When I first run the car in the morning, especially if it's cold outside (fwiw, "cold" here in San Diego means 60 degrees), the car hesitates and lurches. This all began at the time of a major exhaust leak @ the flange on the passenger side exhaust manifold (since replaced). It's improved, but still present. Oddly, once the car has been running for 3 minutes, it settles down and runs really well. See the attached logs. Any thoughts on what's causing this? TIA

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Fuel Pressure erratic

- Thread starter CallPaul

- Start date

-

Sponsors (?)

08GT500

5 Year Member

Hi,

If it’s not cold outside, but started when Motors cold, same symptoms?

As for the cold start I’d first be focused on the CPU’s Coolant temperature sensor, verify your coolant is topped off. Any backfiring? Any backfiring before you repaired the manifold leak?

1) Did you look for codes? May still be there with no CEL.

Check the usuals, condensation around the Plug(s) that entered by the Coil’s Plug boot & rising up when warmer temp’s occur..

2) Fuel Pressure.

-How long was the exhaust leak repair/manifold gasket bad replaced before replacement?

-Fuel pressure regulator, pull a vacuum on it, tube in moth, if bad, you’ll taste fuel, strong vapors.

-Coil packs OE or aftermarket?) Non OE’s seem to have issues more often.

-Check your battery voltage with nothing on, then when it’s idling. Should be 12 V minimum when sitting13.8 when running.

So many things may cause this, any more info from your end will help immensely, Any other details in how it first started (E.G. Hiccup in acceleration, etc..).

Run through the basics, then potential for future issues are easier.to Corner.

It seems to run better with open loop operation, most sensors aren’t yet functioning. It runs normal when warmer, in closed loop, correct?

Check grounds, vacuum leaks, MAF sensor, IAT sensor, etc.

02 or Plug Damage is possible due to the manifold leak, and it’s repair. The vacuum created within a manifold leak will draw in cool air &.cause high combustion temperatures molecules exiting to collide with them, causing mild detonation & thermal shock, enough to hurt an 02 sensor over long term. O2’s also don’t always set off a CEL..

Upstream sensors are what delegate mixture.

Good luck!

-John.

If it’s not cold outside, but started when Motors cold, same symptoms?

As for the cold start I’d first be focused on the CPU’s Coolant temperature sensor, verify your coolant is topped off. Any backfiring? Any backfiring before you repaired the manifold leak?

1) Did you look for codes? May still be there with no CEL.

Check the usuals, condensation around the Plug(s) that entered by the Coil’s Plug boot & rising up when warmer temp’s occur..

2) Fuel Pressure.

-How long was the exhaust leak repair/manifold gasket bad replaced before replacement?

-Fuel pressure regulator, pull a vacuum on it, tube in moth, if bad, you’ll taste fuel, strong vapors.

-Coil packs OE or aftermarket?) Non OE’s seem to have issues more often.

-Check your battery voltage with nothing on, then when it’s idling. Should be 12 V minimum when sitting13.8 when running.

So many things may cause this, any more info from your end will help immensely, Any other details in how it first started (E.G. Hiccup in acceleration, etc..).

Run through the basics, then potential for future issues are easier.to Corner.

It seems to run better with open loop operation, most sensors aren’t yet functioning. It runs normal when warmer, in closed loop, correct?

Check grounds, vacuum leaks, MAF sensor, IAT sensor, etc.

02 or Plug Damage is possible due to the manifold leak, and it’s repair. The vacuum created within a manifold leak will draw in cool air &.cause high combustion temperatures molecules exiting to collide with them, causing mild detonation & thermal shock, enough to hurt an 02 sensor over long term. O2’s also don’t always set off a CEL..

Upstream sensors are what delegate mixture.

Good luck!

-John.

Great reply John, thank you.

Yes, it also does it when it's not cold outside, just seems to be more severe.

I cleaned the MAF and first drive the next morning, it was worse. And yes, once it warms up it settles down (you can see that in my original attachments also).

Test drove it this morning, same symptoms, but I pulled over and unplugged the MAF and, while it had decreased throttle performance, it did eliminate the erratic spikes. Once it warmed up, I plugged it back in and it ran fine.

So I think I've discovered that it's the MAF.

Any other thoughts?

Yes, it also does it when it's not cold outside, just seems to be more severe.

I cleaned the MAF and first drive the next morning, it was worse. And yes, once it warms up it settles down (you can see that in my original attachments also).

Test drove it this morning, same symptoms, but I pulled over and unplugged the MAF and, while it had decreased throttle performance, it did eliminate the erratic spikes. Once it warmed up, I plugged it back in and it ran fine.

So I think I've discovered that it's the MAF.

Any other thoughts?

08GT500

5 Year Member

Hi,

Sorry to hear of your persistent issue. If you pulled the MAF, it should run a, a bad MAF- rare as it is, may be the issue- can be tested with a VOM, as well as it’s input wires awful, and in many cases...it’ll stall.

So, this may indeed be a clue, possibly the cause. But that’s not always indicative as being the culprit. Many sensors are disabled & vehicle runs on a default program until its running closed loop, based on temp., readiness.

Think I’d still want to take a look at that front 02 sensor on the exhaust leak side

I’d also check/verify..

1) Both the male pins on the MAF plug, sockets females, possibly even the wires going to the plug, do a wiggle test, moving the wires with engine running, see if it clears up things at all.

2) Remove/clean/inspect your IAT (Intake Air Temp) sensor? It’s round, and between the MAF & filter on the CAI.

3) Did you inspect MAF’s coils to verify there was no media captured on/within its coil(s)? (Had a small piece off crud in one, drove me nuts once before).

4) Did you clean the MAF with MAF cleaner (CRC MAF cleaner)?. Other products may leave a film or residue & further complicates the issue.

5) Any codes appear by hooking up a Scan-tool & Data logging with..freeze frame data will catch potent

6) Sometimes “clocking” , or rotating the MAF may help, rotate it in 10-15 degree increments may help incoming air strike the MAF more effectively. you may carefully do this with motor running, or mark, tighten, star, drive.

7) COP’s, 4 Coil packs, single Coils may not fail completely but manifest as a weak spark. Input wires may also. How strong is your spark..

8) Check that your IAC is functioning properly, and is correcting the idle as it should, you can unbolt & clean it.

Pull & clean your EGR with MAF cleaner, or equivalent. Any excess buildup will affect power & running condition.

The upper intake can become loaded with Oil & can be seen with a flashlight & looking through its ports, removal is 8 bolts & some vacuum lines, cause is usually a PCV valve, excessive blow by.

Temperature changes things, try pulling a plug wire off at a time when it’s running badly& see if it changes. replace & try another. Hooking up a vacuum gauge to intake will also yield answers. What’s it pulling at idle?

These are just steps to take for PM. If the MAF is the issue, these will help you out in the future, even now

Any questions, fire away.

- John

Sorry to hear of your persistent issue. If you pulled the MAF, it should run a, a bad MAF- rare as it is, may be the issue- can be tested with a VOM, as well as it’s input wires awful, and in many cases...it’ll stall.

So, this may indeed be a clue, possibly the cause. But that’s not always indicative as being the culprit. Many sensors are disabled & vehicle runs on a default program until its running closed loop, based on temp., readiness.

Think I’d still want to take a look at that front 02 sensor on the exhaust leak side

I’d also check/verify..

1) Both the male pins on the MAF plug, sockets females, possibly even the wires going to the plug, do a wiggle test, moving the wires with engine running, see if it clears up things at all.

2) Remove/clean/inspect your IAT (Intake Air Temp) sensor? It’s round, and between the MAF & filter on the CAI.

3) Did you inspect MAF’s coils to verify there was no media captured on/within its coil(s)? (Had a small piece off crud in one, drove me nuts once before).

4) Did you clean the MAF with MAF cleaner (CRC MAF cleaner)?. Other products may leave a film or residue & further complicates the issue.

5) Any codes appear by hooking up a Scan-tool & Data logging with..freeze frame data will catch potent

6) Sometimes “clocking” , or rotating the MAF may help, rotate it in 10-15 degree increments may help incoming air strike the MAF more effectively. you may carefully do this with motor running, or mark, tighten, star, drive.

7) COP’s, 4 Coil packs, single Coils may not fail completely but manifest as a weak spark. Input wires may also. How strong is your spark..

8) Check that your IAC is functioning properly, and is correcting the idle as it should, you can unbolt & clean it.

Pull & clean your EGR with MAF cleaner, or equivalent. Any excess buildup will affect power & running condition.

The upper intake can become loaded with Oil & can be seen with a flashlight & looking through its ports, removal is 8 bolts & some vacuum lines, cause is usually a PCV valve, excessive blow by.

Temperature changes things, try pulling a plug wire off at a time when it’s running badly& see if it changes. replace & try another. Hooking up a vacuum gauge to intake will also yield answers. What’s it pulling at idle?

These are just steps to take for PM. If the MAF is the issue, these will help you out in the future, even now

Any questions, fire away.

- John

First off, thank you!

1) Both the male pins on the MAF plug, sockets females, possibly even the wires going to the plug, do a wiggle test, moving the wires with engine running, see if it clears up things at all. Didn't seem to change things at all.

2) Remove/clean/inspect your IAT (Intake Air Temp) sensor? It’s round, and between the MAF & filter on the CAI. I understand the '02+ have the IAT combined with the MAF and mine appears to be so.

3) Did you inspect MAF’s coils to verify there was no media captured on/within its coil(s)? (Had a small piece off crud in one, drove me nuts once before). Yes, coils looked good.

4) Did you clean the MAF with MAF cleaner (CRC MAF cleaner)?. Other products may leave a film or residue & further complicates the issue. Yes, I used CRC, twice, to no avail.

5) Any codes appear by hooking up a Scan-tool & Data logging with..freeze frame data will catch potent Yes, a couple of times...P0193, P0113 and P0102, which don't surprise me.

6) Sometimes “clocking” , or rotating the MAF may help, rotate it in 10-15 degree increments may help incoming air strike the MAF more effectively. you may carefully do this with motor running, or mark, tighten, star, drive. Again, not possible on '02+

7) COP’s, 4 Coil packs, single Coils may not fail completely but manifest as a weak spark. Input wires may also. How strong is your spark.. Haven't specifically checked it but just replaced plugs & wires and it was running strong previously.

Pull & clean your EGR with MAF cleaner, or equivalent. I will do this next.

I just replaced the MAF and will run it a day or two to see if things settle down.

1) Both the male pins on the MAF plug, sockets females, possibly even the wires going to the plug, do a wiggle test, moving the wires with engine running, see if it clears up things at all. Didn't seem to change things at all.

2) Remove/clean/inspect your IAT (Intake Air Temp) sensor? It’s round, and between the MAF & filter on the CAI. I understand the '02+ have the IAT combined with the MAF and mine appears to be so.

3) Did you inspect MAF’s coils to verify there was no media captured on/within its coil(s)? (Had a small piece off crud in one, drove me nuts once before). Yes, coils looked good.

4) Did you clean the MAF with MAF cleaner (CRC MAF cleaner)?. Other products may leave a film or residue & further complicates the issue. Yes, I used CRC, twice, to no avail.

5) Any codes appear by hooking up a Scan-tool & Data logging with..freeze frame data will catch potent Yes, a couple of times...P0193, P0113 and P0102, which don't surprise me.

6) Sometimes “clocking” , or rotating the MAF may help, rotate it in 10-15 degree increments may help incoming air strike the MAF more effectively. you may carefully do this with motor running, or mark, tighten, star, drive. Again, not possible on '02+

7) COP’s, 4 Coil packs, single Coils may not fail completely but manifest as a weak spark. Input wires may also. How strong is your spark.. Haven't specifically checked it but just replaced plugs & wires and it was running strong previously.

Pull & clean your EGR with MAF cleaner, or equivalent. I will do this next.

I just replaced the MAF and will run it a day or two to see if things settle down.

08GT500

5 Year Member

Hi Paul,

I must apologize for my lapse in responding, left my I phoneXs on the roof of my Car, just received parts- thank god for Digi-Key for components & AppleGate for Apple parts. Repl.screen, LCD & broken (crushed) S. Mount vertical deflection FET, Cap’s.54$.

Wasn’t pretty...found it a mile away from from where I was. lol.

Clocking the MAF....

Ok...I’m not certain how the new MAF worked out, seemed suspicious but I’ll continue from where we were..

You can clock your MAF if flanged, in 90 degree increments, better yet I should’ve mentioned there’s an adapter made I usually run, however- if it wasn’t changed, ran right before- i’ll Nix that for now.

Plugs wires and coils.

Uncertain if you had done routine maintenance prior to the anomaly, or a failure reinforced with an abnormal test based on a calibrated instrument as a precursor to replacement, or replaced some typical(s) with new parts, I’ll caution against this if the latter, unconfirmed- I’m guilty, did it before in a pinch, this is why I don’t go to Vegas to gamble. lol!

It may create new issues more often than not. Is advise against ever throwing parts at an issue(Worse, not OE) I’ll guess you had reason, don’t strike me as one of “them”, lol. (I don’t have a money Tree, don’t think you do, if you know one that does, I’m in the market for a good Treeling. I’ll start with a 5$ one, not greedy.. i’ll work my way up ).

).

If you have old parts swapped out that worked, testing & reinstalling is an idea.

IAT Integration into the MAF.

Your Mustang has the (6) pin MAF and is, in one sensor. Some still split it back off to (2) sensors. It’s a common issue, whether (1) or (2) sensors. As you’re stock in this aspect, if needed, we can take voltage readings from the MAF plug, see if they’re in range, check in parallel while operating, most often occurrence is a wire breakage within, or spray out the connector with electrical contact cleaner, bend the pins slightly, add ‘anti-ox’ to tighten the contact points & decrease high resistance connections.

I’ve also noted routing the MAF harness near Alternator & it’s wiring may cause interference issues As you know already, a very sensitive area.

Low temperature 02 results in a high signal voltage. When the PCM sees a signal voltage higher than 5 volts, throws a P0113. With the manifold exhaust leak you’d had, I’d keep an eye out for that upstream 02. May be slightly damaged, vulnerable (testing an 02 with a VOM on Resistance will destroy it). Best bet is Scantool, watch it.. streaming. If Correcting + to -, good. If it pegs.. not so good.

Cut to the chase...

As your issue is specific to open loop temperature, and the MAF test did what it shouldn’t, as you deduced, I’m thinking

1) MAF

2) The fuel rail pressure transducer.(Data posted).

3) Pump’s check valve not holding pressure for the next cold start.

4) Coolant temperature sensor, a low reading due to air in the System, low coolant.

Or wiring, grounds to all the above.These can all be verified, first.

A quick & handy DX test on both a diaphragm (OBD-1) & combo electrical/Vac (OBD-2) Rail Pressure regulator/Switch, and a returnless F.Pressure sensor, O2 test:

(OBD-2) If an 02 seems lazy watching it’s live Data, try to determine if the sensor is accurately reading the exhaust or not. Remove the fuel pressure regulator vacuum line briefly. The 02 sensor reading should jump rich, reacting to the extra fuel. Reinstall regulator line. Then remove a vacuum supply line from the intake manifold. 02 sensor reading should jump lean, reacting to the unburnt exhaust. If the sensor operates properly, then the sensor may be okay and the problem may be an exhaust leak or vacuum leak unaccounted for by the MAF, Unmetered vacuum leaks at the engine are almost always accompanied by lean codes.

Again, apologize for the delay. Clipped this phone to me now like it’s a pacemaker. Good luck!

Best!

-John

I must apologize for my lapse in responding, left my I phoneXs on the roof of my Car, just received parts- thank god for Digi-Key for components & AppleGate for Apple parts. Repl.screen, LCD & broken (crushed) S. Mount vertical deflection FET, Cap’s.54$.

Wasn’t pretty...found it a mile away from from where I was. lol.

Clocking the MAF....

Ok...I’m not certain how the new MAF worked out, seemed suspicious but I’ll continue from where we were..

You can clock your MAF if flanged, in 90 degree increments, better yet I should’ve mentioned there’s an adapter made I usually run, however- if it wasn’t changed, ran right before- i’ll Nix that for now.

Plugs wires and coils.

Uncertain if you had done routine maintenance prior to the anomaly, or a failure reinforced with an abnormal test based on a calibrated instrument as a precursor to replacement, or replaced some typical(s) with new parts, I’ll caution against this if the latter, unconfirmed- I’m guilty, did it before in a pinch, this is why I don’t go to Vegas to gamble. lol!

It may create new issues more often than not. Is advise against ever throwing parts at an issue(Worse, not OE) I’ll guess you had reason, don’t strike me as one of “them”, lol. (I don’t have a money Tree, don’t think you do, if you know one that does, I’m in the market for a good Treeling. I’ll start with a 5$ one, not greedy.. i’ll work my way up

If you have old parts swapped out that worked, testing & reinstalling is an idea.

IAT Integration into the MAF.

Your Mustang has the (6) pin MAF and is, in one sensor. Some still split it back off to (2) sensors. It’s a common issue, whether (1) or (2) sensors. As you’re stock in this aspect, if needed, we can take voltage readings from the MAF plug, see if they’re in range, check in parallel while operating, most often occurrence is a wire breakage within, or spray out the connector with electrical contact cleaner, bend the pins slightly, add ‘anti-ox’ to tighten the contact points & decrease high resistance connections.

I’ve also noted routing the MAF harness near Alternator & it’s wiring may cause interference issues As you know already, a very sensitive area.

Low temperature 02 results in a high signal voltage. When the PCM sees a signal voltage higher than 5 volts, throws a P0113. With the manifold exhaust leak you’d had, I’d keep an eye out for that upstream 02. May be slightly damaged, vulnerable (testing an 02 with a VOM on Resistance will destroy it). Best bet is Scantool, watch it.. streaming. If Correcting + to -, good. If it pegs.. not so good.

Cut to the chase...

As your issue is specific to open loop temperature, and the MAF test did what it shouldn’t, as you deduced, I’m thinking

1) MAF

2) The fuel rail pressure transducer.(Data posted).

3) Pump’s check valve not holding pressure for the next cold start.

4) Coolant temperature sensor, a low reading due to air in the System, low coolant.

Or wiring, grounds to all the above.These can all be verified, first.

