If you're talking about having to add height to the blower.....(Aren't we now gonna have to stick the blower through the hood?)

But before you go on about modifying this, or raising that,.....let's discuss this for a minute...

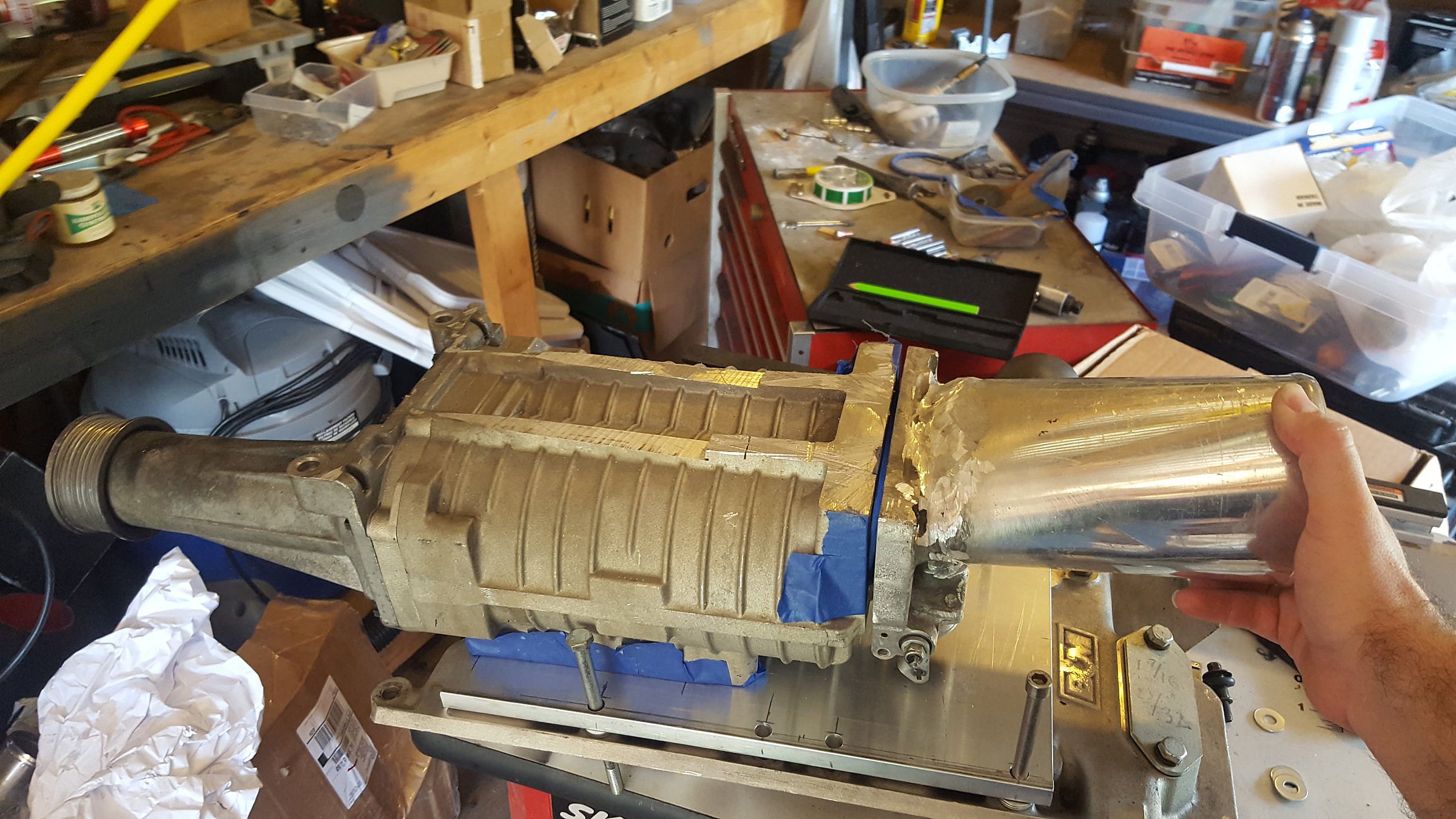

As it sits right now the thing will barely come above the valve covers. It's actually shorter than the high rise intake, I Will measure this out after work.

Firstly,....How is an Eaton blower different from any other "roots type" blower? Isn't there just two rotors cut on a helix pattern spinning to squish air that comes in fat in one hole, and all squished going out the other?

Like this Weiand 174 for example....

Show me where the "blower bypass" is on this thing.

There isn't one.

Now,....Why can't you just rig an inlet into the hole on the end to feed the blower of your Eaton like this one where the big hole is on top,..and let that dog eat? If there has to be some sort of mechanical blower bypass for some stupid reason why cant you just get either a waste gate or a BOV and run a hose to it off of some threaded fitting on a plate bolted to the end?

