Don't waste time with taking it to another mechanic, deal with the codes. Clear the codes per my instructions.

If the codes are still present, then here are the code test paths and how to fix them.

Troubleshoot the fuel pump code first; it may the cause of the O2 sensor problems.

The 542 (Fuel pump secondary circuit fault) and 543 (Fuel pump secondary circuit fault) relate to a problem with the fuel pump electrical circuit. Fuel pump monitor circuit shows no power - Fuel pump relay or battery power feed was open - Power / Fuel Pump Circuits. The fuel pump circuit lost power at one time or another.

See the test path and work your way through it to find and fix the problem. Fuel Pump Troubleshooting for 94-95 GT 5.0 Mustangs

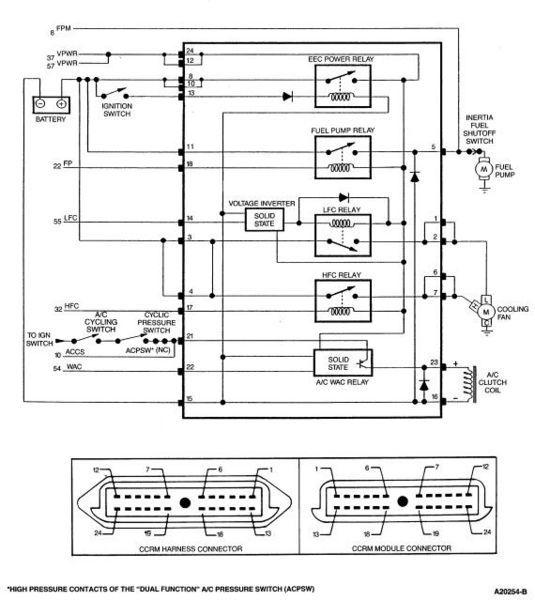

Revised 29-Sep-2014 to add diagrams for CCRM and under hood fuse boxes.

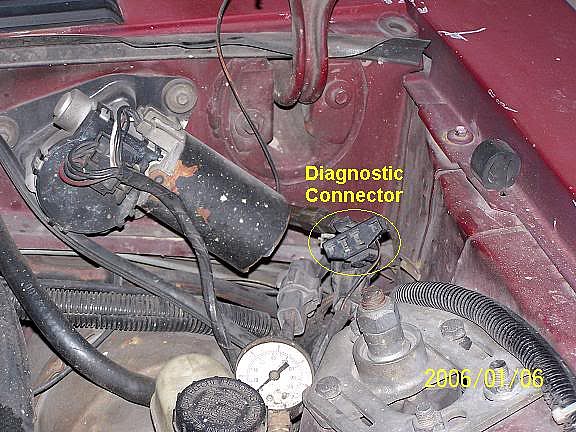

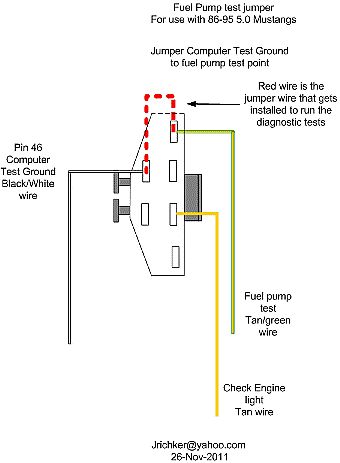

Clue – listen for the fuel pump to prime when you first turn the ignition switch on. It should run for 1-5 seconds and shut off. To trick the fuel pump into running, find the ECC test connector and jump the connector in the lower LH corner to ground.

If the relay & inertia switch are OK, you will have power to the pump. Check fuel pressure – remove the cap from the Schrader valve behind the alternator and depress the core. Fuel should squirt out, catch it in a rag. A tire pressure gauge can also be used if you have one - look for 37-40 PSI. Beware of fire hazard when you do this. Most auto parts stores will reno or loan a fuel pressure test gauge it you have a credit card

No fuel pressure, possible failed items in order of their probability:

A.) Tripped inertia switch – press reset button on the inertia switch. The hatch cars hide it under the plastic trim covering the driver's side taillight. Use the voltmeter or test light to make sure you have power to both sides of the switch

B.) Fuel pump power relay –Note that all the relays on 94-95 models are in the CCRM box under the hood

C.) Clogged fuel filter

D.) Failed fuel pump

E.) Blown fuse in under hood fuse box.

F.) Fuel pressure regulator failed. Remove vacuum line from regulator and inspect for fuel escaping while pump is running.

The electrical circuit for the fuel pump has two paths, a control path and a power path.

