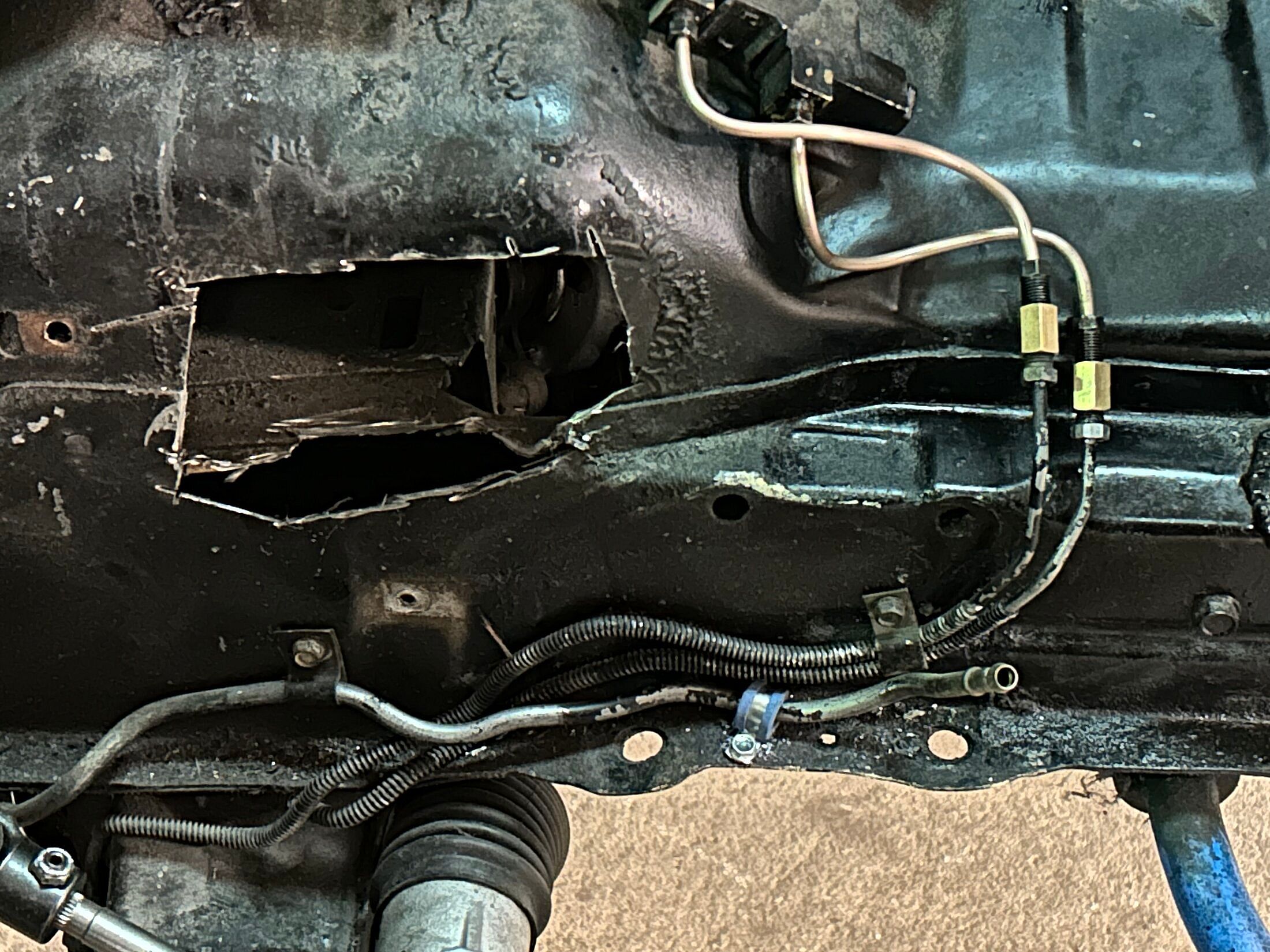

My thought is to use offset bushings to create this angle. By clocking the front and rear offset bushing 180 degrees from each other (front down, back up) then drilling the middle out to create a smooth consistent hole, this would rotate the rack slightly back causing the rack steering shaft to move at a more downward angle. This would create the most clearance. But I obviously am limited by how much I can rotate it to not put the shaft at too extreme of an angle. I just haven’t found anywhere online where anyone else has done this. So I’m questioning if there is a reason no one has done it. Will it cause any steering issues.