This should be in the thread you already started. There is otherwise, no way for folks to know what you've already done.

my apologies. At that point, I took them as completely separate issues (although I'm coming to think that the bad voltage is behind multiple other problems, including the fuel pump protection circuit that led to the new tank, and . . .)

On the 3 wire plug try applying 12v power to the 12v hot in run wire which should be green to see if the rectifier turns on with the engine running....If so you have wiring issues..

I'm not sure which

I've got to do some digesting here, on how an alternator actually functions.

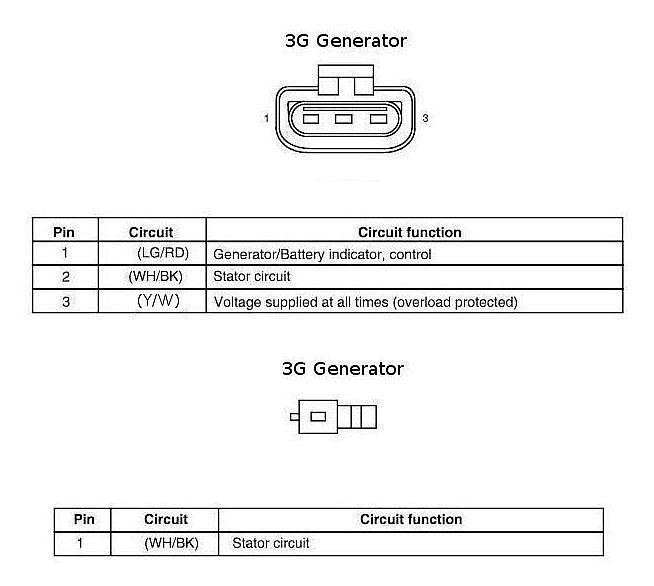

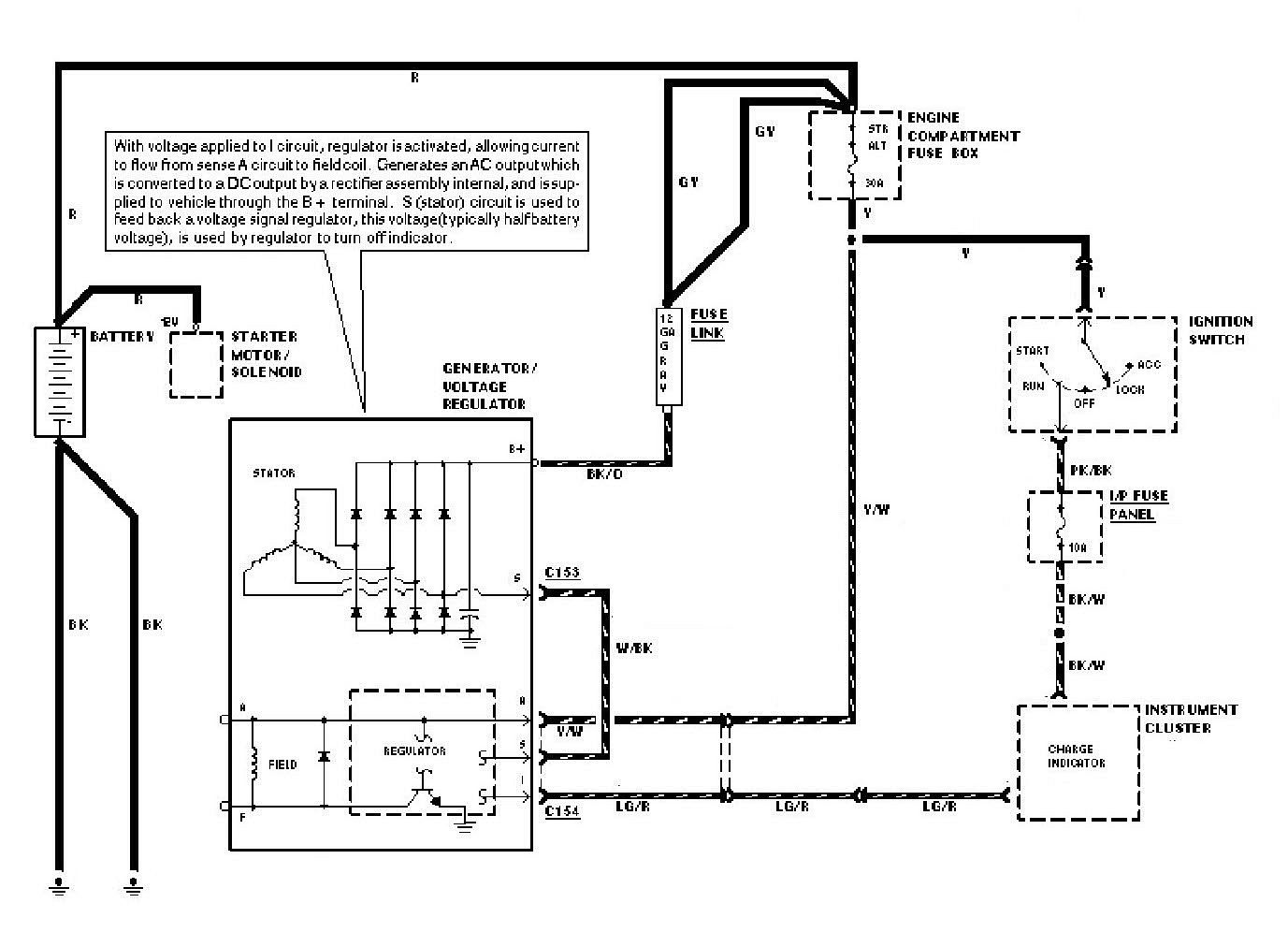

I found these images for the 99 crown Victoria on

https://www.idmsvcs.com/2vmod/alternator/wiring/diagrams/index.html

So is pin 2 W/B the raw alternator output going to the voltage regulator, and available on pin 2 of the voltage regulator circuit?

And regulated current comes out pin 3 Y/W? And is it voltage "at all times" because it connects to the battery by way of the fuse box when off, but would send current back to the battery when the alternator is spinning?

And pin 1 LG/R goes to the battery indicator on the dash?

But if so, is that status from regulator to indicator, or a signal to the regulator to engage?

I suspect the problem is in the headlight harness given the other issues stated........

I'd Pull the harness and unwrap it....If you have a DVOM then you can trace circuits by doing a continuity test.

I have sharp probes coming for my meter on Friday.

So when car is off, I should see 12v on 3 Y/W, and open circuits for the other 2? And 3 LG/R would be ground, such that the indicator on the dash turns on when power is applied by the alternator not running yet?

And when car is on on, 3 Y/W would increase to operating voltage, a bit shy of 14, 2 W/B would be full alternator output of 15-16v.

And 3 LG/R would get operating voltage from the regulator side, which would be the same as the indicator light receives from the other side, causing no voltage drop across the lamp, which would therefore be off?

Or is the voltage passing through from the indicator light telling the alternator to engage the regulator? (so off voltage would still be around battery voltage, with most of the drop across the meter??)

One time a freaky thing happened...I found out the hard way that my alternator was controlled through an idiot light that had a resistor built into the holder and when I changed the lightbulbs to LED it messed with the resistance and messed with the alternators function until I put the correct bulb back in...Even a dead bulb can cause issues as the lightbulb is needed to complete the circuit..

I spent more than a day trying to figure out a heating problem on my '93 Fleetwood. Replacing the thermostat didn't help. And it turned out to be because . . . for reasons comprehensible only to Cadillac engineering, they used a standard thermostat housing coming out of the block, but the "thermostat assembly" or some such is on the bottom of the other side of the block. That housing should be empty, and my problems came about because someone had stuck a thermostat in, which later failed . . .

So if you turn the key to the ON position and you dont see this you may have an issue there...Plug B on the gauge panel pins 2 nd 14 are the ones of interest on most mustangs..

Is that plug in the engine compartment, or undertake dash? and can it be accessed without "heroic" measures like pulling the console (which I already need to do for the heater core).