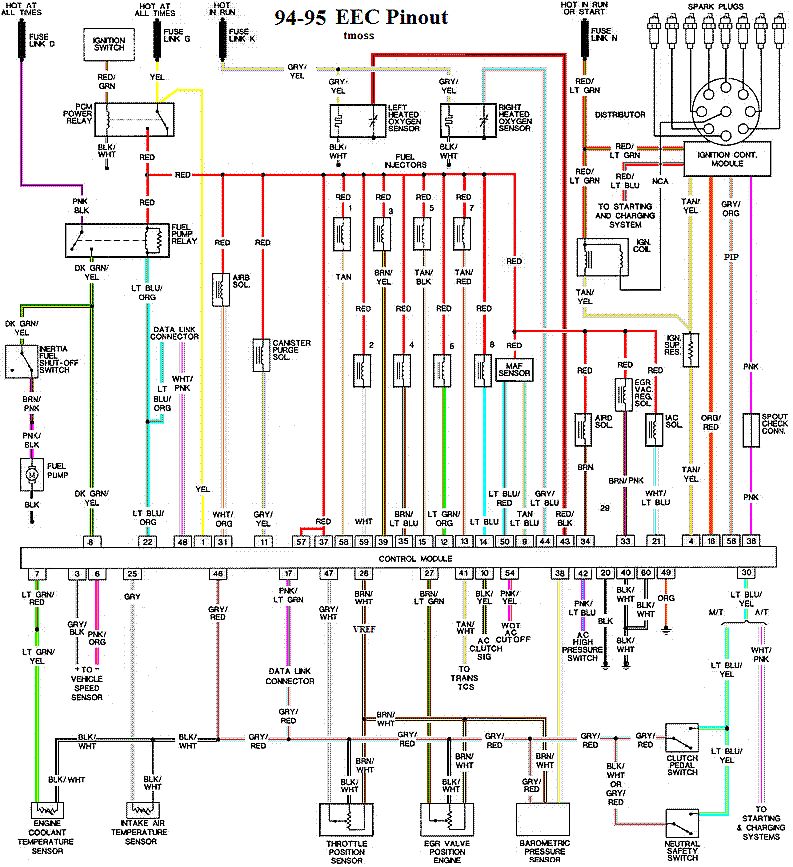

Diagram courtesy of Tmoss & Stang&2birds

The control path consists of the computer, and the fuel pump relay coil. It turns the fuel pump relay on or off under computer control. The switched power (red wire) from the ECC relay goes to the relay coil and then from the relay coil to the computer (light blue\orange wire). The computer provides the ground path to complete the circuit. This ground causes the relay coil to energize and close the contacts for the power path. Keep in mind that you can have voltage to all the right places, but the computer must provide a ground. If there is no ground, the relay will not close the power contacts.

The power path picks up from the under hood fuse box located between the windshield washer filler and the driver's side shock absorber strut tower.. The feed wire from the fuse (pink/black wire) goes to the fuel pump relay contacts. The fuel pump relay is located in the CCRM box on the passenger side of the car up near the radiator. When the contacts close because the relay energizes, the power flows through the pink/black wire to the contacts and through the dark green\yellow wire to the inertia switch. The other side of the inertia switch with the brown\pink wire joins the pink/black wire that connects to the fuel pump. The fuel pump has a black wire that supplies the ground to complete the circuit.

Remember that the computer does not source any power to actuators, relays or injectors, but provides the ground necessary to complete the circuit. That means one side of the circuit will always be hot, and the other side will go to ground or below 1 volt as the computer switches on that circuit.

See

http://www.autozone.com/servlet/UiB..._us/0900823d/80/1d/db/3c/0900823d801ddb3c.jsp for more wiring help for 94-95 cars

Now that you have the theory of how it works, it’s time to go digging.

Power circuits:

Under hood Fuses

Diagram courtesy of Tmoss & Stang&2birds

Click on diagram to enlarge it

CCRM relays - all CCRM relays are located under the hood

CCRM location

Diagram courtesy of http://ww2.justanswer.com

Click on diagram to enlarge it

CCRM Diagram

Diagram courtesy of http://diagrams.hissind.com/

Power feed: Look for 12 volts at the pink/black wire (power source for fuel pump relay). No voltage or low voltage, bad fuse link, bad wiring, or connections.

Relay: Turn on the key and jumper the ECC test connector as previously described. Look for 12 volts at the dark green\yellow wire (relay controlled power for the fuel pump). No voltage there means that the relay has failed, or there is a broken wire in the relay control circuit.

Inertia switch: Check the brown/pink wire, it should have 12 volts. No 12 volts there, either the inertia switch is open or has no power to it. Check both sides of the inertia switch: there should be power on the dark green\yellow (inertia switch input) and brown/pink wire (inertia switch output). Power on the dark green\yellow wire and not on the brown/pink wire means the inertia switch is open. Press on the red plunger to reset it to the closed position. Sometimes the inertia switch will be intermittent or will not pass full power. Be sure that there is 12 volts on both sides of the switch with the pump running and that the voltage drop measured across the switch is less than .75 volts.