A quick & handy DX test on both a diaphragm (OBD-1) & combo electrical/Vac (OBD-2) Rail Pressure regulator/Switch, and a returnless F.Pressure sensor, O2 test:

(OBD-2) If an 02 seems lazy watching it’s live Data, try to determine if the sensor is accurately reading the exhaust or not. Remove the fuel pressure regulator vacuum line briefly. The 02 sensor reading should jump rich, reacting to the extra fuel. Reinstall regulator line. Then remove a vacuum supply line from the intake manifold. 02 sensor reading should jump lean, reacting to the unburnt exhaust. If the sensor operates properly, then the sensor may be okay and the problem may be an exhaust leak or vacuum leak unaccounted for by the MAF, Unmetered vacuum leaks at the engine are almost always accompanied by lean codes.

Again, apologize for the delay. Clipped this phone to me now like it’s a pacemaker. Good luck!

Best!

-John

1. I realized I posted this in the wrong forum; it should be in the V6, not V8 forum; my apologies. However, maybe that's why it got your attention?

2. This really isn't making any sense to me. First it was really occurring in open loop, but now only in closed. My <limited> understanding was that if the MAF (or anything else, for that matter) was throwing an error (or, disconnected), the car would then revert to open loop and just run the preassigned program. If that's the case, it would seem to point towards a fuel delivery issue, it would seem to me (?)

