They're pretty comparable. The AFRs are CNC ported and will slightly outperform out of box TFS cast 170s. The 170s have a ton of potential, though.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Best Cast Iron Heads

- Thread starter Grabbin' Asphalt

- Start date

-

Sponsors (?)

The ARP washers are wide enough to hold them down. The dowel holds the head in place, not the bolt. 10 years ago, no one even knew what step washers were. It's something someone invented for a problem that didn't exist to make money.

Kurt

You don't even need the step washers. Just bolt them on.

Kurt

I could not disagree more. I have seen several cars with blown headgaskets when no step washers were used. I highly doubt that this expense will break the bank..

I actually looked them up. They advertise that they are for keeping the aluminium from collapsing into the bolt hole. It's just never a problem I've had before. I don't see how they could have any effect on the head gasket.

Kurt

Kurt

I think a lot of it has to do with the heads moving around on the deck surface while the engine is running. I think that this is exaggerated as the hp levels and cylinder pressure increase. I would compare this to using smaller bolts in your rear control arm mounts. Sure they may have enough clamping force to tighten to the desired spec but there are more than just linear forces applied to these bolts and I believe that this will result in a failure. I know that the cylinder heads have locating dowels, but they are located on two opposing ends of the cylinder heads. In both cases where I have seen blown head gaskets using no step washers, the gaskets have been pushed out from one of the two center cylinders.

Would you say the 165cc AFR's is a little more torque friendly

and the 170cc TFS is a little more top end friendly??

Haven't I beat this way of thinking out of you guys yet?

They're pretty comparable. The AFRs are CNC ported and will slightly outperform out of box TFS cast 170s. The 170s have a ton of potential, though.

Historically I would have disagreed, but AFR has raised their game with the revised heads. I still wouldn't buy 165s myself, but that's only because I'm crazy.

Historically I would have disagreed, but AFR has raised their game with the revised heads. I still wouldn't buy 165s myself, but that's only because I'm crazy.

What would you do for a 302??

mikestang63

SN Certified Technician

185's

Just to clarify, with a DD if I keep the E=cam, would you have them milled? The pistons would need to be notched I know anyways. Or the 185's only for a wild cam??

No. Nic has TFS TW CNC ported 205s on his 302. He has some super impressive results with them too, but that's an expensive head, and the AFRs are not even cheap.

Anyway, if you're concerned about notching, consider the TFS heads with their "twisted wedge" approach, they can be run with most cams without PTV clearance issues.

To me, the milling question comes down to whether or not you want to shave the heads to gain some compression. If you don't mind running premium, don't have blower or turbo ambitions, and are trying to get the most out of your combo without finding another way to boost compression, then mill 'em. Just leave yourself a little room to flatten them again later before you sell them or reuse them.

Anyway, if you're concerned about notching, consider the TFS heads with their "twisted wedge" approach, they can be run with most cams without PTV clearance issues.

To me, the milling question comes down to whether or not you want to shave the heads to gain some compression. If you don't mind running premium, don't have blower or turbo ambitions, and are trying to get the most out of your combo without finding another way to boost compression, then mill 'em. Just leave yourself a little room to flatten them again later before you sell them or reuse them.

mikestang63

SN Certified Technician

No. Nic has TFS TW CNC ported 205s on his 302. He has some super impressive results with them too, but that's an expensive head, and the AFRs are not even cheap.

Anyway, if you're concerned about notching, consider the TFS heads with their "twisted wedge" approach, they can be run with most cams without PTV clearance issues.

To me, the milling question comes down to whether or not you want to shave the heads to gain some compression. If you don't mind running premium, don't have blower or turbo ambitions, and are trying to get the most out of your combo without finding another way to boost compression, then mill 'em. Just leave yourself a little room to flatten them again later before you sell them or reuse them.

Correctomundo... You can run the TW 170's with the 2.02/1.60 valves on a stock piston as long as the cam lift is under .540 If memory serves me right. BUT.. I would always check the PTV clearance regardless. Cheap insurance.

Just know if you mill the heads it may cause alignment issues with the intake holes and change the pushrod length. Plus it even more of a reason to check PTV clearance.

Correctomundo... You can run the TW 170's with the 2.02/1.60 valves on a stock piston as long as the cam lift is under .540 If memory serves me right. BUT.. I would always check the PTV clearance regardless. Cheap insurance.

