I'm aware of the jrichker's door lock actuator mod which seems like a more permanent solution, but I have a seized actuator I just took off of a friends car and figured I should cut it open and see how it works and thought I would document it since it was going to end up in the trash otherwise!

I cut it along the bottom near the plug with a hacksaw and gently pried it open with a screwdriver which was apparently the spot to cut it open. I then set it in a vise and pressed out the internals by setting the cut open end on one side at a slight angle then pressing against the top piece where your door lock hooks into (opposite of the connector). This pressed out surprisingly easily though I did have to gently grip the opposite end with a vise to finish pulling.

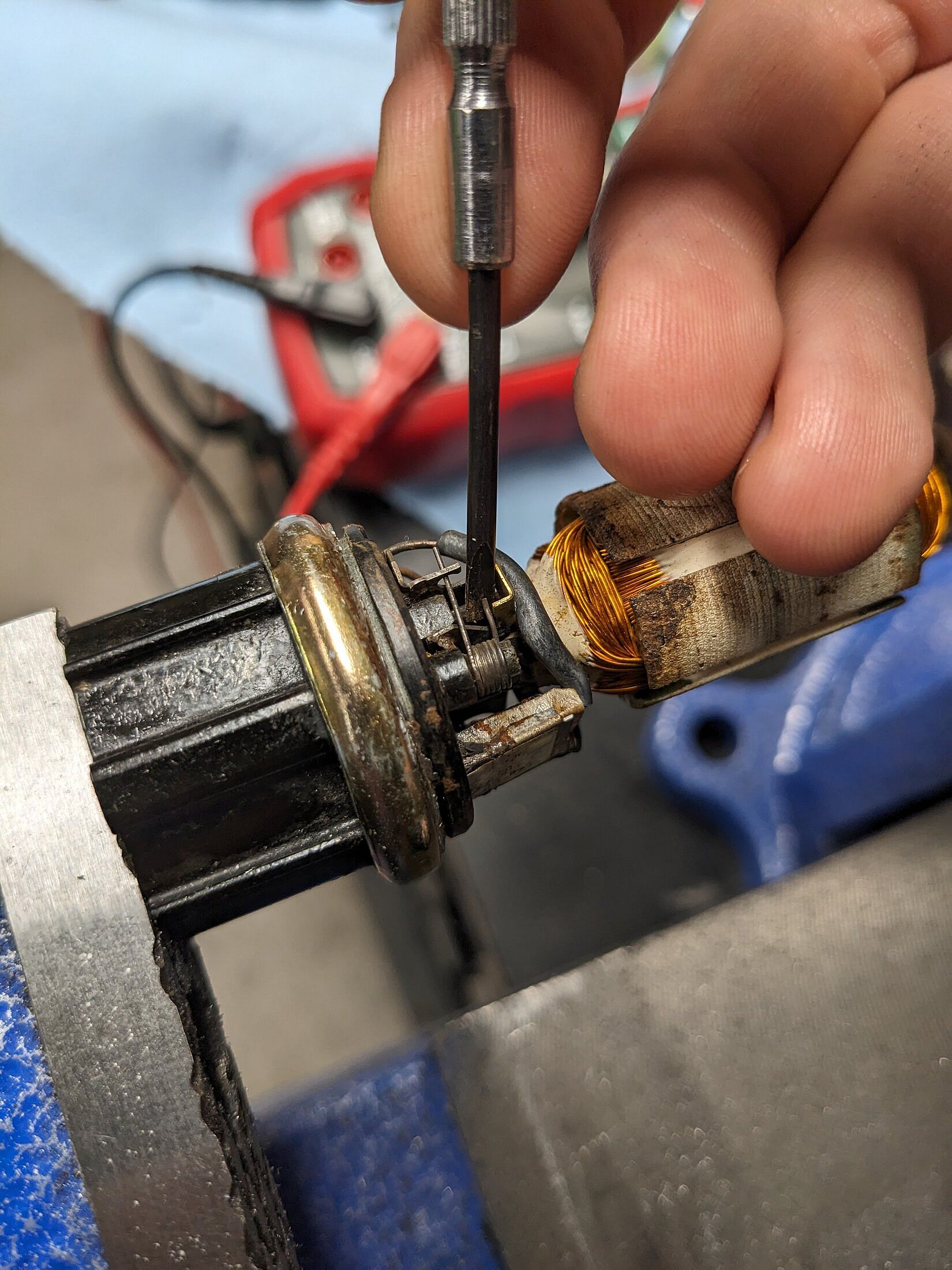

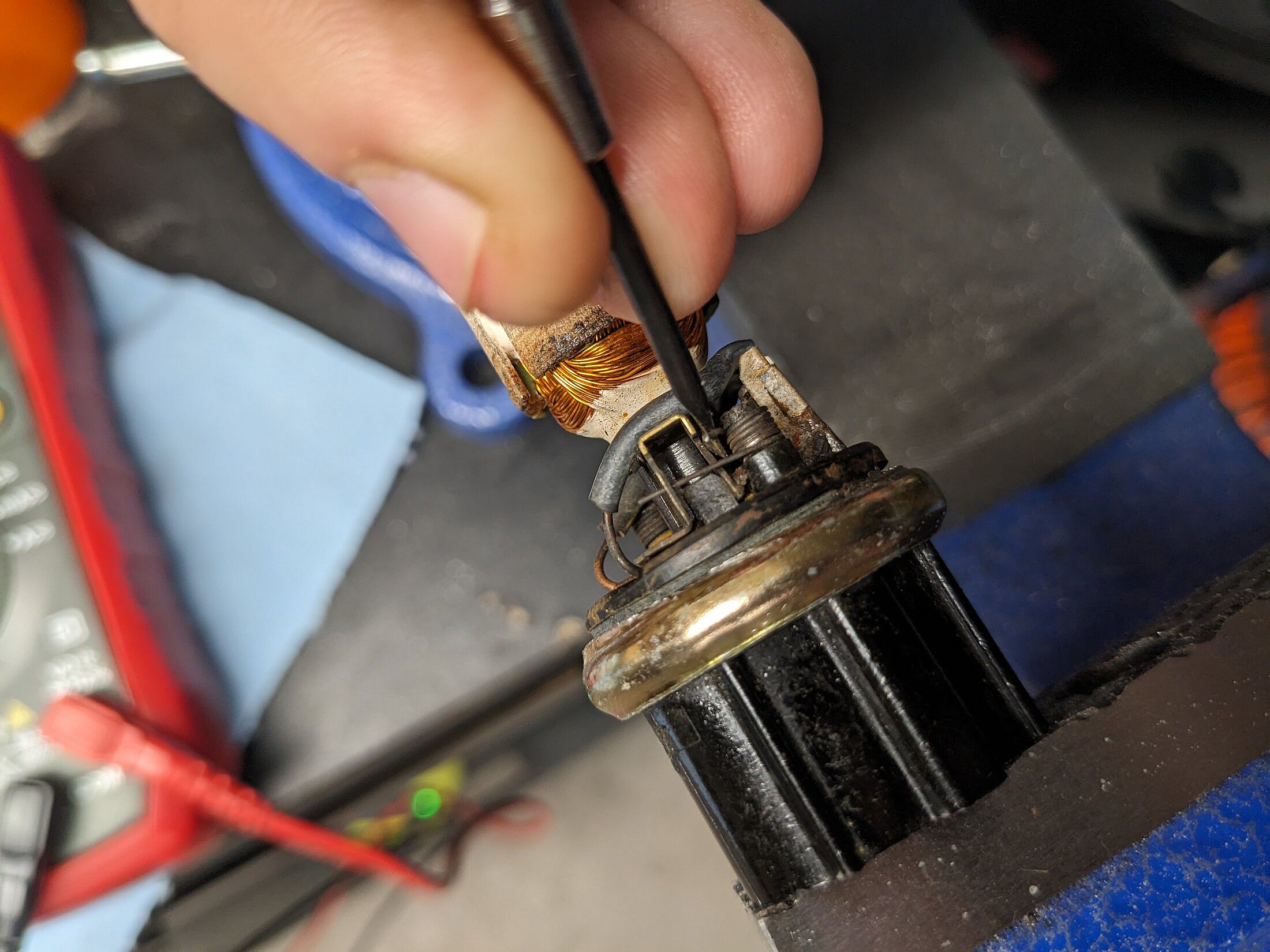

Looks like there are 2 spring tensioned brushes coming in from the connector that contact the center winding assembly. Definitely water intrusion in the actuator from the buildup all around the internals, I was able to clean up most of it.

After cleaning (QD Electronics cleaner and some brushes, and a screwdriver to gently scrape out the inside of the case where there was some debris magnetically attached).

Still need to dig out the multimeter and check the winding, doubtful there is a spec for resistance but can at least find out if there's any sort of break.

Anyone think this is worth trying to rebuild or just a waste of time? I have an LMR unit in my car at the moment and it's pretty weak so thought it could maybe be a fun project, not sure on the best way to reattach after cutting though! Suggestions and advice are welcome, also if it looks like I missed anything please let me know!

I cut it along the bottom near the plug with a hacksaw and gently pried it open with a screwdriver which was apparently the spot to cut it open. I then set it in a vise and pressed out the internals by setting the cut open end on one side at a slight angle then pressing against the top piece where your door lock hooks into (opposite of the connector). This pressed out surprisingly easily though I did have to gently grip the opposite end with a vise to finish pulling.

Looks like there are 2 spring tensioned brushes coming in from the connector that contact the center winding assembly. Definitely water intrusion in the actuator from the buildup all around the internals, I was able to clean up most of it.

After cleaning (QD Electronics cleaner and some brushes, and a screwdriver to gently scrape out the inside of the case where there was some debris magnetically attached).

Still need to dig out the multimeter and check the winding, doubtful there is a spec for resistance but can at least find out if there's any sort of break.

Anyone think this is worth trying to rebuild or just a waste of time? I have an LMR unit in my car at the moment and it's pretty weak so thought it could maybe be a fun project, not sure on the best way to reattach after cutting though! Suggestions and advice are welcome, also if it looks like I missed anything please let me know!

Last edited: