I messed up, and while working under the hood, there was this stupid big black hose just sitting over my intake manifold which I needed to get to, felt like metal but was covered in some foam like insulation. Being the Idiot I am I decided to disconnect that damn hose that was in my way! A disaster, and come to find out pretty much all my r12 refrigerant or Freon escaped that hose at the connection, scared the hell out of me cause I was not expecting that, reminded me of what would happen if you unscrewed the radiator cap after driving all day. I tried to screw the connection back on but like I said pretty much all of the Freon escaped. I've been to jiffy lube and Midas and called a non chain auto shop but doesn't look like anyone can help me. So I'm trying to figure out how to do it my self, any advice on how to do so would be greatly appreciated, like any specific bottles of R12 Freon I should use, what Manifold Gauges, and which vacuum pumps you would suggest, and if you know of any auto chains that would be able to evacuate the remaining R12 from my system. I'd like to mention that I would prefer to just replace the R12 and not go with a R134 conversion kit. (preferably without mentioning how much of an amateur and an idiot I am, I feel stupid enough already)

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Fox 93 Foxbody A/C help.

- Thread starter Ryu

- Start date

-

Sponsors (?)

If you unscrewed the line and it popped off, then all the R12 is gone. At this point, the system is contaminated with moisture, and the orifice line should be replaced.

Getting this back and working again with R12 won't be cheap, as you'll likely spend $40/can (ebay has them) and you'll need 3-4 and you'll need lots of other tools and such. Technically you need a license to buy R12 but i've been buying cans for years off ebay and not one person has ever asked.

The proper way to fix this would be to replace the orifice line and all O-rings while you have the system open. Measure and replace the exact amount of oil that was lost by replacing the line, and then pull a deep vacuum to 500 microns or less. If the condenser is the original serpentine style condenser, you might want to consider replacing it with a modern parallel flow style. Then you will need to charge to 40 ounces of R12. (32-36 if you swapped the condenser out due to reduced internal volume)

If you go with R134a, you still need to replace the orifice line, but I would also replace the condenser with a modern parallel flow style (all that is offered now), replace all the O-ring, take all the parts out and FLUSH all the mineral oil out. Then you would need to add 8-10 ounces of compatible R134a oil, pull a deep vacuum and charge with 32-26 ounces of R134a (accounting for the loss of internal volume due to the parallel flow condenser and some residual mineral oil).

Getting this back and working again with R12 won't be cheap, as you'll likely spend $40/can (ebay has them) and you'll need 3-4 and you'll need lots of other tools and such. Technically you need a license to buy R12 but i've been buying cans for years off ebay and not one person has ever asked.

The proper way to fix this would be to replace the orifice line and all O-rings while you have the system open. Measure and replace the exact amount of oil that was lost by replacing the line, and then pull a deep vacuum to 500 microns or less. If the condenser is the original serpentine style condenser, you might want to consider replacing it with a modern parallel flow style. Then you will need to charge to 40 ounces of R12. (32-36 if you swapped the condenser out due to reduced internal volume)

If you go with R134a, you still need to replace the orifice line, but I would also replace the condenser with a modern parallel flow style (all that is offered now), replace all the O-ring, take all the parts out and FLUSH all the mineral oil out. Then you would need to add 8-10 ounces of compatible R134a oil, pull a deep vacuum and charge with 32-26 ounces of R134a (accounting for the loss of internal volume due to the parallel flow condenser and some residual mineral oil).

When I unscrewed the connection I was able to screw it back on before everything escaped (I would say 90% had escaped), I had just broken the seal jumped back when the Freon started to whistle out, the actual connection didn't unscrew completely. So I don't believe its been contaminated because I was able to tighten the connection before it all escaped, So if were under the impression that it isn't contaminated would I do anything different or is my path still the same as you mentioned? Also is there any specific R12 Freon cans you suggest? and are the tools to fix this problem just the Manifold gauges and the vacuum pump? Or is there something else I need?If you unscrewed the line and it popped off, then all the R12 is gone. At this point, the system is contaminated with moisture, and the orifice line should be replaced.

Getting this back and working again with R12 won't be cheap, as you'll likely spend $40/can (eBay has them) and you'll need 3-4 and you'll need lots of other tools and such. Technically you need a license to buy R12 but I've been buying cans for years off eBay and not one person has ever asked.

The proper way to fix this would be to replace the orifice line and all O-rings while you have the system open. Measure and replace the exact amount of oil that was lost by replacing the line, and then pull a deep vacuum to 500 microns or less. If the condenser is the original serpentine style condenser, you might want to consider replacing it with a modern parallel flow style. Then you will need to charge to 40 ounces of R12. (32-36 if you swapped the condenser out due to reduced internal volume)

If you go with R134a, you still need to replace the orifice line, but I would also replace the condenser with a modern parallel flow style (all that is offered now), replace all the O-ring, take all the parts out and FLUSH all the mineral oil out. Then you would need to add 8-10 ounces of compatible R134a oil, pull a deep vacuum and charge with 32-26 ounces of R134a (accounting for the loss of internal volume due to the parallel flow condenser and some residual mineral oil).

Press the scrader valve on the fill ports quickly. Do you get a squirt of gas? If so, then the system still has pressure and you are lucky. Does the AC work? Is there enough pressure (more than 25psi) to activate the low pressure switch and get the compressor to engage?

You are technically supposed to charge by weight, but you can try and ballpark it using the manifold gauges given the fact you will never find someone who will evacuate and charge R12 these days. You still need to get your hands on a 1-4 cans of R12 (ebay) and a set of manifold gauges. If the AC actually turns on, you probably only need 1-2 cans

These gauges would work. They are for both R12 and R134a. You just won't be using the red/blue adapters for R134a and will connect the blue line directly to the compressor port, and the red line will use the 1/2" acme adapter to connect to the line.

Amazon product ASIN B08V5JWJSBView: https://www.amazon.com/Orion-Motor-Tech-Conditioning-Maintenance/dp/B08V5JWJSB/ref=sr_1_4_sspa?crid=3EZKHA7EKTYY7&keywords=r12+manifold+gauge+set&qid=1659724957&sprefix=R12+manifold%2Caps%2C616&sr=8-4-spons&psc=1&spLa=ZW5jcnlwdGVkUXVhbGlmaWVyPUEyNzRFRUpUSE40QkxZJmVuY3J5cHRlZElkPUEwMzQ0MzQ0MTdHRkc0TlFPWExIJmVuY3J5cHRlZEFkSWQ9QTAzNTcxNzcySk1DVlJZSjlQQTNHJndpZGdldE5hbWU9c3BfYXRmJmFjdGlvbj1jbGlja1JlZGlyZWN0JmRvTm90TG9nQ2xpY2s9dHJ1ZQ==

The tricky part is what to charge to. Hard to say because ambient temps/humidity will play a role here. I'd say you want to see around 30-40psi on the low side and around 175-250 on the high side on a 80-90 degree day. Rule of thumb is High side pressures should be twice ambient temp. On hotter, more humid days, your pressures will be higher.

You are technically supposed to charge by weight, but you can try and ballpark it using the manifold gauges given the fact you will never find someone who will evacuate and charge R12 these days. You still need to get your hands on a 1-4 cans of R12 (ebay) and a set of manifold gauges. If the AC actually turns on, you probably only need 1-2 cans

These gauges would work. They are for both R12 and R134a. You just won't be using the red/blue adapters for R134a and will connect the blue line directly to the compressor port, and the red line will use the 1/2" acme adapter to connect to the line.

Amazon product ASIN B08V5JWJSBView: https://www.amazon.com/Orion-Motor-Tech-Conditioning-Maintenance/dp/B08V5JWJSB/ref=sr_1_4_sspa?crid=3EZKHA7EKTYY7&keywords=r12+manifold+gauge+set&qid=1659724957&sprefix=R12+manifold%2Caps%2C616&sr=8-4-spons&psc=1&spLa=ZW5jcnlwdGVkUXVhbGlmaWVyPUEyNzRFRUpUSE40QkxZJmVuY3J5cHRlZElkPUEwMzQ0MzQ0MTdHRkc0TlFPWExIJmVuY3J5cHRlZEFkSWQ9QTAzNTcxNzcySk1DVlJZSjlQQTNHJndpZGdldE5hbWU9c3BfYXRmJmFjdGlvbj1jbGlja1JlZGlyZWN0JmRvTm90TG9nQ2xpY2s9dHJ1ZQ==

The tricky part is what to charge to. Hard to say because ambient temps/humidity will play a role here. I'd say you want to see around 30-40psi on the low side and around 175-250 on the high side on a 80-90 degree day. Rule of thumb is High side pressures should be twice ambient temp. On hotter, more humid days, your pressures will be higher.

