Looking for advice on getting the AC back up and functioning. I replaced the entire system going in two years ago, but life happened and I haven't been able to finish the job. I got a set of gauges and a vac pump. I could never get it to hold vaccum. When I put it together I left the o-rings that came on the components on and used dielectric grease on all the slip on connections. Tonight I put a little pressure on the low side of the system and can hear a leak on the high pressure connection going to the evaporator. I've got to pull that loose at a minimum. My question is what do I need to do to fix it? New o-ring? Use a different type of grease? I suck at getting those slip on fittings to come off, so I'm not looking forward to the job. Any advice is appreciated.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Progress Thread Therapy Car-- Freshening Up the Lower Intake

- Thread starter Olivethefet

- Start date

-

Sponsors (?)

- Mar 2, 2015

- 6,822

- 5,858

- 203

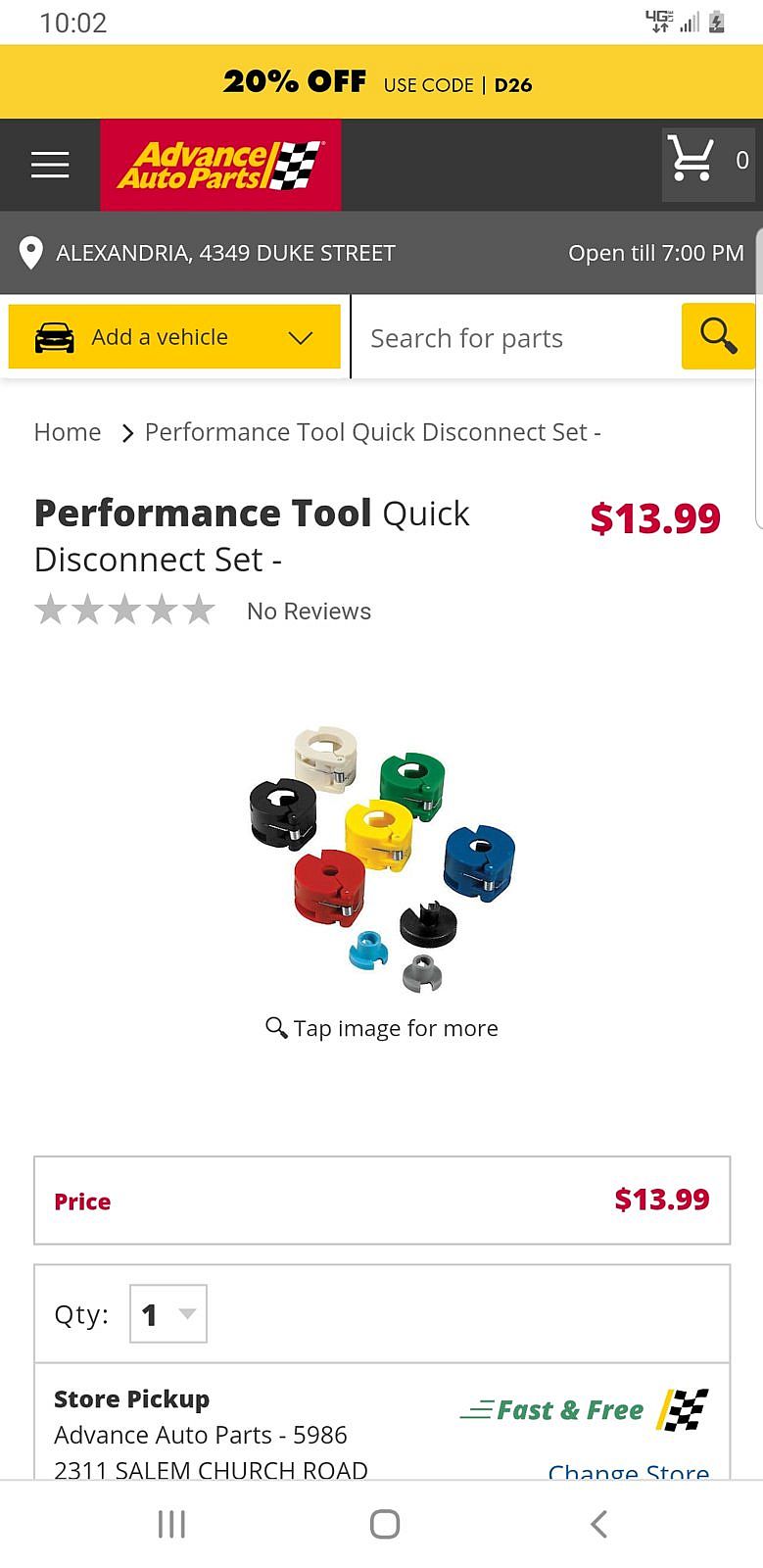

I've got tons of money in tools...but these things are the best quick disconnect tools I have. They just work. A little wd40 or PBblaster on the back side where the tool slides in...a couple twists..and pull. They fit around the fittings so if theres a little pressure it won't spray you. Great for the fuel lines too.

You probably need new o rings. They're not expensive but you've got to size them up. They have little universal AC oring kits that should have the right sizes. If it's still r12 lubricate the prongs with mineral oil...if it's going to be r134a use a little Ester oil..that's what should be used in a retrofitted system.

You probably need new o rings. They're not expensive but you've got to size them up. They have little universal AC oring kits that should have the right sizes. If it's still r12 lubricate the prongs with mineral oil...if it's going to be r134a use a little Ester oil..that's what should be used in a retrofitted system.

You Did put the correct amount of oil in it right? Each piece of that AC unit should have had some oil inside of it before going together. If that system has had a leak or open for two years. Once you find where the leak is and get it sealed. I would vacuum it back out, replace the drier with a fresh one and then re-pressurize it. If that drier has been pulling moisture for two years in an open system it may be junk is all I am saying.

Replacing the O-rings isn't the best fun in the world but advised. Lubricant, I agree with 90sickfox

Replacing the O-rings isn't the best fun in the world but advised. Lubricant, I agree with 90sickfox

