Hey last night while I was installing my harmonic balancer with the installation tool and made a huge mistake of turning the big nut without holding the main assembly with another wrench. Now the adapter that screw into the crank is stuck tight asf in the crank. I tried using vice grips to turn it free but that was a massive fail. How the hell do i get this adapter out the crank??

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Harmonic balancer adapter stuck in crank

- Thread starter SmokeytheFox

- Start date

-

Sponsors (?)

The brown liquid is penetrating oil but that’s the adapter in the centerPics?

- Mar 2, 2015

- 6,811

- 5,849

- 203

The balancer isn't a press fit on a 5.0. It should've just slid on with no need for a tool. At most a block of wood and a few taps with a hammer.

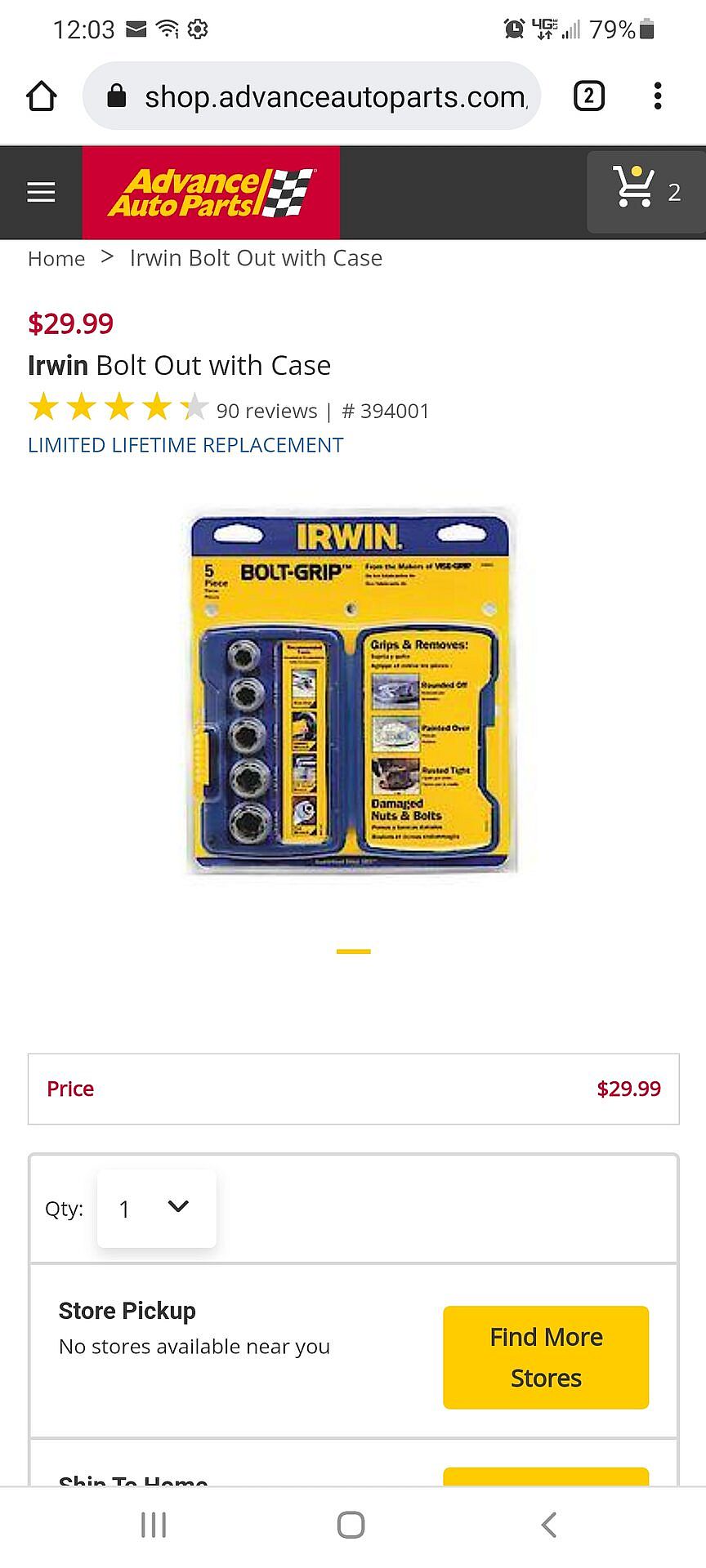

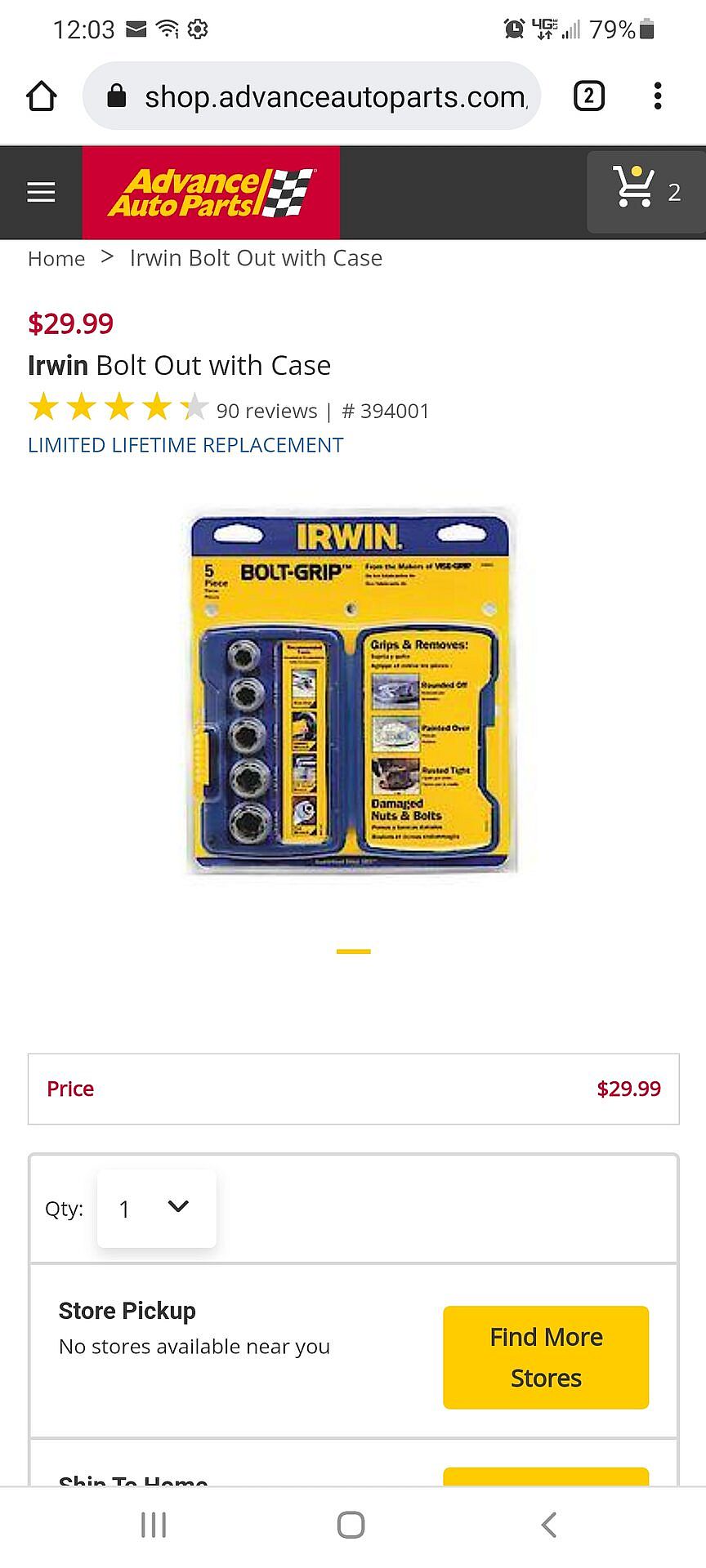

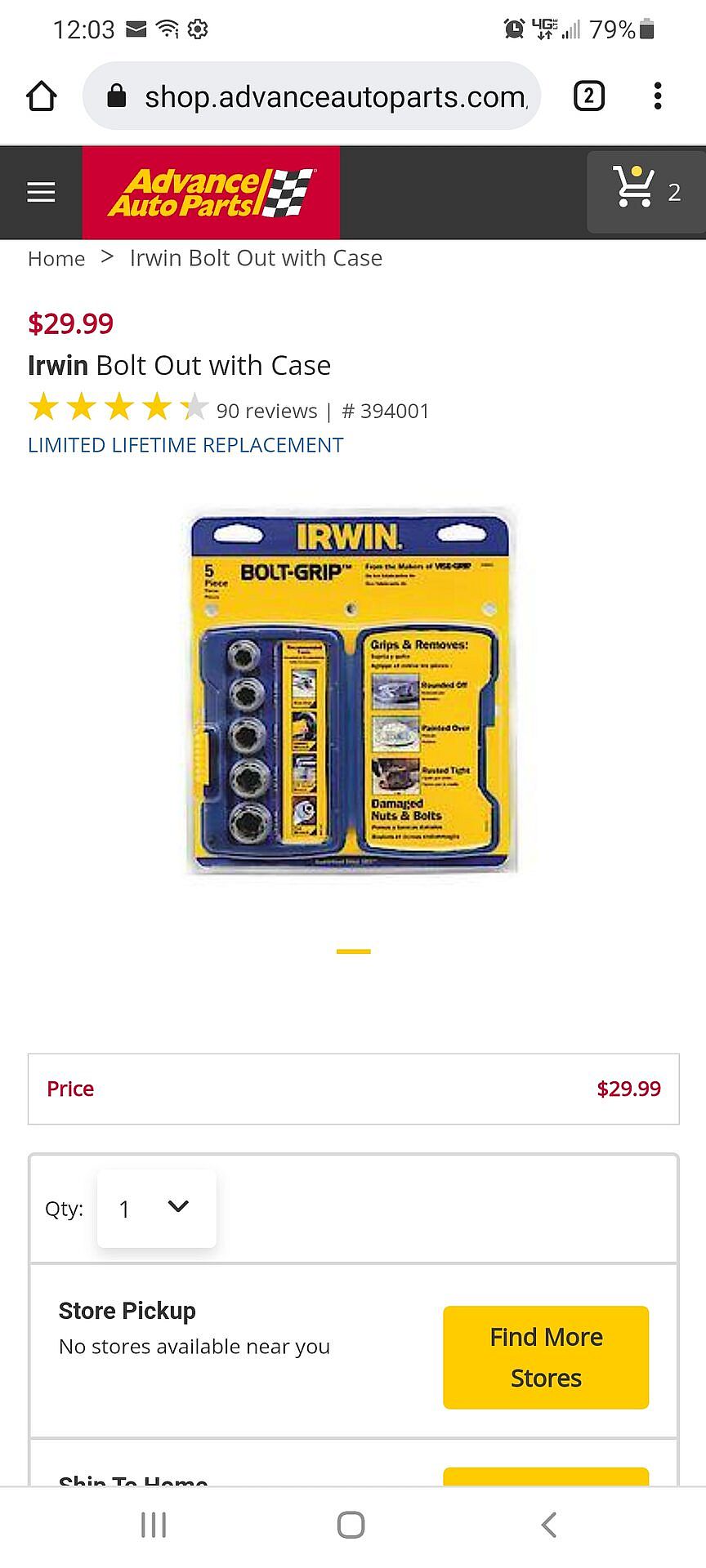

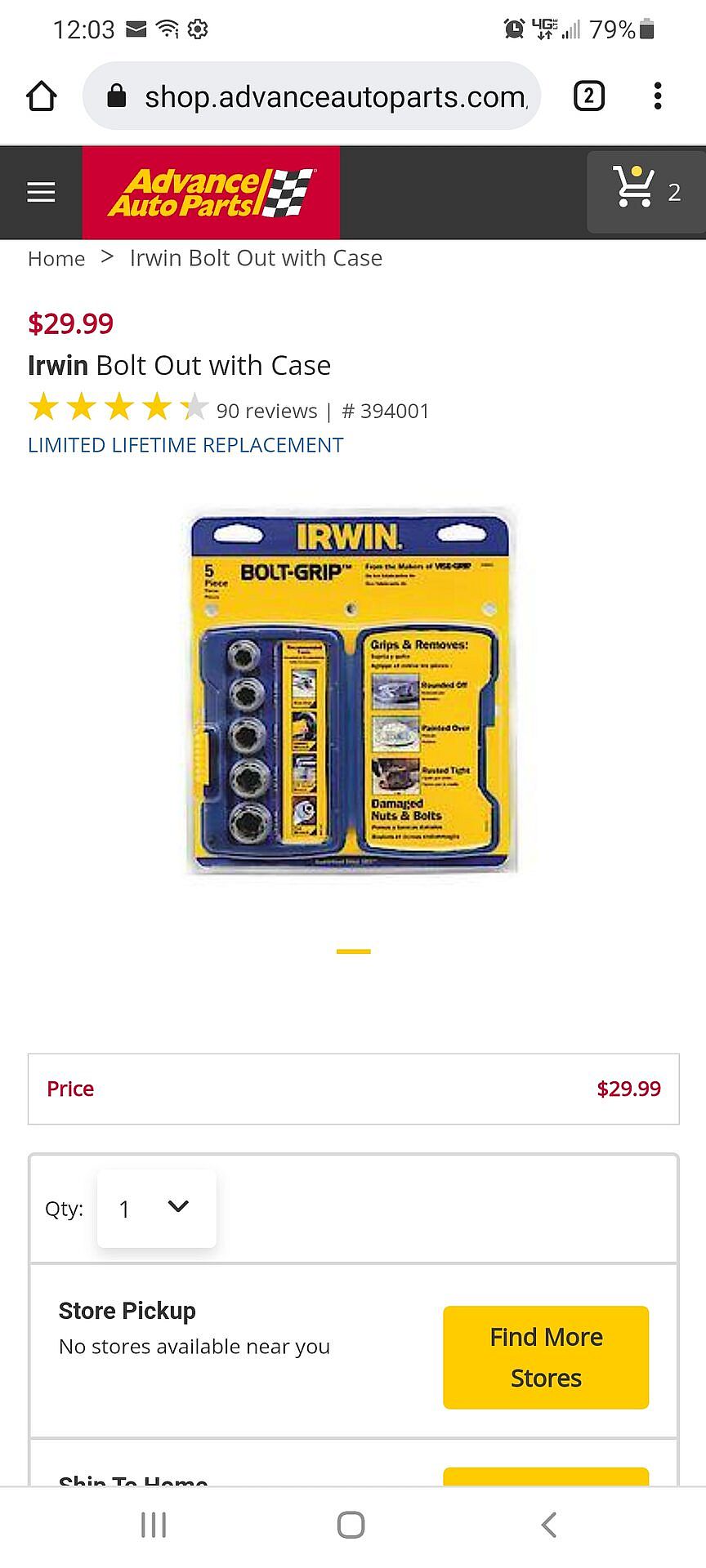

You'll need some heat and a Irwin tool set. The heat may damage the crank seal. To fix that the timing cover will have to come off. Try it first with moderate heat from a propane torch.

The other idea that may work is to weld a nut to it and back it out.

You'll need some heat and a Irwin tool set. The heat may damage the crank seal. To fix that the timing cover will have to come off. Try it first with moderate heat from a propane torch.

