manicmechanic007

5 Year Member

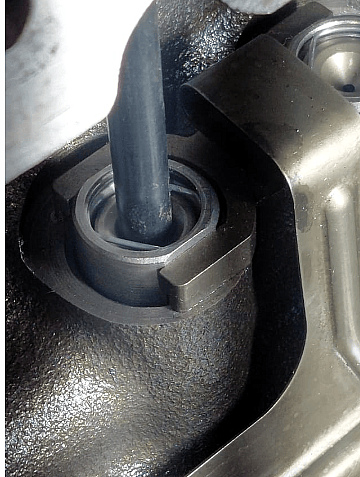

Rotate the engine around while priming the oil pump with a drill

That will pump up the lifters

Then torque the rocker arms down

That will pump up the lifters

Then torque the rocker arms down

That's where I'm confused I guess. According to this guy, lifters should be dry:Rotate the engine around while priming the oil pump with a drill

That will pump up the lifters

Then torque the rocker arms down

That's where I'm confused I guess. According to this guy, lifters should be dry:

View: https://www.youtube.com/watch?v=5EGlb_VpTAw&t=12s

Well darn, sounds like you and Youtube have it all figured out....I don't understand why sbc and rocker arm type matters. In fact, if I recall, in the video, he says it works for all types of pushrod engines with hydraulic lifters. That's why I liked the way he explained it. If I understand correctly, there's like two hundred thousands room for error in the hydraulic lifters, so I think I should be ok regardless

I am not sure why everyone is ganging up on me there was no attempt from me to say your method is wrong. I am simply gathering information from different people/sources and making my own opinion. What i find i post here for feedback. There are different ways of doing this and I'm looking for the way that makes sense to me. Did not mean to offend.Guess a lot of us have been doing it the wrong way for years. I’ll stick with my oil filled lifters as I know how to do it that way. May be different with stud mount rockers.

But not able to find the bagit's always nice to have more tools in the tool bag than you need

Yea, I got new lifters when I bought the new cam, so for me, it's easy to have them dry. Also, since my engine is on an engine stand and I'm slowly assembling it, the intake is already off so again, that approach works best for me and clearest to understand.My post was not directed at you just a general statement of what most of us do works so they way the guy from TFS described it is just uncommon. My biggest issue with his statement is how do you get the lifters dry if you are swapping rockers on an already ran motor? I am not pulling the intake, removing the lifters (some require the cylinder heads to be removed to get them out), drying them out, reinstalling them, and then adjusting the preload on my new rockers.

Lots of ways to approach doing things and hopefully this works for you as it's always nice to have more tools in the tool bag than you need vs. not having enough.