Last night, I decided to put in some work on my GT; guess it was my hot date for the night.

I had been putting this work off until I finished the Cobra, but that won't be happening for a while. So I installed a 03 Cobra steering shaft and new O2 sensors. I also tried to fix what (I hope) was causing the chatter in my front

suspension. This GT had gotten into a wreck before I bought it; the power steering lines from the rack were all bent up. They were on top of the sway bar, instead of below and all the way over by the frame rail. I decided to see if I could twist them around and line them up right. I had to take off the sway bar to do this, of course. A half-hour of cursing and bending metal later, the metal lines were back where they should be and the sway bar was back on. I haven't taken the GT for a drive yet, but I'm eager to find out how well it drives now.

SN95StangMan was kind enough to stop by today, so progress was made.....sorta. It seemed like the Gods did not want us to install the rear axle today no matter how hard we tried. When we started, we realized that the rubber hangers for the exhaust had broken. We needed to hang the exhaust properly so we had room for the axle. OK, I had kept the Cobra's exhaust hangers and brackets just for this reason. The driver's side went on with a bit of a fight. The passenger's side...not so much.

I had dual exhaust installed when this car was a V6. The mechanic fab'd up a decent bracket for the one near the mufflers, easy to unbolt. The "clip-on" nuts weren't on that side, however. No problem, I'll pull them from the Cobra.....crap. Had to get rid of the Cobra earlier this week. So, off to Kragen to improvise a set. The back bracket by the bumper was a threaded rod WELDED on to the frame, right over where the actual bracket attaches.

Out comes the Dremel tool to grind it off. I just hope he didn't thread the rod into the mounting hole.

Problem #2: partway through grinding down the welds, my Dremel tool breaks.

Wonderful. Off to Home Depot for a replacement. One new Dremel tool and a frick-load of metal-cutting bits later, I continue grinding the welds off. Amazing how having the right tool will help, these metal-cutting bits really made short work of the welds. Fortunately, the mechanic only welded the rod on top of the frame, and not into the mounting hole.

To keep busy, SN95StangMan was kind enough to do some work on the Cobra engine while I was busy. I ground the welds flat and shot some paint over the bare metal. The bolt hole for the bracket wasn't tapped, but the 10.9 bolts are great for tapping their own bolt holes. NOW we can hang the exhaust....nope. The mechanic had bent the metal hanger on the exhaust pipe to fit the rod he welded on, and now it doesn't line up. Out comes the propane torch; heated the metal enough to bend it back to where it should have been. Finally, we got the exhaust all hung properly.

After all this we finally get to the rear axle. SN95StangMan & I carried the axle over, set it down on a jack and lined it up. After some wrangling we got the

upper control arms bolted up. We did have problems with the lower ones, which ultimately stopped us. I have a set of powdercoated Mega-Bite Jr's to install, they take a bit of extra time to install. First problem: they use SAE bolts, not Metric. We had to widen the bolt holes in the axle to allow the slightly thicker bolts to fit. After a bunch of grinding with the new Dremel tool, the bolts slid in...but were a quarter-inch too short. The bolt wasn't long enough for the nut to engage all the threads. The only other bolts I had that would work had some bad threads. I couldn't buy any more tonight, so we were done.

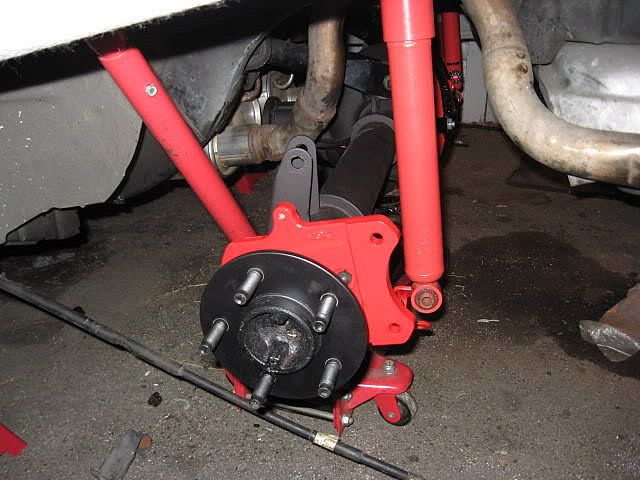

Here's a photo of our almost-installed axle, still resting on the jack:

We then turned to the engine sitting right next to the car. SN95StangMan had removed the valve covers; the rockers still looked new. I wish I had taken a photo of them, didn't think of it until I had torqued the covers back on.

Progress made: Installed painted valve covers and new gaskets. Reinstalled the exhaust manifolds. Reinstalled the oil dipstick. Result:

A big thanks to SN95StangMan for helping out, he was great to have around.

For those that are interested, the last thread is back <a href="http://forums.stangnet.com/showthread.php?p=7330720">here.</a>.

For those that are interested, the last thread is back <a href="http://forums.stangnet.com/showthread.php?p=7330720">here.</a>.

For those that are interested, the last thread is back <a href="http://forums.stangnet.com/showthread.php?p=7330720">here.</a>.

For those that are interested, the last thread is back <a href="http://forums.stangnet.com/showthread.php?p=7330720">here.</a>.

Out comes the Dremel tool to grind it off. I just hope he didn't thread the rod into the mounting hole.

Out comes the Dremel tool to grind it off. I just hope he didn't thread the rod into the mounting hole. Wonderful. Off to Home Depot for a replacement. One new Dremel tool and a frick-load of metal-cutting bits later, I continue grinding the welds off. Amazing how having the right tool will help, these metal-cutting bits really made short work of the welds. Fortunately, the mechanic only welded the rod on top of the frame, and not into the mounting hole.

Wonderful. Off to Home Depot for a replacement. One new Dremel tool and a frick-load of metal-cutting bits later, I continue grinding the welds off. Amazing how having the right tool will help, these metal-cutting bits really made short work of the welds. Fortunately, the mechanic only welded the rod on top of the frame, and not into the mounting hole. Here's a photo of our almost-installed axle, still resting on the jack:

Here's a photo of our almost-installed axle, still resting on the jack:

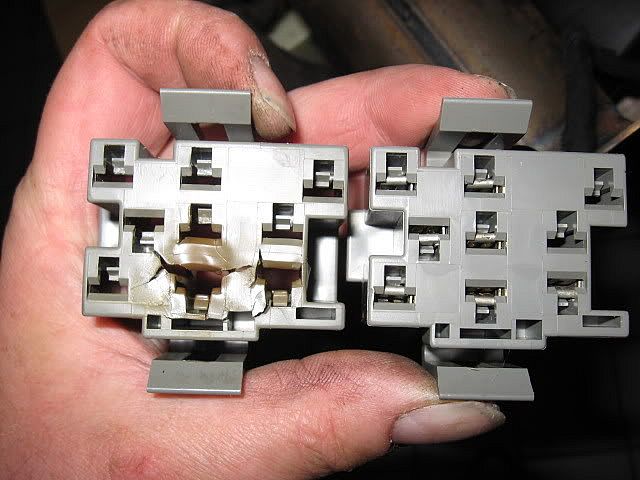

I'd already removed the wiring harness from the dash at this point.

I'd already removed the wiring harness from the dash at this point.