Check balancer from tdc it should point to the 0*mark.

HOW did you find tdc?

HOW are you setting timing? Do you have the spout removed?

Before you waste time and money replacing a balancer, make sure that it needs replacing....

Spend 30 minutes and $7.50 to save you $60. You can't get a better deal than that anywhere...

Prep step:

Joe R’s note: Timing tape (strip of adhesive backed paper with timing marks printed on it) is available from Summit Racing

https://www.summitracing.com/parts/sum-163594/overview/ use it instead of a degree wheel. The cost is about $5 plus shipping.

Clean the balancer rim up real good with acetone or paint thinner. Try not to get the acetone or paint thinner on anything but the balancer rim; it could damage the rubber mounting ring. Some cotton balls or a wadded up ball of paper towel may be the best application tools. Let whatever solvent you used dry completely and then apply the timing tape.et the solvent dry completely and then apply the timing tape.

Line the TDC mark up on the tape with the TDC make on the balancer; make sure it is stuck down good.

TDC location process courtesy of Michael Yount

If you're trying to find ACTUAL tdc for cam installation/degreeing, follow the steps below:

Positive stop – obtain an old spark plug for the Ford engine – most of us have at least one laying around. Put it in your vice, and with a tool of destruction you deem appropriate – cut off the ground tip and bust up the ceramic around the center electrode. Keep pounding to get the ceramic and center electrode removed so you’ve got a good ¾” or so of hollow space inside what used to be the ‘business’ end of the spark plug. If you happen to break the ceramic on the other end of the spark plug, don’t worry about it. Once you’ve got a nice hollow space in the tip of the plug, take a 5/16” tap, and cut threads inside that end of the plug. I found that diameter to go right in without any drilling required. Once you’ve cut threads, screw in a 5/16" bolt about 1.5” to 2” long. Then take your hack saw and cut the head off the bolt. Wouldn’t hurt to take your file/grinder and dress up the freshly cut surface so no sharp edges or shrapnel enter the combustion chamber. Also clean up the threads on the plug so that it easily screws into and out of the plug hole.

Determining TDC – remove the passenger side valve cover. Rotate the engine (socket on crank bolt) until the #1 piston is down the cylinder on the intake stroke. Unscrew the spark plug in that cylinder, and replace it with the positive stop you just made. Only screw the positive stop in hand tight. Install your cam degree wheel and pointer (no easy task in some cases as harmonic balancer and other accessories will have to be removed). You may want to remove all spark plugs at this point because it will make it easier to smoothly turn the engine over in small increments. GENTLY rotate the engine clockwise until the piston comes to rest against the stop. Note the degree wheel reading. GENTLY rotate the engine in the opposite direction until the piston comes to rest against the stop. Note the degree wheel reading. TDC is exactly half way between these readings. Calculate where that position is on the degree wheel, remove the piston stop from the cylinder, and rotate the engine to TDC as you calculated it.

You are now at true TDC.

After you have done that, make sure the TDC mark on the balancer now lines up with the timing pointer. If it doesn't line up then replace the balancer.

If it does line up, you need to look elsewhere for your problem.

Putting the distributor back in and setting the timing.

Revised 28-Jul-2013 to include warning about putting spark plug leads in a different location to attempt a to fix a distributor incorrectly installed.

You can forget about anything beyond this point if you don't have access to a timing light. You will never get the timing set right without one.

Putting the distributor back in is fairly simple. Pull #1 sparkplug, put your finger in the sparkplug hole, crank the engine until you feel compression. Then line up the TDC mark on the balancer with the pointer on the engine block.

The distributor starts out with the #1 plug wire lined up at about 12:00 with you facing it. Align the rotor to about 11:00, since it will turn clockwise as it slides into place.

Align the distributor rotor up with the #1 position marked on the cap, slide the distributor down into the block, (you may have to wiggle the rotor slightly to get the gear to engage) and then note where the rotor is pointing.

If it still lines up with #1 position on the cap, install the clamp and bolt. If not, pull it out and turn 1 tooth forwards or backwards and try again. Put the #1 spark plug back in and tighten it down, put the clamp on the distributor, but don't tighten it too much, as you will have to move the distributor to set the timing.

Note that there is no such thing as one tooth off on a 5.0 Mustang if you follow the spark plug wire order on the distributor cap. If it doesn't align perfectly with #1 position, you can turn the distributor until it does. The only problem is that if you are too far one way or the other, you can't turn the distributor enough to get the 10-14 degree optimum timing range.

Don't move the wires from the positions shown on the cap on fuel injected engines!!!! The #1 position cast into the cap MUST have the spark plug wire for #1 cylinder in it. Do it differently and the timing for the fuel injectors will be off. The computer uses the PIP sensor to time injector operation by sensing the wide slot in the PIP sensor shutter wheel. If the injector timing of #1 and the firing of #1 do not occur at the right time, the injector timing for all other cylinders will be affected.

Setting the timing:

Paint the mark on the harmonic balancer with paint -choose 10 degrees BTC or 14 degrees BTC or something else if you have NO2 or other power adder. I try to paint TDC red, 10 degrees BTC white and 14 degrees BTC blue.

10 degrees BTC is towards the drivers side marks.

Note: setting the timing beyond the 10 degree mark will give you a little more low speed acceleration.

BUT you will need to run 93 octane to avoid pinging and engine damage. Pinging is very hard to hear at full throttle, so it could be present and you would not hear it.

Simplified diagram of what it looks like. Not all the marks are shown for ease of viewing.

ATC ' ' ' ' ' ' ' ' ' '!' ' ' ' ' ' ' ' ' ' BTC

---------------- >

Direction of Rotation as viewed standing in front of the engine.

The ' is 2 degrees.

The ! is TDC

The

' is 10 degrees BTC

Set the timing 5 marks BTC. Or if you prefer, 5 marks towards the driver's side to get 10 degrees.

To get 14 degrees, set it 7 marks BTC. Or if you prefer, 7 marks towards the driver's side to get 14 degrees.

The paint marks you make are your friends if you do it correctly. They are much easier to see than the marks machined into the harmonic balancer hub.

At this point hook up all the wires, get out the timing light. Connect timing light up to battery & #1 spark plug. Then start the engine.

Remove the SPOUT connector (do a search if you want a picture of the SPOUT connector) It is the 2 pin rectangular plug on the distributor wiring harness. Only the EFI Mustang engines have a SPOUT. If yours is not EFI, check for a SPOUT: if you don’t find one, skip any instructions regarding the SPOUT

Warning: there are only two places the SPOUT should be when you time the engine. The first place is in your pocket while you are setting the timing and the second is back in the harness when you finish. The little bugger is too easy to lose and too hard to find a replacement.

Start engine, loosen distributor hold down with a 1/2" universal socket. Shine the timing light on the marks and turn the distributor until the mark lines up with the edge of the timing pointer. Tighten down the distributor hold down bolt, Replace the SPOUT connector and you are done.

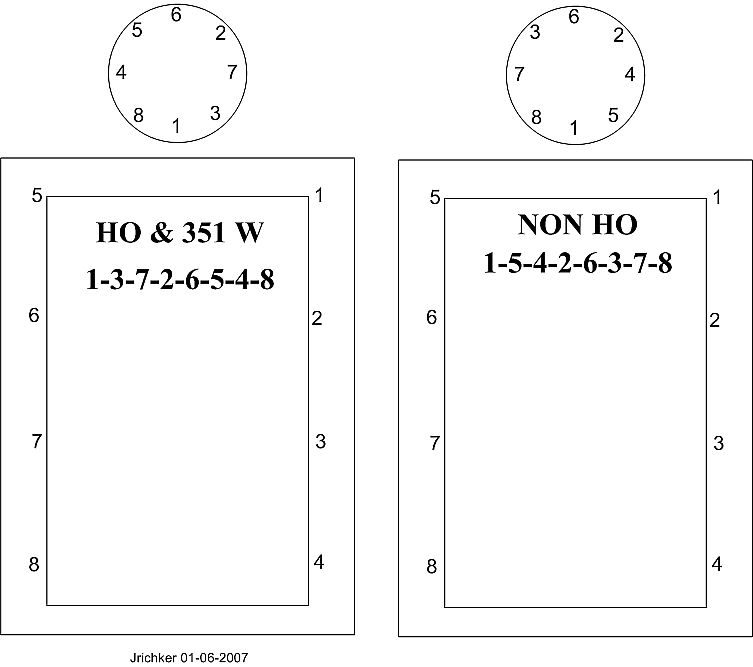

The HO firing order is 1-3-7-2-6-5-4-8.

Non HO firing order is 1-5-4-2-6-3-7-8