Pump wiring: Anytime the ignition switch is in the Run position and the test point is jumpered to ground, there should be at least 12 volts present on the black/pink wire. With power off, check the pump ground: you should see less than 1 ohm between the black wire and chassis ground.

Make sure that the power is off the circuit before making any resistance checks.

If the circuit is powered up, your resistance measurements will be inaccurate.

Fuel tank wiring connector

Control circuits:

Relay: The red wire for the fuel pump relay coil gets its power feed from the ECC relay. No 12 volts here, and the ECC relay has failed or there is bad wiring or bad connections coming from it. The ECC relay is located on top of the computer, which is under the passenger’s side kick panel. It is not easy to get to, you must have small hands or pull the passenger side dash speaker out to access it.

Relay: The light blue/orange wire provides a ground path for the relay power. With the test connector jumpered according to the previous instructions, there should be less than .75 volts. Use a test lamp with one side connected to battery power and the other side to the light blue/orange wire on the fuel pump relay. The test light should glow brightly. No glow and you have a broken wire or bad connection between the test connector and the relay. To test the wiring from the computer, remove the passenger side kick panel and disconnect the computer connector. It has a 10 MM bolt that holds it in place. Remove the test jumper from the ECC test connector. With the test lamp connected to power, jumper pin 22 to ground and the test lamp should glow. No glow and the wiring between the computer and the fuel pump relay is bad.

Computer: If you got this far and everything else checked out good, the computer is suspect .Remove the test jumper from the ECC test connector located under the hood . Remove the plastic cover over the computer wiring, but leave the computer wiring connector plugged into the computer. With the ignition switch in the run position, connect a test lamp to the battery and back probe pin 22, the light blue/orange wire with it. The lamp should glow brightly. No glow and the computer has died a sad death.

If you used a voltmeter instead of a test lamp, you should see less than 1 volt.

See the following website for some help from Tmoss (diagram designer) & Stang&2Birds (website host) for help on 88-95 wiring

http://www.veryuseful.com/mustang/tech/engine/ Everyone should bookmark this site.

Code 41 or 91, or 43 Three digit code 172 or 176 - O2 sensor indicates system lean. Look for a vacuum leak or failing O2 sensor.

Revised 11-Jan-2015 to add check for fuel pressure out of range

Code 41 is the passenger side sensor, as viewed from the driver's seat.

Code 91 is the driver side sensor, as viewed from the driver's seat.

Code 172 is the passenger side sensor as viewed from the driver's seat.

Code 176 is the driver side sensor, as viewed from the driver's seat.

Code 43 is not side specific according to the Probst Ford Fuel injection book.

The computer sees a lean mixture signal coming from the O2 sensors and tries to compensate by adding more fuel. Many times the end result is an engine that runs pig rich and stinks of unburned fuel.

The following is a Quote from Charles O. Probst, Ford fuel Injection & Electronic Engine control:

"When the mixture is lean, the exhaust gas has oxygen, about the same amount as the ambient air. So the sensor will generate less than 400 Millivolts. Remember lean = less voltage.

When the mixture is rich, there's less oxygen in the exhaust than in the ambient air , so voltage is generated between the two sides of the tip. The voltage is greater than 600 millivolts. Remember rich = more voltage.

Here's a tip: the newer the sensor, the more the voltage changes, swinging from as low as 0.1 volt to as much as 0.9 volt. As an oxygen sensor ages, the voltage changes get smaller and slower - the voltage change lags behind the change in exhaust gas oxygen.

Because the oxygen sensor generates its own voltage, never apply voltage and never measure resistance of the sensor circuit. To measure voltage signals, use an analog voltmeter with a high input impedance, at least 10 megohms. Remember, a digital voltmeter will average a changing voltage." End Quote

Testing the O2 sensors 87-93 5.0 Mustangs

Measuring the O2 sensor voltage at the computer will give you a good idea of how well they are working. You'll have to pull the passenger side kick panel off to gain access to the computer connector. Remove the plastic wiring cover to get to the back side of the wiring. Use a safety pin or paper clip to probe the connections from the rear.

Disconnect the O2 sensor from the harness and use the body side O2 sensor harness as the starting point for testing. Do not measure the resistance of the O2 sensor , you may damage it. Resistance measurements for the O2 sensor harness are made with one meter lead on the O2 sensor harness and the other meter lead on the computer wire or pin for the O2 sensor.