Just know if you mill the heads it may cause alignment issues with the intake holes and change the pushrod length. Plus it even more of a reason to check PTV clearance.

FWIW, peak lift has absolutely nothing to do with valve clearance. My setup has .570ish lift and I have plenty of clearance, on true flattop '86 pistons. It's all about where your valves are when the piston is hanging around TDC (exhaust closing/intake opening).

Isn't the 5.0 a non-interference motor? Maybe the rule of thumb is that .540" lift is what makes it an interference engine? Just curious...

FWIW, peak lift has absolutely nothing to do with valve clearance. My setup has .570ish lift and I have plenty of clearance, on true flattop '86 pistons. It's all about where your valves are when the piston is hanging around TDC (exhaust closing/intake opening).

Well I wouldn't say it has nothing to do with it.

Kurt

Isn't the 5.0 a non-interference motor? Maybe the rule of thumb is that .540" lift is what makes it an interference engine? Just curious...

You don't often hear that term used with an engine that has a timing chain. I wonder why??

Kurt

From an interference 351w. For what its worth, lol. This is what happens when your friends don't listen to you when you say checking PTV is a must!

Isn't the 5.0 a non-interference motor? Maybe the rule of thumb is that .540" lift is what makes it an interference engine? Just curious...

I actually don't know if the 5.0 is non-interference in stock form. I've heard people talk about it before, but I've never seen anyone verify it. It's moot though, because we're talking about aftermarket heads and cam, and heads that put the valves in non-stock locations to boot.

Well I wouldn't say it has nothing to do with it.

Kurt

Yep, sticking to my guns on this one. Peak lift happens on the far side of 90 degrees ATDC (for the intake) or BTDC (exhaust)- when the piston is more than halfway down the bore. In a 302, that's more than 1.5" deep in the block. So, for the typical sub-.600" lift cam, you've probably got more than an inch of clearance when peak lift happens.

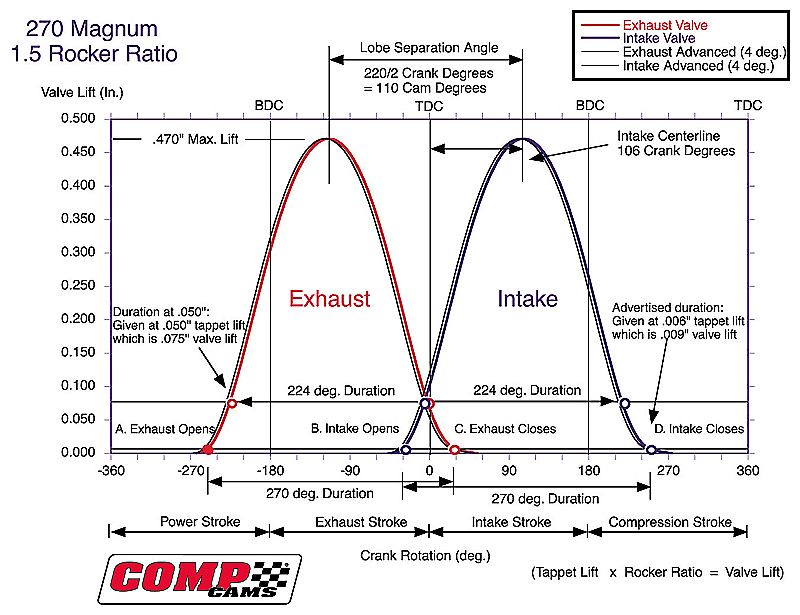

Pic for reference.

If you put a certain amount of lift in an engine with a big valve, it's going to hit the piston. I'm sticking to my guns on this one.

Kurt

Kurt

I have 1.6 frpp pedestal rockers, I'd be back in AFR price range if I bought stud rollers. How much can the AFR's be milled?? I like the high compression n/a. Should I do 165cc or 185cc milled?? I know I would have to notch for the pistons on the 185cc though.

Last edited:

Similar threads

Progress Thread

Evolution of the 'Hudson Heap' plans (87 GT)

- Replies

- 29

- Views

- 3K

- Replies

- 25

- Views

- 2K

- Replies

- 3

- Views

- 1K

- Replies

- 0

- Views

- 688

- Replies

- 17

- Views

- 3K