Kate made me come out of the garage at 5, although if left to me, I woulda stayed down there at least a couple of additional hours. She asks me if I got done what I wanted to get done while we set out on my deck listening to Jazz, and having a drink.

”Nope”.

” Did you get anything you wanted to get done, done?” She asks.

Half....I got half of what I wanted to get done...

” Which was “what“ exactly?”

sigh...

A boot and a bezel....that’s what I got done, I made a shifter bezel, and a shifter boot to cover the shifter.

“Why can’t you just buy a shifter bezel, and that boot thing?”

( At least she is feigning interest in what I was doing down there)

Because it’s a custom interior, they don’t make a shifter bezel for this car...and even though I bought a boot, it was generic,...it still needed to be made to fit.

”What happened to the custom shifter bezel that was on the car....you know, the car that’s been finished already”?

Ball bustin time....

Theres a new transmission in the car,..the old one was for an automatic, now there’s a 6 speed in there. So, that said, I had to make a new one.

” And that took all freakin day”?..

Yes,....because as with all things, I had to cut apart, and shorten the version that was ready for paint, because it was too long, and I couldn’t make the boot fit.

” What were you doing with the needle and red thread?”

Sewing the boot back together that I cut too much out of...in essence, redoing what was already done in the first place.

” Seems to me you’d double check this sht before you get to the “ ready for paint stage””.

So....that’s how this conversation goes...Me trying to tell her that I have to make sht,..but because it’s me, I have to do it more than once for whatever reason on the planet.

Maybe if i measured twice, and cut once...

Guess that all depends on what I’m measuring...trust me when I say,...I measured the freakin thing numerous times...it just was a judgement miscalculation.....( it’s always a judgement miscalculation).

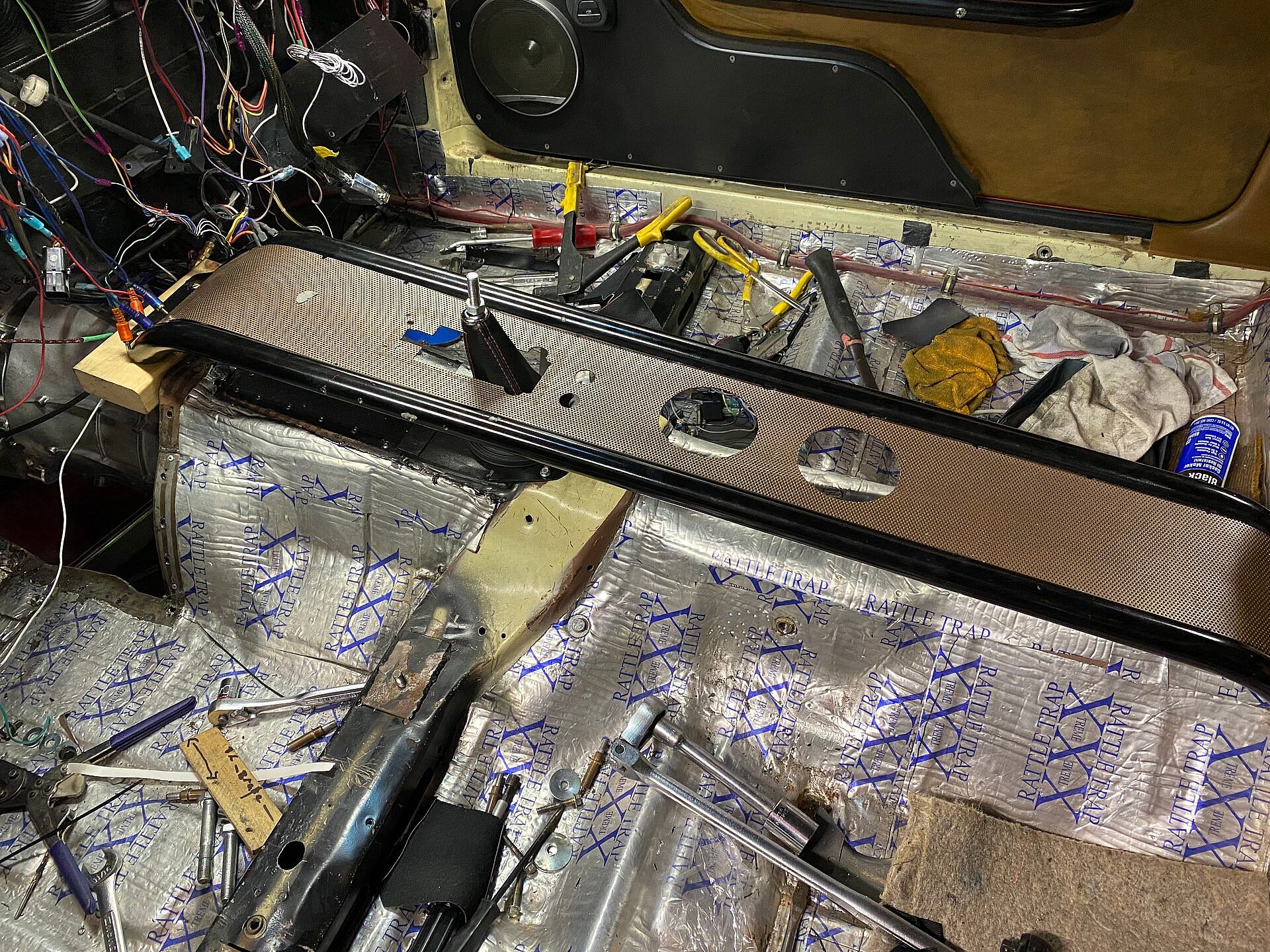

But here the freakin thing is,...still needing a final sanding before adding paint,..This being the after version that is now 5/8” shorter than the previous version..

and..

This Volcano lookin thing..( the horizontal stitches are where I had to sew the thing back together)..There is a metal frame inside that fits inside the bezel, and will rivet in place...Once installed, will be pushed down to cover the shifter and allow for movement of the shift lever.