You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Progress Thread Motivate Me For The Love Of God

- Thread starter 85_SS_302_Coupe

- Start date

-

Sponsors (?)

MY 85 GT

10 Year Member

Nice to see you back..I wondered what happened to you...

I'm still fairly regular over in the Squeaky Wheel. I can't remember why I stopped posting over here so until I remember I suppose I'll stick around

I'm still fairly regular over in the Squeaky Wheel. I can't remember why I stopped posting over here so until I remember I suppose I'll stick around

If I'm not mistaken,...it was probably because one of the regular members here is an ass.....

If I'm not mistaken,...it was probably because one of the regular members here is an ass.....

Well it's been almost 10 years I guess I can give him another chance

Also who has experience with Por-15? I'm thinking about doing my engine bay in black before all this goes in. Thoughts?

I used it under my car while I had my gas tank off. It dries like a glass finish, and is a b*tch to take off, so be sure its what you want before you do it.

I used it under my car while I had my gas tank off. It dries like a glass finish, and is a b*tch to take off, so be sure its what you want before you do it.

I'm finding mixed reviews, one said the stuff isn't even as good as Rust-Oleum rattle can, lots of people say use epoxy or self etching primer. I honestly don't have the time or funds to "do it right" and the last thing I need is another reason for this thing to sit in the garage. I read that this stuff is supposed to be self leveling and can be rolled on (some reviews say that's BS too) so it sounded like it would be easy to do with the engine in the car. The engine bay just looks like hell compared to the rest of the car.

I'm finding mixed reviews, one said the stuff isn't even as good as Rust-Oleum rattle can, lots of people say use epoxy or self etching primer. I honestly don't have the time or funds to "do it right" and the last thing I need is another reason for this thing to sit in the garage. I read that this stuff is supposed to be self leveling and can be rolled on (some reviews say that's BS too) so it sounded like it would be easy to do with the engine in the car. The engine bay just looks like hell compared to the rest of the car.

Mine seemed thin and runny, but they have different types. Silver has some filler in it, black is the standard rust controller. I brushed (plain jane house hold paint brush) mine on, and is does self level. Honestly, I wouldnt want to try to take it off either. It dries glossy, I am not aware if they have a flat/matte finish available or not. I know @Mustang5L5 did his whole undercarriage a number of years ago, and is still pleased with it I believe.

I haven't done my engine bay, but my entire underside, rear axle and under the front fender liners is Poe-15. I'll probably do my floorboards next time I pull my carpet.

Did it 10 years ago. Holding up nicely. No idea what I'll do my engine bay in though. I might go up to the trans tunnel where it meets the firewall with it, but I might want paint paint for the bay

I applied mine with a foam brush and it was pretty thick. Self leveled and coated in one coat.

It's not UV safe though, so exposure to sunlight will damGe it. You would need to topcoat it.

Did it 10 years ago. Holding up nicely. No idea what I'll do my engine bay in though. I might go up to the trans tunnel where it meets the firewall with it, but I might want paint paint for the bay

I applied mine with a foam brush and it was pretty thick. Self leveled and coated in one coat.

It's not UV safe though, so exposure to sunlight will damGe it. You would need to topcoat it.

Honestly I may just mask the whole thing off and rattle can it. I'm pretty good with a spray can, I've done rims that look powdered and I know of at least one type of Rustoleum that is stupid tough and has lasted for years on rims. We'll see.

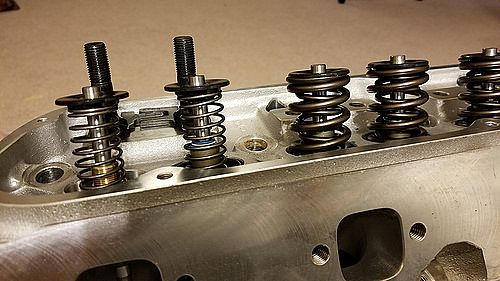

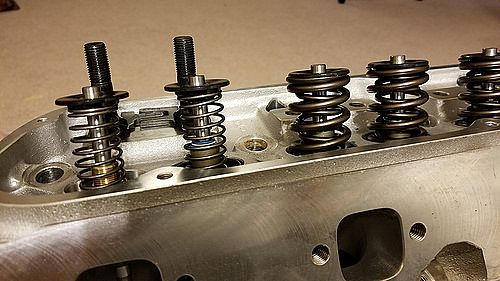

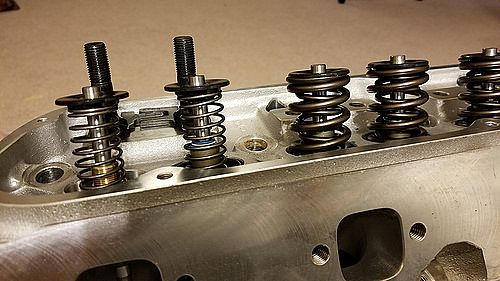

Finally got these little springs on my heads, so I'm one step closer to measuring for pushrods. These things are going to flow like a mofo. I can't wait to see how it runs.

