I scanned through the first 20 or so pages and didn't see if you used them, but what if you were to drop the K member combined with drop spindles? The caveat here would be more money down the rabbit hole and maybe ground clearance unless you were able to come up with some sort of compromise on overall ride height.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Build Thread 1978 Mercury Cyclone. The pig is in the pen.

- Status

- Not open for further replies.

-

Sponsors (?)

I guess I’ll find out. It’s a little over half cut away as of this minute.Question is.....if you raise the tunnel will you have to remake your center console ???

I haven’t used anything other than a stock 94-95 sn95 spindle. I’m already committed, I’m cutting the tunnel. It serves two purposes, I’ll be able to make it fit, and at the same time get to it in the future if I ever need to remove it.I scanned through the first 20 or so pages and didn't see if you used them, but what if you were to drop the K member combined with drop spindles? The caveat here would be more money down the rabbit hole and maybe ground clearance unless you were able to come up with some sort of compromise on overall ride height.

I haven’t used anything other than a stock 94-95 sn95 spindle. I’m already committed, I’m cutting the tunnel. It serves two purposes, I’ll be able to make it fit, and at the same time get to it in the future if I ever need to remove it.

I know where there's an 83 Regal that you pull the transmission from inside the car. Makes it much nicer to do in the rain! A powerglide practically jumps out. Turbo 400, no so much....his fat ass brother 4L80E, needs a sun roof to drop the crane thru.

I know where there's an 83 Regal that you pull the transmission from inside the car. Makes it much nicer to do in the rain! A powerglide practically jumps out. Turbo 400, no so much....his fat ass brother 4L80E, needs a sun roof to drop the crane thru.

Not.

Any.

More.

It wouldn’t have fit with biggest of BFH’s.

But once its up in there, and all bolted in ( that I’ll be able to do completely with a simple 12” extension) I’ll worry about covering it all up.

One things for sure though..even if I could’ve jammed that pig up there...Id’ve never been able to even see the top four bolts much less get a socket up there.

I don’t know for sure that this is how it’ll go back up there, or whether that trans will have to force the floor up higher by the time I try and install it on Thursday. I also am not sure how i’m gonna hold the piece in place if it does go back.

Nothing to do but wait till Thursday.

From looking at the pics, I can tell that the engine isn’t plumb..I’m sure the engine don’t give a phck that it’s a little wonky, but I do have to consider the other guy in my head..I’ll be looking for a way to level that out a little before this is all over.

It’s the LS bolt pattern. For whatever reason, i’m hesitant to cut that should I ever decide to change out to a different trans. I should just say WTH, and cut it because the likelihood that this trans will ever be anywhere else EXCEPT behind this engine are about 90:1Looks like you can cut the 12 o'clock lug right off.

Strength is in the trans tunnel. You'll get it back, as a combination of stich and fillet will do that, and get the space you so clearly need.

A sanity check. Are you personally sure Sure you don't wanna move the engine forward like an LS, Mr CMA?.

The whole center of gravity is well back on your 2JZ, and you've got another 3 inches up front to shift it forhead (Forr'd. Rolled R and straight to the D ).

Anyway. Looks great. Your seat though....

I've been working on my four wheel drive RAV4 project, putting a Ford V8 in it. I'm doing the same thing with my BTR T5 trans. jeremythedestroyer made me see sense!.

Getting butt hurt by a great guy like you putting a Toyota engine in a Ford just isn't a problem when your putting a dancing knitting needle Ford engine in a Toyota! Were now both on the same team Mike! Opposite ends, but the same team!

Get into it hombre!

A sanity check. Are you personally sure Sure you don't wanna move the engine forward like an LS, Mr CMA?.

The whole center of gravity is well back on your 2JZ, and you've got another 3 inches up front to shift it forhead (Forr'd. Rolled R and straight to the D ).

Anyway. Looks great. Your seat though....

I've been working on my four wheel drive RAV4 project, putting a Ford V8 in it. I'm doing the same thing with my BTR T5 trans. jeremythedestroyer made me see sense!.

Getting butt hurt by a great guy like you putting a Toyota engine in a Ford just isn't a problem when your putting a dancing knitting needle Ford engine in a Toyota! Were now both on the same team Mike! Opposite ends, but the same team!

Get into it hombre!

It’s the LS bolt pattern. For whatever reason, i’m hesitant to cut that should I ever decide to change out to a different trans. I should just say WTH, and cut it because the likelihood that this trans will ever be anywhere else EXCEPT behind this engine are about 90:1

You already drilled out internal passages. Who’s gonna want it?

Anybody that wants to swap that trans into their non-computerized Camaro I guess.You already drilled out internal passages. Who’s gonna want it?

I’m not welding that cut out portion back in. Im going to add some type of 1/8” flat bar “skelton”, that i’ll put sections of 18ga plate back to that i’ll weld over. i’m leaving a removable access section to get to the trans bolts.Strength is in the trans tunnel. You'll get it back, as a combination of stich and fillet will do that, and get the space you so clearly need.