GMC blowers have "blow out plugs" that act as a backfire safety precaution,....I'm thinking "Blow off valve" will do the exact same thing...(for about 50 chinee dollah american round eye) If it's for this reason you need all that crap,..then all you need is one of those,...otherwise, I thought boost was a product of how fast you spin the impellers....and not through some sort of restriction like a turbo....

Yes it is a roots blower, however Eaton decided it was necessary to install a bypass between the outlet and inlet of the blower to recirculate air at idle and cruise. The purpose is to reduce noise, rotor wear, and excessive intake temperatures. Remember how loud my m90 was before adding that stupid looking tube, that is/was a bypass. The bypass is wide open under vacuum and closes when you nail the throttle.

Next, How in the hell are you gonna get fuel injectors mounted on the remaining intake runner that isn't covered by this fat little phcker? When I looked at your pics, all I saw was 1/2" thick plate covering the entire intake manifold......

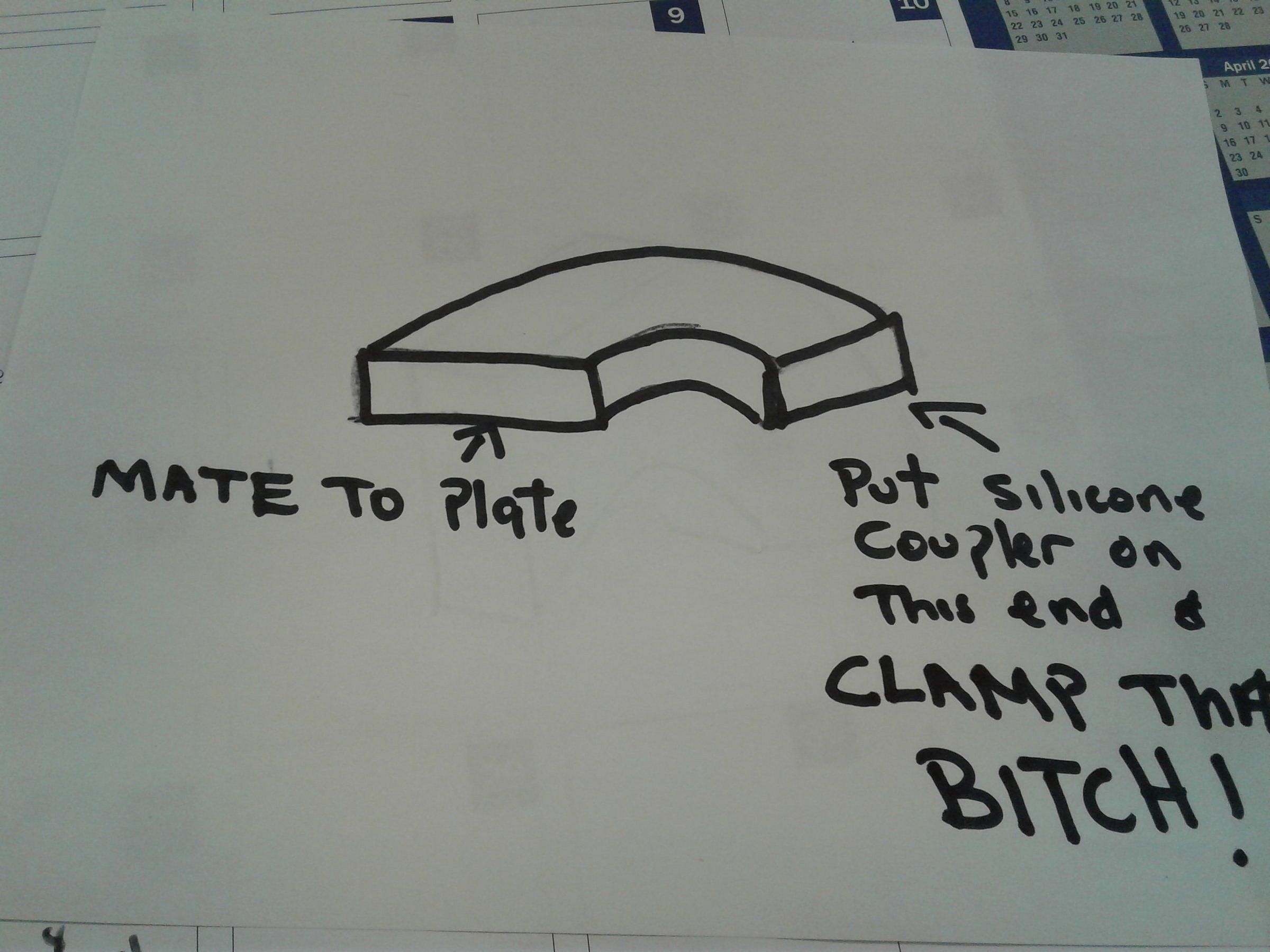

That one will be tricky, the injectors will have to stand straight up, the plate has to be trimmed above the runners for the injector bosses. I will draw my thoughts for this on the plate and we can discuss further.

I'm going to make it work..... how I envy turbo simplicity

I'm going to make it work..... how I envy turbo simplicity