I'll check those tools out. I used the dielectric grease because I talked to the owner of Foxresto.com . He said that is what he uses. The system will be 134.

@kiddiccarus I put the recommend amounts of oil in all the components. I haven't been able to get the system to hold vaccum, but it hasn't been open other than the fact that it has a leak. I would consider a new dryer. I do plan on putting it under vacuum for an extended period of time no matter what.

Willybill32

But at least it's tight!

Looking for advice on getting the AC back up and functioning. I replaced the entire system going in two years ago, but life happened and I haven't been able to finish the job. I got a set of gauges and a vac pump. I could never get it to hold vaccum. When I put it together I left the o-rings that came on the components on and used dielectric grease on all the slip on connections. Tonight I put a little pressure on the low side of the system and can hear a leak on the high pressure connection going to the evaporator. I've got to pull that loose at a minimum. My question is what do I need to do to fix it? New o-ring? Use a different type of grease? I suck at getting those slip on fittings to come off, so I'm not looking forward to the job. Any advice is appreciated.

I bought two different O-ring sets from RockAuto that were listed for my car. One set turned out to be the springs for the connectors and the second a variety of O-ring sizes. My system went back together with no problems.

@Willybill32 I wouldn't feel like I was doing this right if I didn't have to go back and redo things at least twice!

@90sickfox I just check my local Autozone. They have what appears to be the same thing but the name is different. Santech Spring Locking tool set. https://www.autozone.com/test-scan-...ch-spring-locking-tool-set-9-piece/952338_0_0

I have a set of disconnect tools that look like these.

www.autozone.com

I didn't pay that much for my set. I just always seem to have trouble getting the lines to come apart. I watch people in videos using these things and it looks really easy. I'm sure I'm doing something wrong. I'll pick this set up and see if it works any better for me. I'll grab an assortment of AC line o-rings as well.

www.autozone.com

I didn't pay that much for my set. I just always seem to have trouble getting the lines to come apart. I watch people in videos using these things and it looks really easy. I'm sure I'm doing something wrong. I'll pick this set up and see if it works any better for me. I'll grab an assortment of AC line o-rings as well.

