Hi all I have an Aeromotive stealth 340 pump, BBK fuel pressure regulator and 24lb ford injectors . The problem I'm having is that I cannot get the pressure under 39lb the screw just get loose and the pressure stays I can get it to go up so I know it's working to some extent. Do you think it's possible that the pump is over powering the regulator?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Fuel Pump Over Powering Regulator

- Thread starter Pete1p

- Start date

-

Sponsors (?)

You may have a restriction in the return line. Crawl under the car and check it out.

Copied from the FORD RACING PERFORMANCE PARTS catalog:

PROPERLY SIZING FUEL SYSTEM COMPONENTS

Fuel Pumps

The following information is presented assuming the above information has been taken into consideration regarding BSFC, fuel pressure and specific gravity of the fuel being used. Most fuel pumps for electronic fuel injection are rated for flow at 12 volts @ 40 PSI. Most vehicle charging systems operate anywhere from 13.2v to 14.4v. The more voltage you feed a pump, the faster it spins which, obviously, will put out more fuel. Rating a fuel pump at 12 volts then, should offer a fairly conservative fuel flow rating allowing you to safely determine the pump’s ability to supply an adequate amount of fuel for a particular application.

As previously mentioned, engines actually require a certain WEIGHT of fuel, NOT a certain VOLUME of fuel per horsepower. This can offer a bit of confusion since most fuel pumps are rated by volume, and not by weight. To determine the proper fuel pump required, a few mathematical conversions will need to be performed using the following information. There are 3.785 liters in 1 US Gallon. 1 gallon of gasoline (.72 specific gravity @ 65° F) weighs 6.009 LBS.

To be certain that the fuel pump is not run to its very limit, which could potentially be dangerous to the engine, multiply the final output of the fuel pump by 0.9 to determine the capacity of the fuel pump at 90% output. This should offer plenty of ‘cushion’ as to the overall “horsepower capacity” of the fuel pump.

To determine the overall capacity of a fuel pump rated in liters, use the additional following conversions:

(Liters per Hour) / 3.785 = Gallons

Multiply by 6.009 = LBS/HR

Multiply by 0.9 = Capacity at 90%

Divide by BSFC = Horsepower Capacity

So for a 110 LPH fuel pump:

110 / 3.785 = 29.06 Gallons

29.06 x 6.009 = 174.62 LBS/HR

174.62 x 0.9 = 157 LBS/HR @ 90% Capacity

157 / 0.5 = 314 HP safe naturally aspirated “Horsepower Capacity”

Safe “Horsepower Capacity” @ 40 PSI with 12 Volts

60 Liter Pump = 95 LB/HR X .9 = 86 LB/HR, Safe for 170 naturally aspirated Horsepower

88 Liter Pump = 140 LB/HR X .9 = 126 LB/HR, Safe for 250 naturally aspirated Horsepower

110 Liter Pump = 175 LB/HR X .9 = 157 LB/HR, Safe for 315 naturally aspirated Horsepower

155 Liter Pump = 246 LB/HR X .9 = 221 LB/HR, Safe for 440 naturally aspirated Horsepower

190 Liter Pump = 302 LB/HR X .9 = 271 LB/HR, Safe for 540 naturally aspirated Horsepower

255 Liter Pump = 405 LB/HR X .9 = 364 LB/HR, Safe for 700 naturally aspirated Horsepower

Note: For forced induction engines, the above power levels will be reduced because as the pressure required by the pump increases, the flow decreases. In order to do proper fuel pump sizing, a fuel pump map is required, which shows flow rate versus delivery pressure.

That is, a 255 liter per hour pump at 40 PSI may only supply 200 liters per hour at 58 PSI (40 PSI plus 18 lbs of boost). Additionally, if you use a fuel line that is not large enough, this can result in decreased fuel volume due to the pressure drop across the fuel feed line: 255 LPH at the pump may only result in 225 LPH at the fuel rail.

My Comments:

A lot of people oversize the fuel pump by buying a 255LPH pump thinking that the fuel pump regulator will just pass the excess gas back to the tank. It does, but… Did you ever consider that circulating the fuel around as a 255 LPH pump does will cause the gas to pickup engine heat? What happens to hot gasoline? It boils off or pressurizes the fuel tank! With most of the 5.0 Mustangs having the carbon canister removed or disabled, the car stinks like gas, and the gas mileage drops since the hot fuel evaporates away into the air.

Copied from the FORD RACING PERFORMANCE PARTS catalog:

PROPERLY SIZING FUEL SYSTEM COMPONENTS

Fuel Pumps

The following information is presented assuming the above information has been taken into consideration regarding BSFC, fuel pressure and specific gravity of the fuel being used. Most fuel pumps for electronic fuel injection are rated for flow at 12 volts @ 40 PSI. Most vehicle charging systems operate anywhere from 13.2v to 14.4v. The more voltage you feed a pump, the faster it spins which, obviously, will put out more fuel. Rating a fuel pump at 12 volts then, should offer a fairly conservative fuel flow rating allowing you to safely determine the pump’s ability to supply an adequate amount of fuel for a particular application.

As previously mentioned, engines actually require a certain WEIGHT of fuel, NOT a certain VOLUME of fuel per horsepower. This can offer a bit of confusion since most fuel pumps are rated by volume, and not by weight. To determine the proper fuel pump required, a few mathematical conversions will need to be performed using the following information. There are 3.785 liters in 1 US Gallon. 1 gallon of gasoline (.72 specific gravity @ 65° F) weighs 6.009 LBS.

To be certain that the fuel pump is not run to its very limit, which could potentially be dangerous to the engine, multiply the final output of the fuel pump by 0.9 to determine the capacity of the fuel pump at 90% output. This should offer plenty of ‘cushion’ as to the overall “horsepower capacity” of the fuel pump.

To determine the overall capacity of a fuel pump rated in liters, use the additional following conversions:

(Liters per Hour) / 3.785 = Gallons

Multiply by 6.009 = LBS/HR

Multiply by 0.9 = Capacity at 90%

Divide by BSFC = Horsepower Capacity

So for a 110 LPH fuel pump:

110 / 3.785 = 29.06 Gallons

29.06 x 6.009 = 174.62 LBS/HR

174.62 x 0.9 = 157 LBS/HR @ 90% Capacity

157 / 0.5 = 314 HP safe naturally aspirated “Horsepower Capacity”

Safe “Horsepower Capacity” @ 40 PSI with 12 Volts

60 Liter Pump = 95 LB/HR X .9 = 86 LB/HR, Safe for 170 naturally aspirated Horsepower

88 Liter Pump = 140 LB/HR X .9 = 126 LB/HR, Safe for 250 naturally aspirated Horsepower

110 Liter Pump = 175 LB/HR X .9 = 157 LB/HR, Safe for 315 naturally aspirated Horsepower

155 Liter Pump = 246 LB/HR X .9 = 221 LB/HR, Safe for 440 naturally aspirated Horsepower

190 Liter Pump = 302 LB/HR X .9 = 271 LB/HR, Safe for 540 naturally aspirated Horsepower

255 Liter Pump = 405 LB/HR X .9 = 364 LB/HR, Safe for 700 naturally aspirated Horsepower

Note: For forced induction engines, the above power levels will be reduced because as the pressure required by the pump increases, the flow decreases. In order to do proper fuel pump sizing, a fuel pump map is required, which shows flow rate versus delivery pressure.

That is, a 255 liter per hour pump at 40 PSI may only supply 200 liters per hour at 58 PSI (40 PSI plus 18 lbs of boost). Additionally, if you use a fuel line that is not large enough, this can result in decreased fuel volume due to the pressure drop across the fuel feed line: 255 LPH at the pump may only result in 225 LPH at the fuel rail.

My Comments:

A lot of people oversize the fuel pump by buying a 255LPH pump thinking that the fuel pump regulator will just pass the excess gas back to the tank. It does, but… Did you ever consider that circulating the fuel around as a 255 LPH pump does will cause the gas to pickup engine heat? What happens to hot gasoline? It boils off or pressurizes the fuel tank! With most of the 5.0 Mustangs having the carbon canister removed or disabled, the car stinks like gas, and the gas mileage drops since the hot fuel evaporates away into the air.

No, you have a way oversized pump.

You need at most a 190lph pump even then it's more than you need a 340lph is crazy excessive for what you need.

Also when are you setting the pressure? Is this KOEO or running?

You need at most a 190lph pump even then it's more than you need a 340lph is crazy excessive for what you need.

Also when are you setting the pressure? Is this KOEO or running?

No, you have a way oversized pump.

You need at most a 190lph pump even then it's more than you need a 340lph is crazy excessive for what you need.

Also when are you setting the pressure? Is this KOEO or running?

Running vacuum line disconnected from regulator.

Do you still have the stock heads, intake and cam? If that is true, there is no need for 24LB injectors , the stock 19 LB injectors are the best solution.Hi all I have an Aeromotive stealth 340 pump, BBK fuel pressure regulator and 24lb ford injectors . The problem I'm having is that I cannot get the pressure under 39lb the screw just get loose and the pressure stays I can get it to go up so I know it's working to some extent. Do you think it's possible that the pump is over powering the regulator?

In order to need bigger injectors, you need to get more CFM (cubic feet per minute) of air into the engine. When you have more CFM, then you need more fuel. That means better cylinder heads, intake, MAF, cam or pressurized induction (turbo or supercharger); without that trio, you are just wasting money.

Last edited:

Do you still have the stock heads, intake and cam? If that is true, there is no need for 24LB injectors , the stock 19 LB injectors are the best solution.

In order to need bigger injectors, you need to get more CFM (cubic feet per minute) of air into the engine. When you have more CFM, then you need more fuel. That means better cylinder heads, intake, MAF, cam or pressurized induction (turbo or supercharger); without that trio, you are just wasting money.

I have a CAI, pro-m MAF, accufab throttle body, track heat mainifolds and trickflow heads the Cam is stock for now.

It that case, 24 LB injectors and a 155LPH fuel pump would be the best combination.I have a CAI, pro-m MAF, accufab throttle body, track heat mainifolds and trickflow heads the Cam is stock for now.

Stock fuel pressure is 40psi with the vacuum line disconnected. Should drop to 33-36 with manifold vacuum.

Looks like I'll be putting in an order for a 155 thanks guysIt that case, 24 LB injectors and a 155LPH fuel pump would be the best combination.

Unfortunately that is too high in idle and cruise conditions.

I was always lead to believe 39lb was stock (vacuum disconnected and plugged) is that not true?

You want lower pressure at idle, 34 lbs, I think

Your right about that pressure with vacuum line disconnected, thats like when your accelerating to pass a prius or stretching it out between shifts.

Your right about that pressure with vacuum line disconnected, thats like when your accelerating to pass a prius or stretching it out between shifts.

I have to double check but I think that I am at about 35lb and that doesnt line up with the 39 internal reg. statement. I have the top end off right not to double check the old work and found the push rods are a little to long 6.800 I ordered an adjustable to test with but I think I am going to be closer to 6.700. The lifters are also the originals and the rods were well past 0 lash. I think I am starting to get to some of the root issues here

Yes., it is possible to put TOO much fuel pump on an engine with stock fuel lines and then you can't get the pressure set to operate in the required 38-41 PSI range.

Check fuel pressure:

The local auto parts store may rent or loan a fuel pressure test gauge if you don't have one.

Disconnect the vacuum line from the fuel pressure regulator. Check it for evidence of fuel present in the line by removing it and blowing air through it. If you find fuel, the fuel pressure regulator has failed. Reinstall the line; leave the fuel pressure regulator end of the vacuum line disconnected. Then cap or plug the open end of the vacuum line and stow it out of the way.

Connect the fuel pressure test gauge to the Schrader port located just behind the alternator.

Turn the ignition switch on & start the engine. Observe the pressure: you should see 38-41 PSI at idle.

Turn the ignition off; reconnect the vacuum line to the fuel pressure regulator. Then disconnect the fuel pressure test gauge. Watch out for squirting gas when you do this.

Fuel pump pressure test

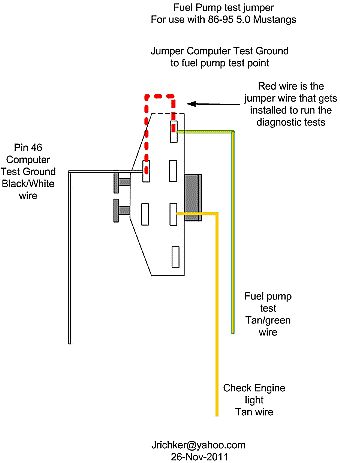

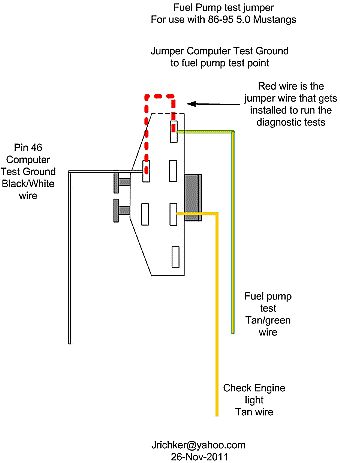

Disconnect the larger of the two fuel lines up by the Schrader valve. It is the return line and does not have the Schrader valve on it. Find a piece of rubber fuel hose and clamp it on the return line coming from the regulator. Stick a bolt in the other end of the hose and make sure that all your connections are tight and leak proof as possible. When this powers up, you don't want fuel squirting everywhere. Hook up the fuel pressure test gauge. Turn the ignition switch on and watch for leaks. You may want to use a helper inside the car to cut the switch off quickly if you have a leak. To trick the fuel pump into running, find the ECC test connector and jump the connector in the Upper RH corner to ground.

Caution!!! You have blocked the return line for the fuel pump! Pressure will rise very quickly past safe levels with a good pump

If the pressure goes up past 55 PSI, the pump is good and the fuel pressure regulator is bad. If the fuel pressure does not hit 55 PSI or more in a few seconds, the pump is bad or you have electrical problems.

Check fuel pressure:

The local auto parts store may rent or loan a fuel pressure test gauge if you don't have one.

Disconnect the vacuum line from the fuel pressure regulator. Check it for evidence of fuel present in the line by removing it and blowing air through it. If you find fuel, the fuel pressure regulator has failed. Reinstall the line; leave the fuel pressure regulator end of the vacuum line disconnected. Then cap or plug the open end of the vacuum line and stow it out of the way.

Connect the fuel pressure test gauge to the Schrader port located just behind the alternator.

Turn the ignition switch on & start the engine. Observe the pressure: you should see 38-41 PSI at idle.

Turn the ignition off; reconnect the vacuum line to the fuel pressure regulator. Then disconnect the fuel pressure test gauge. Watch out for squirting gas when you do this.

Fuel pump pressure test

Disconnect the larger of the two fuel lines up by the Schrader valve. It is the return line and does not have the Schrader valve on it. Find a piece of rubber fuel hose and clamp it on the return line coming from the regulator. Stick a bolt in the other end of the hose and make sure that all your connections are tight and leak proof as possible. When this powers up, you don't want fuel squirting everywhere. Hook up the fuel pressure test gauge. Turn the ignition switch on and watch for leaks. You may want to use a helper inside the car to cut the switch off quickly if you have a leak. To trick the fuel pump into running, find the ECC test connector and jump the connector in the Upper RH corner to ground.

Caution!!! You have blocked the return line for the fuel pump! Pressure will rise very quickly past safe levels with a good pump

If the pressure goes up past 55 PSI, the pump is good and the fuel pressure regulator is bad. If the fuel pressure does not hit 55 PSI or more in a few seconds, the pump is bad or you have electrical problems.

Last edited:

Similar threads

- Replies

- 7

- Views

- 803

- Replies

- 22

- Views

- 1K

- Replies

- 4

- Views

- 705

- Replies

- 25

- Views

- 2K

- Replies

- 8

- Views

- 953