Hi all,

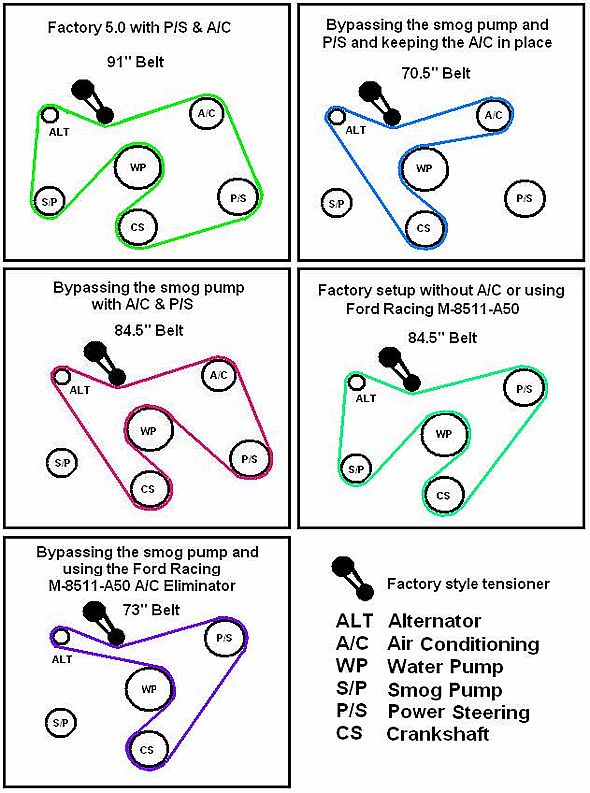

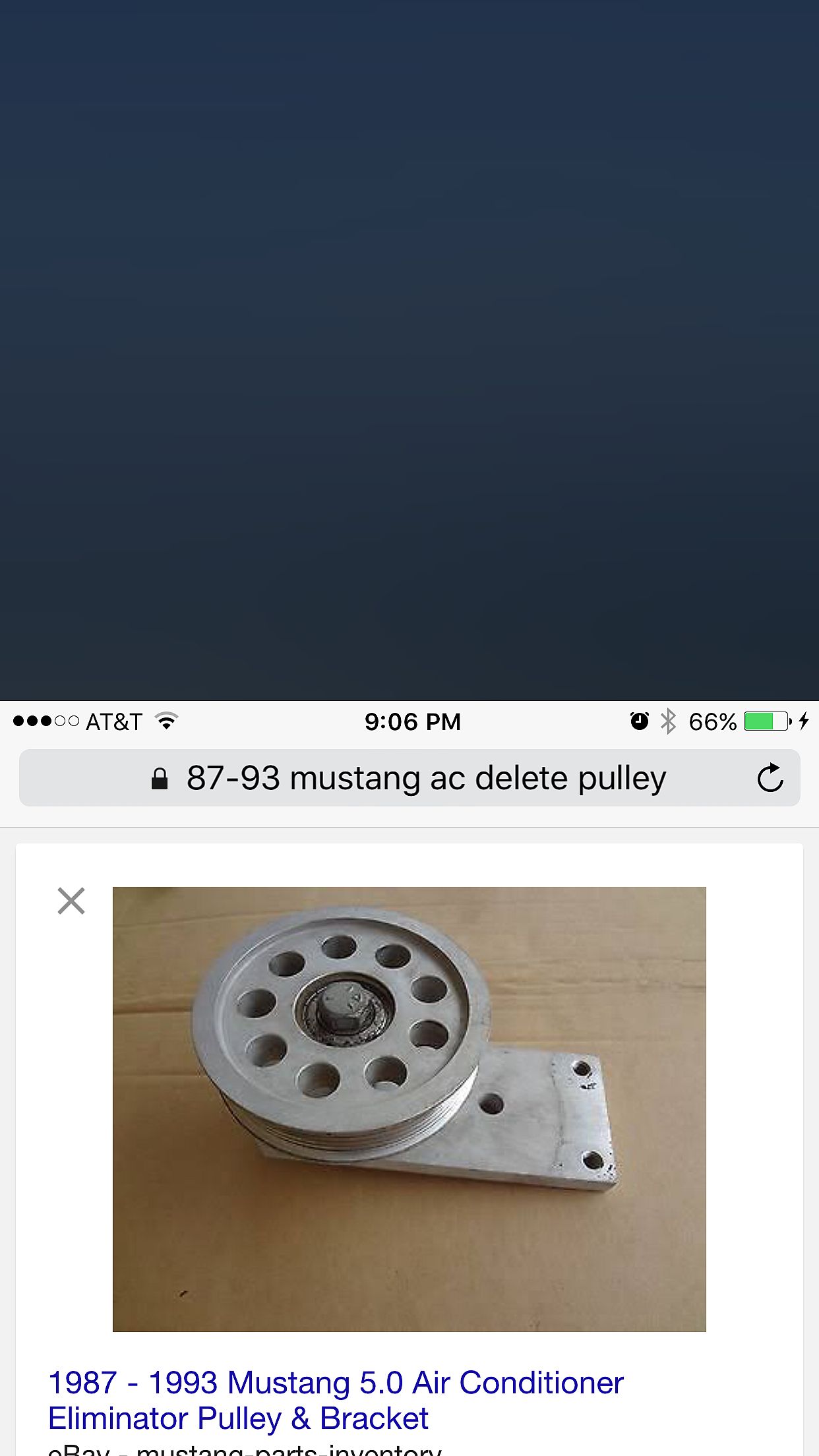

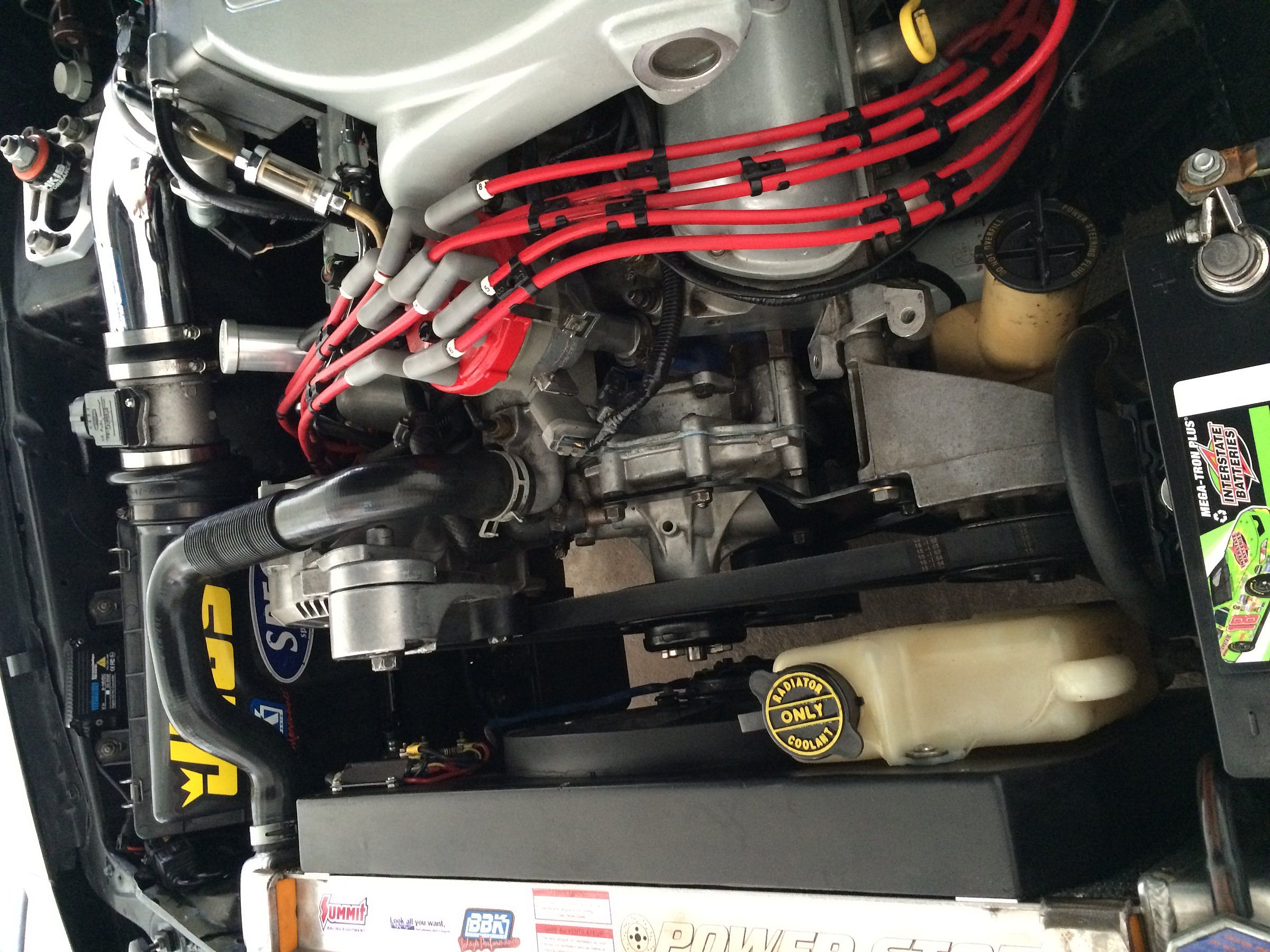

On my 90 GT I'm running a March Performance UD pulleys Kit 1015 I have no issues until I removed the AC system. I wanted to keep the PS pump down in the stock position but the problem is with the WP pulley, the belt rubs when loading the belt tensioner. To solve this problem I replaced the pulley with the stock one and the rubbing problem was solved, the belt runs fine. Well another problem occurred, the temperature went up close to 210 degrees.

I have a 195 degree thermostat because I want to be around 195 - 200 deg. I'm running a Taurus fan with a Delta DC Controller and a Griffin aluminum radiator.

I believe I tried a 180 deg thermostat and the temp went up...

I read that many people run UD crank pulley and stock all the rest of the pulleys and they said no problems, others said they even run a 93 cobra pulley which is even smaller than the GT and no problems.

My 90 gt stock water pulley is smaller than the March one so the pump spins faster, so it should cool down better, or maybe too fast that the water don't spend enough time in the Rad to cool it down?.. Am I missing something here?

PLEASE HELP!!!

On my 90 GT I'm running a March Performance UD pulleys Kit 1015 I have no issues until I removed the AC system. I wanted to keep the PS pump down in the stock position but the problem is with the WP pulley, the belt rubs when loading the belt tensioner. To solve this problem I replaced the pulley with the stock one and the rubbing problem was solved, the belt runs fine. Well another problem occurred, the temperature went up close to 210 degrees.

I have a 195 degree thermostat because I want to be around 195 - 200 deg. I'm running a Taurus fan with a Delta DC Controller and a Griffin aluminum radiator.

I believe I tried a 180 deg thermostat and the temp went up...

I read that many people run UD crank pulley and stock all the rest of the pulleys and they said no problems, others said they even run a 93 cobra pulley which is even smaller than the GT and no problems.

My 90 gt stock water pulley is smaller than the March one so the pump spins faster, so it should cool down better, or maybe too fast that the water don't spend enough time in the Rad to cool it down?.. Am I missing something here?

PLEASE HELP!!!