@90sickfox I just check my local Autozone. They have what appears to be the same thing but the name is different. Santech Spring Locking tool set. https://www.autozone.com/test-scan-...ch-spring-locking-tool-set-9-piece/952338_0_0

I have a set of disconnect tools that look like these.

Santech Master tech spring lock tool set

Shop for Santech Master tech spring lock tool set with confidence at AutoZone.com. Parts are just part of what we do. Get yours online today and pick up in store.

- Mar 2, 2015

- 6,822

- 5,858

- 203

Those type have always been an issue for me too. They work in a tight spot but are a real pain. I think it's the way the circular ones can be twisted to get them past the spring...and the plastic is more forgiving. I use your style on fuel filters and stuff like that where the plastic ones are too bulky.

Willybill32

But at least it's tight!

@Willybill32 I wouldn't feel like I was doing this right if I didn't have to go back and redo things at least twice!

A man after my own heart!

I took the right rear tire off and inspected the brake. Everything looked good. It was loose though. I tightened it up a bit. We'll see if it still has the dragging noise next time I take it out.

When you had the drum off, the hardware was all in its proper place?

When we have that same issue at the shop and pulling the e-brake stops the noise usually the self adjust is not doing its job. If what you did, did not fix the problem. You may need to replace the hardware kit on both sides.

When we have that same issue at the shop and pulling the e-brake stops the noise usually the self adjust is not doing its job. If what you did, did not fix the problem. You may need to replace the hardware kit on both sides.

@90sickfox I picked up the AC line tools today. It was tight getting the one I needed into the spot it needed to go but when I did the line came apart easy!

Now I cant find my oil or r134. The Joy's of moving. I'll pick some up tomorrow or Saturday.

Now I cant find my oil or r134. The Joy's of moving. I'll pick some up tomorrow or Saturday.

Looks all in the right spots.

You do have a high/low spot on that shoe. Could be that it was not adjusted right as you mentioned and fixed. Could be the beginning of the drum getting uneven on the mating surface.

- Looks dry

- Cylinders are not leaking

- Thick Shoes

- Springs look correct

- Adjuster actually looks the newest on there

You do have a high/low spot on that shoe. Could be that it was not adjusted right as you mentioned and fixed. Could be the beginning of the drum getting uneven on the mating surface.

I think I just didnt properly set the adjuster. The springs, wheel cylinder, brake shoes, and drum are all new. Less than 500 miles on the whole thing. I do appreciate the input and will check out anything you think I need to.

NOPE, Visually it looks spot on. Get out on the test drive and see if the adjustments solved things. Pull that e-brake handle weekly to make the adjuster do its job as it should. With what you mentioned in the replacement and time frame I am in agreement on the wear pattern being an adjustment issue.

@kiddiccarus I caved! Ever since you mentioned the drier I've been thinking about it. Now if I don't replace it I'll be worried that I'm going to wreck a brand new system all because I wanted to save $60. I just ordered a new dry. I'm going to pick it up on my way home from work this afternoon. My plan is to get all the leaks fixed with the dryer that is currently on it. Once I know that it will hold vacuum I'll swap out the dryer and put the system under vac for a few hours.

I've still got to figure out a solution to the orifice tube. The heads gets so close to it you could probably only get a few sheets of paper between it and the header. Maybe I can mount it upside down or sideways somehow. IDK, got to think on it....

I've still got to figure out a solution to the orifice tube. The heads gets so close to it you could probably only get a few sheets of paper between it and the header. Maybe I can mount it upside down or sideways somehow. IDK, got to think on it....

- Mar 2, 2015

- 6,822

- 5,858

- 203

I used a heat wrap made by DEI on mine. My car is turbo and it runs almost directly at the turbo flange. I need to figure out how to move that thing...or make a new line.

Book calls for only 30 mins on the Orifice Tube of course that is with a stock engine also. Shoot a Picture of that location, you have the heads that close.

Last edited:

Similar threads

- Replies

- 0

- Views

- 753

- Replies

- 17

- Views

- 2K

- Replies

- 45

- Views

- 3K

- Replies

- 12

- Views

- 743