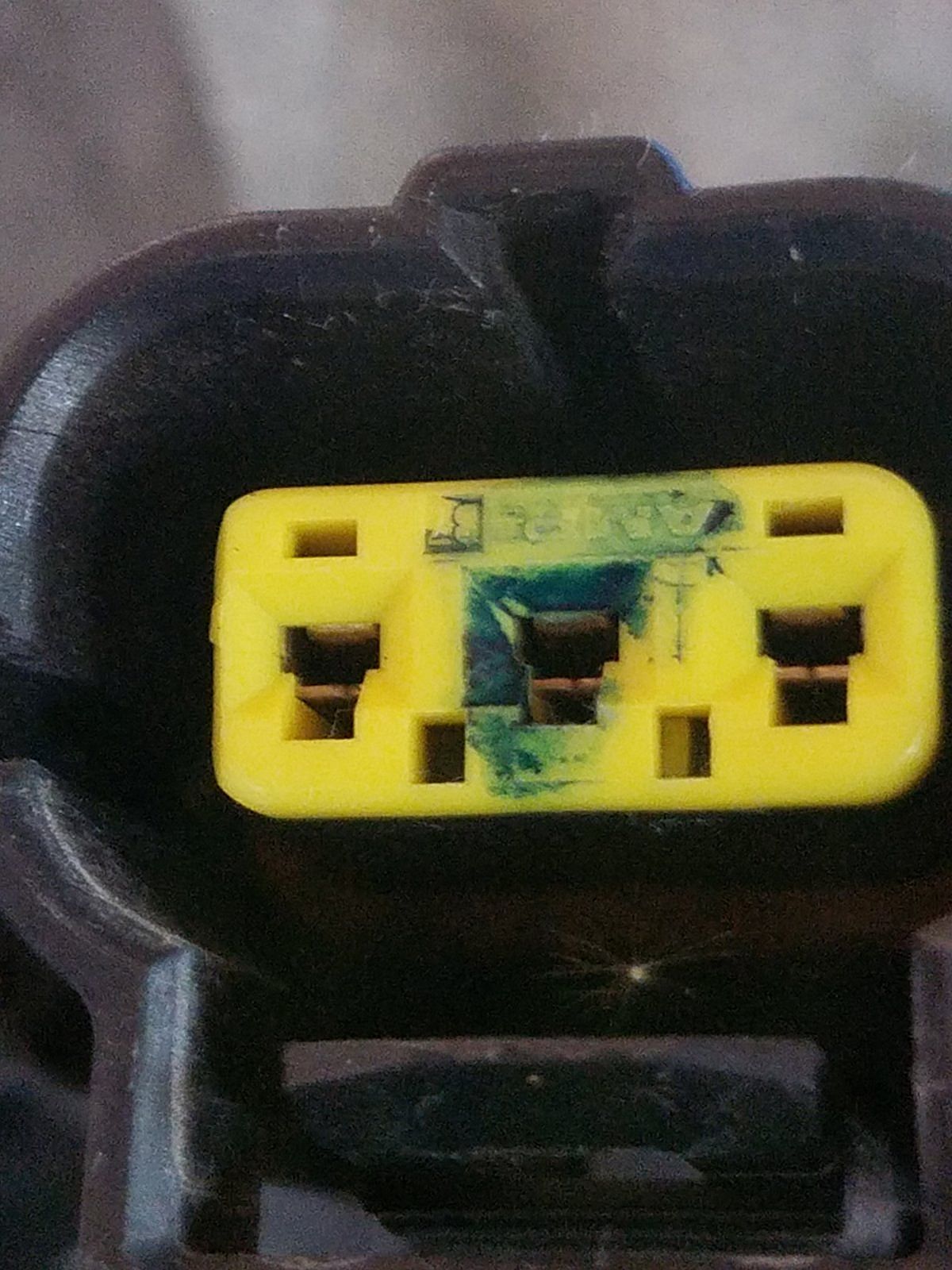

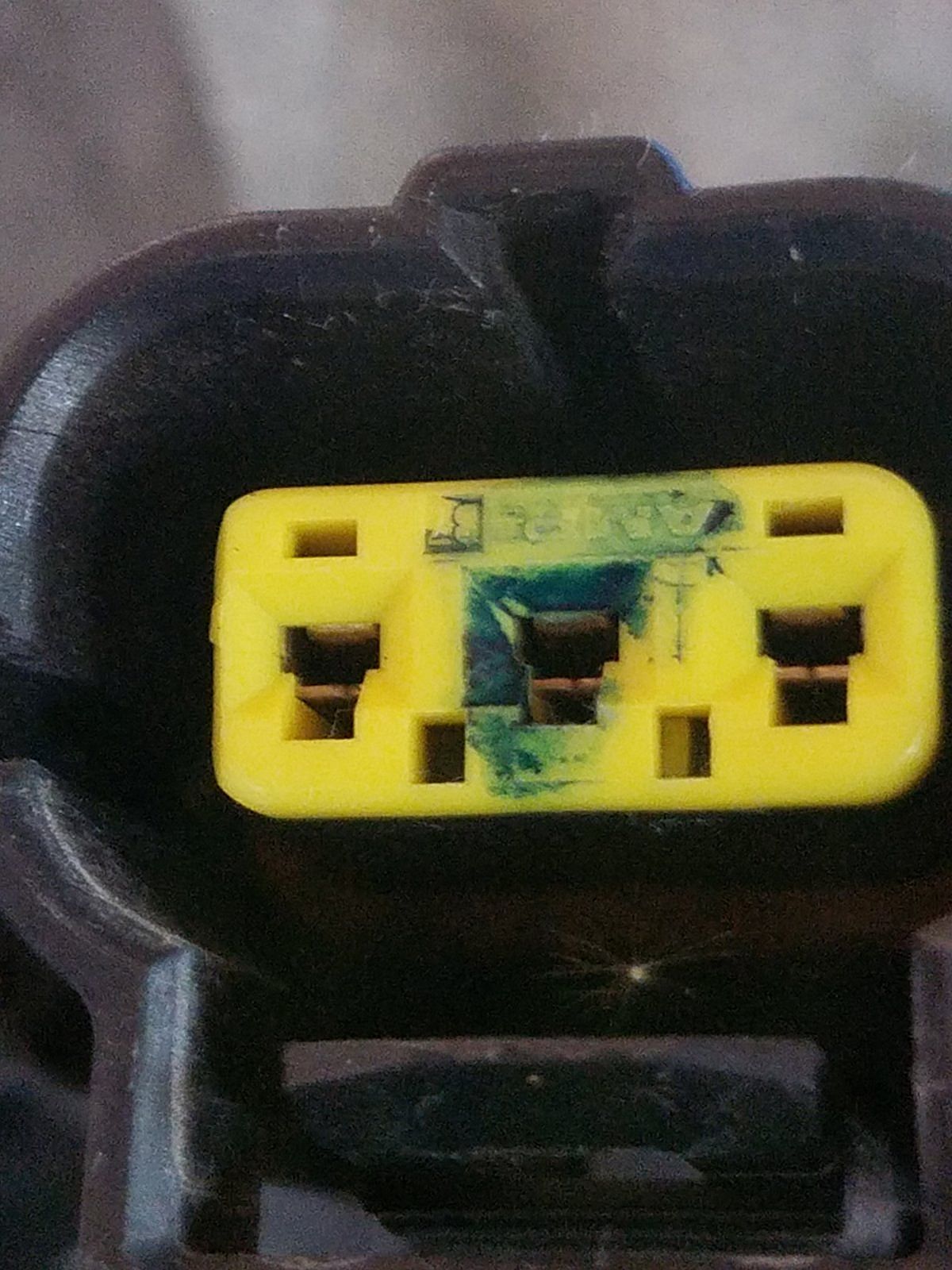

I went through and examined all of the wiring, jiggled connections and only found one that was suspect and it was the FPRS. When I disconnected it, it had a weird green color on/around the middle pin:

It appeared to be as if someone intentionally 'painted' it as I also noticed two short stripes of what likely was the same color 'paint' on the fuel line itself. I tried to clean that off the plug w/out getting anything into it, so it's about 60% gone. I put it back and now the only time the car acts up has been in closed loop, about 20 minutes down the road (it's happened twice in the same spot on the freeway, but did not happen on my last test drive).

The symptoms have diminished considerably (90%?), but I still feel it occasionally, but very minor. I'm trying to get a good readout on my OBD2 when it's acting up. I've been trying to monitor the O2 sensors (especially bank1, sensor1 since that's where the leak occurred), MAF flow, engine RPM, throttle position...what would you like to see to help determine?

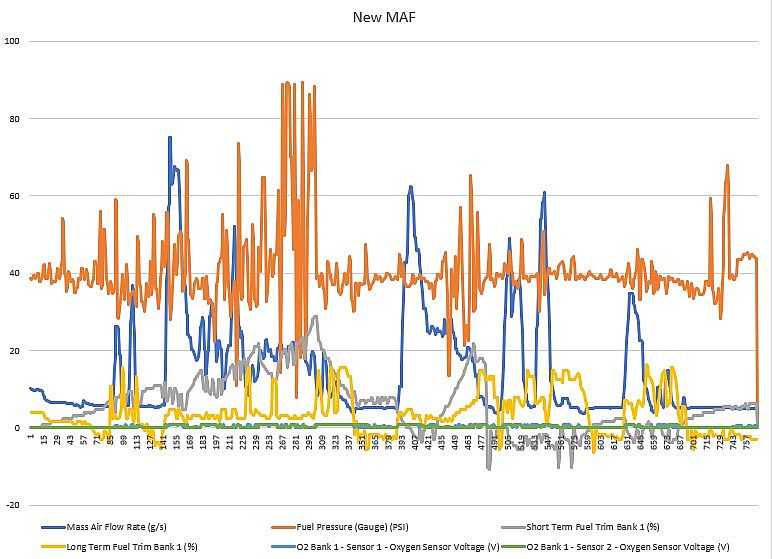

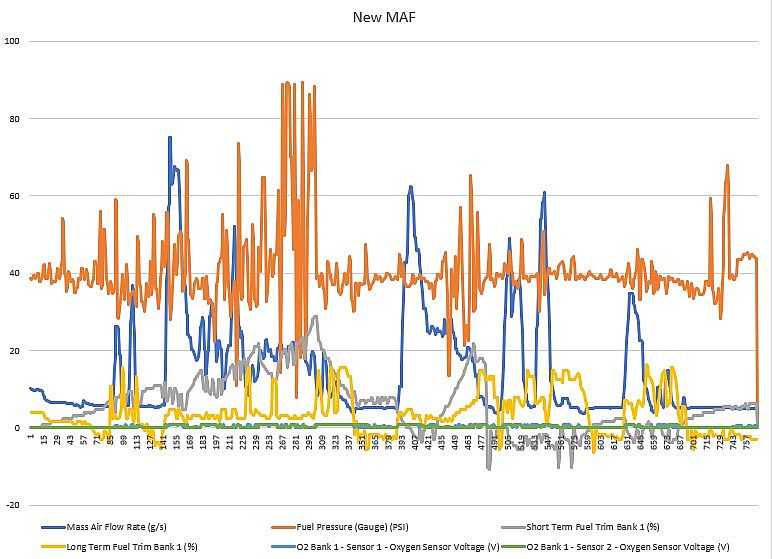

As you can see in my two charts, it doesn't appear that the O2s are lazy (attached; one w/old MAF, one w/new MAF, same day, 3 hours apart):

2. This really isn't making any sense to me. First it was really occurring in open loop, but now only in closed. My <limited> understanding was that if the MAF (or anything else, for that matter) was throwing an error (or, disconnected), the car would then revert to open loop and just run the preassigned program. If that's the case, it would seem to point towards a fuel delivery issue, it would seem to me (?)