I pressed the Schrader valve and got a squirt of, what I assume is the oil, the compressor does engage when I turn the A/C on, so here's hoping I'm lucky enough. So with all that I just need to get some Freon, a manifold gauge, and a vacuum pump and figure it out from there?Press the schrader valve on the fill ports quickly. Do you get a squirt of gas? If so, then the system still has pressure and you are lucky. Does the AC work? Is there enough pressure (more than 25psi) to activate the low pressure switch and get the compressor to engage?

You are technically supposed to charge by weight, but you can try and ballpark it using the manifold gauges given the fact you will never find someone who will evacuate and charge R12 these days. You still need to get your hands on a 1-4 cans of R12 (eBay) and a set of manifold gauges. If the AC actually turns on, you probably only need 1-2 cans

These gauges would work. They are for both R12 and R134a. You just won't be using the red/blue adapters for R134a and will connect the blue line directly to the compressor port, and the red line will use the 1/2" acme adapter to connect to the line.

Amazon product ASIN B08V5JWJSBView: https://www.amazon.com/Orion-Motor-Tech-Conditioning-Maintenance/dp/B08V5JWJSB/ref=sr_1_4_sspa?crid=3EZKHA7EKTYY7&keywords=r12+manifold+gauge+set&qid=1659724957&sprefix=R12+manifold%2Caps%2C616&sr=8-4-spons&psc=1&spLa=ZW5jcnlwdGVkUXVhbGlmaWVyPUEyNzRFRUpUSE40QkxZJmVuY3J5cHRlZElkPUEwMzQ0MzQ0MTdHRkc0TlFPWExIJmVuY3J5cHRlZEFkSWQ9QTAzNTcxNzcySk1DVlJZSjlQQTNHJndpZGdldE5hbWU9c3BfYXRmJmFjdGlvbj1jbGlja1JlZGlyZWN0JmRvTm90TG9nQ2xpY2s9dHJ1ZQ==

The tricky part is what to charge to. Hard to say because ambient temps/humidity will play a role here. I'd say you want to see around 30-40psi on the low side and around 175-250 on the high side on a 80-90 degree day. Rule of thumb is High side pressures should be twice ambient temp. On hotter, more humid days, your pressures will be higher.

You do not need a vacuum pump. You just need the gauges and some R12. You might even want to hook up the gauges to see what sort of pressure you have now.

Does the compressor cycle more frequently? Even when topped off properly it should cycle on a 70 degree day, but on a 90 degree humid day it should remain engaged pretty much constantly. If it's doing that, you are probably ok.

How much do you feel like you actually lost? A tiny squirt? or was it a good blast? I would almost be tempted to just leave it alone and see what the performance is like first.

Does the compressor cycle more frequently? Even when topped off properly it should cycle on a 70 degree day, but on a 90 degree humid day it should remain engaged pretty much constantly. If it's doing that, you are probably ok.

How much do you feel like you actually lost? A tiny squirt? or was it a good blast? I would almost be tempted to just leave it alone and see what the performance is like first.

I've lost enough to where the A/C Isn't cold and its barely cooler then outside temp (and it just Isn't cutting it in the weather where I'm at), when I unscrewed the line it was a good blast for sure. The compressor engages and disengages constantly when driving and sitting with the A/C on (today was hot upper 80s and humid). About how to use the manifold gauges, do I have the car running while refilling?You do not need a vacuum pump. You just need the gauges and some R12. You might even want to hook up the gauges to see what sort of pressure you have now.

Does the compressor cycle more frequently? Even when topped off properly it should cycle on a 70 degree day, but on a 90 degree humid day it should remain engaged pretty much constantly. If it's doing that, you are probably ok.

How much do you feel like you actually lost? A tiny squirt? or was it a good blast? I would almost be tempted to just leave it alone and see what the performance is like first.

Middleagecrisis

Active Member

I'll probably get roasted numerous times for posting this opinion, but so be it. So you don't need the manifold gauges to just install freon. I've got a R134A kit that I bought at one of the chain stores (Autozone, O'reilly's, etc.) that came with screw on adapters to convert R-12 to R134A and is simply a hose, a gauge, a connector that screws into the freon can. I've installed R134A into older systems more times than I can remember and never had an issue with that freon working in an older system. You will have to purge the remaining R12 and vacuum the system out using a vacuum pump that you can rent from any of the auto part chain stores. I doubt that you had the system opened up long enough to allow enough moisture to get into the system to cause problems. If the system won't take the higher R134A freon, you probably have a bad o-ring, but the vacuum pump will show that you can't hold a steady vacuum when you evacuate the system, prior to putting in the freon. I run the freon pressure at the high range of the green on the kit gauge, and my 'stang a/c keeps up on the hottest Texas days.

I've lost enough to where the A/C Isn't cold and its barely cooler then outside temp (and it just Isn't cutting it in the weather where I'm at), when I unscrewed the line it was a good blast for sure. The compressor engages and disengages constantly when driving and sitting with the A/C on (today was hot upper 80s and humid). About how to use the manifold gauges, do I have the car running while refilling?

Sounds like it does need a can or two.

I suggest doing some homework on this before attempting. It’s not hard but steps need to be done in specific order.

Here’s a good video to watch and learn from. Keep in mind this is 134a so some of the fitting and the pressures he quotes will not apply to R12. R134a operates at a higher pressure differential so the low side pressure will be at a lower pressure, and the high side at a higher pressure than with r12 at the same ambient conditions.

View: https://youtu.be/ey7Vhm9ZI_U

Watch this and maybe jump around to a few other videos on YouTube. You’ll find many start from pulling a vacuum but since you are just topping off your are kinda starting from a different point. Ac work can be tricky.

I can’t really tell you how much more to add. Ac systems are normally charged by weight. The machine would reclaim the old refrigerant (r134a these days) and then refill the appopriate amount. In this case you kinda need to just add some and observe.

I will say that with my a/c (filled with R12) on an 85 degree day/40% RH, my pressures are 160 high/ 35psi low side and I get a vent temp of around 35 degrees at idle. Unfortunately that is the only pressure data point I have handy but you can kinda compare to that when you hook your gauges up. You can’t compare to r134a pressures as they will be very different.

Here’s a really good auto ac forum as well. I learned a bunch here. Guys there probably forgot more than I’ll ever know

Edit: just to add. One of the guys on that forum gave me this tip for R12. 1500 RPM, ac on high, hold for 90 seconds and then rear pressures. High side should be 2.2-2.7 times the ambient temp. Good rule of thumb to target.

Last edited:

When did ford stop using R12?

1994 was 100% phase in I believe. Some 1993 models got it early. I owned a 93 Lincoln mark 8 that was 134a which makes sense as it was the first of that model year.

Production of R12 stopped in 1996.

You'll be able to tell when it's close by watching the gauges. Stop adding refrigerant when low side pressure pretty much stops rising (around 35#) & only high side does. This indicates liquid refrigerant starting to back up in condenser & full column of liquid to metering device (proper charge). System has no reciever. Usually around 160-175# head pressure.

