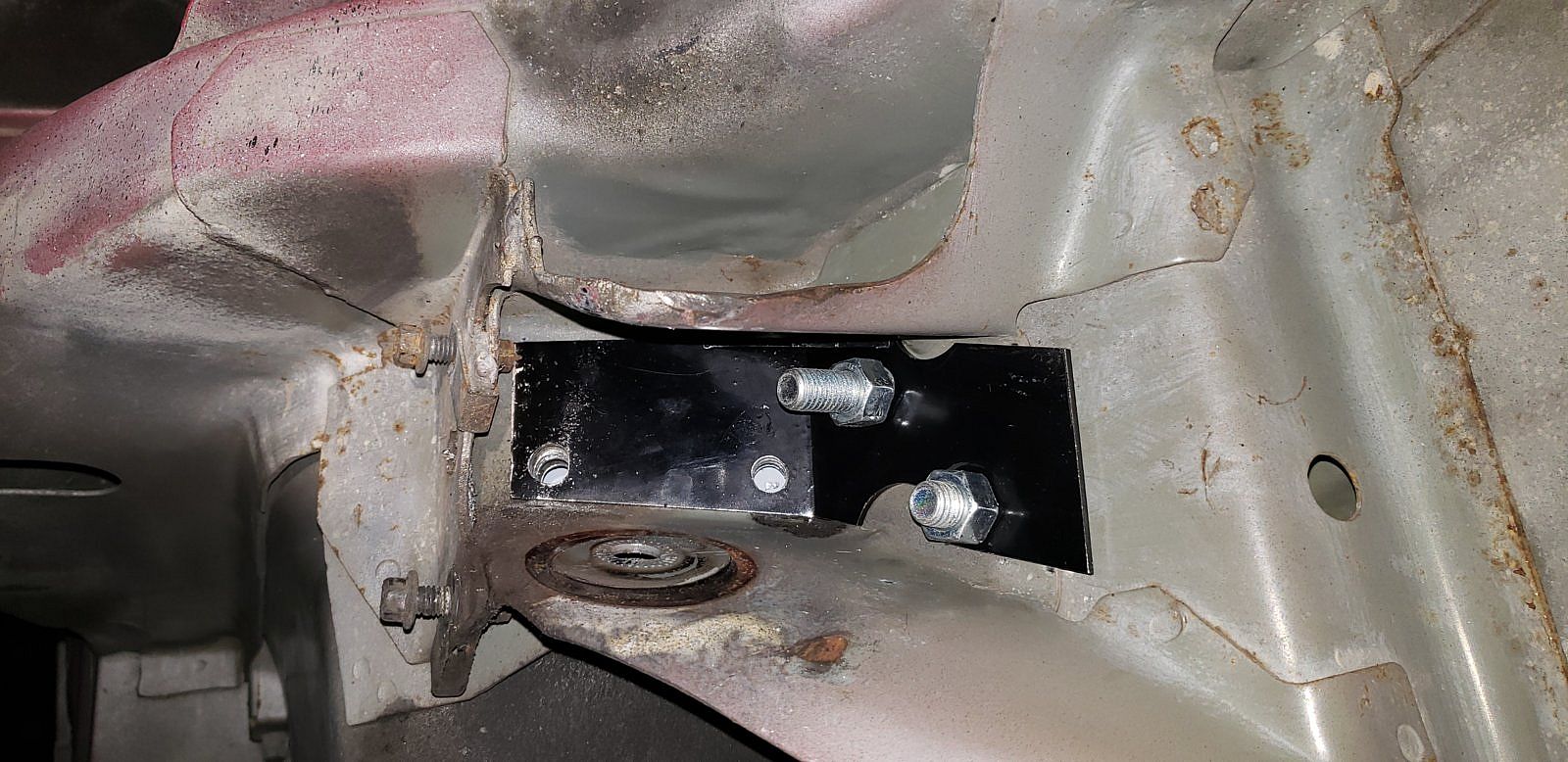

Got to ratchet jawing on the phone last night, so didn't do much. I did get one of the new springs on and the strut.

The lift made this soooooo much easier. As for shiny..... I live down a freaking gravel road. All the shiny will not last. It was so nasty though, and once I started cleaning one thing it looked so much better I just kept going. For now it does look a lot better. Eventually it will get paint and I'll be one of those people that parks waaaaay out in the parking lot. Thats if I go somewhere with it that has a big parking lot. No need to tempt fate by driving your shiny toy to Wally-World, and just beg for people to run carts into your

I knew a guy once that would intentionally park as close as he possibly could to a car that was clearly parked away from everything else to protect it. It was a total d-bag thing to do in my opinion. As least he parked on the passenger side of the offending car so the person could at least get into their car.