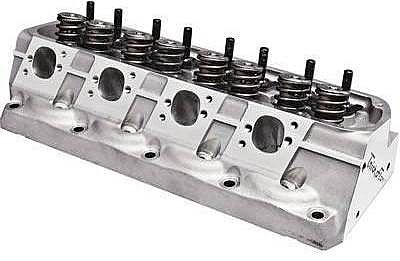

More than any other question I get everyday, "How big should the primaries be on my long tube headers?" is still number one. More than "Are the primaries equal length?", or "Are the headers stainless steel or mild steel?", or even "How much are the Long Tube Headers?" It's a legitimate question, probably based on the theory that if the primaries are too small it will hurt power. I used the word "theory" because in many cases, smaller diameter primaries may boost power. There are many questions that need to be addressed before you decide on the diameter of the primary tubes on a set of headers, such as maximum expected horsepower, is it a race car, a street car, a street/strip car, engine displacement, transmission (stick or automatic), vehicle weight, cylinder head, and on and on. If the engine is a Small Block Ford (289, 302, 351W, etc.) there is typically one common issue, and it's the cylinder head and in particular, the exhaust valve. The stock exhaust valve on the Mustang 5.0L (302) engine is 1.45" in diameter. In the vast majority of aftermarket aluminum cylinder heads, the exhaust valve diameters have been increased to 1.60". This is a pretty big improvement (about 11%), but 1.60" diameter is still smaller than 1 5/8" (which is 1.625"). And we must remember that the exhaust does not flow through a 1.60" diameter hole (the outside diameter of the head of the valve) but through the valve seat, which is probably about 1 1/2" in diameter, which is further reduced by having the stem of the valve in the way. So, the real question should be, "Why would anyone want a primary tube larger in diameter than the initial restriction found around the exhaust valve area?"

Okay, I have not addressed the original question of "how big". If you are interested in this discussion, let me know and I will be more than happy to go into it further and provide some answers...

George Klass - RCI Headers

www.rciheaders.com

(909) 552-3690

[email protected]

Okay, I have not addressed the original question of "how big". If you are interested in this discussion, let me know and I will be more than happy to go into it further and provide some answers...

George Klass - RCI Headers

www.rciheaders.com

(909) 552-3690

[email protected]

Last edited: