- Jul 7, 2005

- 1,563

- 1,197

- 164

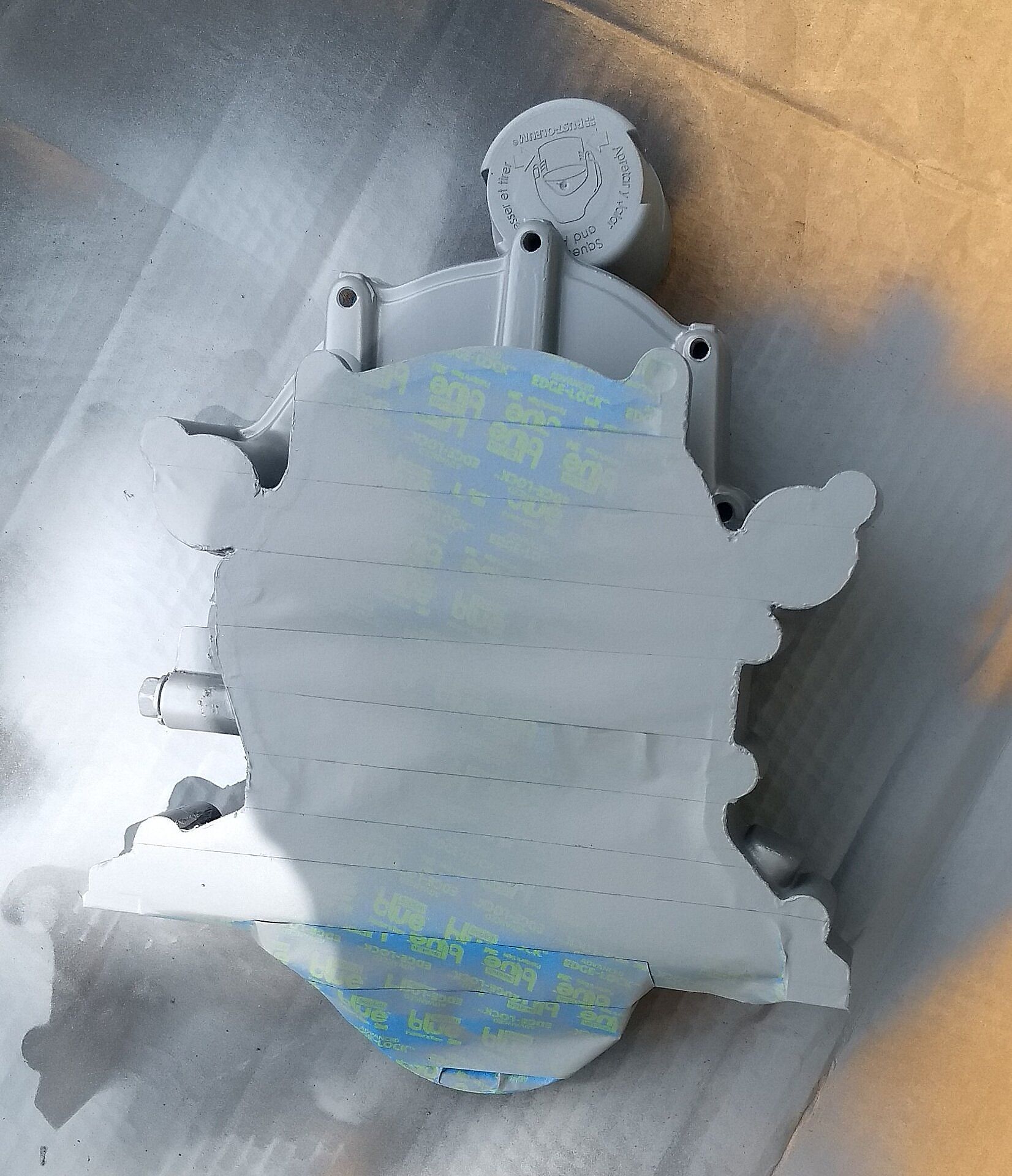

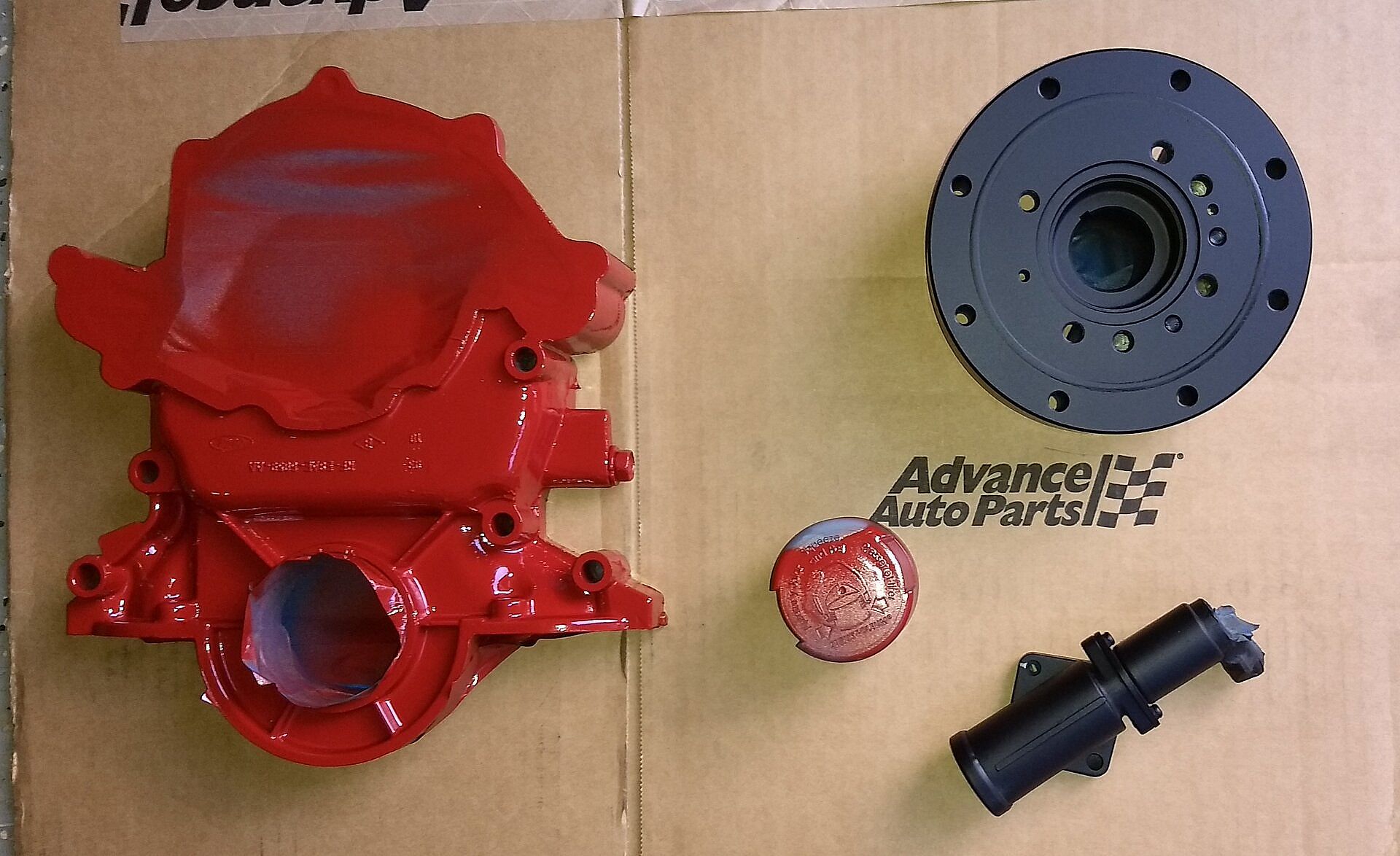

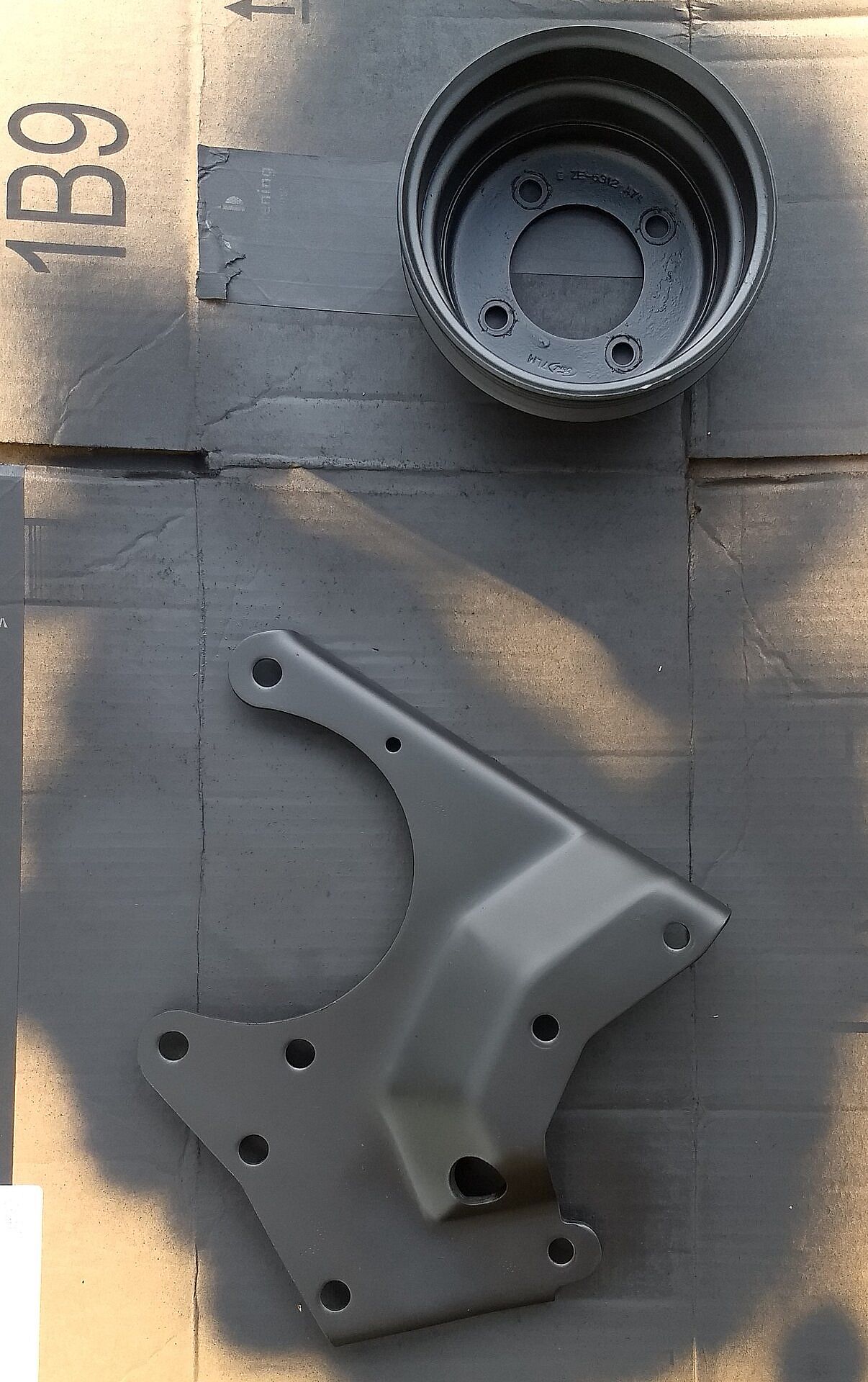

Not much to show for today's work since all I did was finish cleaning the timing cover. I did smooth out a few of the casting slag and casting lines in the timing cover, so that when I paint it it comes out cleaner. I also cleaned up the timing pointer and the balancer as well. Due to all the rain the painting is on halt.

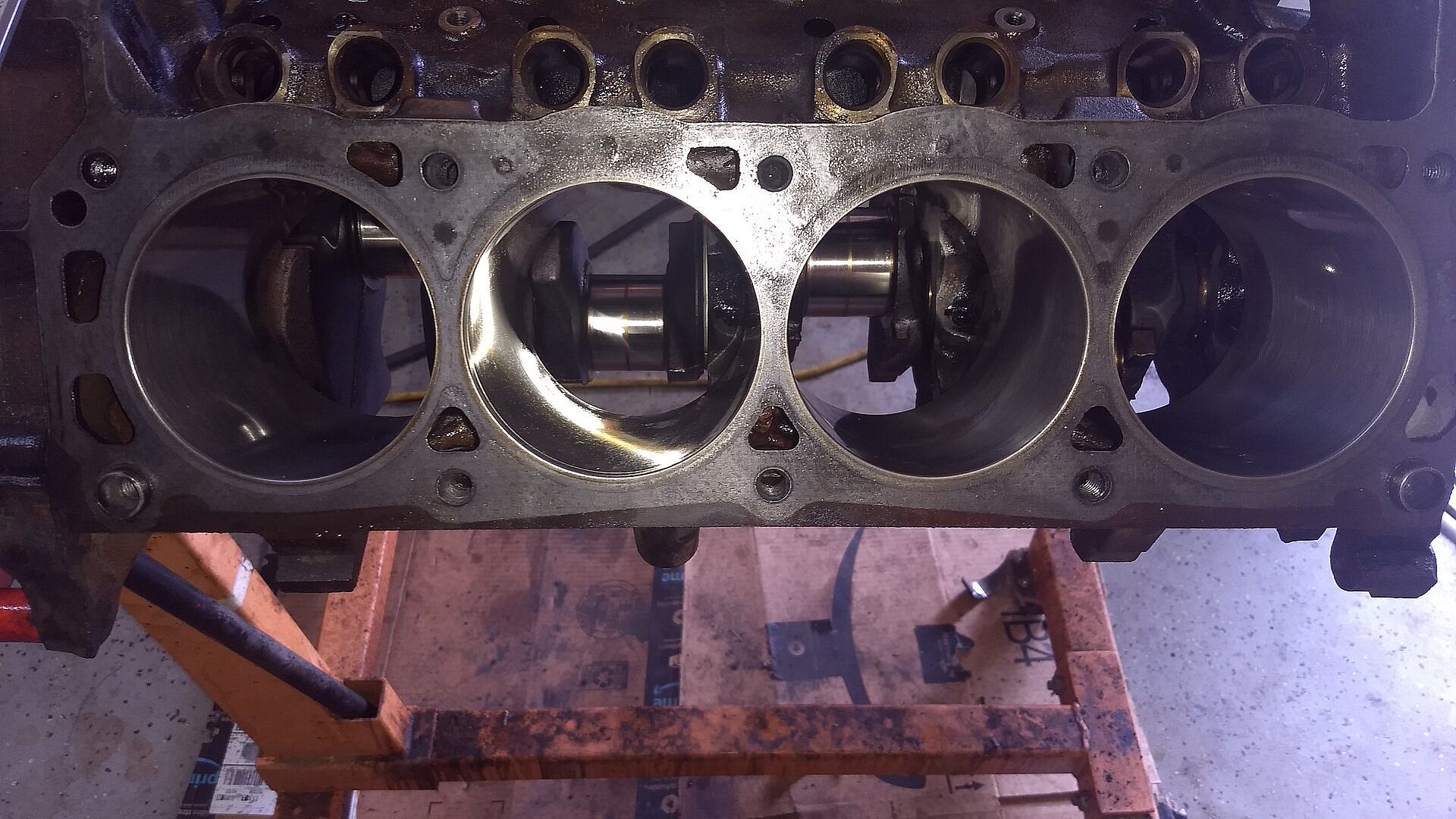

Next step is to work on the lower intake porting/gasket matching. I can then run the ball honer that I got down the ports to smooth them out as much as possible. I can then get it painted, install the heater tubes, and the new 60lb injectors.

Slowly get everything ready to go for this weekend.

Next step is to work on the lower intake porting/gasket matching. I can then run the ball honer that I got down the ports to smooth them out as much as possible. I can then get it painted, install the heater tubes, and the new 60lb injectors.

Slowly get everything ready to go for this weekend.