At least it gets me started..too many other things to worry about.The torque reduction on shift is a standard feature of the microsquirt tcu, fairly easy to setup. No real magic happening there, but it's nice to know he is willing to share a tune file to start with.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Build Thread 1978 Mercury Cyclone. The pig is in the pen.

- Status

- Not open for further replies.

-

Sponsors (?)

Adapt the 4r70 to it. No tranny control to worry about. You can do that later either by making the 4r70 automatic shifting or switching to the Yota or a GM tranny.

The torque reduction on shift is a standard feature of the microsquirt tcu, fairly easy to setup.

Yep. Set one of these up yesterday while I was waiting for my ice cream at the Cold Stone.

Ok well... someone set one up while I waited for my ice cream at Cold Stone.

now that is multitasking at its finestYep. Set one of these up yesterday while I was waiting for my ice cream at the Cold Stone.

Ok well... someone set one up while I waited for my ice cream at Cold Stone.

That’s awesome Mike. Glad to see you’ve found a source to help you stick with it. His car sure seems like the essence of hot rodding. A little of this from this car, some of that from that car. Whatever it takes to reach the goal. Can’t wait to see you get to work on it.

Last edited:

Well,...sitting here at the house..waiting on the truck to get here....and then it came.

trebor3170

mine usually gets hard with the car on

"Hello Hooray Let the show begin

I've been ready

Hello Hooray Let the lights grow dim

I've been ready

Ready as this audience that's coming here to dream

Loving every second, every moment, every scream"

Alice Cooper

I've been ready

Hello Hooray Let the lights grow dim

I've been ready

Ready as this audience that's coming here to dream

Loving every second, every moment, every scream"

Alice Cooper

If I had hair,....i wouldn’t have any now.

I took 2hours today so that I could meet the driver at my house and take delivery of that engine. Because the driver called me when he was 20 minutes away, and because I’m only 5 minutes away from my house while I’m at work, I waited till the last minute to meet the guy.

That meant that I had almost 2hours to piddle around.

The objective was to get the stock exhaust manifold off with all of the dual turbo menagerie so that I could determine if that turbo manifold was gonna work or not.

Three hours later...and it’s still not off. I’ve never seen such a complicated mess of inaccessible bolts, housings, lines, tubes brackets, and pipes in my life..( well...BMW’s sht is overly complicated too,...but this is a 15 year old engine.)

Even though it’s supposed to be old, All of the vacuum lines are still supple, and the bolts that have been exposed to exhaust heat are not heat seized..the problem is.....” how the phck did they get a wrench behind there to tighten these bolts?”

Which makes it an even bigger problem now that I have to get a wrench in there to get them loose.

4 bolts remain out about 2dozen that are holding the exhaust manifold on the side of the head. One is starting to round off..

( if you could only hear the screams......every time that wrench twisted off the nut...it was like an insane person with turrets was working in the garage)

After 2.5 hours, I had to stop....(They were probably not expecting me to just leave for the rest of the day) I was drenched, I had to shower and get back into work clothes and leave that...I’ll return to it when I get outta here in a few hours.

The transmission is a big problem..the A340 is only rated to handle no more than 500 ft-lbs of torque, and will not tolerate a full throttle 3-4 shift..the stuff I’m reading says to make sure to gear your car so that you’ll be at redline in 3rd gear if you intend to drag race it, and never shift into 4th at wot, because the clutch in the converter will fail. Nextly, It’s Electronic, I’ll have to build some sort of TCU to control it....and then after all that.....is the tail shaft...

This transmission has no output shaft that will allow a slip yoke to slide into..it has to be adapted..I have to create a way for the driveshaft to move throughout the movement of the reared.......if I use the A340.

There is no adapter for the 4r70w out there..I’m gonna have to make it. The reasons to use that trans is that the driveshaft fits. It fits the car, the shifter works, I don’t have to have a TCU but at the same time, can always change the VB back to electronic, and have that capability. There is a $500+ converter in the trans, and additional components added to help it stand the abuse.

But...if I can make a spacer to adapt the 2j bell pattern to the SBF pattern, I gotta deal with spacing the flex plate back the same amount..and here’s the problem with that...the bolt pattern in the 2j crank leaves no room to bolt the Ford Flex plate to it..the spacer hub I have to have made will have to have the existing A340 flex plate bolted on and ( since it’s smaller in diameter) the ford flex plate spaced off of that however thick I build the bell housing adapter, with a concentric hub that will ride inside the 2j crank, and bolt to the ford flex plate to allow the converter to stick its hub into.

( I just figured all this sht out while I was writing this)

I took 2hours today so that I could meet the driver at my house and take delivery of that engine. Because the driver called me when he was 20 minutes away, and because I’m only 5 minutes away from my house while I’m at work, I waited till the last minute to meet the guy.

That meant that I had almost 2hours to piddle around.

The objective was to get the stock exhaust manifold off with all of the dual turbo menagerie so that I could determine if that turbo manifold was gonna work or not.

Three hours later...and it’s still not off. I’ve never seen such a complicated mess of inaccessible bolts, housings, lines, tubes brackets, and pipes in my life..( well...BMW’s sht is overly complicated too,...but this is a 15 year old engine.)

Even though it’s supposed to be old, All of the vacuum lines are still supple, and the bolts that have been exposed to exhaust heat are not heat seized..the problem is.....” how the phck did they get a wrench behind there to tighten these bolts?”

Which makes it an even bigger problem now that I have to get a wrench in there to get them loose.

4 bolts remain out about 2dozen that are holding the exhaust manifold on the side of the head. One is starting to round off..

( if you could only hear the screams......every time that wrench twisted off the nut...it was like an insane person with turrets was working in the garage)

After 2.5 hours, I had to stop....(They were probably not expecting me to just leave for the rest of the day) I was drenched, I had to shower and get back into work clothes and leave that...I’ll return to it when I get outta here in a few hours.

The transmission is a big problem..the A340 is only rated to handle no more than 500 ft-lbs of torque, and will not tolerate a full throttle 3-4 shift..the stuff I’m reading says to make sure to gear your car so that you’ll be at redline in 3rd gear if you intend to drag race it, and never shift into 4th at wot, because the clutch in the converter will fail. Nextly, It’s Electronic, I’ll have to build some sort of TCU to control it....and then after all that.....is the tail shaft...

This transmission has no output shaft that will allow a slip yoke to slide into..it has to be adapted..I have to create a way for the driveshaft to move throughout the movement of the reared.......if I use the A340.

There is no adapter for the 4r70w out there..I’m gonna have to make it. The reasons to use that trans is that the driveshaft fits. It fits the car, the shifter works, I don’t have to have a TCU but at the same time, can always change the VB back to electronic, and have that capability. There is a $500+ converter in the trans, and additional components added to help it stand the abuse.

But...if I can make a spacer to adapt the 2j bell pattern to the SBF pattern, I gotta deal with spacing the flex plate back the same amount..and here’s the problem with that...the bolt pattern in the 2j crank leaves no room to bolt the Ford Flex plate to it..the spacer hub I have to have made will have to have the existing A340 flex plate bolted on and ( since it’s smaller in diameter) the ford flex plate spaced off of that however thick I build the bell housing adapter, with a concentric hub that will ride inside the 2j crank, and bolt to the ford flex plate to allow the converter to stick its hub into.

( I just figured all this sht out while I was writing this)

I win!

