Fuel Quantity gauge troubleshooting 87-93 Mustangs

Revised 8-Apr-2017 to add warning about non-interchangeable fuel tank senders between 79-86 and 87-93 Mustangs.

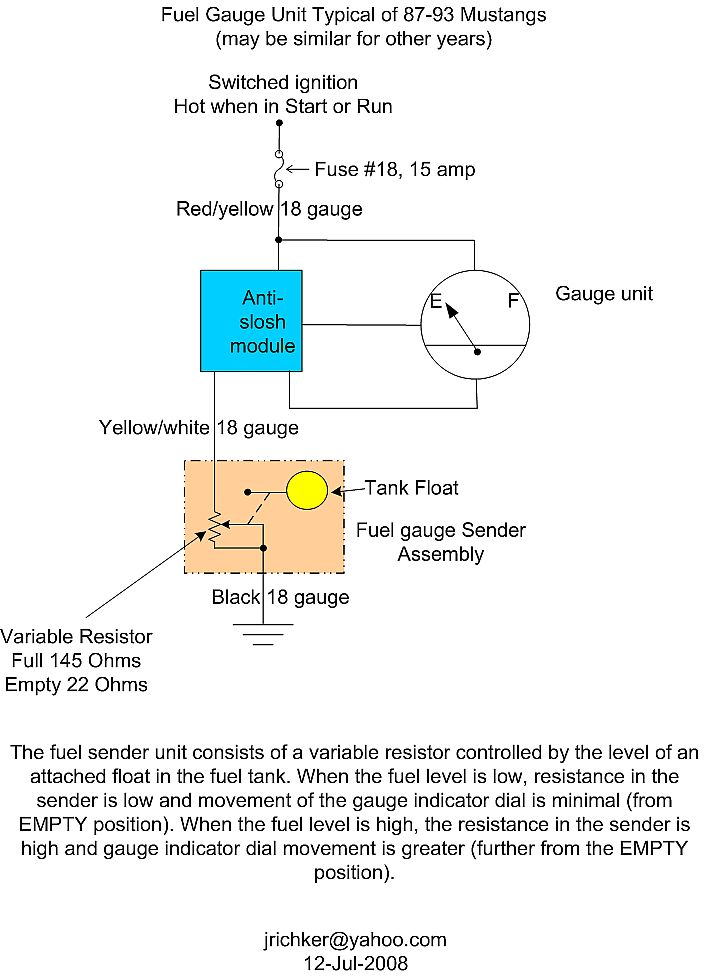

The red/yellow wire (power supply to gauge & sender) should have 12 volts when the ignition is in the start or Run position.

Troubleshooting the gauge and sender circuit:

Since the sender uses a variable resistor, sum the resistor values of 22 Ohms (empty value) & 145 Ohms (full value). That gets you 167, which you divide by 2: that gets you 83.5. So in theory, 83.5 ohms is 1/2 full. A trip to Radio Shack for the closest combination of resistors to make 83.5 ohms gets you one 68 Ohm (Catalog #: 271-1106) + one 15 Ohm (Catalog #: 271-1102) for a total of 83 Ohms at the cost of $2 plus tax. Wire the resistors in series to make a resistor pack and cover it with heat shrink tubing or electrical tape. The 83 Ohms is close enough to the 83.5 Ohm figure that it shouldn't matter. Disconnect the electrical connector shown in the diagram for the tank sender unit. Connect one end of the resistor pack to the yellow/white wire on the body side fuel sender electrical connector and the other end of the resistor pack to ground. Make sure nothing is touching that isn't supposed to and turn the ignition switch to Run. If I am correct, the fuel gauge will read 1/2 full, or very close to it. If it does not, then the odds are that the gauge or anti-slosh unit are bad.

How and why the test works…

Most of the fuel gauge failures give a stuck on full or stuck on empty as a problem symptom. Using a resistor combination that mimics 1/2 tank allows you to decide if the gauge and anti-slosh module are the problem source.

If the gauge reads about 1/2 tank with the resistor combination, that points to the sender as being the culprit.

If the gauge reads full or empty with the resistor pack in place of the sender, then the gauge or anti-slosh module is at fault.

Fuel gauge sender testing and replacement

The next steps require dropping the fuel tank and removal of the fuel level sender. Here are some useful tips...

I have done the tank removal three times, and the main issues are getting the car up on jack stands and getting the gas out of the tank. DO NOT try to do this job without jack stands. Becoming a pancake is not part of the repair process.

Pumping out the old gas:

If the old pump still works, you can use it to pump the tank out.

1.) Separate the pressure line (the one with the Schrader valve on it) using the fuel line tools.

Look in the A/C repair section for the fuel line tools. They look like little plastic top hats. You will need the 1/2" & 5/8" ones. The hat shaped section goes on facing the large part of the coupling. Then you press hard on the brim until it forces the sleeve into the coupling and releases the spring. You may need someone to pull on the line while you press on the coupling.

OR

View: https://www.youtube.com/watch?v=vRTjYAxvaCs

Use a piece of garden hose to run from the pressure line to your bucket or gas can. Make sure it is as leak proof as you can make it. Fire and explosion are not part of the repair process...

2.) Jumper the fuel pump test point to ground.

Turn the ignition switch to the Run position. the fuel pump will pump the tank almost dry unless the battery runs down first.

Some 5 gallon paint pails lined with garbage bags are good to hold the gas. The garbage bags provide a clean liner for the pails and keep the loose trash out of the gas so you can reuse it. If you decide to use a siphon, a piece of 1/2" garden hose stuck down the filler neck will siphon all but a gallon or so of the gas.

Remove the filler neck bolts and put them in a zip bag. Disconnect the supply & return lines by removing the plastic clips from the metal tubing. If you damage the clips, you can get new ones form the auto part store for just a few dollars. I have used tie-wraps, but that is not the best choice. Then you remove the two 9/16" nuts that hold the T bolts to the straps. Put the nuts in the zip bag with the filler bolts. Pull the plastic shield down and away from the tank. Once the tank drops a little bit you can disconnect the wiring for the pump & fuel quantity sender.

The fuel gauge sender assembly comes out by removing a large metal ring that unscrews from the tank. There is a separate mounting/access plate for the fuel pump and fuel gage. You are supposed to use a brass punch to tap on the ring so that you don't make sparks. Look closely at the rubber O ring gasket when you remove the fuel gauge sender.

When you install the metal ring that holds the sender in place, watch out for the gasket O ring. Some RTV may be helpful if the ring is not in excellent condition.

The tank to filler pipe seal is a large rubber grommet. Inspect it for hardening, tears and damage. At $20 from the Ford dealer, it might be a good idea to replace it.

I used a floor jack to help lift the tank back in place. You may find that it is the only time you really can make good use of a helper.

All resistance measurements should be made with the power off.

Note from bstrd86 - 86 and older fuel tank sender units are 73 ohms empty, 8-12 ohms full. The 87-93 fuel tank senders are of 22 Ohms empty & 145 Ohms full. The two different groups of sensors are not interchangeable

The yellow/white wire will show a voltage that varies with the movement of the float on the sender unit. To test the sender, set your Ohmmeter or DVM on low Ohms. Then disconnect the sender and connect the Ohmmeter or DVM to the yellow/white and black wires from the sender unit. Move the float arm while watching the Ohmmeter or DVM. You should see the reading change from 22 to 145 ohms +/- 10%.

If the Ohmmeter or DVM resistance readings are way off, replace the tank sender unit.

Use extreme caution if you do the next step. Fumes from the gas tank can easily ignite and cause a fire or explosion.

With the sender unit out of the tank and connected to the body wiring harness, turn the ignition switch to the Run position. Move the float arm and the fuel gauge indicator should move. If you are very careful, you can use a pair of safety pins inserted in the connector for the yellow/white and black wires to measure the voltage as you move the float arm. The voltage will change, but I have no specs for what it should be.

Do not short the safety pins together or to ground. If you do, you may damage the anti-slosh module or create a spark. A spark with the fuel tank open could cause a fire or an explosion.

If the voltage does not change and the tanks sender passed the resistance tests, the anti-slosh module or gauge is bad.

The 87-89 module is shown below.

Sorry, the link may not work...

This is what the 90-93 module looks like.

LRS has the 90-93 module as a standard catalog item, cost is about $160

Inexpensive anti-slosh module repair - should work on 87-93 anti-slosh modules

Copied from DrBob

I worked on an 88 Mustang today that had similar symptoms. Short version, I took the “anti slosh module” off of the back of the instrument cluster and replaced the electrolytic capacitor. Fixed it for $1.39 with a part from Radio Shack.

In an attempt to help other folks, here’s the long version.

Remove the “anti slosh module” located on the back of the instrument cluster. There was a single Torx screw holding mine to the cluster.

Find the electrolytic capacitor. It will be the largest, 2 wire component on the board. The capacitor may have a red or blue plastic wrapper on it. Mine was red.

The wrapper should have printing on it. Look for printing that looks something like this:

100uF+25V

The “100uF” tells you this is a 100 micro Farad capacitor. The “+25V” tells you the capacitor is rated for 25 Volts. Yours may be different. You may use a higher voltage part but don't use a lower rated voltage part. If you use a lower voltage part the capacitor might open later on down the road or it could be as bad as catching fire.

If you can’t find the printing you’ll need to remove the part. You have to anyway so nothing wasted. However pay close attention to the way the capacitor is oriented on the board.

One end of the capacitor will be bare metal with a wire sticking out. The other end should have some sort of insulation over it with a wire sticking out. The bare metal end is the negative end while the insulated end is the positive end. Pay attention to which end is connected to which hole on the board.

Get a replacement part. I got mine at Radio Shack, $1.39. Here’s the info:

100µF 35V 20% Axial-Lead Electrolytic Capacitor

Model: 272-1016 | Catalog #: 272-1016

See

www.Digikey.com for better capacitors – these are rated for automotive use and 105° C temp which is needed to survive the hot environment found in automotive electrical circuits.

P/N

4215PHCT-ND $2.10

OR

P/N 4201PHCT-ND $2.59

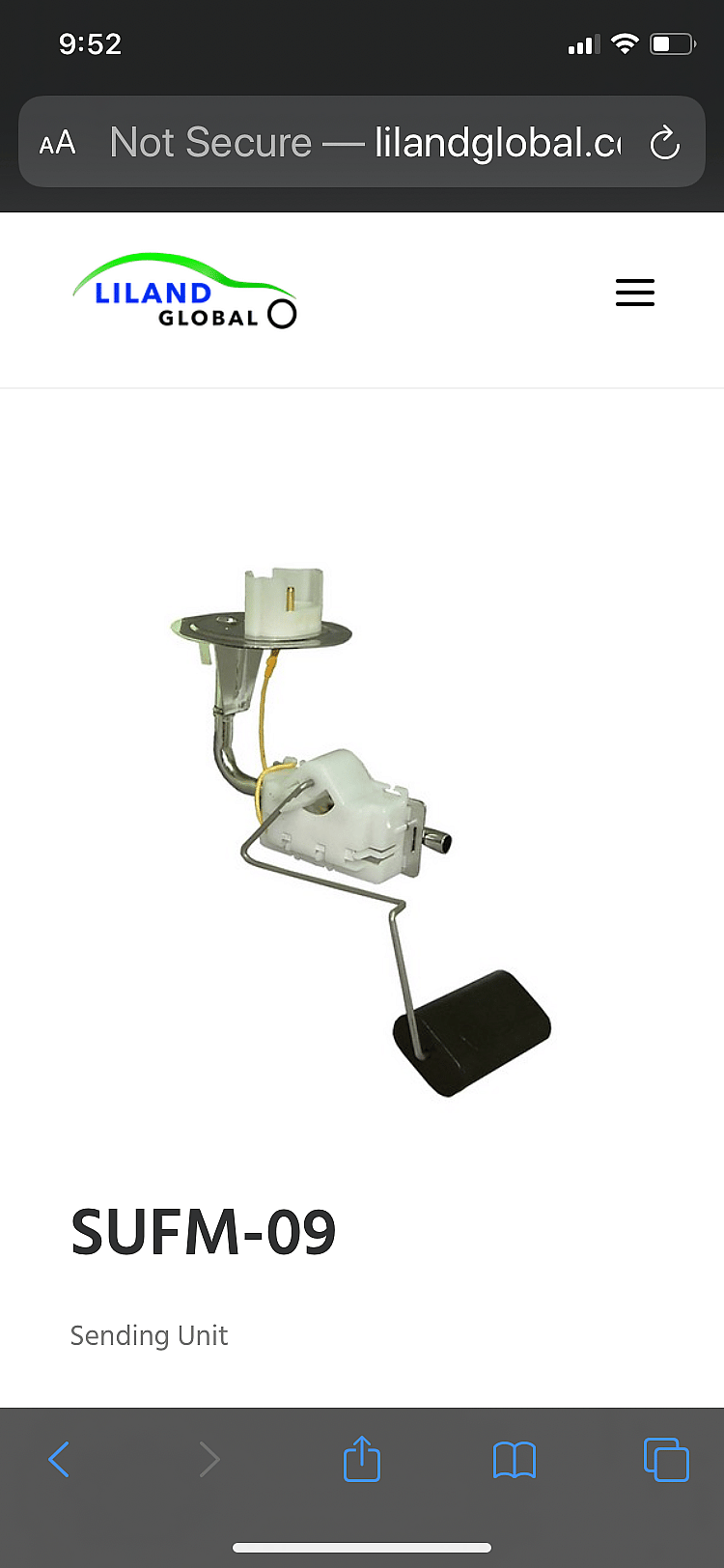

Fuel tank sender unit:

http://www.latemodelrestoration.com/products/Mustang-Gas-And-Fuel-Tank-Sending-Unit

Be sure to get the lock ring and a new seal if you order the tank sender unit.

http://www.latemodelrestoration.com/item/LRS-9307A/1979-93-Mustang-Fuel-Pump-Sending-Unit-Lock-Ring-And-Seal\[/B]