....to install new lower intake gaskets (lower to heads)? I need to know the best way to approach it, the torquing order, where to use rtv and what kind etc. I need to do this this weekend. Please help! Oh, and I guess I'm going to use Fel-Pro 1250's (Professional Products Typhoon Intake and Edelbrock Performer RPM heads).

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Will someone tell me the proper way....

- Thread starter 1988WHTGT

- Start date

-

Sponsors (?)

Here's some tips...

Tools: a good torque wrench is a must have item. A razor blade scraper that holds a single edge razor blade from Home Depot or Ace hardware is another handy thing. Get a Chilton or Haynes shop manual - you'll need it for the bolt torques and patterns. The intake manifold has an especially odd pattern.

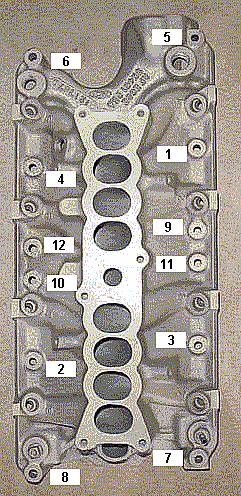

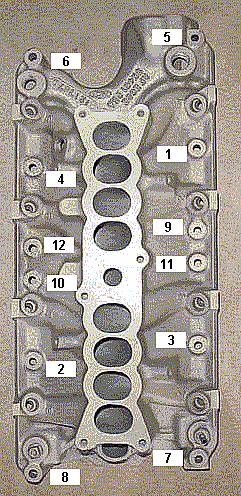

Diagram courtesy of Tmoss & Stang&2birds

The bolts are torqued down in a 3 step process.

Step 1 8 ft/lbs

Step 2 16 ft/lbs

Step 3 23-25 ft/lbs

You'll need access to a timing light to set the timing after you re-stab the distributor. Look in the A/C repair section for the fuel line tools. They look like little plastic top hats. You will need the 1/2" & 5/8" ones. The hat shaped section goes on facing the large part of the coupling. Then you press hard on the brim until it forces the sleeve into the coupling and releases the spring. You may need someone to pull on the line while you press on the coupling. Put some motor oil on them when you put the line back together.

The A/C Compressor comes off with lines still connected. Mark all the electrical, smog and vacuum lines with tags to help you remember where to re-connect them. If you have a digital camera, take several pictures.

Whatever you do, don't skimp on cleaning the gasket surfaces. New gaskets need to seat against bare metal and not the residue left from the old gaskets in order to seal leak free. This is the most time consuming and tiresome part of the job. Look for little things that need to be replaced like the short hose from the thermostat hosing to the water pump, damaged vacuum lines and hose clamps that are rusted or broken.

Plan on cutting the thermostat to water pump hose, or removing the thermostat housing. Also plan on removing the distributor to get clearance to remove the intake manifold. Remove #1 spark plug, stick your finger in the spark plug hole and crank. When your finger gets air moving past it, stop cranking. Turn the engine until the timing marks line up with the pointer. Now you can pull the distributor out.

My favorite trick that saves time and effort is the stay in place gasket. Be sure that you scrape (don't use a wire brush) all the old gasket material off, then clean all the surfaces with acetone or MEK.

When the surfaces are clean, use weather strip adhesive on the head to manifold surface, and on the side of the gasket that mates to the head. Follow the instructions on the tube or can and when it gets tacky, press the gasket down on the head.

Clean the area where the rubber rails mount to the block in front and in the rear with more acetone or MEK and do the same trick with the weather strip adhesive that you did to the heads.

Coat the rubber seals and the gasket area around the water passages with Blue Silicone gasket sealer and put it together. Whoopee! no leaks, and no gaskets that shifted out of place.

Tools: a good torque wrench is a must have item. A razor blade scraper that holds a single edge razor blade from Home Depot or Ace hardware is another handy thing. Get a Chilton or Haynes shop manual - you'll need it for the bolt torques and patterns. The intake manifold has an especially odd pattern.

