I realize that i'm new here and that i haven't formed any "forum friendships" yet but i just needed a place to vent...

So about 2 weeks ago i took a very long drive to see a car in another state. I was super excited and at the same time tired of seeing the rotted out SH1T for foxbody's local to me. This one looked great in the pics, sounded pretty damn good too. The previous owner was responsive and answered all of my questions.. I had my finances in order and took the ride..

The good:

-3yr old paint - done "mostly right" -- as in - door panels removed, windshield removed, Headlights/taillights removed.. (Saw a video of it getting painted).. it was an acceptable job.

-NO RUST.. I went top to bottom - looked over all the known bad places - everything is GOOD. Strut Towers are solid as a rock, Rear hatch is perfect, underside of doors have nothing, Floors are clean, pinch welds are mostly straight and not rusted..

-Interior is clean (new headliner and carpet) Retrofitted 2017 Mustang seats in the front too so it adds some modern touches and i actually like it.

The bad:

-I suspect that theres a fuel issue - although its unconfirmed. Car seems like it runs obnoxiously rich.. if i have it idling in my garage, i smell like gas.

-The clutch just went - i've literally had the car for less than 100 miles.. (i test drove it, it was grabbing high in the pedal but i didn't think it was that bad)..I guess it was..

-The motor - its a 351w, with all the 5.0 EFI stuff. It has aluminum head and its makes a crap ton of noise.. I think its the valves/rockers.. preying its not a Rod or multiple Rods... When i first heard it, i thought it was just injector cycling.. But - maybe not..

-The Tach is messed up - it revs up to 3k only.. even when i know im well beyond that..

-The stock temp gauge doesnt work - but an aftermarket one installed by the previous owner does.. I hate it.. i just want the stock gauges..UGH..

-The Speedo bounces at lower speeds 30mph and slower..

-Electrical - I suspect there to be other electrical issues based on some odd behavior by the radio.

There are other odds and ends that to be honest, i was looking forward to "working on".. but with each new discovery i feel more and more defeated.. I know (after reading some of the posts here ) that the guys on this forum would probably laugh at my list of issue and just blow through fixing them but i'm likely less skilled and certainly less knowledgeable so the task seem daunting.. AND Expensive..

sorry for the rant..

Part 2 - pick up where the previous post left off...

"The Tach is messed up - it revs up to 3k only.. even when i know I'm well beyond that." Look for a miswire of the ignition system or missing 22KΩ resistor in the feed wire to the tach and computer. Computer code 18 is the clue to a miswire or defective or missing 22KΩ resistor in the tach feed. I'll post more on that once you post the results of the computer code dump.

[ii]The stock temp gauge doesn't work - but an aftermarket one installed by the previous owner does.. I hate it.. i just want the stock gauges..UGH[/I]" The temp sender resides in the driver's side lower intake manifold. It has a single wire push on electrical connector. The PO probably removed the stock temp sender and put the temp sender for the aftermarket gauge in its place. here's a fix for that...Alternate placement for a temp gauge sender:

Revised 24 July 2011 to add better temp sender location description and the necessity to loop the fluid flow through the heater circuit.

How it works:

If you want any kind of operation similar to stock, the ECT/heater feed line is the best place for a temp sender or fan thermo sensor. After all, the computer uses the ECT to pick up data on how warm the engine is. Putting the temp sender in the same line as the ECT is a simple way to get the best possible accuracy at minimum cost and complication.

Some things to keep in mind:

Just be sure that you haven’t blocked the coolant return because of a leaky heater core. For this to work correctly, the coolant needs to flow from the ECT sensor tubing back to the water pump. That means a leaky heater circuit gets looped rather than just plugged up. Join the rubber hoses together with a hose splice from Home Depot rather than plug them up.

Where to put it:

Use the heater feed that comes off the intake manifold that has the ECT sensor in it. Cut the rubber hose that connects the manifold water feed to the heater and splice in a tee adapter for the temp gauge sender. That way you will get the most accurate temp readings since the coolant is always flowing through the heater circuit in a stock car. Remember to include a ground wire if you use an electrical sender.

Tee adapter info:

Make a pilgrimage to your local hardware or home supply center and get some copper pipe and a tee that fits the temp gauge sender. Solder two pieces of copper pipe onto a copper pipe tee with threads in the tee part. Find the correct brass fitting to match the temp sender threads to the tee fitting.

"-The Speedo bounces at lower speeds 30mph and slower.." Speedometer cable replacement for 87-93 Mustangs

Revised Jun 15 2019 to add lubricant application recommendations .

How the speedometer works:

The indicator pointer has no direct connection to the speedo cable. It uses a drum with magnets on it to couple to the pointer. The drum turns and tries to twist the circular steel disk that is mounted on the pointer spindle. The magnetic force is all that connects the drum to the circular disk. There is very little clearance between the disk and drum, only a few thousands of an inch. Sometimes dust or dirt collects on the drum and disk surfaces that face each other. Cleaning the drum and disk with the brake parts cleaner would be the next thing to try.

Lubrication warning

Only use a graphite based lubricant for the speedo cable; other types of lubricant may damage the speedometer head unit. The graphite based lubricant is available at most auto parts stores in a small tube. Use lots of the graphite based lubricant, and wear throwaway gloves when you do it. The best method is to goop the cable up before you install it; the graphite-based lubricant goes everywhere and it is a mess to clean up. Pull the cable out of the housing and squirt as much as you can in the transmission end of the cable. A piece of rubber tubing to couple the snout on the tube to the cable housing is the best plan. Hold the transmission end of the cable and the lubricant tube as high as possible so that gravity helps keep the graphite flowing into the cable housing. Then coat the cable with the graphite based lubricant and feed it into the housing from the speedometer end of the housing.

A speedometer that bounces around is either a cable problem (top cause) or a speedometer drive gear that is chewed up. When you remove the cable drive end, check the teeth on the driven gear (the one attached to the cable) or the drive gear (the one on the transmission output shaft) Late Model Restoration (http://www.latemodelrestoration.com/products/79-93-Mustang-Transmission-Speedometer-Correction) has a complete range of replacement speedometer gear sets.

Speedometer cable replacement .

Note: All 89-93 cars have a VSS sensor even if they do not have cruise control. The 87-88 only have a VSS sensor if they have cruise control.

Speedo cable housing assembly without cruise control:

The VSS equipped cars have a speedo cable with a different fitting on the transmission end of the cable. It is the fitting on the LH side of the following picture.

Speedo cable housing assembly with cruise control

Preparation: if you are only going to replace the inner part of the speedo cable, get lots of newspaper or a painter’s drop cloth to cover the inside front of the car. About the time you have the dirty, oily speedo cable core all over your lap and the inside of the car, you will thank me for this suggestion.

Replacing only the inner cable: see steps 1- 6, 12, 13, 17-21

Replacing the housing and inner cable as an assembly: see steps 1-11, 13-21

Inside the car:

1.) Remove the shield around the steering column that covers the ignition switch & turn indicator switch.

2.) You now have access to the two screws that hold the lower part of the cluster housing in place. Remove them and place them in a zip bag.

3.) Use a stubby or an offset Philips screwdriver to remove the two screws on the top of the cluster housing. The screws are up close to the windshield, so they can be hard to get at.

4.) The cluster housing will now slide forward: depending on your particular car, you may or may not have to disconnect the wiring for the headlights, hazard lights, or cluster wiring. All of the wiring uses plastic connectors with plastic spring clips on them. To release the connectors, lift the plastic clips and pull straight back.

5.) The speedo cable is secured in the speedo head by a white plastic clip. Depress the clip or squeeze it and pull the cable out of the speedo head. This can be tricky, but it will come out if you have the white clip depressed enough.

Speedo head cable clip

Photos courtesy of Almost Stock

6.) With speedo cable removed from the speedo head, try twisting the cable end with your fingers. If it turns more than 1/4 turn, the cable may either be broken or you have damage at the other end where the cable mates to the VSS sensor or speedo pickup gear in the transmission.

Outside the car, replacing the cable housing assembly.

The following steps are necessary only if you plan on replacing the cable & cable housing assembly.

7.) If you are going to the replace the cable housing, the next step is important. Tie a study string or wire to the VSS sensor end of the cable housing. This string or wire is to be used to fish the cable housing back through the maze of wires that is under the dash. If all you are going to do is replace the inner cable, you can omit this step.

8.) Jack up the car, all 4 tires must be off the ground. Place jackstands under the car for safety.

9.) Locate the VSS sensor on the driver’s side of the transmission tailshaft housing. The speedo cable housing will be secured in the VSS sensor with a hairpin clip Do not remove the clip!!!: The hairpin clip stays in place. If you remove it, the odds are that you will not be able to get the cable to stay in place on re-installation. Pull firmly straight back on the cable housing and it will come out. A considerable amount of effort may be required to get the cable out of the VSS sensor, but it will pull out.

10.) Release the cable housing from the clips that secure it to the car body.

Inside the car:

11.) If all you are going to do is replace the inner cable, you can omit this step.

The housing assembly can then be pulled out and the fish string or wire can be removed from the old cable housing and secured to the new one.

12.) You can omit this step if you are replacing the cable & cable housing assembly.

The inner cable can be removed by pulling it out of the housing assembly. Watch out for the lubricant so that you don’t get it on the car’s interior.

13.) You can omit this step if you are replacing the cable & cable housing assembly.

Thread the pre-lubricated inner cable into the housing, turning it as you go. When you are all the way in with the new cable, it will engage the VSS sensor and stop turning.

Outside the car, replacing the cable housing assembly.

The following steps are necessary only if you plan on replacing the cable & cable housing assembly.

14.) Use the fish string or wire to feed the cable housing assembly through the dash wiring and out the cable hole in the firewall.

15.) Secure the cable in the body clips, making sure that the cable isn’t rubbing against the exhaust pipe.

16.) Push the cable housing assembly into the VSS sensor until it snaps in past the hairpin clip. If possible, spread the two protruding legs of the hairpin clip and the cable will slide in easily. Connect VSS wiring connector back to VSS sensor.

Inside the car:

17.) Push the cable housing back into the speedo head unit. You should be able to feel the white clip click into place.

18.) Reconnect all the wires & connectors on the speedo head unit.

19.) Re-install the cluster unit in the dash & tighten the 4 screws that hold it in place.

20.) Re-install the cover for the ignition switch & turn signal.

21.) If the car is up on jackstands, start the car, place it in gear & watch the speedo to see if it works OK. If you didn’t jack the car up, take a test drive.

"Electrical - I suspect there to be other electrical issues based on some odd behavior by the radio." Recall on Ford Ignition switches:

Revised 7-June-2014 to add Torx bit picture and source. Also added replacement ignition switch wiring pigtail picture, part numbers and sources.

Some of the symptoms of ignition switch problems are things that don’t work or are intermittent like radio, turn signals, wipers or heater.

There was a FREE recall on Ford ignition switches. They overheat and sometimes catch fire. That burns up the steering column and sometimes the car interior. Since this is very old information, you may not be able to get the switch replaced for free anymore. The auto parts stores sell the switches for $13-$15.

While you are working on the switch, check the wiring and connector closely. A replacement connector with new wiring pigtails is available from most auto parts stores

AutoZone and Advanced Auto Parts have the same Part Number: 434 - may have to order, not always in stock

Advanced Auto Parts alternate part number: PT5534

Saleen0679 was nice enough to dig this up for us awhile back: How to replace ignition switch on 1979-1993 Mustangs.

http://www.mustangandfords.com/how-to/engine/5657/

Torx bit set from Advance Auto Parts

Autocraft torx bit set – have small hole in tip for tamper proof screws.