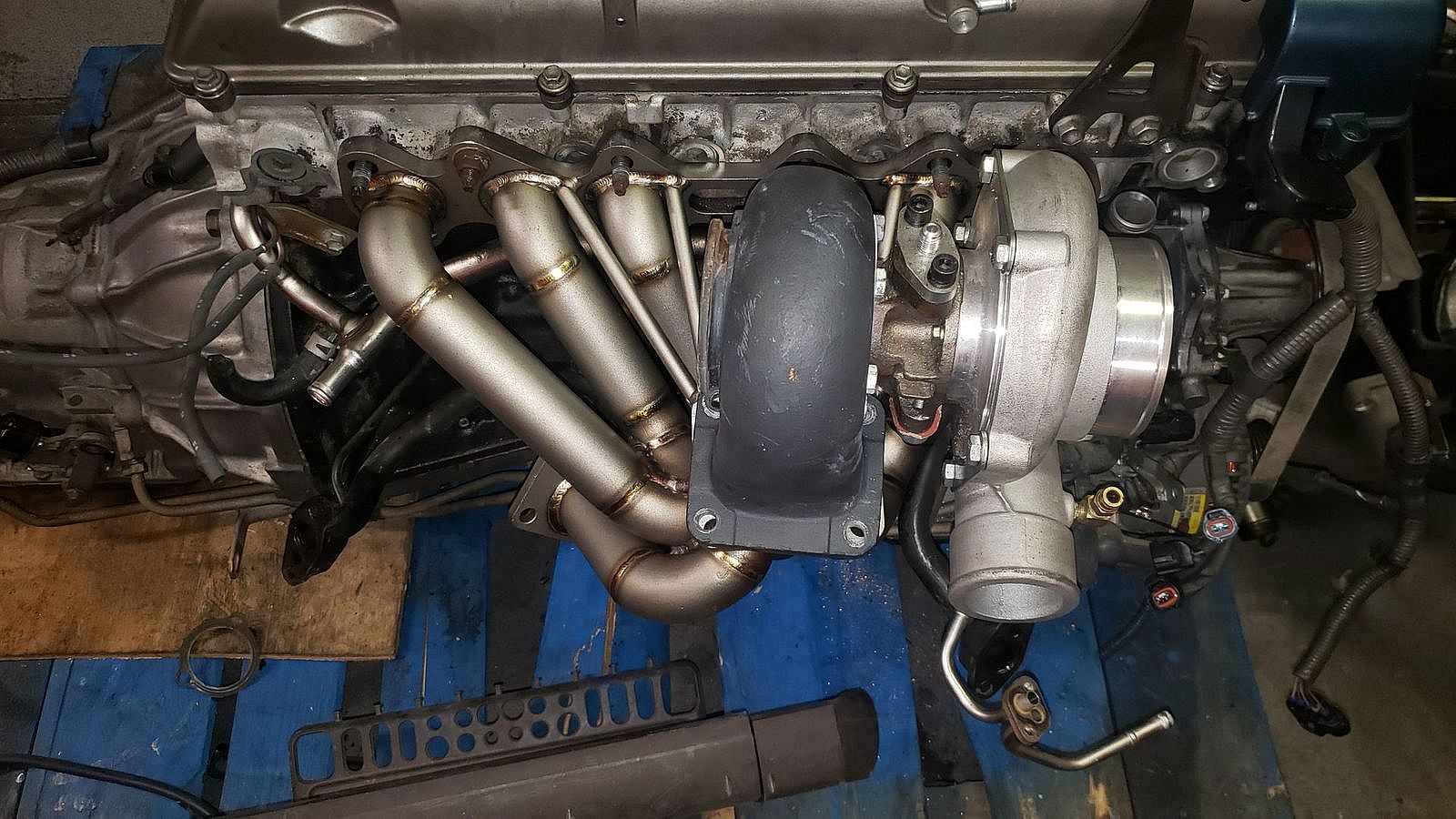

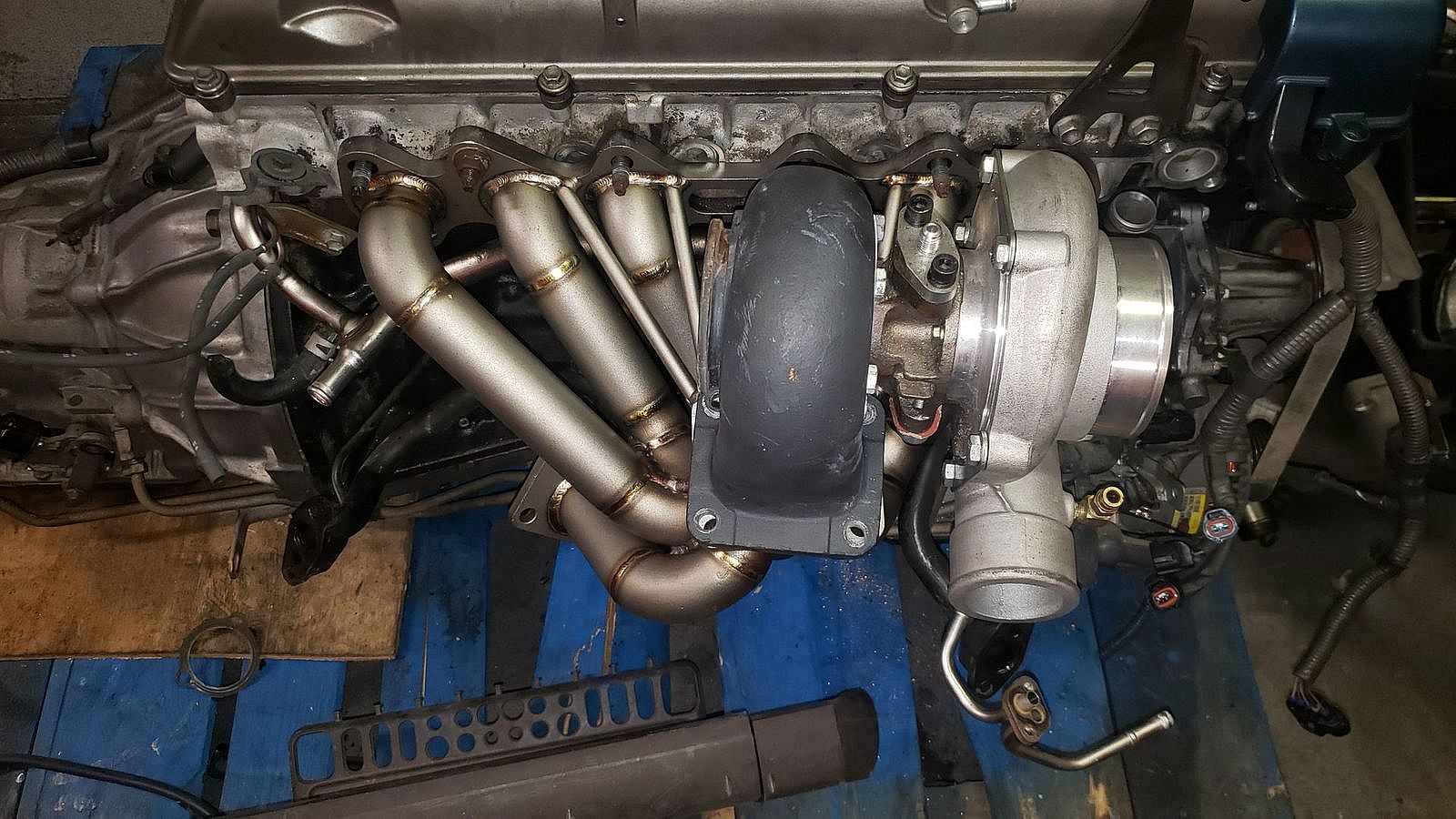

Finally got the heavy assed cast iron monstrosity off of the side of the tooges. The exhaust ports are all sooty as you'd expect for a street car, but everything looks good so far.

Except this thing.

It's too far down,.and angled. the turbo is in a terrible place, with no clear path for the oil return.

Besides...

There's no way in hell this turbo is gonna ever fit. This bitch is goin back.

Finally got the heavy assed cast iron monstrosity off of the side of the tooges. The exhaust ports are all sooty as you'd expect for a street car, but everything looks good so far.

Except this thing.

It's too far down,.and angled. the turbo is in a terrible place, with no clear path for the oil return.

Besides...

There's no way in hell this turbo is gonna ever fit. This bitch is goin back.

Mike I assume you could make a very simple header yourself in almost no time. Dont overthink it.

Not a SS one for 400 I can't. Besides, even if I had all the stuff to do it for free.....ever try to cut 1/2" thick SS?Mike I assume you could make a very simple header yourself in almost no time. Dont overthink it.

After this one gets refunded, ill spend an extra 100 on then one that looks like it'll work better, and we'll see. If the fitment sucks on that one, then I'll build one out of mild steel I guess.

How about an adapter plate to move the turbo housing to a more desirable location?

I probably would have sawzalled the stock  off to access the bolts. My patience seem to be getting thinner and thinner.

off to access the bolts. My patience seem to be getting thinner and thinner.

off to access the bolts. My patience seem to be getting thinner and thinner.

off to access the bolts. My patience seem to be getting thinner and thinner.lemosley1973

Doing something with a heavy tranny now

Was that an example of (what's his name?) was talking about when he said he hated working on Toyotas?

That header is gone. There are others out there that look to locate the turbo more forward, with tubes that aren't bent down so tightly you can't get a freakin nut to start on the bottom of the flange.

And while there is a lot of adapter plates to mate something to the rear of a 2jz...there is absolutely NOTHING to mate a sbf bell to one.Adapter plates are all over the web Mike. Should be able to find something cheap that will make the turbo sit comfortably in the big arse monster engine bay.

NOTHING to mate a sbf bell to one.

That would be [awesome] but I would have been very surprised if there was one cuz...

Oh hey; How's your FEP thread?

- Status

- Not open for further replies.