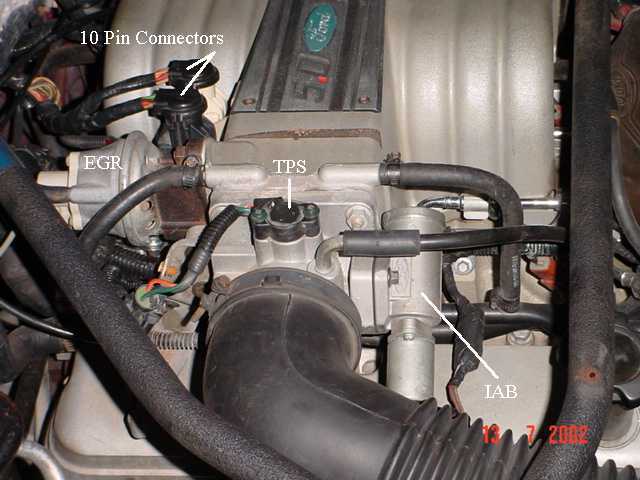

So I had a 65mm frpp throttle body on my covra intake, I did have the so called magic number on it  .98v but from what we all know .50v - .99v is supposed to be fine and within the computer over all final number. Cannot remember what that number is, someone who knows it could verify that number.

.98v but from what we all know .50v - .99v is supposed to be fine and within the computer over all final number. Cannot remember what that number is, someone who knows it could verify that number.

I then bought and installed a 75mm throttle body and put my fairly new tps back on it from the 65mm tb. So i do the .98v just because and it ran very well. So later i adjusted the idle and i had to reset the tps voltage. Problem is, i borrowed my buddies volt meter before and he was outta' town. So my neighbor had one but it didn't show tbe final number, it only showed .7, .8, .9 or 1. So i got it set on .9 just because. But then I drove the car and it ran like a raped ape, it was very noticeable in the powerband and breaks the tires loose way more easier than before. So I was like sh!t, what f@cking tps number is this at cause it was way different than before. So I did look for my own volt meter that I had stored, finally found it a retested that the final number and it came out to .93v. Have no idea what my final WOT number is but f@ck, but .5 volts made a world of difference. So if your bored go test up or down on your set up maybe you'll notice something too. Maybe I'm able to notice it more cause I'm in the 280-300rwhp neighborhood but it was a HUGE difference, makes me wanna go do a dyno again, seriously

but it was a HUGE difference, makes me wanna go do a dyno again, seriously

.98v but from what we all know .50v - .99v is supposed to be fine and within the computer over all final number. Cannot remember what that number is, someone who knows it could verify that number.

.98v but from what we all know .50v - .99v is supposed to be fine and within the computer over all final number. Cannot remember what that number is, someone who knows it could verify that number.I then bought and installed a 75mm throttle body and put my fairly new tps back on it from the 65mm tb. So i do the .98v just because and it ran very well. So later i adjusted the idle and i had to reset the tps voltage. Problem is, i borrowed my buddies volt meter before and he was outta' town. So my neighbor had one but it didn't show tbe final number, it only showed .7, .8, .9 or 1. So i got it set on .9 just because. But then I drove the car and it ran like a raped ape, it was very noticeable in the powerband and breaks the tires loose way more easier than before. So I was like sh!t, what f@cking tps number is this at cause it was way different than before. So I did look for my own volt meter that I had stored, finally found it a retested that the final number and it came out to .93v. Have no idea what my final WOT number is but f@ck, but .5 volts made a world of difference. So if your bored go test up or down on your set up maybe you'll notice something too. Maybe I'm able to notice it more cause I'm in the 280-300rwhp neighborhood

but it was a HUGE difference, makes me wanna go do a dyno again, seriously

but it was a HUGE difference, makes me wanna go do a dyno again, seriously

Last edited: