I installed electric fans a while ago and they worked when I installed them, not however the relay just clicks rapidly and the fans do not work. I have checked and I have power going all the way to the fans and the fans also work when tied directly to the battery by bypassing the relay and fuses for the fan. it is currently on its own 2x 30amp (fuses) circuits on an aux fuse block. I'm thinking that my alternator is not up to the task of the fans? however I do not want to put the money into it right now if I do not need to.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Relay Clicking

- Thread starter rbreith

- Start date

-

Sponsors (?)

The relays are clicking and the fans are not running because there is not enough power to run them.

There are 2 possible sources for your problem.

1.) The alternator isn't putting out enough power.Use a good Multimeter to check the voltage at the battery when the fans and accessory loads like lights, AC or heater are on. Start the engine, let it warm up for a minute and then add electrical load one at a time. Watch the voltmeter drop as load is added. With a good alternator, the voltage at the battery with the engine running at a fast idle should be 13.8-14.5 volts,

If you don't have a high current alternator, you can forget about using an electric fan. The stock 65 amp alternator on 86-93 Mustangs isn't big enough to run the fan and the rest of the car.

Electric fan = 3G alternator if you want long life & reliability from your car.

The electric fan saves some HP. The stock fan's parasitic drag runs from 7-12 HP depending on who you talk to. The electric fan uses about 1/2 HP of power from the electrical system.

Figure this:

Ignition system & computer = 12 amps

Fuel pump = 12 amps

Exterior lights = 15 amps

Fan (heater or A/C) = 15 amps (can run between 5-25 amps depending on setting)

Radio & instruments = 10 amps

Wipers = 10 amps

That's grand total of 74 amps from a 65 amp alternator. Talk about overdrawn at the bank!

See http://www.stangnet.com/mustang-forums/threads/3g-alternator-install-a-how-to.646825/#post-6673702 for how to install a 3G alternator.

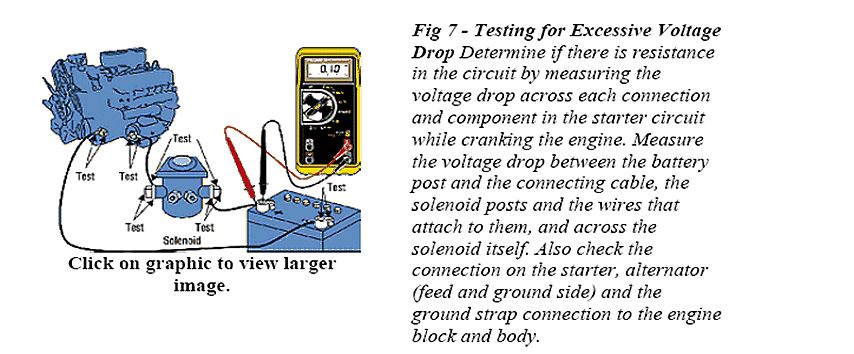

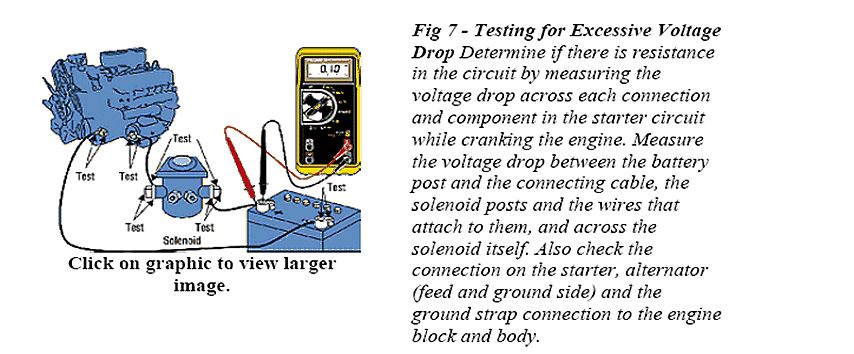

2.) You have a bad connection somewhere.You will need a Multimeter to find bad connections. The tech note says grounds, but it can be used for any type of connection.

Voltage drop testing of connections and grounds.

Use a Digital Volt Meter (DVM) to measure the voltage drop across a connection or wire. Adding length to the test leads may be required, and does not affect the accuracy of the test. Use 16-18 gauge wire for the test leads if you have to lengthen them.

Voltage drop increases with the increase of current in a circuit and it also increases with heat. Put a maximum current load on a bad wire or connection and it gets hot and drops more voltage across the wire or connection. As it heats up, resistance increases which makes more heat. Round and round you go in a vicious circle until something catches fire or fails.

Voltage drop testing must be done while the usual load is on the circuit. If it is a starter, it has to be tested while cranking the starter. If it is lights, A/C or fan, they must be turned on high while testing. Fail to do this and you will not get accurate results

1.) Most grounds use the negative battery post as their starting point. Keep this in mind when checking grounds.

2.) The voltage will be small if the ground is good: less voltage drop = better connection.

3.) Be sure that the power to the circuit is on, and the circuit is being used in its normal manner. For instance, if it is a light circuit, the lights on that circuit should be powered on.

4.) To measure grounds, place one DVM lead on the battery negative post and the other on the wire or connector that goes to ground.

5.) 5.) Voltage drops should not exceed the following:

200 mV Wire or cable

300 mV Switch

100 mV Ground

0 mV to <50 mV Sensor Connections (sensors are low voltage devices and small drops can have a large effect on the devices dependent on sensor accuracy)

0.0V Connections

A voltage drop lower that spec is always acceptable.

6.)

See http://assets.fluke.com/appnotes/automotive/beatbook.pdf for help for help troubleshooting voltage drops across connections and components. .

[/b]

[/b]

There are 2 possible sources for your problem.

1.) The alternator isn't putting out enough power.Use a good Multimeter to check the voltage at the battery when the fans and accessory loads like lights, AC or heater are on. Start the engine, let it warm up for a minute and then add electrical load one at a time. Watch the voltmeter drop as load is added. With a good alternator, the voltage at the battery with the engine running at a fast idle should be 13.8-14.5 volts,

If you don't have a high current alternator, you can forget about using an electric fan. The stock 65 amp alternator on 86-93 Mustangs isn't big enough to run the fan and the rest of the car.

Electric fan = 3G alternator if you want long life & reliability from your car.

The electric fan saves some HP. The stock fan's parasitic drag runs from 7-12 HP depending on who you talk to. The electric fan uses about 1/2 HP of power from the electrical system.

Figure this:

Ignition system & computer = 12 amps

Fuel pump = 12 amps

Exterior lights = 15 amps

Fan (heater or A/C) = 15 amps (can run between 5-25 amps depending on setting)

Radio & instruments = 10 amps

Wipers = 10 amps

That's grand total of 74 amps from a 65 amp alternator. Talk about overdrawn at the bank!

See http://www.stangnet.com/mustang-forums/threads/3g-alternator-install-a-how-to.646825/#post-6673702 for how to install a 3G alternator.

2.) You have a bad connection somewhere.You will need a Multimeter to find bad connections. The tech note says grounds, but it can be used for any type of connection.

Voltage drop testing of connections and grounds.

Use a Digital Volt Meter (DVM) to measure the voltage drop across a connection or wire. Adding length to the test leads may be required, and does not affect the accuracy of the test. Use 16-18 gauge wire for the test leads if you have to lengthen them.

Voltage drop increases with the increase of current in a circuit and it also increases with heat. Put a maximum current load on a bad wire or connection and it gets hot and drops more voltage across the wire or connection. As it heats up, resistance increases which makes more heat. Round and round you go in a vicious circle until something catches fire or fails.

Voltage drop testing must be done while the usual load is on the circuit. If it is a starter, it has to be tested while cranking the starter. If it is lights, A/C or fan, they must be turned on high while testing. Fail to do this and you will not get accurate results

1.) Most grounds use the negative battery post as their starting point. Keep this in mind when checking grounds.

2.) The voltage will be small if the ground is good: less voltage drop = better connection.

3.) Be sure that the power to the circuit is on, and the circuit is being used in its normal manner. For instance, if it is a light circuit, the lights on that circuit should be powered on.

4.) To measure grounds, place one DVM lead on the battery negative post and the other on the wire or connector that goes to ground.

5.) 5.) Voltage drops should not exceed the following:

200 mV Wire or cable

300 mV Switch

100 mV Ground

0 mV to <50 mV Sensor Connections (sensors are low voltage devices and small drops can have a large effect on the devices dependent on sensor accuracy)

0.0V Connections

A voltage drop lower that spec is always acceptable.

6.)

See http://assets.fluke.com/appnotes/automotive/beatbook.pdf for help for help troubleshooting voltage drops across connections and components. .

Last edited:

Results of tests.

battery: 13.40

12v power source 13.50 grounded to battery

12v power source 13.50 grounded to terminal end

12v power source 13.50 grounded to connector

12v power at relay plug 13.53 grounded to battery

12v power at relay plug 13.50 grounded to terminal

12v power at relay plug 13.50 grounded at connector

12v power at relay plug 13.50 grounded at relay

Driver fan 13.55 grounded to battery

Driver fan 13.51 grounded to terminal

Driver fan 13.28 grounded to fan

Pass fan 13.55 grounded to battery

Pass fan 13.53 grounded to terminal

Pass fan 13.32 grounded to fan

Pass fan pulling 13.39 (power going in and having one tester on the female neg and one tester on the male neg)

Driver fan overheated before I got a chance to check.

fans were tested with the other fan disconnected.

one fan will not run even with the other disconnected.

I have a crappy harbor freight millimeter and cant figure out how to make it show resistance.

battery: 13.40

12v power source 13.50 grounded to battery

12v power source 13.50 grounded to terminal end

12v power source 13.50 grounded to connector

12v power at relay plug 13.53 grounded to battery

12v power at relay plug 13.50 grounded to terminal

12v power at relay plug 13.50 grounded at connector

12v power at relay plug 13.50 grounded at relay

Driver fan 13.55 grounded to battery

Driver fan 13.51 grounded to terminal

Driver fan 13.28 grounded to fan

Pass fan 13.55 grounded to battery

Pass fan 13.53 grounded to terminal

Pass fan 13.32 grounded to fan

Pass fan pulling 13.39 (power going in and having one tester on the female neg and one tester on the male neg)

Driver fan overheated before I got a chance to check.

fans were tested with the other fan disconnected.

one fan will not run even with the other disconnected.

I have a crappy harbor freight millimeter and cant figure out how to make it show resistance.

You did not do a voltage drop test, so there is no way that you will find bad connections. Read my post over again, follow the instructions, go to Fluke and read http://assets.fluke.com/appnotes/automotive/beatbook.pdf for help for help troubleshooting voltage drops across connections and components.

When you have read the tech note on checking voltage drops and done the voltage drop tests, then post your results.

When you have read the tech note on checking voltage drops and done the voltage drop tests, then post your results.

Similar threads

- Replies

- 4

- Views

- 400

- Replies

- 0

- Views

- 1K

- Replies

- 6

- Views

- 1K

- Replies

- 12

- Views

- 842