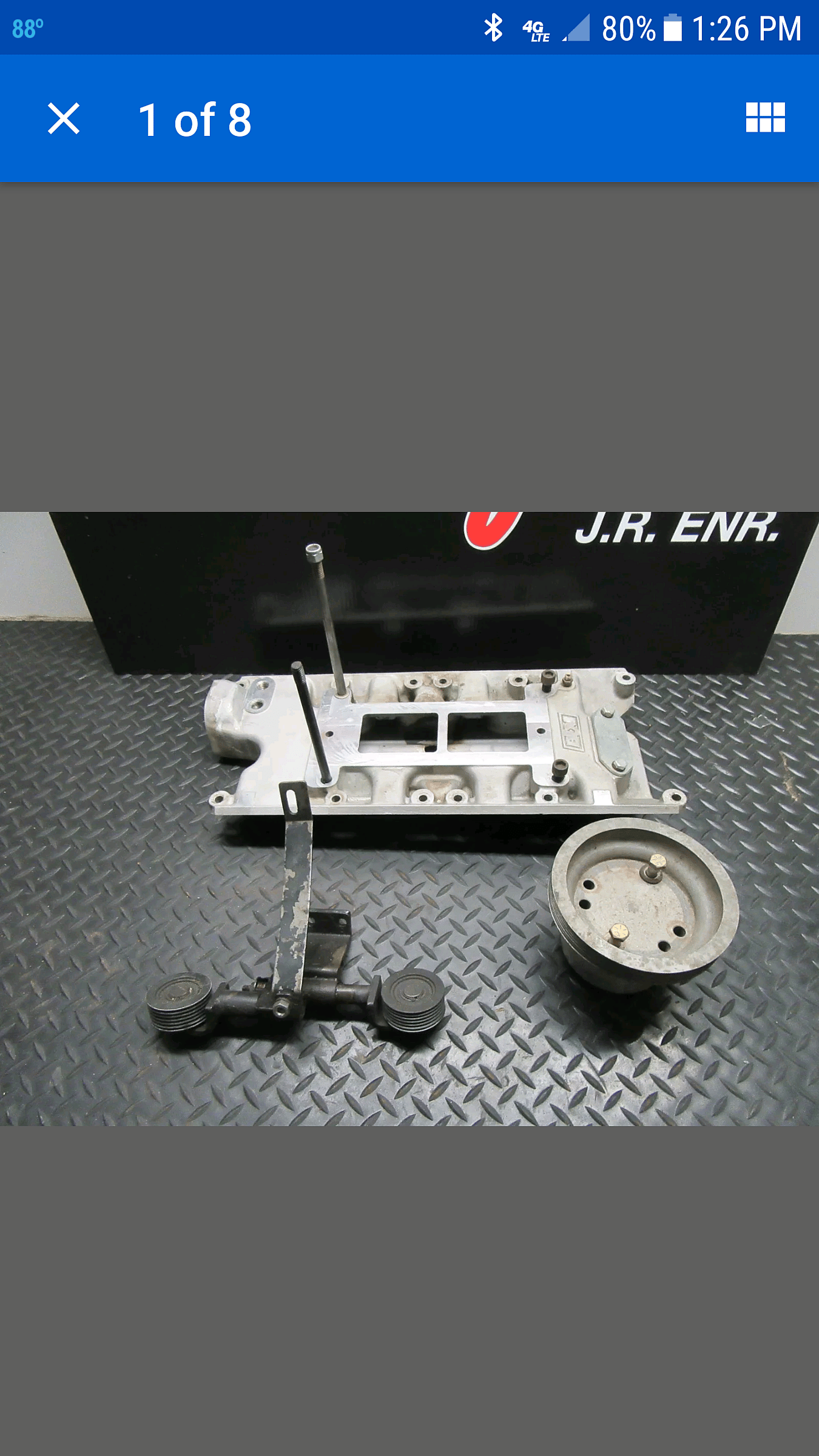

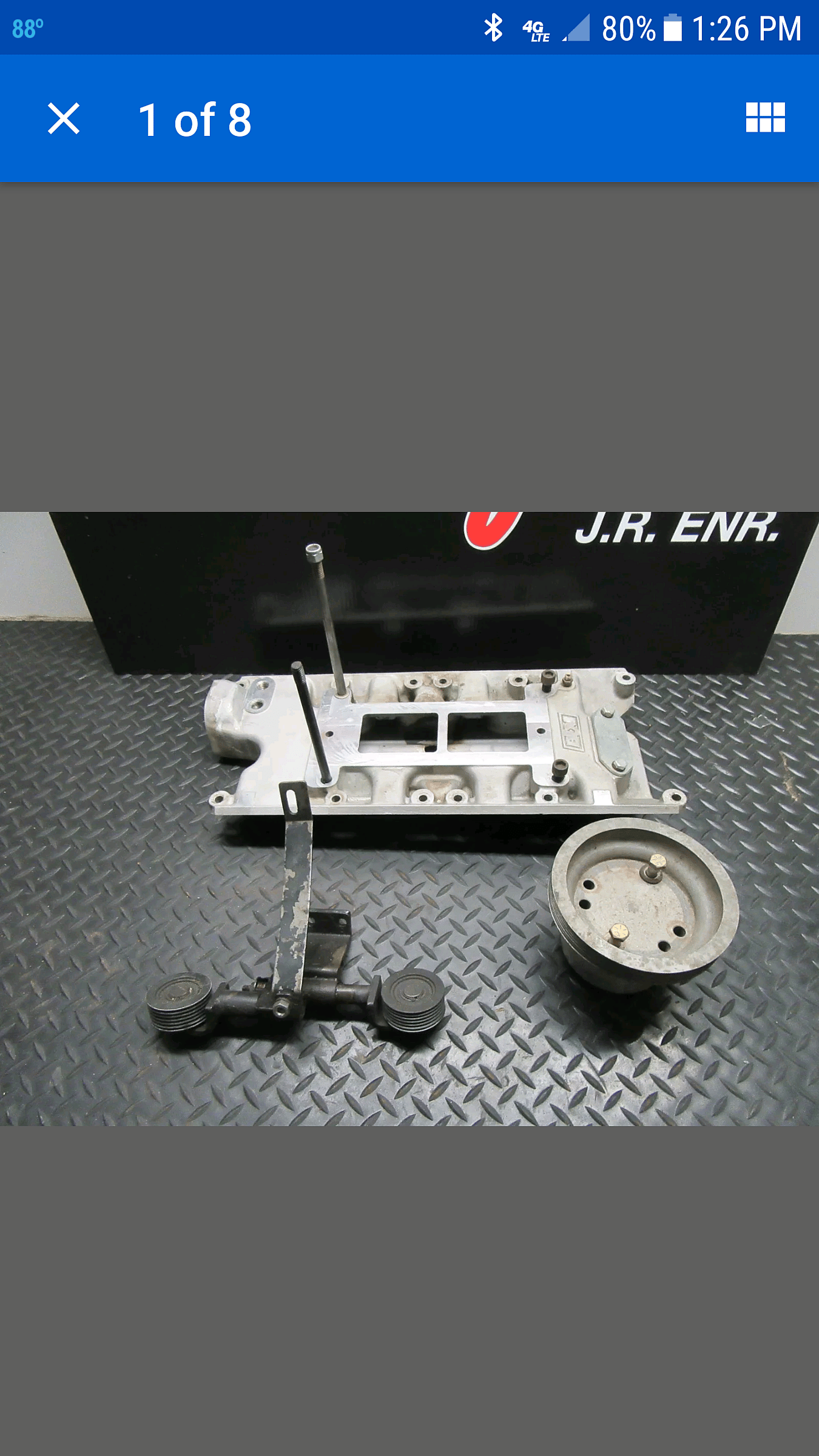

Hey hey Mike I found a sweet solution.....

EBay item 182621751306

It's a b&m blower intake manifold it would cost around 300$ total shipped what do you guys think? This would make it real simple to get that sucker between the valve covers...

EBay item 182621751306

It's a b&m blower intake manifold it would cost around 300$ total shipped what do you guys think? This would make it real simple to get that sucker between the valve covers...