and opened so it could attach with the plate that would go there. He told me the unit was gone through and redone and is in good working order but he wanted a flowzilla, which he found and is why he sold that blowzilla. So basically I think I might be stuck unless I just want a blowzilla and hope to find the correct manifold or have that one fabricated. He also said to offer the guy 2500 lol but I told him this guy is stuck but now maybe I can tell him a few things and see if maybe he will get rid of it.When I swapped mine, there was a different manifold. I remember sealing it to the top of the blower with the RED loc-tite looking stuff. I'm racking my brain trying to recall the differences and I recall so far is that the Flowzilla manifold was a little taller and was dual plane inside so that the bypass air passed into the lower section, flow to the driver side, then up over and back toward the passenger side. I do not believe that the old manifold can be used instead.

Caveat: I have no idea what if any changes were made since my kit. It was 18 years ago that I bought it.

I do still have the instructions somewhere either in the garage or on an old hard drive. You might also look at Kenne Bell's website and see if you can download the instructions. I'm also pretty sure they still have their parts list on-line. You should be able to find the pressure manifold for the Flowzilla kit.

If all else fails, email them. Tell em you have the inlet and need to know what other items are required along with some install instructions. I also recall that everything had to be installed super loose and tightened in stages to convince all of the pieces to properly fit together.

Ha ha I’m still on the fence but you are right. I’ll at least let him know what I know now and see if I can get him to budge on that price. Or I could just run it like this guys setup lol! Is this possible?I would still buy it. For $3500 and WITH the inlet.

There are guys right here on this forum that can modify that manifold. TMOSS comes immediately to mind but others as well. The images make it look cherry and here's the best part:

That blower in its current form is still a HUGE improvement. It looks great, and you have MOST of the parts for the upgrade.

Take my money!

You'll need a MAF too and maybe a 4 inch Anderson PowerPipe and filter.

You'll need a MAF too and maybe a 4 inch Anderson PowerPipe and filter.So you can run the flowzilla inlet as such in the pic but still run it to the other side of the manifold? I have 11r 190s, 1.6s, Tmoss ported gt40 tubular, f cam, 60lb injectors with pro-m 80, 70 tb currently but yes id go bigger if I were to buy this and use flowzilla inlet, also running an aero 340 and I have a 4 inch Anderson power pipe as well. I know it’s kind of a lot for current set up but still runs well and this was all in plan for adding my power adder of choice and not having to back track. Real question is going to be, how am I going to sneak this one pass the wife if I pull the trigger!!Totally possible. I ran that setup for years before I converted to Flowzilla.

You'll love it. Of that, I have no doubt. Gives you plenty of time to learn and ride while you plan to mount the Flowzilla. When you do... Might I also suggest an Accufab 80mm TB and spacer?You'll need a MAF too and maybe a 4 inch Anderson PowerPipe and filter.

The blowzilla setup however, should only require installation, fuel injectors, pump, and tune. Optional but highly recommended is a wideband in the right bank.

I do [not] recommend any type of FMU or secondary pump (like T-Rex). A walbro 255L high pressure is more than adequate. A Kenne Bell Boost-A-Pump and Spark is also recommended. The BAP is more optional than the Spark IMO but I have both.

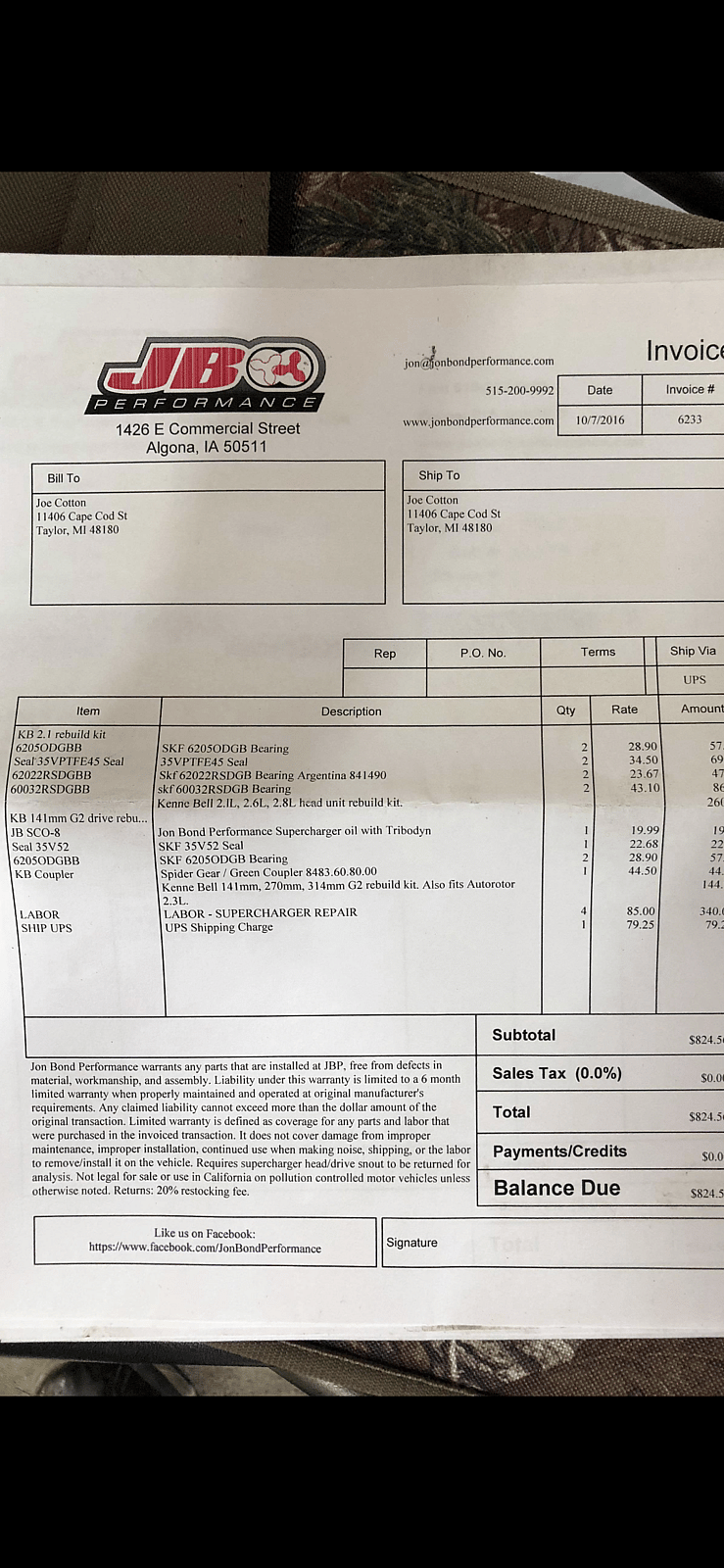

Gotcha man that’s what I was needing to know. So I talked with the guy today on the phone. Said he picked up the dyno tech flowzilla inlet off a guy who knew some one that worked for them, but it obviously hasn’t been tapped to be able to screw that plate onto it. I think the system is cool even though there seems to be a lot of haters on bc of the heat soak issues. So I already went full tilt and was like well I could say screw and have it fab’d up and run a cooler and well got damn I don’t even own the thing or know if I will. I just always get way ahead of myself! Think it could be really fun and hopefully boost me from me 328hp into the 400s maybe possibly?!?! I was always worried that maybe if I went stroker this would be a problem with this kit but I’ve seen plenty of 331,347,363s with this kit. Good thing is this guy previously had it looked through and rebuilt.Thought Process:

Install the kit the way it is. Don't make any changes to it. Purchase the Flowzilla inlet and put it on a shelf for now.

All the mods you have should support this thing nicely. Run the smallest blower pulley you can that doesn't slip with a GatorBack belt and enjoy the ride!

Take your time pulling plan and pieces together for the Flowzilla inlet. For that inlet to work, all of the external blower piping will have to go 'bye bye' and you'll either need to find the pressurized inlet somewhere or modify the one that you have to accept the internal bypass and additional air mass.

The point is: It's not an emergency to install the Flowzilla but you will eventually want to. I have no doubt. With no other changes, I gained 3 lbs of boost. More when I went to the 80mm TB (another 1 to 1.5ish). I have my inlet opened up as much as is reasonable, I think.

Holy crap I just watched that guy vid on YouTube it was crazy. Is he still a member and doing this sort of side work. This just got me real excited.The dude that initially created that manifold has a thread about it here:

https://www.stangnet.com/mustang-fo...intercooler-kit-for-fox-body-and-sn95.851948/

Ha ha if this guy will bring up to me it’s gonna be game on. Just waiting to see what he will do. I know he had several pulleys for the snout, think he said an 80mm tb and some truck crank pulleyDammit. Now you have me thinking about this thing again

It already scares the bajesus outtah me. Just what I need is some more....

I'll merge these posts in a sec.

Thought you would also like to know that you are approaching a point where under-drive pulleys are actually worth a flyingF...

You can get a crank over-drive pulley, under-drive all of the accessories, and also run a larger pulley on the blower while still spinning to max. - Those whole combination greatly reduces belt slip from having to use small pulleys on the blower snout.

Ha ha if this guy will bring up to me it’s gonna be game on. Just waiting to see what he will do. I know he had several pulleys for the snout, think he said an 80mm tb and some truck crank pulley

Dang not a bad price for that s trim but it’s a little rough.Hey guys I dont know if any of you frequent the Junk Yard Doggs website but he has a ton of stuff on there right now and its all priced well.

https://usedautopartsdepot.com/?vie...ion_326172=326172&filter_option_326176=326176

quite a few blowers and some cylinder heads at good prices