It's been a few decades since I've changed valve seals and I've researched a lot of this however I haven't seen or heard anything on reusing the rocker arm retaining nuts, or torque specs, or any issues to watch out for. I have a fairly stock 89 5.0 with some bolt ons. Any advice appreciated

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Engine Valve Seals

- Thread starter rotorhead22

- Start date

-

Sponsors (?)

I am " old school" too and can relate.....

I just redid some " P " heads that came on the Explorer engine I purchased......

Alex's parts was very helpful with what they offer...

I reused my valves, my valve guides were Ok... I had my machine shop do a simple valve job and I used Vitron seals ( alex's parts) that were " push " on.....

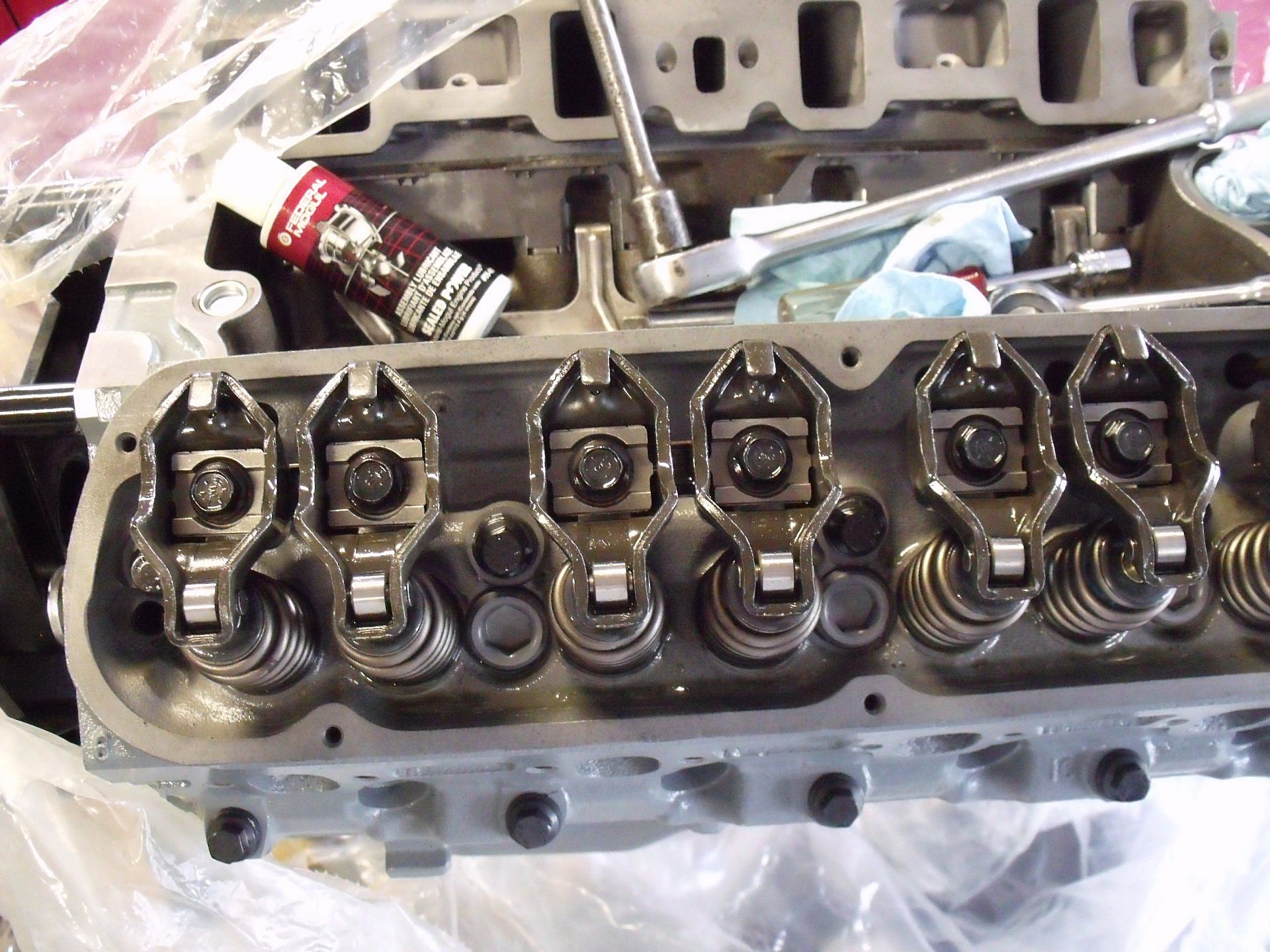

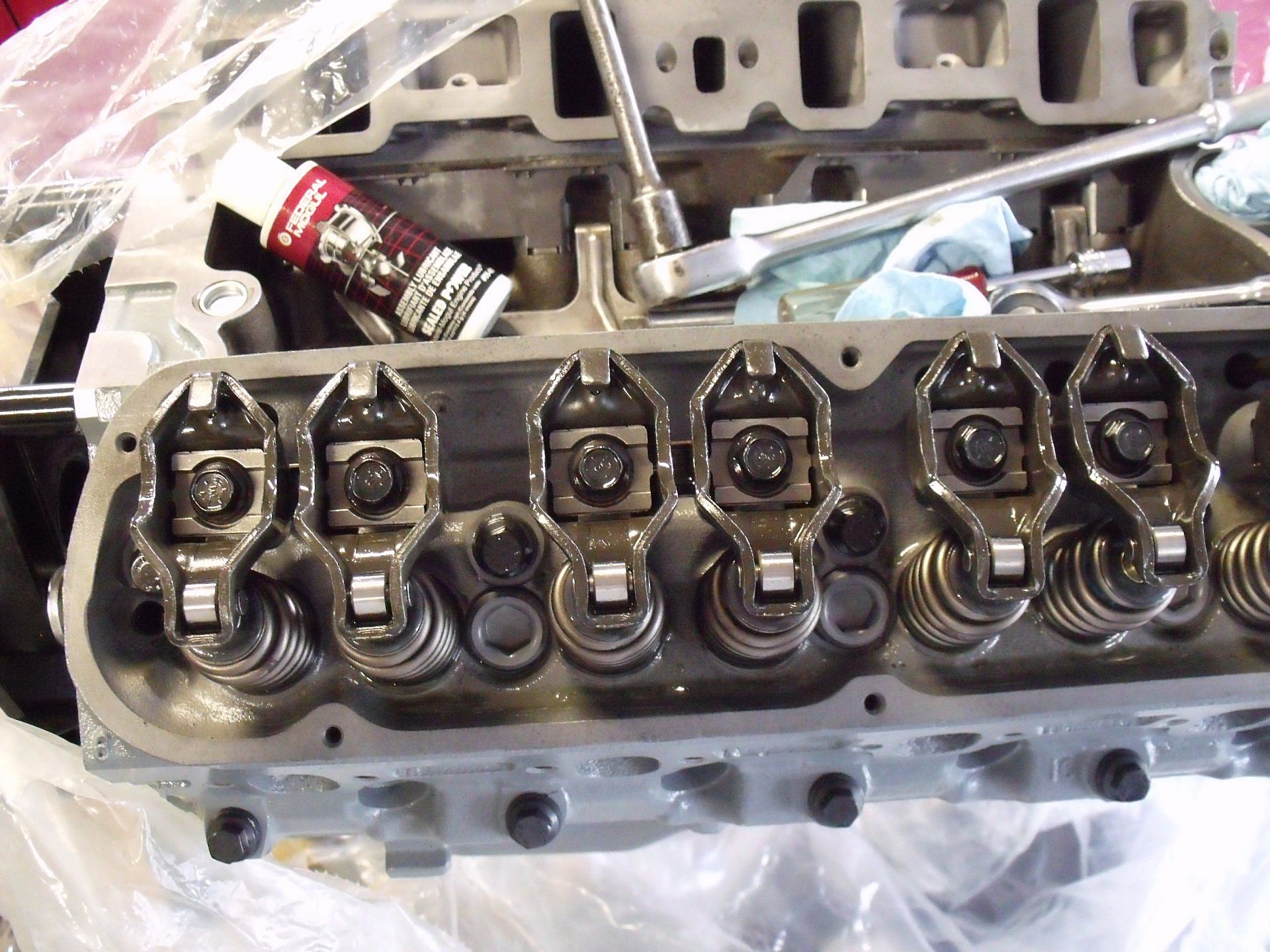

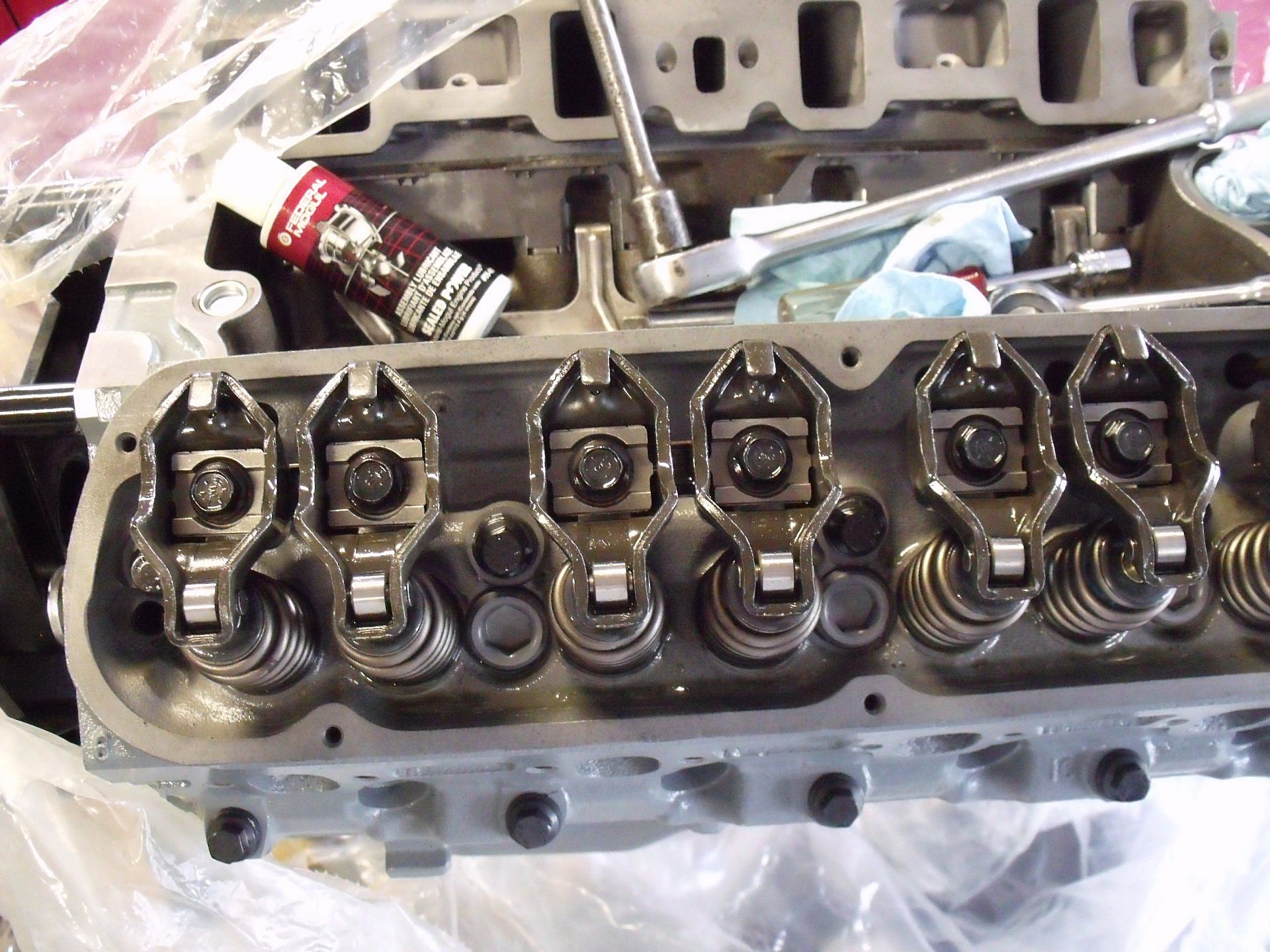

