I woke up this morning and took the wife out to breakfast at IHOP, if you haven't had some of there new pancakes they are pretty good. From there we shot over to JR @karthief place, we traded some parts I got all the brackets and bolts I need and he got a MM strut tower brace.

I spent my afternoon cleaning and sandblasting those parts, then I used some paint .

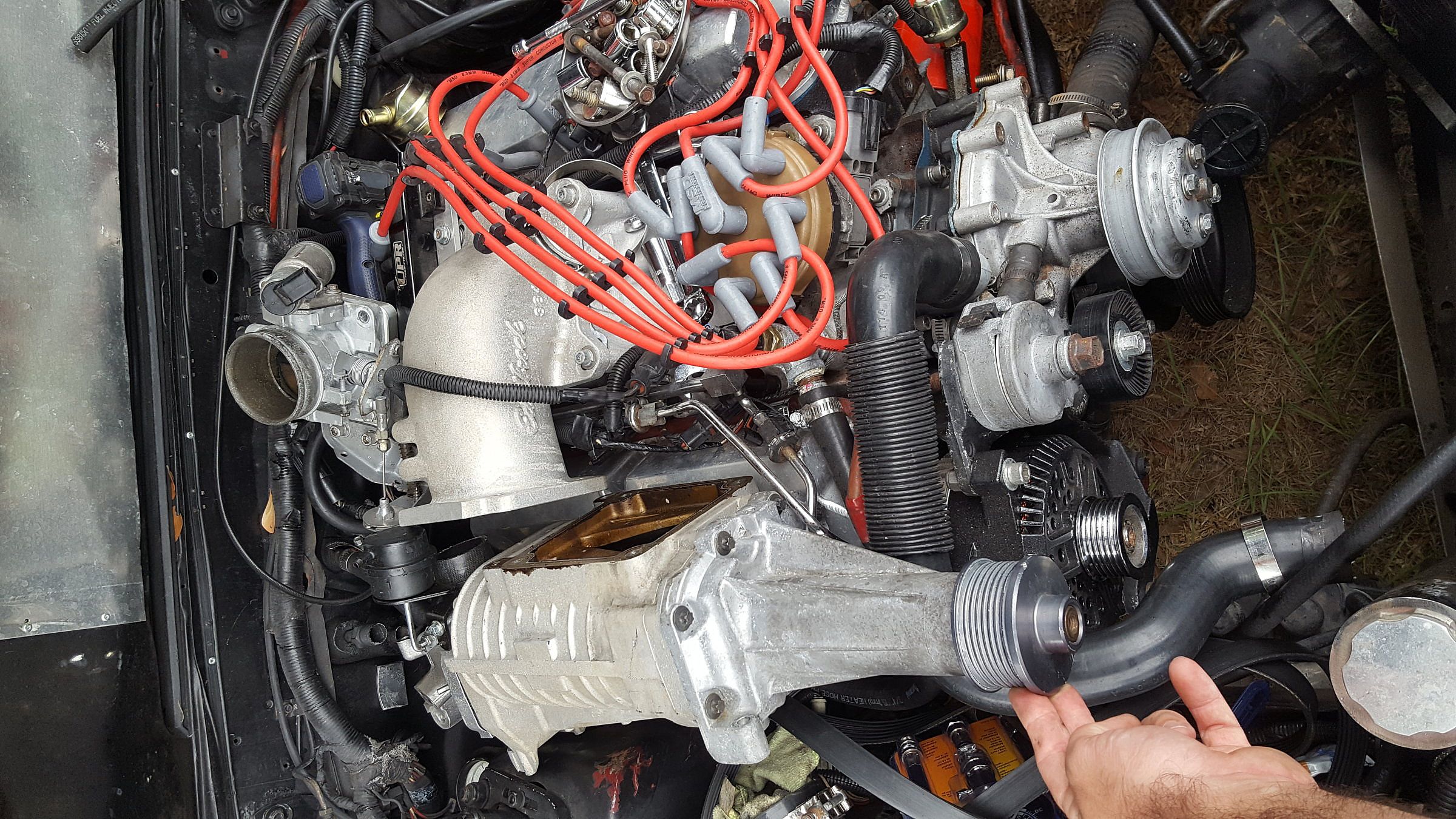

looking good.

looking good.

Now to remove old stuff and install these. I'm torn however my pressure line on the current power steering pump leaks.... will I need a new pump if I replace the line?

I spent my afternoon cleaning and sandblasting those parts, then I used some paint .

Now to remove old stuff and install these. I'm torn however my pressure line on the current power steering pump leaks.... will I need a new pump if I replace the line?