Backside view of the computer wiring connector:

87-90 5.0 Mustangs:

Computer pin 43 Dark blue/Lt green – LH O2 sensor

Computer pin 29 Dark Green/Pink – RH O2 sensor

The computer pins are 29 (L\RH O2 with a dark green/pink wire) and 43 (LH O2 with a dark blue/pink wire). Use the ground next to the computer to ground the voltmeter. The O2 sensor voltage should switch between .2-.9 volt at idle.

91-93 5.0 Mustangs:

Computer pin 43 Red/Black – LH O2 sensor

Computer pin 29 Gray/Lt blue – RH O2 sensor

The computer pins are 29 (LH O2 with a Gray/Lt blue wire) and 43 (RH O2 with a Red/Black wire). Use the ground next to the computer to ground the voltmeter. The O2 sensor voltage should switch between .2-.9 volt at idle.

Testing the O2 sensors 94-95 5.0 Mustangs

Measuring the O2 sensor voltage at the computer will give you a good idea of how well they are working. You'll have to pull the passenger side kick panel off to gain access to the computer connector. Remove the plastic wiring cover to get to the back side of the wiring. Use a safety pin or paper clip to probe the connections from the rear. The computer pins are 29 (LH O2 with a red/black wire) and 27 (RH O2 with a gray/lt blue wire). Use pin 32 (gray/red wire) to ground the voltmeter. The O2 sensor voltage should switch between .2-.9 volt at idle.

Note that all resistance tests must be done with power off. Measuring resistance with a circuit powered on will give false readings and possibly damage the meter. Do not attempt to measure the resistance of the O2 sensors, it may damage them.

Testing the O2 sensor wiring harness

Most of the common multimeters have a resistance scale. Be sure the O2 sensors are disconnected and measure the resistance from the O2 sensor body harness to the pins on the computer. Using the Low Ohms range (usually 200 Ohms) you should see less than 1.5 Ohms.

87-90 5.0 Mustangs:

Computer pin 43 Dark blue/Lt green – LH O2 sensor

Computer pin 29 Dark Green/Pink – RH O2 sensor

Disconnect the connector from the O2 sensor and measure the resistance:

From the Dark blue/Lt green wire in the LH O2 sensor harness and the Dark blue/Lt green wire on the computer pin 43

From the Dark Green/Pink wire on the RH Os sensor harness and the Dark Green/Pink wire on the computer pin 29

91-93 5.0 Mustangs:

Computer pin 43 Red/Black – LH O2 sensor

Computer pin 29 Gray/Lt blue – RH O2 sensor

Disconnect the connector from the O2 sensor and measure the resistance:

From the Red/Black wire in the LH O2 sensor harness and the Red/Black wire on the computer pin 43

From the Dark Green/Pink Gray/Lt blue wire on the RH Os sensor harness and the Gray/Lt blue wire on the computer pin 29

94-95 5.0 Mustangs:

Computer pin 29 Red/Black – LH O2 sensor

Computer pin 27 Gray/Lt blue – RH O2 sensor

From the Red/Black wire in the LH O2 sensor harness and the Red/Black wire on the computer pin 29

From the Dark Green/Pink Gray/Lt blue wire on the RH Os sensor harness and the Gray/Lt blue wire on the computer pin 27

There is a connector between the body harness and the O2 sensor harness. Make sure the connectors are mated together, the contacts and wiring are not damaged and the contacts are clean and not coated with oil.

The O2 sensor ground (orange wire with a ring terminal on it) is in the wiring harness for the fuel injection wiring. I grounded mine to one of the intake manifold bolts

Check the fuel pressure – the fuel pressure is 37-41 PSI with the vacuum disconnected and the engine idling. Fuel pressure out of range can cause the 41 & 91 codes together. It will not cause a single code, only both codes together.

Make sure you have the proper 3 wire O2 sensors. Only the 4 cylinder cars used a 4 wire sensor, which is not compatible with the V8 wiring harness.

Replace the O2 sensors in pairs if replacement is indicated. If one is weak or bad, the other one probably isn't far behind.

Code 41 can also be due to carbon plugging the driver’s side Thermactor air crossover tube on the back of the engine. The tube fills up with carbon and does not pass air to the driver’s side head ports. This puts an excess amount of air in the passenger side exhaust and can set the code 41. Remove the tube and clean it out so that both sides get good airflow: this may be more difficult than it sounds. You need something like a mini rotor-rooter to do the job because of the curves in the tube. Something like the outer spiral jacket of a flexible push-pull cable may be the thing that does the trick.

If you get only code 41 and have changed the sensor, look for vacuum leaks. This is especially true if you are having idle problems. The small plastic tubing is very brittle after many years of the heating it receives. Replace the tubing and check the PVC and the hoses connected to it.

If you used a voltmeter instead of a test lamp, you should see less than 1 volt.

If you used a voltmeter instead of a test lamp, you should see less than 1 volt.