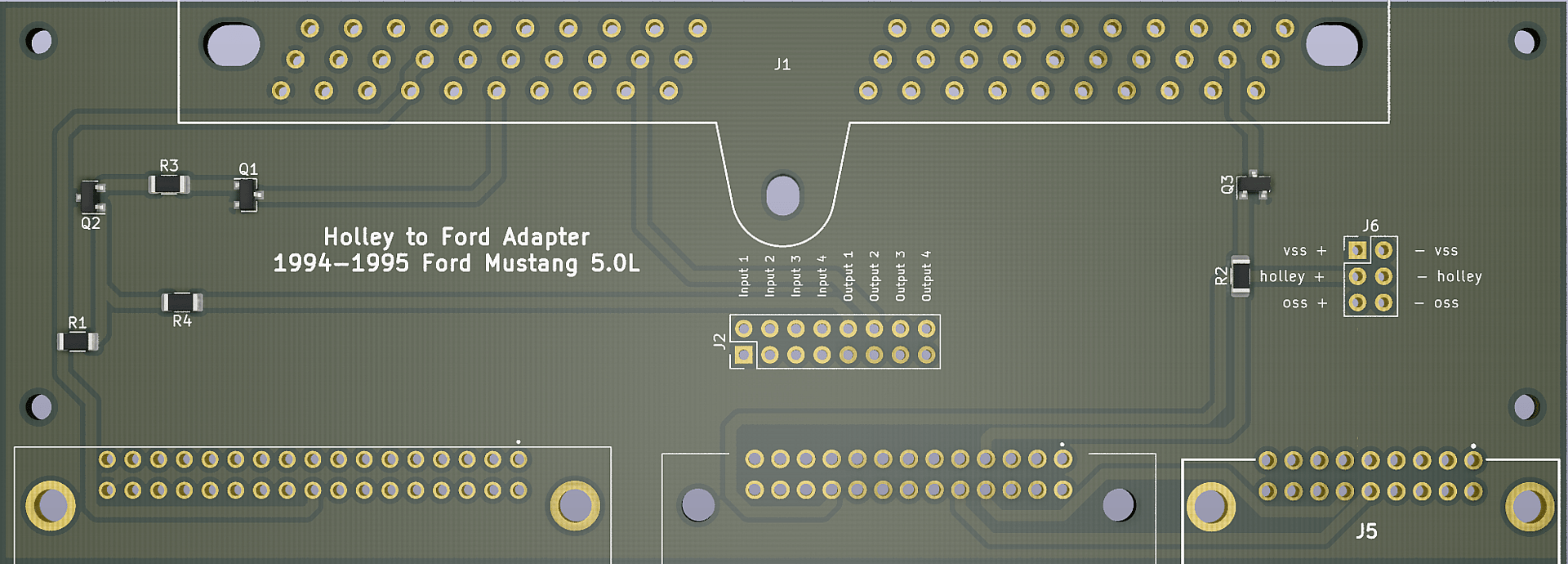

Since Holley makes the almost plug and play option for the Fox Body cars there really isn't anything for the 94/95 folks. For us we have the CCRM and remote TFI which can all be dealt with, but I decided to just make an adapter. The idea here is, you plug the adapter board directly into the EEC-IV connector, then run the pigtail to under the passenger seat location. Then plug the pigtail into the Holley. This would allow for the use of all the factory wiring, IAT and ECT sensors as well. Meaning you really only need the Holley ECU, a wide band oxygen sensor and main power harness.

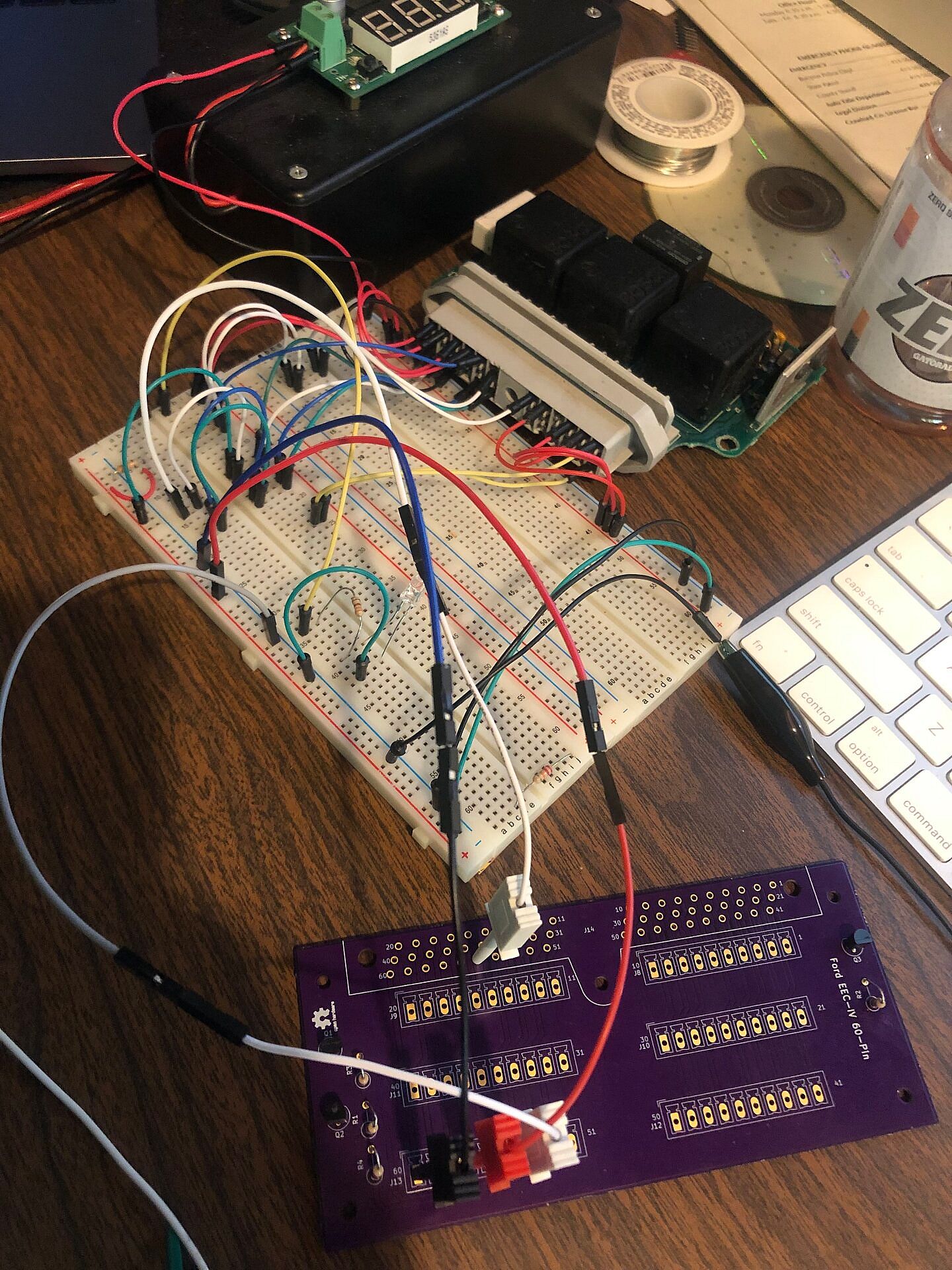

Now this is a "Development" Board pictured below. The production board will have a header style connector on the other side versus soldering wires. The idea here is to make sure everything works as designed. The spots for transistors and resistors is to allow "like" function of the cooling fan and fuel pump. Holley's fuel pump trigger is 12v and Ford factory was a Ground. This board resolves that issue, and resolves the issue of the ECU grounding the low speed fan to keep it off. It will function just like the factory did. This also incorporates A/C functions as well.

It will require a "sub" harness that I'd include as well for the wide band oxygen sensor, along with fuel, oil and map sensors. Production version you will just plug that sub harness direction into the adapter board and away you go. Doing it this way also allows ALL gauges to function.

Anyways sorry for this being so long, but wanted to share. I don't mention which Holley EFI because the idea is, this will work with Terminator X, Terminator X Max, HP, and Dominator.

Now this is a "Development" Board pictured below. The production board will have a header style connector on the other side versus soldering wires. The idea here is to make sure everything works as designed. The spots for transistors and resistors is to allow "like" function of the cooling fan and fuel pump. Holley's fuel pump trigger is 12v and Ford factory was a Ground. This board resolves that issue, and resolves the issue of the ECU grounding the low speed fan to keep it off. It will function just like the factory did. This also incorporates A/C functions as well.

It will require a "sub" harness that I'd include as well for the wide band oxygen sensor, along with fuel, oil and map sensors. Production version you will just plug that sub harness direction into the adapter board and away you go. Doing it this way also allows ALL gauges to function.

Anyways sorry for this being so long, but wanted to share. I don't mention which Holley EFI because the idea is, this will work with Terminator X, Terminator X Max, HP, and Dominator.