Part No. AC571/W1386 Cost approx. $12 +tax

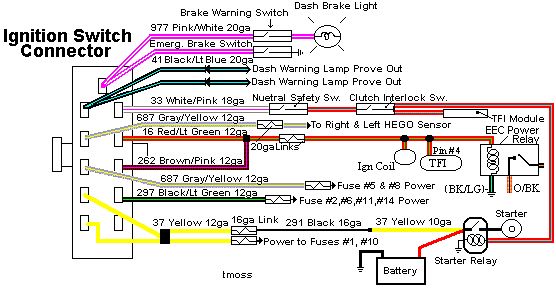

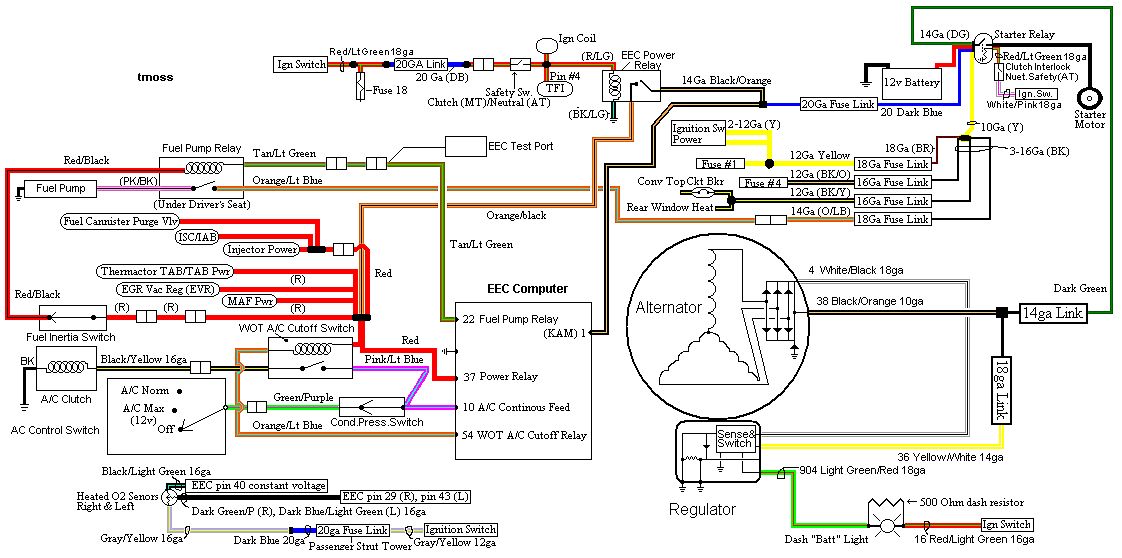

Diagrams courtesy of Tmoss & Stang&2birds

Ignition switch wiring

Fuel, alternator, A/C and ignition wiring

See the following website for some help from Tmoss (diagram designer) & Stang&2Birds (website host) for help on 88-95 wiring http://www.veryuseful.com/mustang/tech/engine/ Everyone should bookmark this site.

Complete computer, actuator & sensor wiring diagram for 91-93 Mass Air Mustangs

http://www.veryuseful.com/mustang/tech/engine/images/91-93_5.0_EEC_Wiring_Diagram.gif

Complete computer, actuator & sensor wiring diagram for 88-91 Mass Air Mustangs

http://www.veryuseful.com/mustang/tech/engine/images/88-91_5.0_EEC_Wiring_Diagram.gif

Ignition switch wiring

http://www.veryuseful.com/mustang/tech/engine/images/IgnitionSwitchWiring.gif

Fuel, alternator, A/C and ignition wiring

http://www.veryuseful.com/mustang/tech/engine/images/fuel-alt-links-ign-ac.gif

O2 sensor wiring harness

http://www.veryuseful.com/mustang/tech/engine/images/mustangO2Harness.gif

Vacuum diagram 89-93 Mustangs

http://www.veryuseful.com/mustang/tech/engine/images/mustangFoxFordVacuumDiagram.jpg

HVAC vacuum diagram

http://www.veryuseful.com/mustang/tech/engine/images/Mustang_AC_heat_vacuum_controls.gif

TFI module differences & pin out

http://www.veryuseful.com/mustang/tech/engine/images/TFI_5.0_comparison.gif

Fuse box layout

http://www.veryuseful.com/mustang/tech/engine/images/MustangFuseBox.gif

87-92 power window wiring

http://www.veryuseful.com/mustang/tech/engine/images/mustang87-92 PowerWindowWiring.gif

93 power window wiring

http://www.veryuseful.com/mustang/tech/engine/images/mustang93PowerWindows.gif

Visual comparison of the Ford Fuel Injectors, picture by TMoss:

http://www.veryuseful.com/mustang/tech/engine/images/Ford_Injector_Guide.jpg

Odd electrical problems with the stock temp and oil pressure gauges: The secondary power ground is between the back of the intake manifold and the driver's side firewall. It is often missing or loose. It supplies ground for the alternator, A/C compressor clutch and other electrical accessories such as the gauges. The clue to a bad ground here is that the temp gauge goes up as you add electrical load such as heater, lights and A/C.