Diagram courtesy of Tmoss & Stang&2birds

The bolts are torqued down in a 3 step process.

Step 1 8 ft/lbs

Step 2 16 ft/lbs

Step 3 23-25 ft/lbs

You'll need access to a timing light to set the timing after you re-stab the distributor. Look in the A/C repair section for the fuel line tools. They look like little plastic top hats. You will need the 1/2" & 5/8" ones. The hat shaped section goes on facing the large part of the coupling. Then you press hard on the brim until it forces the sleeve into the coupling and releases the spring. You may need someone to pull on the line while you press on the coupling. Put some motor oil on them when you put the line back together.

The A/C Compressor comes off with lines still connected. Mark all the electrical, smog and vacuum lines with tags to help you remember where to re-connect them. If you have a digital camera, take several pictures.

Whatever you do, don't skimp on cleaning the gasket surfaces. New gaskets need to seat against bare metal and not the residue left from the old gaskets in order to seal leak free. This is the most time consuming and tiresome part of the job. Look for little things that need to be replaced like the short hose from the thermostat hosing to the water pump, damaged vacuum lines and hose clamps that are rusted or broken.

Plan on cutting the thermostat to water pump hose, or removing the thermostat housing. Also plan on removing the distributor to get clearance to remove the intake manifold. Remove #1 spark plug, stick your finger in the spark plug hole and crank. When your finger gets air moving past it, stop cranking. Turn the engine until the timing marks line up with the pointer. Now you can pull the distributor out.

My favorite trick that saves time and effort is the stay in place gasket. Be sure that you scrape (don't use a wire brush) all the old gasket material off, then clean all the surfaces with acetone or MEK.

When the surfaces are clean, use weather strip adhesive on the head to manifold surface, and on the side of the gasket that mates to the head. Follow the instructions on the tube or can and when it gets tacky, press the gasket down on the head.

Clean the area where the rubber rails mount to the block in front and in the rear with more acetone or MEK and do the same trick with the weather strip adhesive that you did to the heads.

Coat the rubber seals and the gasket area around the water passages with Blue Silicone gasket sealer and put it together. Whoopee! no leaks, and no gaskets that shifted out of place.

Attachments

Evilfox

New Member

Here is a tip not mentioned in the above post. Goto Home Depot, Ace, wherever and buy four 4 1/2" long bolts for your intake manifold. Then cut the heads off the bolts. Then when you put the gasket on screw the now headless bolts into the 1, 4, 7 and 8 positions on the above picture. Then all you have to do is drop the manifold over the bolts and you won't have to screw around with making sure the gasket is lined up or not.

Follow Jrichkers steps, its very straight forward and thats all you need to know. I had this man help me install my heads and intake and we did it just how he explained, the weather strip adhesive works perfect for keeping the gaskets in place on the head before mounting the manifold. Dont be afraid to jump in, just a bunch of nuts and bolts, just remember where everything goes.

Here is a tip not mentioned in the above post. Goto Home Depot, Ace, wherever and buy four 4 1/2" long bolts for your intake manifold. Then cut the heads off the bolts. Then when you put the gasket on screw the now headless bolts into the 1, 4, 7 and 8 positions on the above picture. Then all you have to do is drop the manifold over the bolts and you won't have to screw around with making sure the gasket is lined up or not.

This is excellent advice. Since I have 3 vehicles with 5.0's, I went to the hardware store and bought a 12" piece of threaded rod in the proper size and thread pitch, cut it into 3" sections and keep them in my "special tools" drawer. Having them to guide the manifold on makes it really simple to get it lined up right the first time every time. :SNSign:

pony502

New Member

All good info guys but you forgot to tell him not to use the cork pieces in the front and rear. Some fel-pro kits come w/ rubber strips that hold themselves in place or you can just use a good ol' bead of high temp silicone

Similar threads

- Replies

- 0

- Views

- 538

- Replies

- 1

- Views

- 371

- Replies

- 35

- Views

- 3K

Progress Thread

Evolution of the 'Hudson Heap' plans (87 GT)

- Replies

- 29

- Views

- 3K