I went through and examined all of the wiring, jiggled connections and only found one that was suspect and it was the FPRS. When I disconnected it, it had a weird green color on/around the middle pin:

It appeared to be as if someone intentionally 'painted' it as I also noticed two short stripes of what likely was the same color 'paint' on the fuel line itself. I tried to clean that off the plug w/out getting anything into it, so it's about 60% gone. I put it back and now the only time the car acts up has been in closed loop, about 20 minutes down the road (it's happened twice in the same spot on the freeway, but did not happen on my last test drive).

The symptoms have diminished considerably (90%?), but I still feel it occasionally, but very minor. I'm trying to get a good readout on my OBD2 when it's acting up. I've been trying to monitor the O2 sensors (especially bank1, sensor1 since that's where the leak occurred), MAF flow, engine RPM, throttle position...what would you like to see to help determine?

As you can see in my two charts, it doesn't appear that the O2s are lazy (attached; one w/old MAF, one w/new MAF, same day, 3 hours apart):

08GT500

5 Year Member

Hi Paul,

Hope you’re doing well.

I’m comfortable with and enter all help threads, categories, topics, 60’s to 2016, 4Cyl, I-6, V6, V8 Cyl, Carb, EFI, F.I. I do look at issues people may prevent one from getting to work, hurting the.car- quickly, to save them some money from taking it to a shop, but helping others how I can is why I do it.

I’d realized your car wasn’t an SN95, 2nd Text, V-6 to V-8 control systems, returnless fuel systems, sensors operate much the same.

Soo, the connector I’d noted was expanded slightly, and corroded on the FPRS, looks like possibly that blue Maybe a chemical used in attempt to improve the connection? Is the connector plug retainer snapped to snap the 2 together, or is it OK?

Almost looks like blue loctite, lol. As pictured, there’s significant corrosion on that middle upper female connector, were you able to remove it? If you have a needle file, you could remove that and expose the surface underneath.

A few flat passes with flat blade x-acto razors gently, not gouging (media is not going to enter the fuel rail).,Anti corrosive will help, along with slightly bending to ensure no intermittent connection.

Are you still getting any CEL’s or CPU codes with your Scantool? I’’d think your fuel pressure/rail codes are gone,

Are you running a CAI? Either way I’d do a quick test of how tight everything beyond the MAF is, every intake line and the intake Tube connections, themselves. Just a quick run through of any unmonitored MAF air making its way in.

Can you do a text sheet readout, rather than a graph) of how it’s running now, & are you able to do a drive cycle, whereas if a CEal pops it’ll log all the info before and after, it’ll show what caused the CEL to trigger.

If that’s not possible, I’ll delve into this later today, near 4AM, wanted to

ask about codes

1) How does the motor run when you note an issue as described? It’s intermittent, 2) DIDNT occur last time you drove it- how does the motor react?

3) Can you do a drive cycle monitor, if so, that anomaly described will show. the anomaly you’re picking up.

4) Does the motor have the power it always did, any hesitation, last full tank cycle of fuel, when was any added last? Run the highest octane you have, I.e. 93, or 91.

5) When you click for leaks in the intake, spray the butterfly (CRC) if it’s carbonized, and it’s bore.

6) Car Idle smoothly, any vibration in the steering wheel, or sitting in to 2,500Rpm’s

7) Air filter cleaned recently? If a reusable K&N, was it re-oiled?

(Ok, i’ll read the other info when you type it up, make a solid plan from there for the most useful testing I can view, need it under a load,. What do you have for Scantools, and are you running a Tune of any kind over the OEM program?.

Tall to you later, keep in mind. there’s a time period that the CPU may take a bit to relearn.

Talk to you later-k? Good luck!

P.S. See if you may perform a drive

cycle test, or a ‘snapshot’.

Can you snap a pic of the motor? 1 passenger engine side front to back, another from the drivers side. If you can, it’ll make things a bit easier.

Take care!

John

Hope you’re doing well.

I’m comfortable with and enter all help threads, categories, topics, 60’s to 2016, 4Cyl, I-6, V6, V8 Cyl, Carb, EFI, F.I. I do look at issues people may prevent one from getting to work, hurting the.car- quickly, to save them some money from taking it to a shop, but helping others how I can is why I do it.

I’d realized your car wasn’t an SN95, 2nd Text, V-6 to V-8 control systems, returnless fuel systems, sensors operate much the same.

Soo, the connector I’d noted was expanded slightly, and corroded on the FPRS, looks like possibly that blue Maybe a chemical used in attempt to improve the connection? Is the connector plug retainer snapped to snap the 2 together, or is it OK?

Almost looks like blue loctite, lol. As pictured, there’s significant corrosion on that middle upper female connector, were you able to remove it? If you have a needle file, you could remove that and expose the surface underneath.

A few flat passes with flat blade x-acto razors gently, not gouging (media is not going to enter the fuel rail).,Anti corrosive will help, along with slightly bending to ensure no intermittent connection.

Are you still getting any CEL’s or CPU codes with your Scantool? I’’d think your fuel pressure/rail codes are gone,

Are you running a CAI? Either way I’d do a quick test of how tight everything beyond the MAF is, every intake line and the intake Tube connections, themselves. Just a quick run through of any unmonitored MAF air making its way in.

Can you do a text sheet readout, rather than a graph) of how it’s running now, & are you able to do a drive cycle, whereas if a CEal pops it’ll log all the info before and after, it’ll show what caused the CEL to trigger.

