I have gone through the surging idle checklist over and over. I'm pulling my hair out and wasting so much time!

1990 Mustang GT. Stock engine except roller rockers, kenne bell supercharger, cold air intake, new accel injectors and timing chain, MSD billet distributor, MSD coil, Flex-a-Lite cooling module.

Here's what I know:

Intermittent Code 96: Cant locate or find the problem! Code definitions vary from secondary power circuit as the problem. Or, power to the ECU. And, possibly the primary circuit but this should set a code 95 from what I know. Checked all circuits and am not finding anything.

Engine sporaticaly misses and runs rough when timing light is transferred to different plug wires. Took MSD super conductor wires off ... seems to run just a hair better. Still have MSD coil on it but may change back to stock on that too. All brand new stuff.

Engine is down on the vacuum gauge averaging about 14 in hg. As I go up some inclines it drops to just about zero but cruises at 18-20 no load. And on decel it goes up to 22-23 from what i recall.

*********************************************************************

Timing set @ 8 degrees BTDC as per Kenne Bell with 93 octane gas.

HEGO - 3.6 Ohms between heater (spec calls for 2-5 Ohms). Have battery voltage with key "on" harness side (disconnected) between power wire and I believe signal return wire as book says I should have. Sensors were replaced 2 years ago and have about 5,000 miles on them

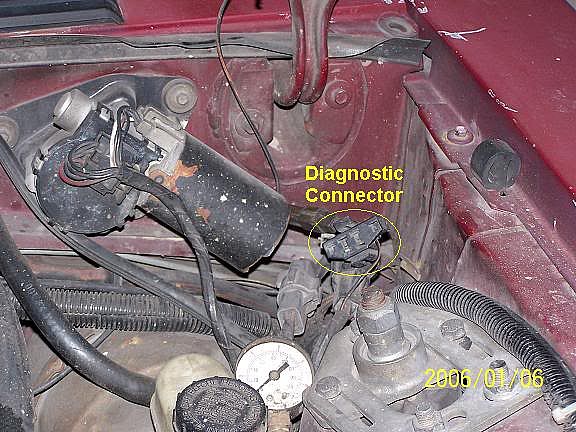

Bat ground to test connector "signal return" wire - 1.6 ohms

Bat ground to TPS - 1.6 ohms

Bat ground to ECT 1.7 ohms

Bat ground to EGR - 1.6 ohms

Bat ground to ACT - can't get to it ... under supercharger ... just replaced ACT ... checked circuit when supercharger was off and it was okay. no codes relating to this.

ECT Ohms out and matches temp/resistance chart in my book at whatever temp the motor is.

Ign/Key On

IAC - battery voltage on one wire - return wire showed .55 volts.

TPS - VREF wire shows 4.97 volts. TPS voltage setting .96 volts

EGR - VREF wire shows 4.97 volts couldn't get to other wires ... no egr codes

ECT - VREF wire shows 4.68 volts ... return wire shows .08 volts measuring with the connector off. With connector on VREF was around 2.1 volts due to the resistance. This voltage reading checked out with chart in my book.

MAP/BP

Connector disconnected: Measured 5.0 volts on MAP/BP signal wire and 5.0 volts on VREF. IS THIS CORRECT WITH THE CONNECTOR DISCONNECTED?

Checked pins 20, 40, 60, 46, and a few other pins on 60 pin connector to BAT ground ... not more than 2 ohms. All injectors showing BAT voltage on 60 pin connector.

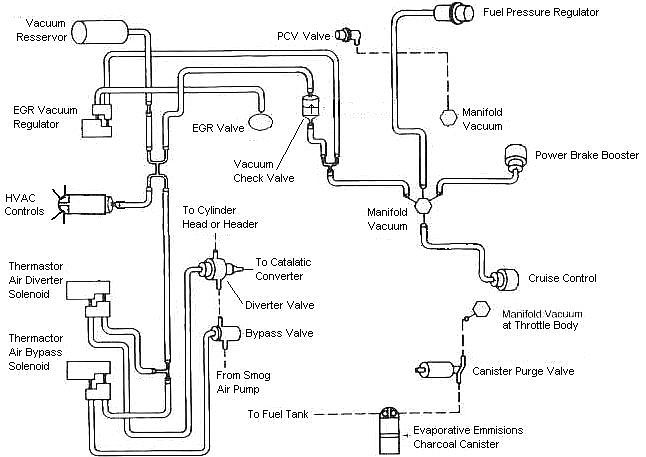

Checked for vacuum leaks, cant find any. Disconnected all lines .. no vacuum change. Checked with propane nothing ... though with supercharger on motor, its almost impossible to check manifolds etc. except near front of motor. Cleaned EGR valve, MAF sensor, and IAC valve numerous times. Reset idle several times. Just barely idles with IAC disconnected sometimes cuts out.

Fuel pressure checked: 32 psi w/vacuum and 39 w/out vacuum or possibly 42 (its been awhile. Pressure was steady and system holds pressure as it should. New fuel pump and regulator installed two years ago including new gas tank.

Compression test done measure fairly uniform around 120-125 psi one was 115 psi using a Harbor Freight gauge. Leakdown test showed a low leakage rate (not sure what it was but it was good). Pressure tested cooling system ... no leakdown after 20 minutes.