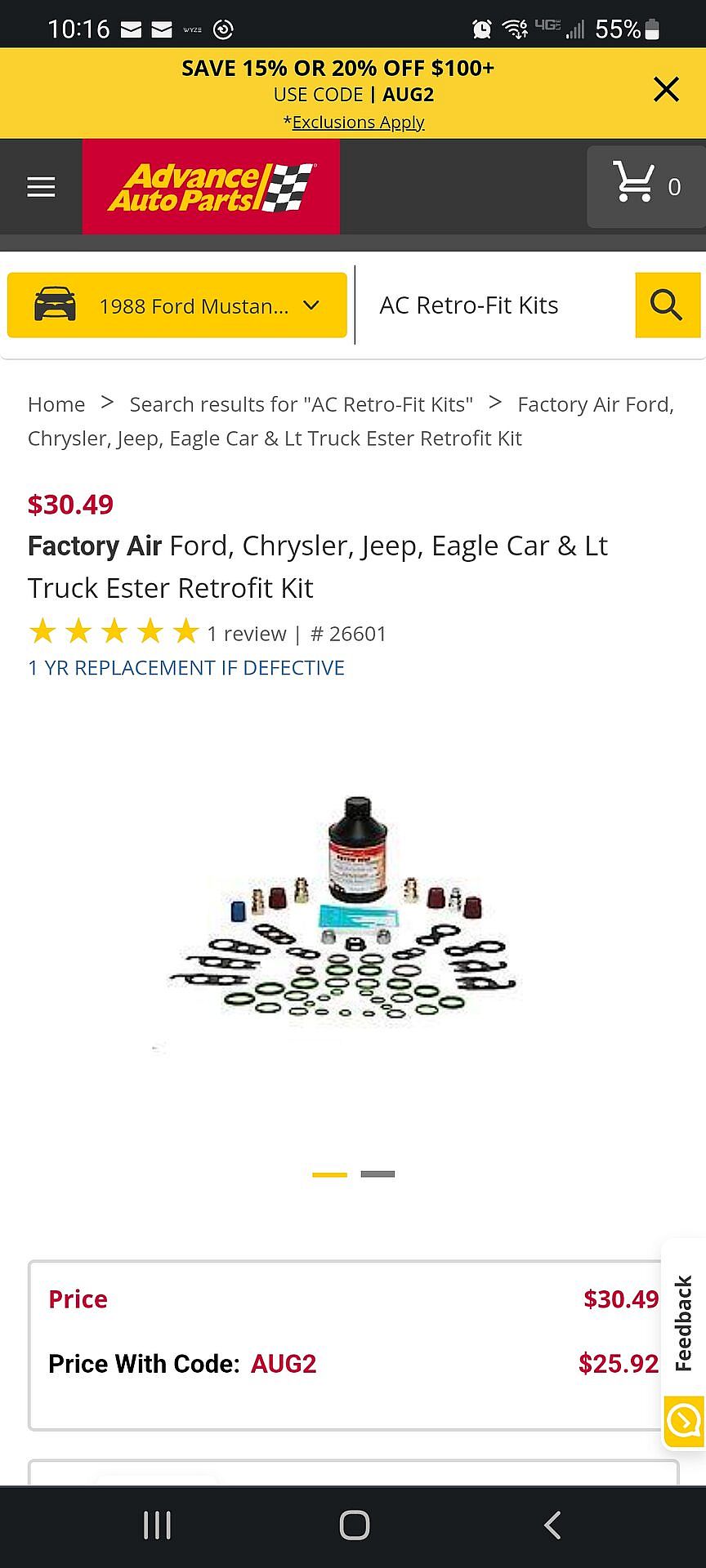

I’ve gotten to trying to recharge my system but I’ve run into a hose attachment issue. I’m not sure how to attach the hose to the cars A/C ports. In the picture the red attachment is for r134 ports but I can’t seem to find r12 attachments for the blue hose for r12 of the same kind so do I just screw the blue hose onto the low pressure port? If I do I’m a little afraid of breaking the Schrader valve. so it just seems like I’m missing the r134 quick attachment equivalent. is that right? Basically am I missing a piece here on my manifold gauges? and need to find one somewhere, or do I just attach the blue hose directly to the low side port on the compressor?

Attachments

I think I'm looking for a coupler or something that has a female end that fits onto the cars r12 ports that converts into a male end that accepts the r134 quick couplers, that would be perfect, anyone know of something like that cause my searches have come up short.

The compressor fitting (low side) is a 1/4” flare

The fitting on the ac line (high side) is 1/2” ACME

Can’t look up the right 134a fitting at the moment

The fitting on the ac line (high side) is 1/2” ACME

Can’t look up the right 134a fitting at the moment

Similar threads

- Replies

- 7

- Views

- 814

- Replies

- 5

- Views

- 807

- Replies

- 13

- Views

- 756

- Replies

- 3

- Views

- 530