If that’s not possible, I’ll delve into this later today, near 4AM, wanted to

ask about codes

1) How does the motor run when you note an issue as described? It’s intermittent, 2) DIDNT occur last time you drove it- how does the motor react?

3) Can you do a drive cycle monitor, if so, that anomaly described will show. the anomaly you’re picking up.

4) Does the motor have the power it always did, any hesitation, last full tank cycle of fuel, when was any added last? Run the highest octane you have, I.e. 93, or 91.

5) When you click for leaks in the intake, spray the butterfly (CRC) if it’s carbonized, and it’s bore.

6) Car Idle smoothly, any vibration in the steering wheel, or sitting in to 2,500Rpm’s

7) Air filter cleaned recently? If a reusable K&N, was it re-oiled?

(Ok, i’ll read the other info when you type it up, make a solid plan from there for the most useful testing I can view, need it under a load,. What do you have for Scantools, and are you running a Tune of any kind over the OEM program?.

Tall to you later, keep in mind. there’s a time period that the CPU may take a bit to relearn.

Talk to you later-k? Good luck!

P.S. See if you may perform a drive

cycle test, or a ‘snapshot’.

Can you snap a pic of the motor? 1 passenger engine side front to back, another from the drivers side. If you can, it’ll make things a bit easier.

Take care!

John

FPRS; fits snugly, not broken in any way. I'd also thought of Loctite(!) or a dielectric grease, but it sure looks like it was painted on the rail also. I'll work on cleaning it up further.

It was not throwing any CELs, until I just ran it again this morning (taking son to school). Pulled codes and, guess what? Yep, P0193, FRPS High. By Jove, I think we've found it!

Motor runs well, no power loss when no issue present; when I have the issue, it also runs well, except for the intermittent nature of what feels like fuel cutoff.

Did two drive cycles, issue appeared both times, data attached.

Car idles fine, no vibration in wheel.

Air filter replaced about 3 months ago.

OBD2 is MyBlueDriver, no tune over OEM.

CPU may take a bit to relearn...that's why I've been delayed in responding earlier, giving it time to settle in, but it's been long enough now.

It was not throwing any CELs, until I just ran it again this morning (taking son to school). Pulled codes and, guess what? Yep, P0193, FRPS High. By Jove, I think we've found it!

Motor runs well, no power loss when no issue present; when I have the issue, it also runs well, except for the intermittent nature of what feels like fuel cutoff.

Did two drive cycles, issue appeared both times, data attached.

Car idles fine, no vibration in wheel.

Air filter replaced about 3 months ago.

OBD2 is MyBlueDriver, no tune over OEM.

CPU may take a bit to relearn...that's why I've been delayed in responding earlier, giving it time to settle in, but it's been long enough now.

Attachments

Last edited:

08GT500

5 Year Member

Hi Paul,

Superb log info.& pic’s.! Think the blue drops on your fuel system bolts are Afterlock, Loctite 290, factory uses it. Can retain preinstalled bolts.

Uncertain whether that’s in your connector, or it’s some other compound added to help that connection, a little acetone on a q-tip should do the trick.

LMR sells FPRS connectors you can solder & shrink in, if the plug’s pins are are also questionable..

The center FPRS pin appears as though it got hot, or the last owner tried tightening it up, whatever they’d done, the connection was indisputably lacking, ticking away...

The numerical values of your log helped immensely, can see the drop off in both, cascading events also correctly respond to/correct the condition, watching the numbers as inverted. Good pics! Clean!

Regardless if this is the only issue or not (likely is), it’s working the pump- hard, and running rich to lean.

I’d think your FDPM is fine, but agree the evidence points at the FPRS itself as the culprit in causing this fuel pressure issue..

An open between the sensor and the ECU, or a wire from the FDPM shorted to ground within the pump wiring, or at the pump may also cause fuel pressures to to run erratic..

As a double check, there’s a quick test I’d typed down below to verify the supporting wiring, voltages as OK. It’s helpful in ruling out other issues, references.

Many also run a 15$ Mech.fuel pressure gauge on the rail. Are helpful & they don’t lie. Something to consider.

FPRS TEST:

1. This is for the wiring at the FPRS .With a VOM, check voltage at the reference Red/Pink (RD/PK) Wire, shows up about 2.2VDC per 30 PSI of fuel pressure.

2. Is Your reference voltage lower than 2V or higher than 4.5V?. Check the Brown/White (BR/WH) input wire to verify it’s 5.0 v.. Your Ground wire is the Grey/Red (GY/RD) wire, check it to the battery to verify it’s a good, solid ground. If feed voltage and ground to the sensor are OK but the FPRS signal output is too high, (generally verifying data log with a Mechanical Gauge, Pressure/Flow test set) it’s likely a faulty FRPS Sensor.

If the voltage on the RD/PK wire is low or abnormal at the sensor, output is high compare to the voltage at pin 63 RD/PK at the ECU connector. If the voltage shows more than 4.5v at the ECU, the wire’s likely partially or fully open between the ECU or FPRS sensor. (There’s also a Junction box that this Pink wire lands in between the FRPS/ECU on the fenderwell, L.H., if I recall). You’ll need to follow it & locate where the issue is by following the wire, if it exists.

5) If one of the wires going to, into or within the tank is grounded out, it may also cause the pump to run full tilt, sporadic, or not at all. If pressure anomaly exists,

Some friendly FYI’s, food for thought, may help to know, someday.

After Fuel pressure’s around 37-40lbs again. If you have any hesitation afterwards, feel free!

Basic version of your Fuel Pump circuit:

The Pink wire from the FRPS goes to the ECU, and based on it’s voltage, the ECU sends a voltage signal to the FDPM to increase/decrease fuel pump speed/output to achieve proper pressure. The FDPM controls the pumps speed/output by sending PWM (Pulse Width Modulated) power down to the pump (It’s just a fancy way of saying it controls the Cycles/Sec (or Hertz), rather than higher or lower Voltage.

A typical VOM will show whether voltage is present or not present in the pump’s wiring, but wont decipher whether the pump’s being commanded to run faster, or slower.

An Oscilloscope, frequency counter is used to read this. The voltage will remain as a solid voltage with a VOM.

- If an FDPM fails, you usually wont even get the initial fuel pump prime.

