I am by no means taking credit for any of this but I could not find where it was all in one place. Mustang5L5 had a thread over on the Corral about installing a 94-97 fuel pump hanger in a Fox tank but the issue is the supply line on the 94-97 unit is 3/8" and not 5/16" so the factory plastic line from the hanger supply to the inline filter could not be used. Not sure what Mustang5L5 ended up doing but he did link this video where a guy shows how to install the fittings without heat or hot water:

View: https://youtu.be/V7UzCvZTbJI

Within the comments on the video a guy posted a link on how to do this in the car and it seems to work pretty well and would work outside the car if you do not have a vise. I am going to cut and paste it here as I hate linking other forums as they could disappear and the information with it. So this is from LS1tech.com and the member that posted it goes by 1936 LS1 (I put the pictures in the thread where I thought they made the most sense as they were just at the bottom of his):

As promised, here’s a step-by-step on how to install fittings on factory-style nylon fuel line WITHOUT having to buy the expensive (IMO) tool that Dorman sells.

Here’s what you’ll need:

A roll of tubing (Dorman 800-072 is the 3/8”)

The appropriate fittings for your job

Some light lubricant (I used hydraulic jack oil)

The line clamp from a brake line flaring kit (don’t worry if you don’t have this, there’s an alternative)

A caulking gun

A single edge razor blade or tubing cutter that used for air line (gotta be something that won’t crush as it cuts)

To start, make a clean cut of the tubing. I used a single edge razor blade.

Next, insert the end of the tubing through the end of the caulk gun as shown.

Now, clamp the tubing in the flaring tool clamp using the hole in the clamp that corresponds with the size of your tubing. Leave only enough tubing sticking out to fit all the way on to the fitting (I've actually got a little too much sticking out in my pic). Clamp it tightly, but only hand tight. It won’t slip. You don’t need it as tight as is required when flaring brake lines. If you’ve done that job, you know what I’m talking about.

Now seat the clamp in the far end of the caulk gun as shown. Be mindful of the tubing past the clamp. Don’t let it get any pressure on it and get kinked.

Now add a little light lubricant to the fitting. Just enough to get it shiny, it doesn’t need to be dripping wet.

Great, now it’s time to assemble! Move the plunger forward in the gun until there’s just enough room for the fitting between the plunger and the tubing. Align the fitting with the end of the tubing and hold them in alignment with your fingers while you start to squeeze the handle of the caulk gun.

Watch closely because it only takes 2-3 clicks to seat the fitting fully.

Take the clamp off of your tubing and you’re ready to move on to the next one!

Alternative clamping method

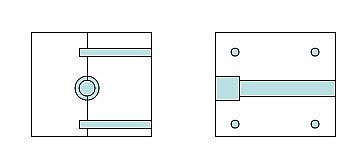

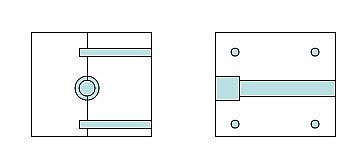

If you don’t have a flaring tool clamp there is another option. I’ve seen this a couple of places online but haven’t built one myself.

You’ll need:

a short (4-6”) 2X4 (or two 1X4s the same length)

a band saw or access to one

4 – 1.5” wood screws

Drill bits slightly smaller than your tubing OD (outside diameter) (ex. 5/16” hole for 3/8” tubing)

I got the pic of this type clamp below from another site so to give credit where it’s due, here’s the link...

http://forums.pelicanparts.com/porsc...-fittings.html

That poster actually oversized one end so the fitting would go down in there too.

You can see how to build it from the pics. You could also use 2 1X4’s screwed together and drill the hole on the seam where they meet. If doing more than one size line, you could put two different size holes in one clamp.

EDIT: I added two more pics. There were some negative comments made about the way the joint in the first set of pics I took ended up so, to show that they got better after my first attempt I added a couple of pics. The tubing clamp does leave marks on the outside of the tubing but apparently the Dorman tool does as well. The wooden clamp probably wouldn't. The marks are superficial and have no effect on the integrity of the tubing.

Fuel Line Holder he built:

I found another DIY video that had another way to do it:

View: https://youtu.be/xFCQccnuvl4

View: https://youtu.be/V7UzCvZTbJI

Within the comments on the video a guy posted a link on how to do this in the car and it seems to work pretty well and would work outside the car if you do not have a vise. I am going to cut and paste it here as I hate linking other forums as they could disappear and the information with it. So this is from LS1tech.com and the member that posted it goes by 1936 LS1 (I put the pictures in the thread where I thought they made the most sense as they were just at the bottom of his):

As promised, here’s a step-by-step on how to install fittings on factory-style nylon fuel line WITHOUT having to buy the expensive (IMO) tool that Dorman sells.

Here’s what you’ll need:

A roll of tubing (Dorman 800-072 is the 3/8”)

The appropriate fittings for your job

Some light lubricant (I used hydraulic jack oil)

The line clamp from a brake line flaring kit (don’t worry if you don’t have this, there’s an alternative)

A caulking gun

A single edge razor blade or tubing cutter that used for air line (gotta be something that won’t crush as it cuts)

To start, make a clean cut of the tubing. I used a single edge razor blade.

Next, insert the end of the tubing through the end of the caulk gun as shown.

Now, clamp the tubing in the flaring tool clamp using the hole in the clamp that corresponds with the size of your tubing. Leave only enough tubing sticking out to fit all the way on to the fitting (I've actually got a little too much sticking out in my pic). Clamp it tightly, but only hand tight. It won’t slip. You don’t need it as tight as is required when flaring brake lines. If you’ve done that job, you know what I’m talking about.

Now seat the clamp in the far end of the caulk gun as shown. Be mindful of the tubing past the clamp. Don’t let it get any pressure on it and get kinked.

Now add a little light lubricant to the fitting. Just enough to get it shiny, it doesn’t need to be dripping wet.

Great, now it’s time to assemble! Move the plunger forward in the gun until there’s just enough room for the fitting between the plunger and the tubing. Align the fitting with the end of the tubing and hold them in alignment with your fingers while you start to squeeze the handle of the caulk gun.

Watch closely because it only takes 2-3 clicks to seat the fitting fully.

Take the clamp off of your tubing and you’re ready to move on to the next one!

Alternative clamping method

If you don’t have a flaring tool clamp there is another option. I’ve seen this a couple of places online but haven’t built one myself.

You’ll need:

a short (4-6”) 2X4 (or two 1X4s the same length)

a band saw or access to one

4 – 1.5” wood screws

Drill bits slightly smaller than your tubing OD (outside diameter) (ex. 5/16” hole for 3/8” tubing)

I got the pic of this type clamp below from another site so to give credit where it’s due, here’s the link...

http://forums.pelicanparts.com/porsc...-fittings.html

That poster actually oversized one end so the fitting would go down in there too.

You can see how to build it from the pics. You could also use 2 1X4’s screwed together and drill the hole on the seam where they meet. If doing more than one size line, you could put two different size holes in one clamp.

EDIT: I added two more pics. There were some negative comments made about the way the joint in the first set of pics I took ended up so, to show that they got better after my first attempt I added a couple of pics. The tubing clamp does leave marks on the outside of the tubing but apparently the Dorman tool does as well. The wooden clamp probably wouldn't. The marks are superficial and have no effect on the integrity of the tubing.

Fuel Line Holder he built:

I found another DIY video that had another way to do it:

View: https://youtu.be/xFCQccnuvl4

Attachments

Last edited: