As I said in my "progress" thread:

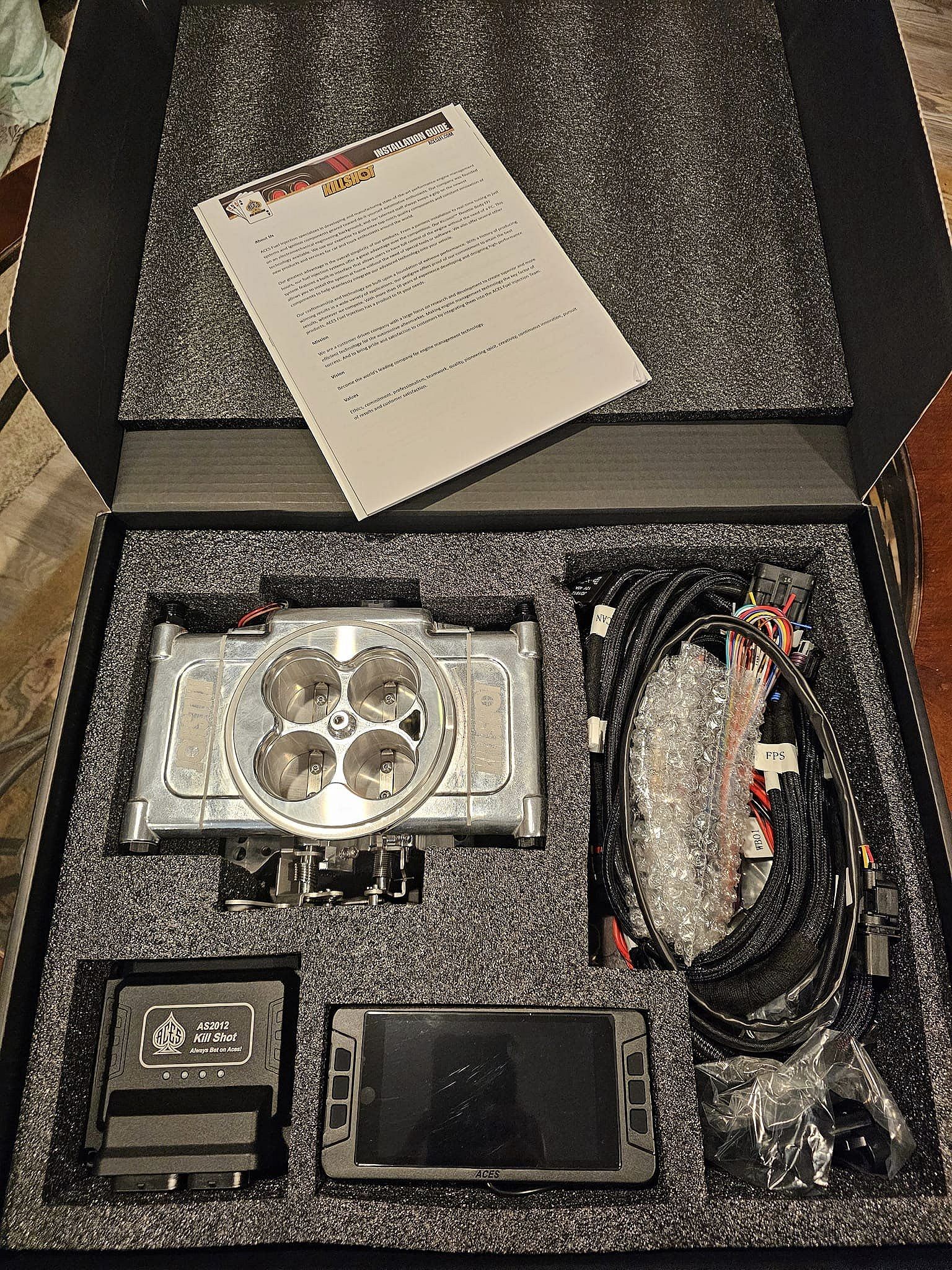

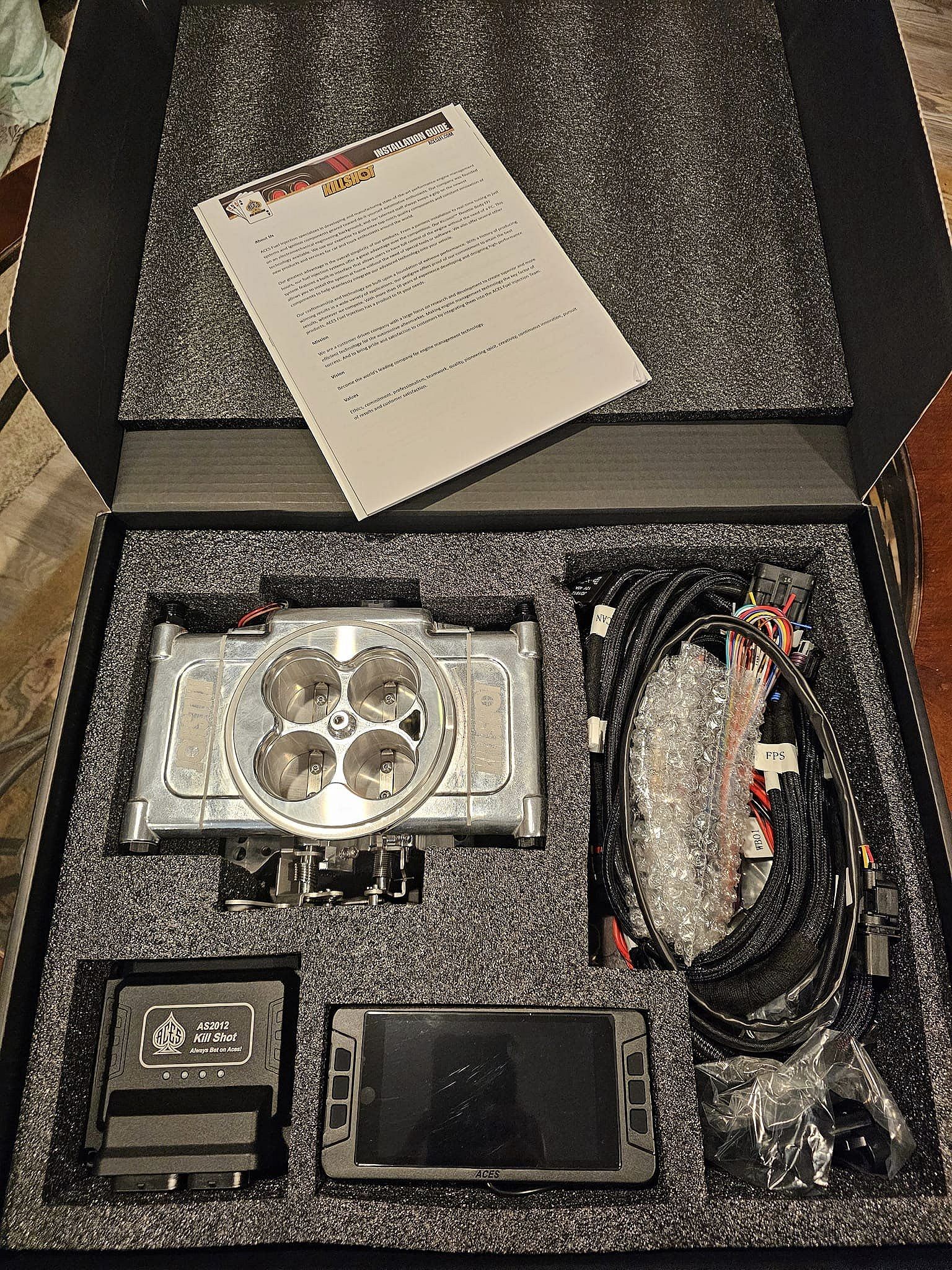

I finally ordered all of the parts I think I need to complete the conversion on my 302. I'm ditching the 650 double pumper and going with the Aces Killshot. I took advantage of their discounts over the Christmas holiday and got the system for <$800 because I'm tired of fiddling with the carb. I threw this carb together from all of the miscellaneous parts I had. It works, but tuning it seems to be more challenging than I want to deal with in a "toy." The thought is that the FI setup will make it more reliable, require less maintenance and upkeep, and make it a little easier to drive.

To keep this all in one thread, here's an edited version of the quote above:

I went ahead and ordered the remainder of what I think I'll need to complete the install of the fuel injection system I bought. Here's the list of stuff that I've bought over the last couple months:

Aces Killshot TBI system:

acesefi.com

acesefi.com

Second gauge for redundancy and a pressure sensor to link to the Aces system with 2 inline fittings to incorporate them.

6AN fuel hose - 10' of rubber and 10' of PTFE with fittings (black for the rubber and blue/red anodized for PTFE).

25' of 3/8 Copper/Nickel fuel line

10 - 3/8" compression union fittings (in case bending the hard lines don't work like I hope.)

Inline 10 micron filter

An Aeromotive 18683 Fuel Pump and Hanger for a Fox Mustang (since I have a Fox tank in my car.... )

)

New fuel level sender and connector for 83-86 Mustangs to remove the stock sender that I had to modify.

Clamps to secure the hard lines to the body

In addition to the above, I decided to purchase some tools to make the job easier:

Adjustable AN wrenches

AN vice jaws

A new, beefier tube bender than the one I have

1/8" letter stamps

The plan is to use the PTFE set with the anodized fittings to designate the pressure side from the tank through the throttle body to the regulator. I intend to use the black fittings and rubber hose to designate the return line. The compression fittings at each end of the hard lines are all black, so the thought is to try to use the letter stamps to mark their designations once they're all assembled to hopefully eliminate/minimize any kind of distortion from their use. As for running 2 gauges and the sensor, I'm going to keep one gauge on the regulator to make adjusting pressure easier. The second will be on the upstream side of the throttle body while the sensor will be on the downstream side.

I will also be doing some additional work while I have it apart. As it is now, my fuel tank straps are held in with through bolts on one side through the spare tire well. I used self tapping screws on the other side. The plan is to use the new rivnut tool I bought a while back and replace the self tapping screws with actual bolts. I also think that I'll tack weld the bolt heads in the spare tire well so I don't have to attempt to hold one end of the bolt while I tighten the nuts under the car - in all honesty, I don't even remember how I did it the first time.

Anyway, this is the plan I have in my head. I'll update as I go along....

So as I sit here and do whole lot of nothing - I went ahead and ordered the remainder of what I think I'll need to complete the install of the fuel injection system I bought. Unfortunately I don't have any kind of ETA for when I'll get started - not being very mobile kind of puts a damper on actually working on projects.....

3 more days until my follow-up and hopefully having this cast removed. I'm hoping that I'll be able to start bearing weight again. If I'm ok'd I'm planning on getting a jump on this, I kind of figure the house projects will be put on hold for a few months so my ankle can fully heal before I attempt to get on a ladder. But here's the list of stuff that I've bought over the last couple months:

Aces Killshot TBI system:

Fuel pressure regulator with gauge

Aces EFI Killshot™ TBI System

ACES EFI Killshot EZ Tune EFI system is one of the most powerful 4-bbl TBI systems on the market! 650 hp ,4 sets of 100 lb/hr Injectors, designed for 4150 style flange manifolds, 5 Inch handheld tuner with GPS speedometer Features - Remote-mounted ECU to avoid dreaded heat-and-vibration -...acesefi.com

Second gauge for redundancy and a pressure sensor to link to the Aces system with 2 inline fittings to incorporate them.

6AN fuel hose - 10' of rubber and 10' of PTFE with fittings (black for the rubber and blue/red anodized for PTFE).

25' of 3/8 Copper/Nickel fuel line

10 - 3/8" compression union fittings (in case bending the hard lines don't work like I hope.)

Inline 10 micron filter

An Aeromotive 18683 Fuel Pump and Hanger for a Fox Mustang (since I have a Fox tank in my car....)

Clamps to secure the hard lines to the body

Edit: added a new fuel level sender and connector for 83-86 Mustangs to remove the stock sender that I had to modify.

In addition to the above, I decided to purchase some tools to make the job easier:

Adjustable AN wrenches

AN vice jaws

A new, beefier tube bender than the one I have

1/8" letter stamps

The plan is to use the PTFE set with the anodized fittings to designate the pressure side from the tank through the throttle body to the regulator. I intend to use the black fittings and rubber hose to designate the return line. The compression fittings at each end of the hard lines are all black, so the thought is to try to use the letter stamps to mark their designations once they're all assembled to hopefully eliminate/minimize any kind of distortion from their use. As for running 2 gauges and the sensor, I'm going to keep one gauge on the regulator to make adjusting pressure easier. The second will be on the upstream side of the throttle body while the sensor will be on the downstream side.

I will also be doing some additional work while I have it apart. As it is now, my fuel tank straps are held in with through bolts on one side through the spare tire well. I used self tapping screws on the other side. The plan is to use the new rivnut tool I bought a while back and replace the self tapping screws with actual bolts. I also think that I'll tack weld the bolt heads in the spare tire well so I don't have to attempt to hold one end of the bolt while I tighten the nuts under the car - in all honesty, I don't even remember how I did it the first time.

Anyway, this is the plan I have in my head. I'll update as I go along, but the big question I have for everyone - should I start a new thread just for this or should I keep it in this thread? What I was thinking is if it's in it's own thread it would make it easier for anyone to reference and I could just post a link in this one....

I finally ordered all of the parts I think I need to complete the conversion on my 302. I'm ditching the 650 double pumper and going with the Aces Killshot. I took advantage of their discounts over the Christmas holiday and got the system for <$800 because I'm tired of fiddling with the carb. I threw this carb together from all of the miscellaneous parts I had. It works, but tuning it seems to be more challenging than I want to deal with in a "toy." The thought is that the FI setup will make it more reliable, require less maintenance and upkeep, and make it a little easier to drive.

To keep this all in one thread, here's an edited version of the quote above:

I went ahead and ordered the remainder of what I think I'll need to complete the install of the fuel injection system I bought. Here's the list of stuff that I've bought over the last couple months:

Aces Killshot TBI system:

Aces EFI Killshot™ TBI System

ACES EFI Killshot EZ Tune EFI system is one of the most powerful 4-bbl TBI systems on the market! 650 hp ,4 sets of 100 lb/hr Injectors, designed for 4150 style flange manifolds, 5 Inch handheld tuner with GPS speedometer Features - Remote-mounted ECU to avoid dreaded heat-and-vibration -...

acesefi.com

acesefi.com

Fuel pressure regulator with gaugeSecond gauge for redundancy and a pressure sensor to link to the Aces system with 2 inline fittings to incorporate them.

6AN fuel hose - 10' of rubber and 10' of PTFE with fittings (black for the rubber and blue/red anodized for PTFE).

25' of 3/8 Copper/Nickel fuel line

10 - 3/8" compression union fittings (in case bending the hard lines don't work like I hope.)

Inline 10 micron filter

An Aeromotive 18683 Fuel Pump and Hanger for a Fox Mustang (since I have a Fox tank in my car....

New fuel level sender and connector for 83-86 Mustangs to remove the stock sender that I had to modify.

Clamps to secure the hard lines to the body

In addition to the above, I decided to purchase some tools to make the job easier:

Adjustable AN wrenches

AN vice jaws

A new, beefier tube bender than the one I have

1/8" letter stamps

The plan is to use the PTFE set with the anodized fittings to designate the pressure side from the tank through the throttle body to the regulator. I intend to use the black fittings and rubber hose to designate the return line. The compression fittings at each end of the hard lines are all black, so the thought is to try to use the letter stamps to mark their designations once they're all assembled to hopefully eliminate/minimize any kind of distortion from their use. As for running 2 gauges and the sensor, I'm going to keep one gauge on the regulator to make adjusting pressure easier. The second will be on the upstream side of the throttle body while the sensor will be on the downstream side.

I will also be doing some additional work while I have it apart. As it is now, my fuel tank straps are held in with through bolts on one side through the spare tire well. I used self tapping screws on the other side. The plan is to use the new rivnut tool I bought a while back and replace the self tapping screws with actual bolts. I also think that I'll tack weld the bolt heads in the spare tire well so I don't have to attempt to hold one end of the bolt while I tighten the nuts under the car - in all honesty, I don't even remember how I did it the first time.

Anyway, this is the plan I have in my head. I'll update as I go along....

It's now been ordered. I guess it's not a necessity really, but there's no reason to leave the mechanical fuel pump in it's place, is there?

It's now been ordered. I guess it's not a necessity really, but there's no reason to leave the mechanical fuel pump in it's place, is there?