Car runs great other than what is listed above at the top. Just do not understand what is causing these problems. Idle is better after putting 20 year old plug wires back on rather than new MSD wires but still gets bad at idle at redlights or taking off sometimes it spits and sputters. I find it is better to start it and immediately throw it into gear and start driving rather than let it idle and be all choppy. However, at red lights sometimes I find myself throwing it in park to even it out some though it feels like it is still running rough. Normal driving, there is hesitation especially can be felt in overdrive cruising at 45-50 light load.

What else can I do ... feel like I am chasing a chicken with its head cut off but not catching it! I'm great with cars and have a lot of technical expertise on these cars but get some weird problems on my own cars. I do much better at solving other Mustang owners problems ... that is why I have taken the time to give you all of the information I have to date. Any good ideas will certainly be entertained and I look forward to help in resolving this/these conditions.

Oh, I do have a header leak at the collector ... got new headers ... just gotta find the time to install them while going through checking things as I think of them each day. Just got rear-ended by a guy behind me at a redlight who decides to take off into my bumper after he stopped for the red ... idiots. Anyway, I will be fixing the headers and rear bumper but also want to get new ideas and or opinions because I'm out of ideas!!! thank you , in advance for your help!

1990 Mustang GT. Stock engine except roller rockers, kenne bell supercharger, cold air intake, new accel injectors and timing chain, MSD billet distributor, MSD coil, Flex-a-Lite cooling module.

Here's what I know:

Intermittent Code 96: Cant locate or find the problem! Code definitions vary from secondary power circuit as the problem. Or, power to the ECU. And, possibly the primary circuit but this should set a code 95 from what I know. Checked all circuits and am not finding anything.

Engine sporaticaly misses and runs rough when timing light is transferred to different plug wires. Took MSD super conductor wires off ... seems to run just a hair better. Still have MSD coil on it but may change back to stock on that too. All brand new stuff.

Engine is down on the vacuum gauge averaging about 14 in hg. As I go up some inclines it drops to just about zero but cruises at 18-20 no load. And on decel it goes up to 22-23 from what i recall.

*********************************************************************

Timing set @ 8 degrees BTDC as per Kenne Bell with 93 octane gas.

HEGO - 3.6 Ohms between heater (spec calls for 2-5 Ohms). Have battery voltage with key "on" harness side (disconnected) between power wire and I believe signal return wire as book says I should have. Sensors were replaced 2 years ago and have about 5,000 miles on them

Bat ground to test connector "signal return" wire - 1.6 ohms

Bat ground to TPS - 1.6 ohms

Bat ground to ECT 1.7 ohms

Bat ground to EGR - 1.6 ohms

Bat ground to ACT - can't get to it ... under supercharger ... just replaced ACT ... checked circuit when supercharger was off and it was okay. no codes relating to this.

ECT Ohms out and matches temp/resistance chart in my book at whatever temp the motor is.

Ign/Key On

IAC - battery voltage on one wire - return wire showed .55 volts.

TPS - VREF wire shows 4.97 volts. TPS voltage setting .96 volts

EGR - VREF wire shows 4.97 volts couldn't get to other wires ... no egr codes

ECT - VREF wire shows 4.68 volts ... return wire shows .08 volts measuring with the connector off. With connector on VREF was around 2.1 volts due to the resistance. This voltage reading checked out with chart in my book.

MAP/BP

Connector disconnected: Measured 5.0 volts on MAP/BP signal wire and 5.0 volts on VREF. IS THIS CORRECT WITH THE CONNECTOR DISCONNECTED?

Checked pins 20, 40, 60, 46, and a few other pins on 60 pin connector to BAT ground ... not more than 2 ohms. All injectors showing BAT voltage on 60 pin connector.

Checked for vacuum leaks, cant find any. Disconnected all lines .. no vacuum change. Checked with propane nothing ... though with supercharger on motor, its almost impossible to check manifolds etc. except near front of motor. Cleaned EGR valve, MAF sensor, and IAC valve numerous times. Reset idle several times. Just barely idles with IAC disconnected sometimes cuts out.

Fuel pressure checked: 32 psi w/vacuum and 39 w/out vacuum or possibly 42 (its been awhile. Pressure was steady and system holds pressure as it should. New fuel pump and regulator installed two years ago including new gas tank.

Compression test done measure fairly uniform around 120-125 psi one was 115 psi using a Harbor Freight gauge. Leakdown test showed a low leakage rate (not sure what it was but it was good). Pressure tested cooling system ... no leakdown after 20 minutes.

Car runs great other than what is listed above at the top. Just do not understand what is causing these problems. Idle is better after putting 20 year old plug wires back on rather than new MSD wires but still gets bad at idle at redlights or taking off sometimes it spits and sputters. I find it is better to start it and immediately throw it into gear and start driving rather than let it idle and be all choppy. However, at red lights sometimes I find myself throwing it in park to even it out some though it feels like it is still running rough. Normal driving, there is hesitation especially can be felt in overdrive cruising at 45-50 light load.

What else can I do ... feel like I am chasing a chicken with its head cut off but not catching it! I'm great with cars and have a lot of technical expertise on these cars but get some weird problems on my own cars. I do much better at solving other Mustang owners problems ... that is why I have taken the time to give you all of the information I have to date. Any good ideas will certainly be entertained and I look forward to help in resolving this/these conditions.

Oh, I do have a header leak at the collector ... got new headers ... just gotta find the time to install them while going through checking things as I think of them each day. Just got rear-ended by a guy behind me at a redlight who decides to take off into my bumper after he stopped for the red ... idiots. Anyway, I will be fixing the headers and rear bumper but also want to get new ideas and or opinions because I'm out of ideas!!! thank you , in advance for your help!