Finally got these little springs on my heads, so I'm one step closer to measuring for pushrods. These things are going to flow like a mofo. I can't wait to see how it runs.

Three things:Honestly I may just mask the whole thing off and rattle can it. I'm pretty good with a spray can, I've done rims that look powdered and I know of at least one type of Rustoleum that is stupid tough and has lasted for years on rims. We'll see.

Finally got these little springs on my heads, so I'm one step closer to measuring for pushrods. These things are going to flow like a mofo. I can't wait to see how it runs.

#1. This^ and a tigged set of SS headers,....a Cnc'd ported head is the best looking thing that is this industry.

#2. I hope it isn't your intention to do anything more to the head regarding that header gasket.

#3. Laid on properly, a rattle can paint job on a smaller project (like the upper 2/3rds of an engine compartment) will look every bit as good as some of the fully painted bays done while the engine was out. I'll spare you the over-published pic of my red cars bay, but that was a glorified rattle can two tone job, done in engine enamel (Better resistance to heat and solvents). I thought it looked really good. I'd do that before I got all gooey messing with POR-15.

You wouldn't think twice about "what?"Meh. I wouldn't think twice about it.

The header alignment.You wouldn't think twice about "what?"

Three things:

#1. This^ and a tigged set of SS headers,....a Cnc'd ported head is the best looking thing that is this industry.

#2. I hope it isn't your intention to do anything more to the head regarding that header gasket.

#3. Laid on properly, a rattle can paint job on a smaller project (like the upper 2/3rds of an engine compartment) will look every bit as good as some of the fully painted bays done while the engine was out. I'll spare you the over-published pic of my red cars bay, but that was a glorified rattle can two tone job, done in engine enamel (Better resistance to heat and solvents). I thought it looked really good. I'd do that before I got all gooey messing with POR-15.

1) Yeah, I hadn't fully appreciated the CNC finishing on these heads until I pulled the valve out and got a better look inside.

2) Oh no, I'm not touching those ports. The headers might be a little overkill, but at least I know they won't be choking the exhaust ports out one bit now.

3) Engine enamel isn't a bad idea. I've used this Rustoleum on rims in the past and they lasted for years without fading or chipping. I figure rims are exposed to the sun and elements a lot more than an engine bay, but then an engine bay sees a lot of heat so maybe ceramic engine enamel is a better choice?

I used this..

And did this..

And that was without any prep at all, I just sprayed the factory finish. I don't think I'm going to wet sand or fill holes or anything like that on the engine bay either. At this point just spray bombing it would be a huge improvement. Next time I have the engine out maybe I'll do it right, so the more I think about it, doing it in Por-15 may be a bad idea if it's not easy to sand/grind off.

You can get POR 15 in a matte, semi-gloss or gloss coating.

This was my red car floor after I took off all the seam sealer and replaced part of the floor pans. It’s dried in this picture. I used the flat in front of the seat brace. Only reason it’s different is that I got my stuff free.

I used a small foam roller and a cheap paint brush.

It does self level. The difference between it and the other products you’ve mentioned is that it seals the panel when dry. Really just meaning that it is far less porous then the other paints. You let both applied products set in water for a period of time, the POR15 (or other rust encapsulator) will take far longer to break down.

Just put something underneath it when using. When it dries, it’s a btch.

This was my red car floor after I took off all the seam sealer and replaced part of the floor pans. It’s dried in this picture. I used the flat in front of the seat brace. Only reason it’s different is that I got my stuff free.

I used a small foam roller and a cheap paint brush.

It does self level. The difference between it and the other products you’ve mentioned is that it seals the panel when dry. Really just meaning that it is far less porous then the other paints. You let both applied products set in water for a period of time, the POR15 (or other rust encapsulator) will take far longer to break down.

Just put something underneath it when using. When it dries, it’s a btch.

Similar threads

- Replies

- 1

- Views

- 382

- Replies

- 10

- Views

- 1K

- Replies

- 7

- Views

- 641

- Replies

- 25

- Views

- 1K