-It appears as that 02 sensor where the exhaust leak is correcting normally via data logging provided, I’ve viewed logs of stock OBD-2 Mustangs with much less fuel pressure variances that couldn’t even alter injector pulses quick enough to stay running, much less functionally drive, it’s a remarkably healthy Pony from a collaborative systemic standpoint. A fighter.Throw that FRPS in already, lol!

Just wanted to convey the info at the end in, if you ever come across it, you’ll know. Just a friendly FYI.

Hope that helps, Good luck! Keep me posted...

-John

Superb log info.& pic’s.! Think the blue drops on your fuel system bolts are Afterlock, Loctite 290, factory uses it. Can retain preinstalled bolts.

Uncertain whether that’s in your connector, or it’s some other compound added to help that connection, a little acetone on a q-tip should do the trick.

LMR sells FPRS connectors you can solder & shrink in, if the plug’s pins are are also questionable..

The center FPRS pin appears as though it got hot, or the last owner tried tightening it up, whatever they’d done, the connection was indisputably lacking, ticking away...

The numerical values of your log helped immensely, can see the drop off in both, cascading events also correctly respond to/correct the condition, watching the numbers as inverted. Good pics! Clean!

Regardless if this is the only issue or not (likely is), it’s working the pump- hard, and running rich to lean.

I’d think your FDPM is fine, but agree the evidence points at the FPRS itself as the culprit in causing this fuel pressure issue..

An open between the sensor and the ECU, or a wire from the FDPM shorted to ground within the pump wiring, or at the pump may also cause fuel pressures to to run erratic..

As a double check, there’s a quick test I’d typed down below to verify the supporting wiring, voltages as OK. It’s helpful in ruling out other issues, references.

Many also run a 15$ Mech.fuel pressure gauge on the rail. Are helpful & they don’t lie. Something to consider.

FPRS TEST:

1. This is for the wiring at the FPRS .With a VOM, check voltage at the reference Red/Pink (RD/PK) Wire, shows up about 2.2VDC per 30 PSI of fuel pressure.

2. Is Your reference voltage lower than 2V or higher than 4.5V?. Check the Brown/White (BR/WH) input wire to verify it’s 5.0 v.. Your Ground wire is the Grey/Red (GY/RD) wire, check it to the battery to verify it’s a good, solid ground. If feed voltage and ground to the sensor are OK but the FPRS signal output is too high, (generally verifying data log with a Mechanical Gauge, Pressure/Flow test set) it’s likely a faulty FRPS Sensor.

If the voltage on the RD/PK wire is low or abnormal at the sensor, output is high compare to the voltage at pin 63 RD/PK at the ECU connector. If the voltage shows more than 4.5v at the ECU, the wire’s likely partially or fully open between the ECU or FPRS sensor. (There’s also a Junction box that this Pink wire lands in between the FRPS/ECU on the fenderwell, L.H., if I recall). You’ll need to follow it & locate where the issue is by following the wire, if it exists.

5) If one of the wires going to, into or within the tank is grounded out, it may also cause the pump to run full tilt, sporadic, or not at all. If pressure anomaly exists,

Some friendly FYI’s, food for thought, may help to know, someday.

After Fuel pressure’s around 37-40lbs again. If you have any hesitation afterwards, feel free!

Basic version of your Fuel Pump circuit:

The Pink wire from the FRPS goes to the ECU, and based on it’s voltage, the ECU sends a voltage signal to the FDPM to increase/decrease fuel pump speed/output to achieve proper pressure. The FDPM controls the pumps speed/output by sending PWM (Pulse Width Modulated) power down to the pump (It’s just a fancy way of saying it controls the Cycles/Sec (or Hertz), rather than higher or lower Voltage.

A typical VOM will show whether voltage is present or not present in the pump’s wiring, but wont decipher whether the pump’s being commanded to run faster, or slower.

An Oscilloscope, frequency counter is used to read this. The voltage will remain as a solid voltage with a VOM.

- If an FDPM fails, you usually wont even get the initial fuel pump prime.

-It appears as that 02 sensor where the exhaust leak is correcting normally via data logging provided, I’ve viewed logs of stock OBD-2 Mustangs with much less fuel pressure variances that couldn’t even alter injector pulses quick enough to stay running, much less functionally drive, it’s a remarkably healthy Pony from a collaborative systemic standpoint. A fighter.Throw that FRPS in already, lol!

Just wanted to convey the info at the end in, if you ever come across it, you’ll know. Just a friendly FYI.

Hope that helps, Good luck! Keep me posted...

-John

Once again, incredible help, thank you!

I was hoping to update you before you went through all your trouble, but I'm selfishly glad I didn't (not enough run tests to verify yet but...). I replaced the FRPS and in two test drives, it's running flawlessly (yay!!!).

So, it appears that we've solved it (fingers crossed). I'll update you if I have any further negative developments.

Thanks again for all your tremendous help John.

I was hoping to update you before you went through all your trouble, but I'm selfishly glad I didn't (not enough run tests to verify yet but...). I replaced the FRPS and in two test drives, it's running flawlessly (yay!!!).

So, it appears that we've solved it (fingers crossed). I'll update you if I have any further negative developments.

Thanks again for all your tremendous help John.

08GT500

5 Year Member

Hi Paul,

Likewise, Happy to help & glad to hear that’s cleared up. This was an interesting thread.

Datalogging’s an invaluable tool, of great diagnostic value. Don’t see it that often, much less on a thread’s first page.

Don’t believe you need to run back diagnostics at this point, if you datalog the fuel pressure and verify it as stable within OEM parameters, I’m pretty optimistic it’s a done deal, but I never say never, lol!

Good luck, Paul!

- John

Likewise, Happy to help & glad to hear that’s cleared up. This was an interesting thread.

Datalogging’s an invaluable tool, of great diagnostic value. Don’t see it that often, much less on a thread’s first page.

Don’t believe you need to run back diagnostics at this point, if you datalog the fuel pressure and verify it as stable within OEM parameters, I’m pretty optimistic it’s a done deal, but I never say never, lol!

Good luck, Paul!

- John

Similar threads

- Replies

- 3

- Views

- 820

- Replies

- 2

- Views

- 776

- Replies

- 2

- Views

- 1K

- Replies

- 0

- Views

- 906