I’m finally getting the top end of my engine back together (‘95 5.0) and have a couple questions. It’s been 25 years since I’ve done it and seem to have forgotten a few things!

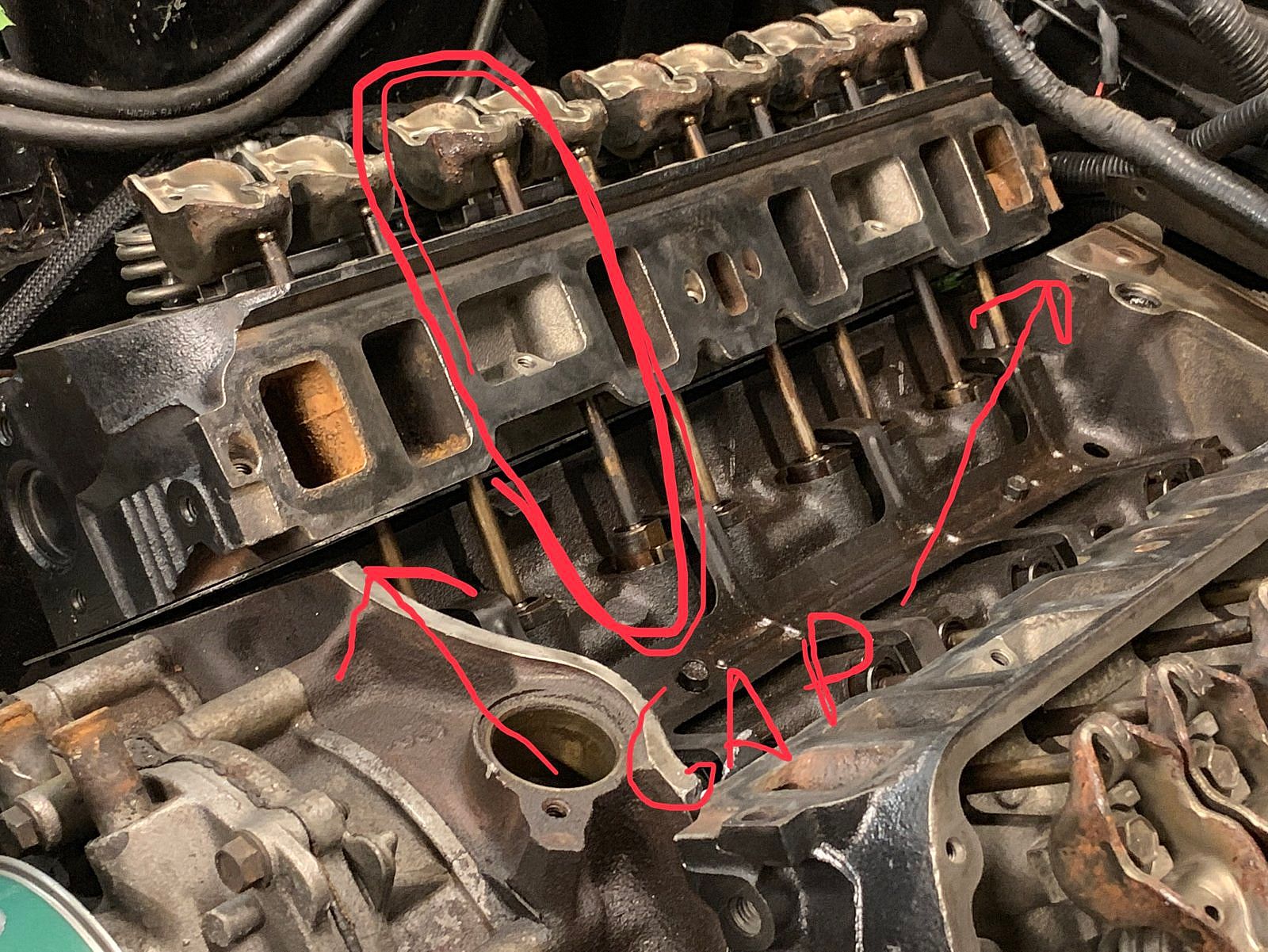

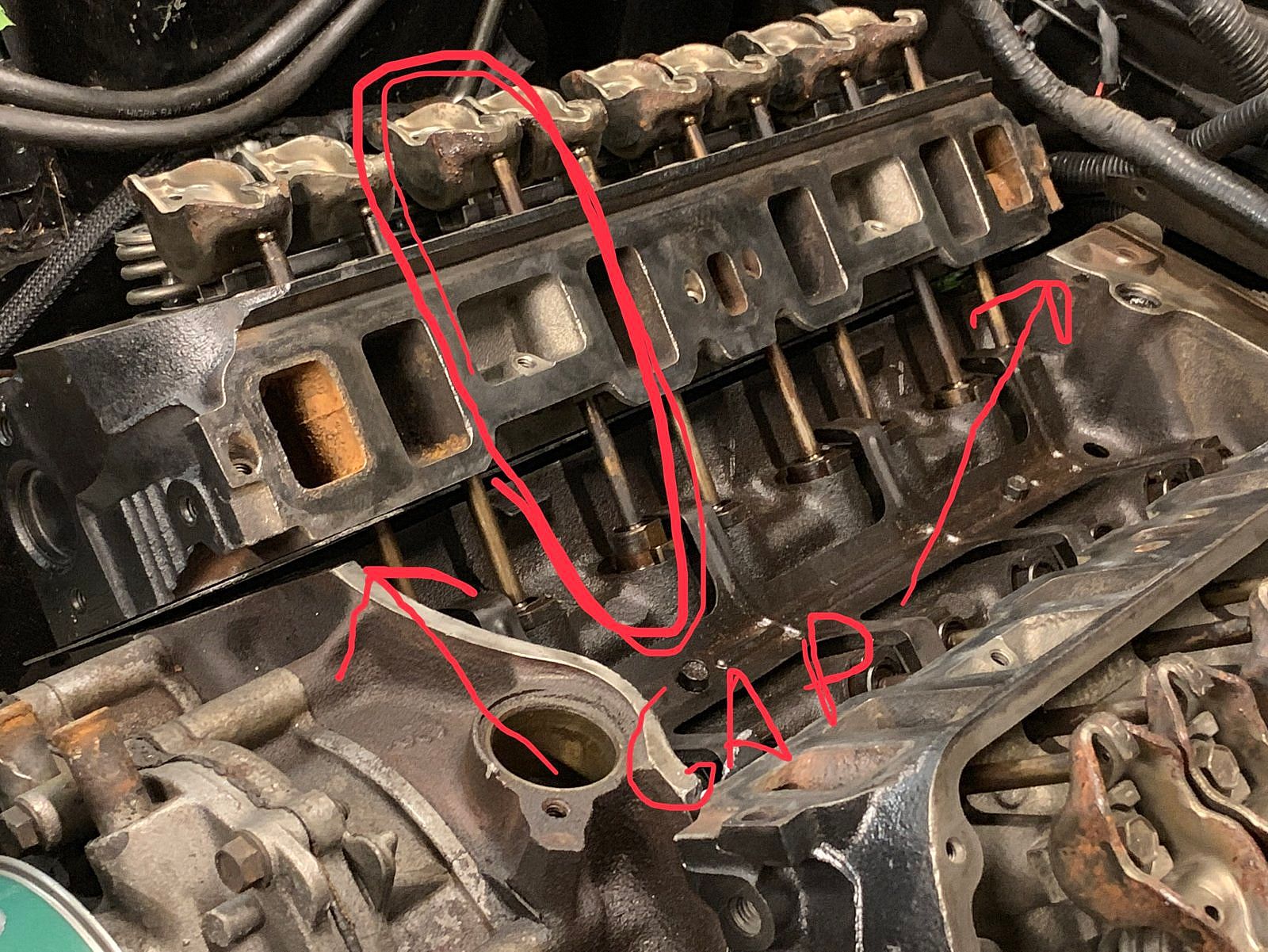

1.) in the pic below you can see a gap between the head and deck on the manifold side. Without pushrods it sits flush. The circled pushrod is the culprit (I assume a cam lobe is in the up position). Is this normal? Is it ok to partially tighten down the first head bolt to compress spring so it sits flush or will that screw with torque readings? Was trying to avoid having to pull rockers off and install rods after torquing head.

2.) Any idea what proper torque settings are for ARP bolts? GT40P heads if it matters. Someone mentioned settings to me awhile back but can’t find where.

1.) in the pic below you can see a gap between the head and deck on the manifold side. Without pushrods it sits flush. The circled pushrod is the culprit (I assume a cam lobe is in the up position). Is this normal? Is it ok to partially tighten down the first head bolt to compress spring so it sits flush or will that screw with torque readings? Was trying to avoid having to pull rockers off and install rods after torquing head.

2.) Any idea what proper torque settings are for ARP bolts? GT40P heads if it matters. Someone mentioned settings to me awhile back but can’t find where.