The other idea that may work is to weld a nut to it and back it out.

I was chastised for installing my HB without an install tool. I was sure it is not a press on item, but that did not matter to the mechanic.The balancer isn't a press fit on a 5.0. It should've just slid on with no need for a tool. At most a block of wood and a few taps with a hammer.

You'll need some heat and a Irwin tool set. The heat may damage the crank seal. To fix that the timing cover will have to come off. Try it first with moderate heat from a propane torch.

The other idea that may work is to weld a nut to it and back it out.

After making sure the balancer felt and sounded seated, I torqued the bolt, test ran it after everything else was reassembled, and checked the torque again. It had not changed, so I ran it down the road. Thanks for the peace of mind, @90sickfox .

@SmokeytheFox to confirm, the piece that’s in there is a tube that’s threaded in the inside and outside? Here is what I would do.

Soak up the rest of the penetrating oil and use carb cleaner to degrease the inside threads. Use the air compressor to blow out the carb cleaner and clean again. Get a grade 5 or better bolt the right size for the threads and use new Red thread locker to keep it in the threads of the insert. The insert should have less grab to the crank than the bolt to the insert at that point. If all is clean and the Loctite is fresh, you will end up with the parts out of the car and stuck together enough to need heat to get them apart. If not, you’ll have dirty threads and will still need to use the tools in the picture, a left hand drill bit and easy out, or welding a nut on.

- Mar 2, 2015

- 6,811

- 5,849

- 203

That piece stuck in there looks like the end of a puller. The piece the threaded part spins inside that looks like a cone. ( I could be wrong ). It would be used for removing the balancer not installing. If using the tool I just described always use the crank bolt threaded in a bit behind it to avoid this.

No thats a completely tool. This is the installer which is an adapter that threads into the crank with a giant nut and press. You're suppose to hold the assembly with a wrench while your turning the nut or that adapter is just gonna tighten up in the crank. Makes putting on the balancer extremely easy when i use it correctly. This time I was rushing and fcked myself by not paying attention lolThat piece stuck in there looks like the end of a puller. The piece the threaded part spins inside that looks like a cone. ( I could be wrong ). It would be used for removing the balancer not installing. If using the tool I just described always use the crank bolt threaded in a bit behind it to avoid this.

No thats a completely different tool. This is the installer which is an adapter that threads into the crank with a giant nut and press. You're suppose to hold the assembly with a wrench while your turning the nut or that adapter is just gonna tighten up in the crank. Makes putting on the balancer extremely easy when i use it correctly. This time I was rushing and fcked myself by not paying attention lol

the proper size bolt extractor can't get a grip since theres no ridges on the sides of the adapter. I'll try the bolt and loctite method in the morning. Im nervous tho, it'd be just my luck to have the bolt snap.I was chastised for installing my HB without an install tool. I was sure it is not a press on item, but that did not matter to the mechanic.

After making sure the balancer felt and sounded seated, I torqued the bolt, test ran it after everything else was reassembled, and checked the torque again. It had not changed, so I ran it down the road. Thanks for the peace of mind, @90sickfox .

@SmokeytheFox to confirm, the piece that’s in there is a tube that’s threaded in the inside and outside? Here is what I would do.

Soak up the rest of the penetrating oil and use carb cleaner to degrease the inside threads. Use the air compressor to blow out the carb cleaner and clean again. Get a grade 5 or better bolt the right size for the threads and use new Red thread locker to keep it in the threads of the insert. The insert should have less grab to the crank than the bolt to the insert at that point. If all is clean and the Loctite is fresh, you will end up with the parts out of the car and stuck together enough to need heat to get them apart. If not, you’ll have dirty threads and will still need to use the tools in the picture, a left hand drill bit and easy out, or welding a nut on.

That’s why I suggest a grade 5 bolt. It’s hardened, but not so much that it will be difficult to drill out if you break it. A grade 8 will be fine if you have LH carbide bits from McMaster Carr.the proper size bolt extractor can't get a grip since theres no ridges on the sides of the adapter. I'll try the bolt and loctite method in the morning. Im nervous tho, it'd be just my luck to have the bolt snap.

manicmechanic007

5 Year Member

Long before anyone ever made an install tool for a damper

People like me were hammering them on

I still do most of the time

An expensive brass hammer is your friend

A cheap HF brass hammer is friendly too

Should be able to get the tool part out of the crank with a pilot bearing puller?

People like me were hammering them on

I still do most of the time

An expensive brass hammer is your friend

A cheap HF brass hammer is friendly too

Should be able to get the tool part out of the crank with a pilot bearing puller?

Every balancer on a 5.0 I’ve done has been an interference fit.The balancer isn't a press fit on a 5.0. It should've just slid on with no need for a tool. At most a block of wood and a few taps with a hammer.

You'll need some heat and a Irwin tool set. The heat may damage the crank seal. To fix that the timing cover will have to come off. Try it first with moderate heat from a propane torch.

The other idea that may work is to weld a nut to it and back it out.

Is the adaptor broken off in the crank?

Never mind, just saw the picture of the tool you’re using, looks different than the one I have. If all else fails, see if you can weld a nut on the end a turn it out.

Monkeybutt2000

Mustang Master

Gonna agree here,I've never been able to just slide on a balancer. The balancer I have on my current engine had to be honed to fit the crank.Every balancer on a 5.0 I’ve done has been an interference fit.

Is the adaptor broken off in the crank?

Never mind, just saw the picture of the tool you’re using, looks different than the one I have. If all else fails, see if you can weld a nut on the end a turn it out.

manicmechanic007

5 Year Member

You may end up having to drill the threaded adapter / insert out

I would spare no expense buying a series of left hand drill bits

I buy left hand bits regularly

It is not easy to find the big ones

The crank thread is 5/8-18

Do not drill more than 9/16 maybe 14mm and then pic the remains out

If you are lucky the insert will come screwing out with the 1/2 left hand bit

I would spare no expense buying a series of left hand drill bits

I buy left hand bits regularly

It is not easy to find the big ones

The crank thread is 5/8-18

Do not drill more than 9/16 maybe 14mm and then pic the remains out

If you are lucky the insert will come screwing out with the 1/2 left hand bit

+1 on the SBF interference fit balancer. I’ve never had a Ford engine that the balancer “slid on”

Well,…wait a minute…They all actually “slid on”.

As long as you beat them with a hammer.

Well,…wait a minute…They all actually “slid on”.

As long as you beat them with a hammer.

Me neither and I have had them off plenty of times . I never beat the front of my crankshaft with a hammer either that’s sort of weird to me . Literally used the same bolt that holds the balancer on and a half Inch rachet and nice and easy Everytime the balancer slowly goes on with no drama.+1 on the SBF interference fit balancer. I’ve never had a Ford engine that the balancer “slid on”

Well,…wait a minute…They all actually “slid on”.

As long as you beat them with a hammer.

Only exceptions would be like an ati or something like that .

even the current engine has a friction fit balancer.

Topped off with a required 275ft/lb bolt torque to hold that bitch on.

Topped off with a required 275ft/lb bolt torque to hold that bitch on.

Me neither and I have had them off plenty of times . I never beat the front of my crankshaft with a hammer either that’s sort of weird to me . Literally used the same bolt that holds the balancer on and a half Inch rachet and nice and easy Everytime the balancer slowly goes on with no drama.

Only exceptions would be like an ati or something like that .

That’s how I’ve always installed them. Seems easy enough to rachet them in, back it off, and then torque to spec

ChaseRoads

do I need to lube this area?

Similar threads

- Replies

- 17

- Views

- 3K

- Replies

- 65

- Views

- 4K

- Replies

- 6

- Views

- 2K

Suspension

Front LCA rebuild **FAIL**

- Replies

- 20

- Views

- 2K