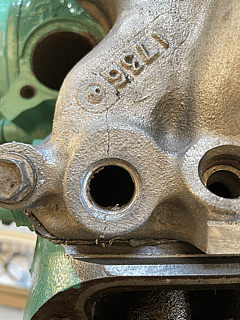

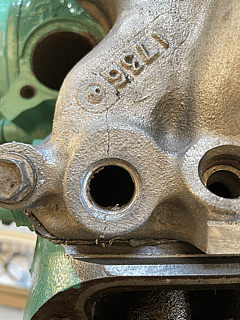

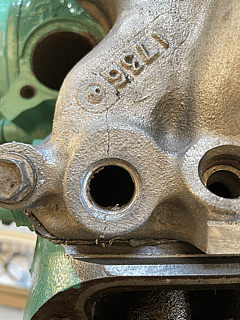

I was tightening a coolant temperature sensor when the intake manifold cracked. Can this be fixed with something like JB weld?

Yeah me as well it was probably less than 3/4 of the way in when the manifold let go. That feeling of dread when you hear that crack, haha. But I blame myself because I put some teflon tape on it and I think it was enough to widen the diameter of the threads on the sensor. That was an expensive lesson. I will only be using thread sealer from now on.Same thing happened to me last week, changed the temperature sensor with a new one that I bought at LMR and crack!! Threads didn't even go all the way in the manifold and it cracked

Lol , same here, my life flashed before my eyes when I heard the crack, couldn't believe itYeah me as well it was probably less than 3/4 of the way in when the manifold let go. That feeling of dread when you hear that crack, haha. But I blame myself because I put some teflon tape on it and I think it was enough to widen the diameter of the threads on the sensor. That was an expensive lesson. I will only be using thread sealer from now on.