I hate reusing parts that are 23 years old, so I will be using new pushrods and I was going to put new rocker arms and decided to upgrade to these Lunati roller tip rocker arms.... The reason for using the lunati roller " tip " rockers was not for horsepower but the claim is they will prevent or stop altogether any valve guide wear....

I just redid some " P " heads that came on the Explorer engine I purchased......

Alex's parts was very helpful with what they offer...

I reused my valves, my valve guides were Ok... I had my machine shop do a simple valve job and I used Vitron seals ( alex's parts) that were " push " on.....

I hate reusing parts that are 23 years old, so I will be using new pushrods and I was going to put new rocker arms and decided to upgrade to these Lunati roller tip rocker arms.... The reason for using the lunati roller " tip " rockers was not for horsepower but the claim is they will prevent or stop altogether any valve guide wear....

CAMTWO1070

Active Member

The only real way to prevent valveguide wear is to do measurements and get the right length pushrods to attain proper valvetrain geometry and seeings theyre aftermarket rockers theyre gonna sit at a different height as stock stamped steel rockers......I am " old school" too and can relate.....

I just redid some " P " heads that came on the Explorer engine I purchased......

Alex's parts was very helpful with what they offer...

I reused my valves, my valve guides were Ok... I had my machine shop do a simple valve job and I used Vitron seals ( alex's parts) that were " push " on.....

I hate reusing parts that are 23 years old, so I will be using new pushrods and I was going to put new rocker arms and decided to upgrade to these Lunati roller tip rocker arms.... The reason for using the lunati roller " tip " rockers was not for horsepower but the claim is they will prevent or stop altogether any valve guide wear....