They sell harness wrap on Amazon cheap and is way better to rewrap a harness with than using ooey gooey vinyl electrical tape..

I have some coming from Walmart today or tomorrow. I dumped amazon prime when I discovered that my neighborhood gets noticeably faster delivery from Walmart, and at the same or lower cost.

The ignition switch turns the alternator regulator on too..Depending on the year the wire is green and could also be red.

so I should get close to battery voltage from the plug when disconnected?

As you can see theres a spot in the tune where the ECU controls the alternator too.......

great

Good Luck

thanks. I'll poke as much as I can before my leads get here.

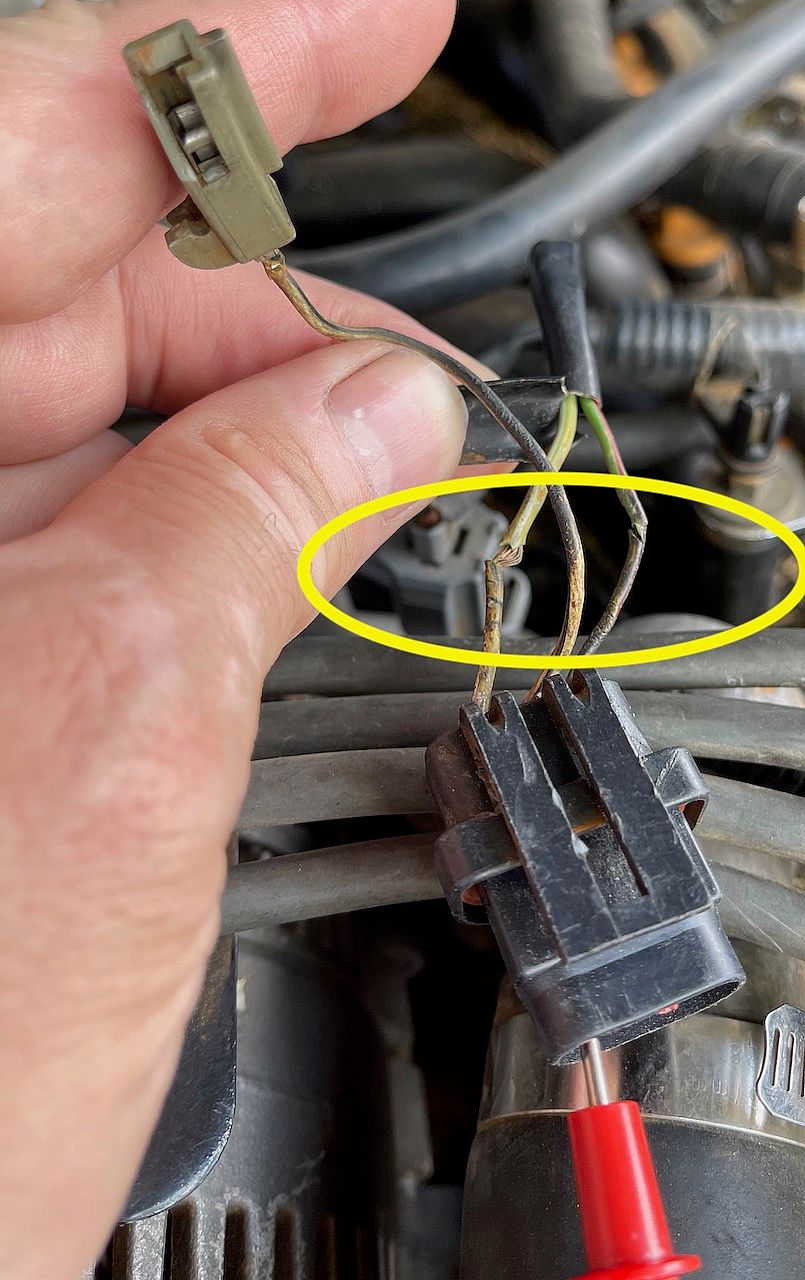

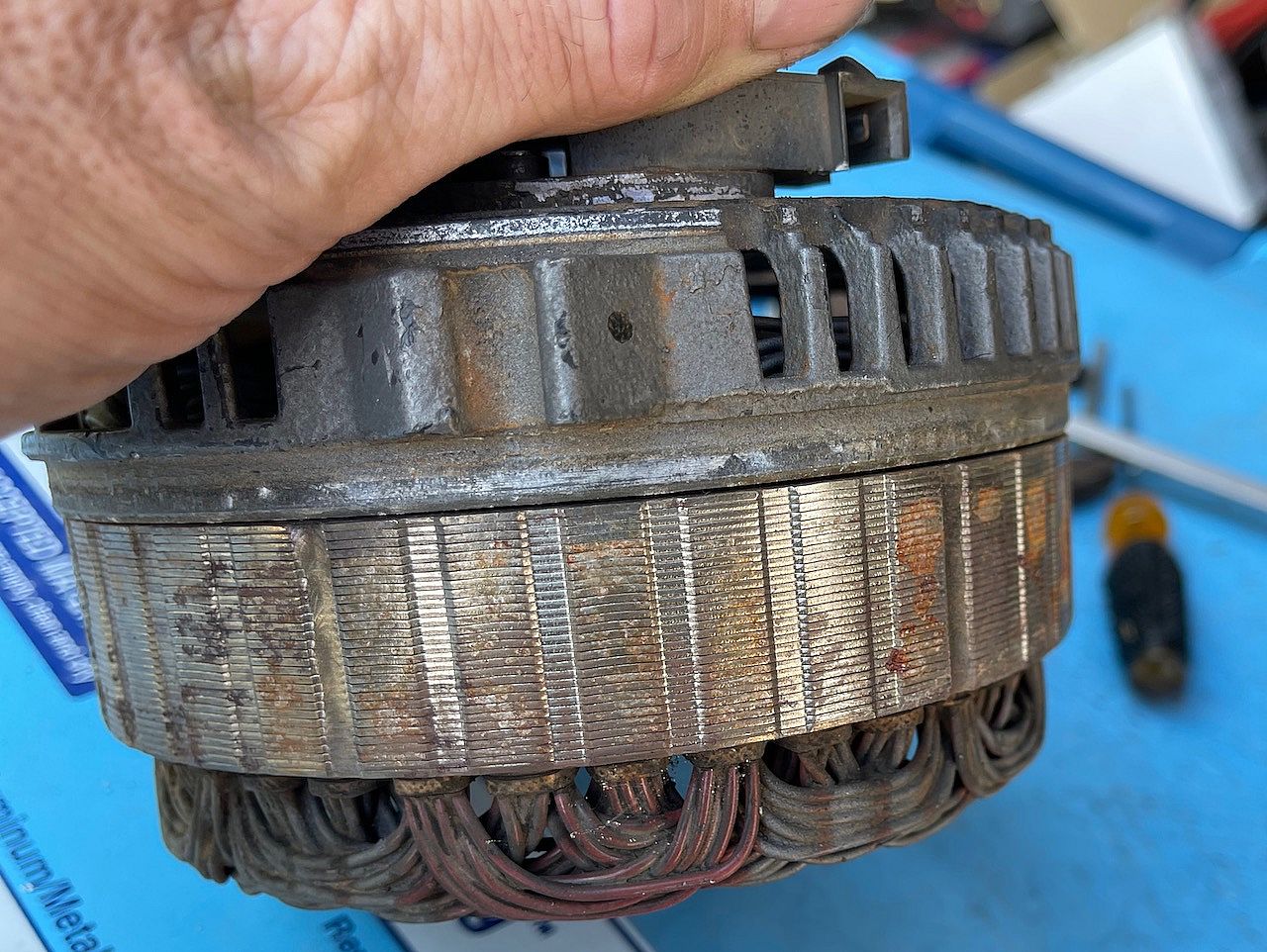

Oh, and the wiring on the plug doesn't look so good . . .

for that matter, should the wire from that middle pin be connected somewhere?

thanks

and one more question: is there a way to test the voltage regulator I removed out of circuit? everything I'm finding is just to check the system voltage.