A sanity check. Are you personally sure Sure you don't wanna move the engine forward like an LS, Mr CMA?.

The whole center of gravity is well back on your 2JZ, and you've got another 3 inches up front to shift it forhead (Forr'd. Rolled R and straight to the D ).

Anyway. Looks great. Your seat though....

I've been working on my four wheel drive RAV4 project, putting a Ford V8 in it. I'm doing the same thing with my BTR T5 trans. jeremythedestroyer made me see sense!.

Getting butt hurt by a great guy like you putting a Toyota engine in a Ford just isn't a problem when your putting a dancing knitting needle Ford engine in a Toyota! Were now both on the same team Mike! Opposite ends, but the same team!

Get into it hombre!

- May 8, 2006

- 703

- 240

- 84

See, everyone thought I was just promoting hooliganism with the "buy a plasma cutter" comments. Actually, I was, but I can't help but say it might actually have helped in transitioning sound deadening into smoke.

I had a plasma cutter. After I finished the build on the Monster ( the first time) I sold it, and the tubing bender that I used to make the dash and door bars. Even if I had it still, I couldn't/wouldn't use it. The cut wouldve been even more wonky than it is now, and probably way more ragged. Mostly because inside a car the freakin thing is a fire hazard.See, everyone thought I was just promoting hooliganism with the "buy a plasma cutter" comments. Actually, I was, but I can't help but say it might actually have helped in transitioning sound deadening into smoke.

Its done now anyway.

Well it’s in there. Partially.

I still have to create a new rear mount for the tail shaft, and if I can get away for a couple of hours tomorrow to run the drive shaft to my guy, I’ll have that part fixed.

Before I can even look at a new mount, I gotta put the exhaust back in place..it looks like the tail shaft mount bolts are right over where the exhaust ran before.

It didn’t just go up there by no means, it had to go in/out about 3 times before I could make the thing fit. I had to cut off the top bolt boss after all, and part of the bellhousing on the exhaust side. The rear cooler line ran into the floor where the old mount ears used to be, and that part of the floor was reinforced with 1/8” plate.

I tried to beat the floor there, but with a piece of 1/8” plate perimeter welded, and bent at an angle to follow the floor contour there...It didn’t take kindly to being beat on.

I ended up burning up my brand new HF drill trying to cut a 3” hole there instead.

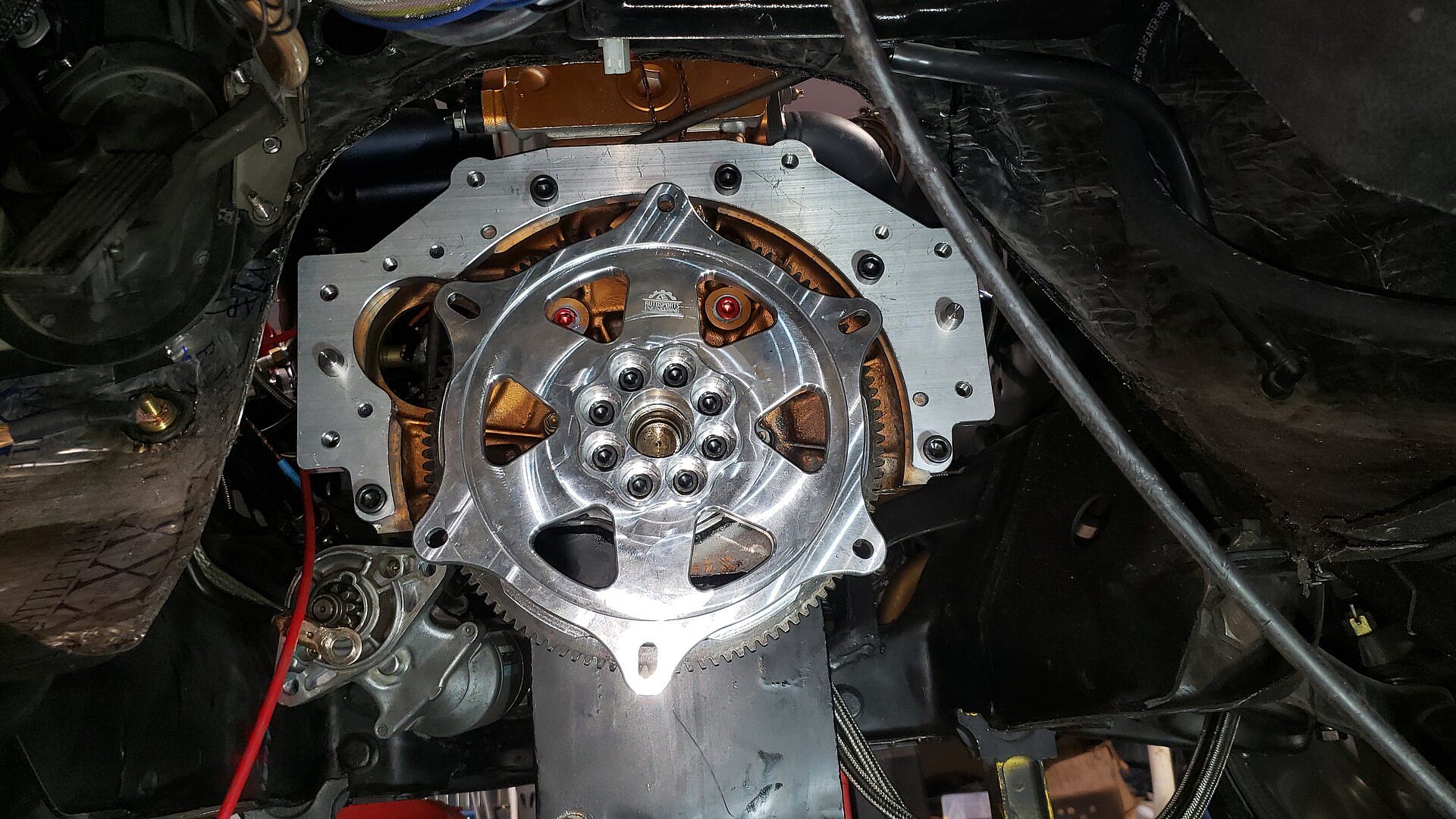

I do have to say this about the trans though...the fact that the entire bottom of the bellhousing comes off makes installing the converter bolts a snap.

Ill tackle trying to re-make the floor on Sunday I guess. I bought 100.00 worth of 20ga. steel, and 1/8” flat bar to do that.

I still have to create a new rear mount for the tail shaft, and if I can get away for a couple of hours tomorrow to run the drive shaft to my guy, I’ll have that part fixed.

Before I can even look at a new mount, I gotta put the exhaust back in place..it looks like the tail shaft mount bolts are right over where the exhaust ran before.

It didn’t just go up there by no means, it had to go in/out about 3 times before I could make the thing fit. I had to cut off the top bolt boss after all, and part of the bellhousing on the exhaust side. The rear cooler line ran into the floor where the old mount ears used to be, and that part of the floor was reinforced with 1/8” plate.

I tried to beat the floor there, but with a piece of 1/8” plate perimeter welded, and bent at an angle to follow the floor contour there...It didn’t take kindly to being beat on.

I ended up burning up my brand new HF drill trying to cut a 3” hole there instead.

I do have to say this about the trans though...the fact that the entire bottom of the bellhousing comes off makes installing the converter bolts a snap.

Ill tackle trying to re-make the floor on Sunday I guess. I bought 100.00 worth of 20ga. steel, and 1/8” flat bar to do that.

Attachments

Last edited:

- May 8, 2006

- 703

- 240

- 84

Have you tried pulling the carpet over and rough setting your center console yet? Just curious if you can see if there are mods you can an do to your burgeoning tunnel vice the console.

I think everything will be the same fitment up to the bellhousing. I’m gonna cut the piece that I cut out along the line where the trans bell starts to flare, and put that rear section in. That piece has the two studs that the front of the console attaches to, and it’ll be the anchor point for the front half that’ll butt against the firewall. That piece is gonna the pain in the ass to deal with I think.Have you tried pulling the carpet over and rough setting your center console yet? Just curious if you can see if there are mods you can an do to your burgeoning tunnel vice the console.

- May 8, 2006

- 703

- 240

- 84

Good, out of all the unique monsterisms, I've grown to really like the way your console came out.I think everything will be the same fitment up to the bellhousing. I’m gonna cut the piece that I cut out along the line where the trans bell starts to flare, and put that rear section in. That piece has the two studs that the front of the console attaches to, and it’ll be the anchor point for the front half that’ll butt against the firewall. That piece is gonna the pain in the ass to deal with I think.

Took the drive shaft to my guy this morning, It’s done. Tack another 160.00 onto the 4l80 conversion.

I’m not complaining mind you, the fact that I was able to take the drive shaft to this guy at 10:30, and he was done with it in an hour makes me glad I’ve got these connections.

So then,..a rear mount, and whatever it takes to cover the gigantic hole in the tunnel, some odd and ends, and this ordeal will be behind me.

On a side note...I removed the exhaust cam bolt....oil poured out of the hole. It appears our buddy Jeff @TOOLOW91 knows about possible oil leaks when changing out cams in a 2jz. I sealed the hole with liquid Teflon and even put an o-ring on the bolt. it looks like there is a recessed area in the cam gear where that Oring will sit and seal the bolt as well.

I’m not complaining mind you, the fact that I was able to take the drive shaft to this guy at 10:30, and he was done with it in an hour makes me glad I’ve got these connections.

So then,..a rear mount, and whatever it takes to cover the gigantic hole in the tunnel, some odd and ends, and this ordeal will be behind me.

On a side note...I removed the exhaust cam bolt....oil poured out of the hole. It appears our buddy Jeff @TOOLOW91 knows about possible oil leaks when changing out cams in a 2jz. I sealed the hole with liquid Teflon and even put an o-ring on the bolt. it looks like there is a recessed area in the cam gear where that Oring will sit and seal the bolt as well.

Last edited:

- Status

- Not open for further replies.