To get the measurement you need a dial indicator to figure half lift of camshaft then set that number at the rocker and see how the roller looks by eye..

.At half lift you want that yellow line at a perfect 90* angle with the valvestem...

This engine has a .477" lift w/ 1.6 rockers and half of .477" is .2385". At .2385 the fulcrum centerlines need to make A PERFECT 90*

View attachment 704889

You can use a sharpie to black out the tip to attain a witness mark and roll the engine 1 full turn to get the roller tops to make a mark..

If you run pushrods that are even .050" too short it will put undue stresses on the valveguides....Its all about the wear pattern on the valvestem tips...You want the pattern as centered and as thin as possible...

When O look at where the roller tips are in relation to the hvalvestem tips I see one valve cocked in an angle slightly...That tells me the pushrods may not be the correct length and are too short.......

This is with pushrods that are.100" too short..

When VTG isnt correct the rocker arms dont sit on the valvestem tips correctly

Heres a shot of the line being too high and too wide....

Heres what proper valvetrain geometry looks like...

Good Luck

Attachments

Last edited:

Perhaps this was part of the vacuum leak I have been chasing to include a corner intake bolt loose

CAMTWO1070

Active Member

Could be especially if you decked the block and milled the heads plus when those processes are done and not modded for an adjustable valvetrain they sell shim kits for the pedestal mount rockers to finetune proper Valvetrain geometry..Sometimes at full pump-up the valve just hangs off the seat very so minutely it will cause running issues that seem like vacuum leaks...Perhaps this was part of the vacuum leak I have been chasing to include a corner intake bolt loose

A vacuum gauge while running will tell you important info plus also doing a cylinder leakdown test using a cylinder leakdown tester tool on each cylinder while priming the oilpump to fully pump the lifters up will tell you if the valves arent totally sealing too...

A similar thing happened in my 1978 Hurts Olds w/350 rocket engine after refurbing he heads because of burnt valves/valveseats..... A .025" thick pedestal shim on each pedestal fixed the issue to keep my 10.5:1 compression ratio.

I found out on my 410w I had to retorque the intake bolts a few times and on the third time I even torqued the bolts to 28ftlbs and so far so good.....Another thing I found is I needed to use sealant on the bolt threads and shoulders because the holes arent blind..

Sometimes the conventional thickness off the shelf FelPro intake gaskets dont seal right after sending heads to a machine shop and thicker intake gaskets are needed and if you used racing gaskets like Edelbrock #7227 Intake gaskets those types arent recommended for street use...

A really good machine shop will recommend torque specs for the headbolts also tell you or even supply proper brand and thickkness headgaskets also intake gaskets to use after doing the headwork to keep the engine as close to AERA specs as possible.............

Before I put the intake gaskets and seal down the intake I put a super bright light inside the lifter galley then I tighten down the intake without gaskets and turn out the lights to make the garage pitch dark then I peek down the runners with an inspection camera attached to my cellphone and look inside the runners to see how good or how bad the intake seals to the heads without gaskets and also note the gap thicknesses on the china rails too and also to note I never use the rubbber or caulk china rail gaskets either,,,,I use The Right Stuff gasket maker.........

Nothing is too straight forwards when you modify stock parts........Unless the valveseats are replaced and recut to A.E.R.A specs and proper thickness headgaskets are properly spec'd and used to make up for block decking and head milling also to mention when the valves and valveseats are recut the valves in essence raise up and that makes the pushrods looser also to add that the actual geometry and shape of the Lunati Rockers doesnt exactly mirror stock stamped steel rocker arms......

Even the lifter body heights changes the A.E.R.A number sometimes pretty substantial to where different length pushrods &/or pedestal shims are also needed...

These lifters came in the same boxes...Upon disassembly and cleaning them before installation I noticed this....

Look at the differences in heights.........When I put the lifter in to see how much difference in rocker nut adjustment and there was a .065" max difference with one that was .013" larger in rocker nut adjustment heights so I sent them back...

Good Luck

Last edited:

So I finally have the beast up and running after taking everything back apart because I thought that I had not adjusted the valve lash correctly due to the rockers were rattling, turns ot you got to wait till the lifters pump up and that noise will go away. Go figure, right?

Cheapskate207

The left one hangs a little lower

Similar threads

- Replies

- 1

- Views

- 349

- Replies

- 5

- Views

- 1K

Progress Thread

H/C Swap Problems/Ideas

- Replies

- 3

- Views

- 373

- Replies

- 0

- Views

- 178

- Replies

- 6

- Views

- 907